Summary of Contents for SPRT SP-EU8010

- Page 1 SPRT ® SP-EU8010/EU8011 PRINTING UNIT USER’S MANUAL (Ver 1.00) Beijing Spirit Technology Development Co.,Ltd...

- Page 2 Safety Instruction Safety warming 1)The print head is heating parts, during printing and end printing, do not touch the print head and surrounding parts. 2)Do not touch the surface of the print head and connection socket, avoid the electrostatic damage the print head. Notice 1) Printing units should be installed in a flat, stable place;...

-

Page 3: Table Of Contents

Content Brief Introduction ............................1 Chapter 1 Characteristics and performance .................... 2 1.1 Print performance ...........................2 1.2 Print paper ............................2 1.3 Character set ...........................2 1.4 Interface ............................3 1.5 Printing control command ......................3 1.6 Power supply ...........................3 1.7 Dimension and installation instructions ..................4 1.8 Dam-board Function ........................ -

Page 4: Brief Introduction

Brief Introduction SP-EU8010/EU8011 printer is a new thermal line panel printer, with drop-in paper easy loading,auto cutter, black mark detecting function ,it has a faster printing speed and it is more reliable. SP-EU8010/EU8011 printer is easy to operate, widely used in multiple fields, especially apply to queuing machine, POS for bank and various commercial fields that require document printing. -

Page 5: Chapter 1 Characteristics And Performance

Chapter 1 Characteristics and performance 1.1 Print performance ● Printing method:direct line thermal; ● Print Paper: thermal paper; thermal black mark paper; thermal label paper ● Space between label paper: 2-3mm ● Printing paper width:79.5±0.5mm, 82±0.5mm。 ● Resolution:8dot/mm,576dot/line ● Printing speed: Receipts:150mm/s(max); Label: 130mm/s(max) ●... -

Page 6: Interface

1.4 Interface ● RS232 serial port: PDK-5PIN socket(pin point),support XON/XOFF and DTR/DSR. Baud rate:1200,2400,4800,9600,19200,38400,57600,115200bps adjustable. Data structure:One start bit + (7 or 8)data + one stop bit. Verify:No validation or odd and even check is optional. ●USB port: Standard USB port. PH-4PIN port. 1.5 Printing control command ●... -

Page 7: Dimension And Installation Instructions

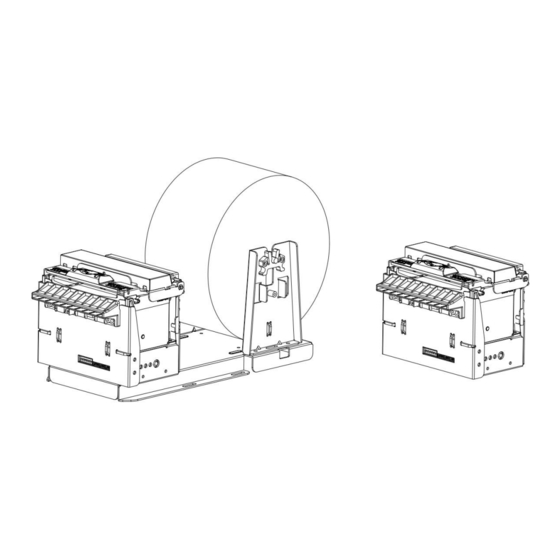

1.7 Dimension and installation instructions SP-EU8010SU (Standard Model) - Page 8 SP-EU8010SU (fixed plate on the bottom and front are optional accessories)

- Page 9 SP- EU8011SU...

-

Page 10: Dam-Board Function

1.8 Dam-board Function When using the dam-board, lift the buffer shaft first, and then insert it into the hole. 1.9 Work Environment ● Working stability: 0 ~ 50℃ Operating Relative Humidity: 10% ~ 80% ● Storage stability: -20 ~ 60℃ Storage relative humidity: 10% ~ 90%... -

Page 11: Chapter 2 Operating Instructions

Chapter 2 Operating instructions 2.1 Printing Unit components SP-EU8010SU... -

Page 12: Instructions For Paper Install

SP- EU8011SU Note: The upper part is called printer mechanism after open the cover, hereinafter referred to as printer head 2.2 Instructions for paper install 2.2.1 Paper Loading Thermal paper installed as below: In the state of power-on, pull out a little from the paper roll, then put the paper into the mouth of printing mechanism, the printer will auto paper feeding . -

