Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Advantage Controls NANO XL

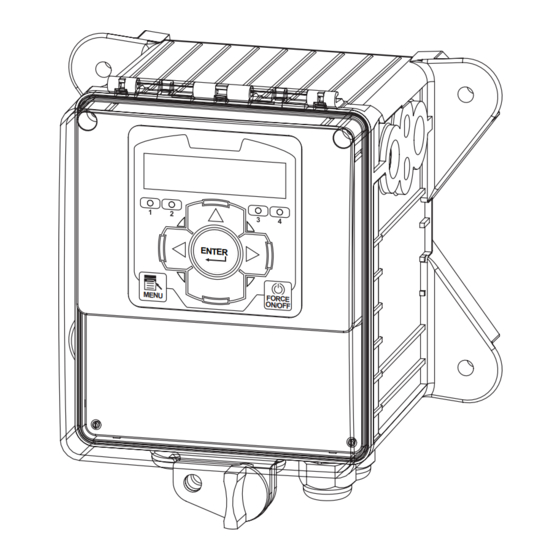

- Page 1 Manual NANO XL Conductivity Installation Maintenance Repair EN TE R Manual ME NU FO RC E ON /OF F Advantage Controls 4700 Harold-Abitz Dr. Muskogee, OK 74403 Phone: 1 (918) 686-6211 Fax: (888) 686-6212 www.advantagecontrols.com 05/2024 E-mail: support@advantagecontrols.com...

-

Page 2: Table Of Contents

Table of Contents Contents Page Introduction ................. 3 Description .................. 3 Features ..................3 III. Installation Electrical Wiring ................4 Mounting Instructions ..............4 Logic and Relay Cards ............... 5 Front Panel Description .............. 9 System Operation Overview ............9 Description of Menus .............. -

Page 3: Introduction

Introduction NANO XL microprocessor based controllers are designed to provide a wide range of control functions for recirculating water treatment systems. The controller is programmed through a front panel keypad and can be configured to provide a customized control system for your application. Your particular unit’s functions can be determined by comparing the units model number to the Model Numbering table listed below. -

Page 4: Installation Electrical Wiring

III. Installation Electrical Wiring The controller has an internal regulated power supply that will operate in the range of approximately 100 to 240 VAC on the incoming wiring. Output relay(s) are protected with a replaceable fuse. Relay output voltage will equal the incoming line voltage. Prewired units are supplied with a 16 AWG cable with a 3-wire grounded USA 120 volt plug for incoming power and 18 AWG 3-wire grounded receptacle cords for all control relay outputs. -

Page 5: Logic And Relay Cards

Relay Relay Relay Relay FUSE FUSE FUSE RELAY 4 RELAY 2 RELAY 3 RELAY 1 RELAY 2 Power In Relay 1 Relay 2 Relay 3 Relay 4 Nano XL-C Logic Card MOD2 Cond Temp Conductivity Module PULSE FLOW MOD3 MOD4... - Page 6 Electrode Installation Controllers may come configured for various circulating water systems. Listed below are instructions for cooling tower and boiler typical installations. Your specific installation requirements may differ but should conform to these instructions as much as possible for proper operation. Cooling Tower The standard probe(s) and/or flow assembly for cooling tower installations is constructed of schedule 80 PVC and supplied with 3/4”...

- Page 7 Boiler Standard boiler electrodes have a MNPT stainless steel bushing and are supplied with a FNPT cross designed for mounting in the skimmer (surface) blowdown line. Sampling of the boiler’s water can be achieved using one of two typical plumbing configurations (continuous sampling or timed and/or hold sampling).

- Page 8 Typical Continuous Sampling Boiler Installation Diagrams Fully ported gate or ball valve Throttling device 1" Continuous blow down line Electrode within a 1" cross with electrical 1/2" pipe connection vented Electrically between probe actuated and throttle blow down device and valve flush valve Warning - Do not use on bottom blowdown lines, only continuous or surface blowdown lines.

-

Page 9: Front Panel Description

Front Panel Description Press MENU to access menus or go back one layer in menu structure. MENU Wed 10:59:57am Press FORCE to activate relays manually. FORCE ON/OFF Press ENTER to go a layer deeper in menu, ENTER to initiate a setting change and to set change. ENTER Use up or down arrows to navigate through menu selections or setting options. -

Page 10: Conductivity Sampling Methods

Conductivity Sampling Methods Continuous - Typical for most tower applications. The controller is constantly reading the sensor and activating the bleed relay based on readings relationship to the set point, set point direction and differential. Example: A rising set point of 1500 and differential of 50 the bleed relay would activate when the conductivity rises above 1500 and stays on until the reading drops to 1450. -

Page 11: Maintenance

Maintenance The only required maintenance for normal uninterrupted operation of your controller is cleaning of the electrode(s). After initial start up, it is a good idea to clean the electrode frequently until a schedule based on need has been developed. Since each application is unique, it is difficult to estimate the required frequency of cleaning. -

Page 12: Nanotron-C & B2 Menu Map

Calibration Relay 1 Set Relay 2-4 Set Mode Setting Mode Setting Temp 077°F Password 0000 Select WM 1, 2 or 1 + 2 Con 02500µS Flow Sw: Close Continuous Setpoint 01500 Pulse Timer WM = 1 + 2 On in 0010 gl Force Bleed? N Diff 0100 Run Time mm:ss... - Page 13 Diagnostics Water Meter Clock Set Relay Test Pulse Output 4-20 Output On For mm:ss In = COND1 Reset WM1 N In = WM1 Nano-XL Set Time WM 1 Units 4mA=00100 Relay 1 LoRate= 000.0 Set Date FW: ?.?.? WM 1 Value 20mA=01000 Relay 2 HiRate= 700.0...

-

Page 14: Warranty & 30 Day Billing Memo Policy

Manufacturer’s Product Warranty Advantage Controls warrants units of its manufacture to be free of defects in material or workmanship. Liability under this policy extends for 24 months from date of installation. Liability is limited to repair or replacement of any failed equipment or part proven defective in material or workmanship upon manufacturer’s examination. - Page 15 - Notes -...

- Page 16 Get the Advantage in Water Treatment Equipment! Advantage Controls can give you the Advantage in products, knowledge and support on all of your water treatment equipment needs. Cooling Tower Controllers Boiler Blow Down Controllers Blow Down Valve Packages Solenoid Valves...

Need help?

Do you have a question about the NANO XL and is the answer not in the manual?

Questions and answers