Page 13: Solution For Paper Jam Of Cutter

Note: make sure the paper is cut flat when loading. 2.2.2 Solution for paper jam of cutter If the cutter is jammed, turn off the power and turn on the printer again, the cutter will recover. 2.3 Interface Connection 2.3.1 Solution for paper jam of cutter... -

Page 14: Serial Interface Connection

2.2.3 Anti-jamming and Anti-pulling function During printer work, the user tears paper, pull the paper and jams the paper. This type of operation triggers the printer's Anti-jamming and Anti-pulling function, as follows: (1) The user tears paper, pull the paper will triggers the printer's Anti-jamming and Anti-pulling function, the printer will automatically cut paper to avoid other abnormal phenomena such as paper dislocation caused by tear paper and pull paper. -

Page 15: Usb Interface

The baud rate and data structure have been set as 115200bps/8 data bits/no calibration and 1 stop bit under connected as serial. SP-EU8010/SP-EU8011 printer’s serial interface can be connected to the standard of RS-232C interface.The correct wiring method is as shown in Figure 2-2. -

Page 16: Power Supply Connection

2.3.3 Power supply connection SP-EU8010/SP-EU8011 printer is externally connected to 24V±10%, 2A power supply, and the socket is VH3.96-2PIN type. The shape and pin definition are shown in Figure as below. Pin No. Signal +24VDC Fig 2-6 Definition of power socket and pin 2.4 Lights and buttons operation... - Page 17 3,Automatic recovery error, the lights will flash continuous. 4,Paper out,lack of light long on paper. When printing on the rubber roller no longer test for a lack of printer paper, only check whether have paper. Show as below: a. Non-recoverable error, the lights will flash for many times later will lighting for a period, then circulation, the times of the lights flashing show the errors type.

-

Page 18: Normal Working Mode

2.5 Normal working mode When printer is off,【printing rubber roller】is closed, then open the power button, Status indicators and paper out indicator shine alternately twice and then off, printer enter into the normal working mode. 2.6 Paper loading(Manual operating) Press 【 FEED 】 button in power-on state, the normal paper will began loading, let go of the 【FEED】button, paper loading will stop;... -

Page 19: The Printer Parameters Setting

To terminate hexadecimal dump, Press FEED button three times. It is means the printer has enter into HEX printing mode, under this mode all the input content will be printed out as HEX DUMP, the paper will online after press the 【FEED】button once, totally three times, print out "*** Completed ***", quit HEX DUMP mode. -

Page 20: Printer Upgrade

2.12 Printer upgrade 2.12.1 Upgrade firmware under holding. the printer standby state, use the upgrade tool ‘UpdateFirmware.exe’ on the PC to perform firmware upgrade. 1) . Upgrade by using USB port When using a USB port to upgrade, select the USB option in the port bar and open the port for upgrading 2) .Upgrade by using COM port When using COM port to upgrade, select the corresponding COM port in the port bar, and... -

Page 21: Installation And Use Notes

2.Label size (One piece of label paper is rectangular or nearly rectangular), it does not support irregular shaped labels 2.14 Installation and use notes 1.The connection between the paper exit and the paper exit position of the device suggested to be one of the following figures. 2. -

Page 22: Chapter 3 Other Information

3.The printer must be firmly installed to prevent the printer from shifting due to external force and causing paper blockage.If installed on the sliding rail, it is necessary to make the sliding rail limit mechanism. 4.In the process of use, it is necessary to wait for the printer to finish cutting paper before tearing/taking paper, so as to avoid paper blocking and deviation caused by paper tearing. -

Page 23: Label Paper Description

Printing position: As shown in the figure above, the black mark should be printed on the right edge of the non-print surface (only the black mark on the non-print text surface of the printing paper is supported). Width range:Height≥12mm(when using 80mm black mark paper) Height range: 4mm≤Height≤6mm Reflectance to infrared light: <10% (the reflectance of the rest of the paper's black mark width to infrared light >65%) - Page 24 Full setting: Printer Printer head Printer Printer Baud Language Densit Font Speed head head roller head roller head rate dots Printer Printer Printer black Re-print function head head head mark when paper out Baud rate: FEED FEED FEED 9600 19200 38400 57600 FEED...

- Page 25 Normal paple mode and black mark mode: FEED FEED The manufacturer has the right to modify the contents of this instructions without prior notice! Beijing Sprinter Technology development CO. LTD. Address: 4F, #3Building, No.1YUAN, No.26, 4th Ave.Chuangye Minddle Road, Shangdi information industry park, Haidian District, Beijing Postcode:100085 TELE:010-51661178...

Need help?

Do you have a question about the SP-EU8010 and is the answer not in the manual?

Questions and answers