Subscribe to Our Youtube Channel

Summary of Contents for Aimco DynaTorque PT 52 Series

- Page 1 DynaTorque PT 52 Series – Stall Tools 52/600 & 52/1000 Owner’s Manual PO Box 16460, Portland OR 97292-0460 • 800-852-1368 • Fax 800-582-9015 www.aimco-global.com...

- Page 3 PAGE 1 OF 16 CONTENTS PAGE Safety Introduction Features and Functions Set up Instructions Operating Instructions Maintenance Specification Declaration of Conformity Trouble shooting Glossary of terms MODEL NUMBERS COVERED BY MANUAL:- _____________________________________ MAXIMUM PART CODE DIRECTION MODEL TOOL TYPE TORQUE Tool stalls 18039.F06 Forward (Clockwise) only.

- Page 4 PAGE 2 OF 16 SAFETY IMPORTANT: DO NOT OPERATE THE TOOL BEFORE READING THESE INSTRUCTIONS. FAILURE TO DO SO MAY RESULT IN PERSONAL INJURY OR DAMAGE TO THE TOOL. This tool is intended for use with threaded fasteners. Any other use is not recommended. The use of ear protectors is recommended.

- Page 5 PAGE 3 OF 16 INTRODUCTION ® The Pneutorque 52mm series are air driven power tools designed for applying torque to threaded fasteners. There are models to cover torque capacities of 600 N.m and 1000 N.m. These models are available in 2 types: Stall Tool These tools use the air pressure set on an external pressure regulator to determine the stall torque.

- Page 6 PAGE 4 OF 16 FEATURES AND FUNCTIONS REPLACEABLE DRIVE SQUARE All tools are fitted with a ¾” (19mm) drive square that can easily be replaced. A 1” drive square (Part Code 18545) is also available. TRIGGER The trigger controls the flow of air. The more the trigger is pressed the more air flows into the tool. This allows for slow positioning of socket and reaction plate.

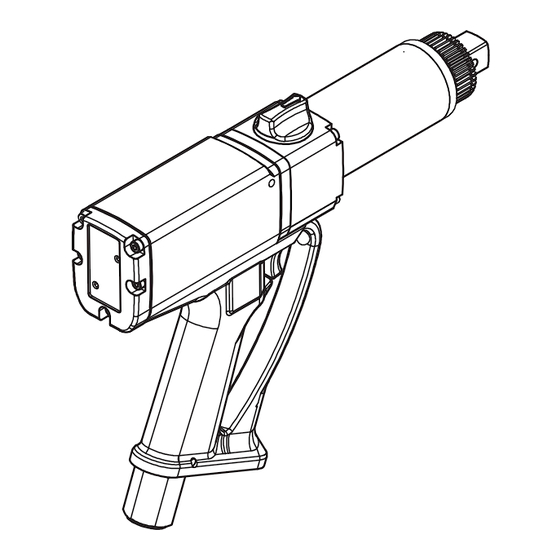

- Page 7 PAGE 5 OF 16 Figure 1 3. If running the tool with oil, check the oil level in the lubricator and fill to the correct level if required. (see MAINTENANCE section) TIP. These tools have been designed to run with a clean, dry, unlubricated air supply if required, but this is not essential.

- Page 8 PAGE 6 OF 16 TORQUE REACTION _________________________________________________________ When the Pneutorque® is in operation the reaction arm rotates in the opposite direction to the output drive square and must be allowed to rest squarely against a solid object or surface adjacent to the bolt to be tightened.

- Page 9 PAGE 7 OF 16 SETTING CLOCKWISE/COUNTER-CLOCKWISE OPERATION ________________________ Clockwise (Arrow towards drive square) Figure 4a Counter-clockwise (Arrow away from drive square) Figure 4b TIP: To help set the clockwise / counter-clockwise operation run the tool in neutral position before re-engaging. Neutral position Figure 4c WARNING:...

- Page 10 PAGE 8 OF 16 SETTING TORQUE FOR BOLT TIGHTENING ______________________________________ STALL TOOL – MODEL 18039 AND 18040 ________________________________________ These tools use the air pressure set on an external pressure regulator unit to determine the stall torque. They are supplied with an Air Pressure Graph which relates torque output to air pressure. Set the torque output as follows:- 1.

- Page 11 PAGE 9 OF 16 NOTE: THE TORQUE REGULATOR WILL NOT GIVE FULL CONTROL OVER THE ENTIRE RANGE OF THE TOOL. THE RANGE OF THE REGULATOR IS FROM FULL TORQUE TO APPROXIMATELY 50% OF FULL TORQUE VALUE. TIP: If a lower torque level is required it may be achieved by reducing the mains air pressure to the tool. NOTE: REPEATABILITY OF THE TOOL MAYBE AFFECTED BY THE USE OF THIS REGULATOR.

- Page 12 PAGE 10 OF 16 OPERATING INSTRUCTIONS WARNING: KEEP HANDS CLEAR OF THE REACTION ARM. WARNING: WHEN USING THIS TOOL IT MUST BE SUPPORTED AT ALL TIMES IN ORDER TO PREVENT UNEXPECTED RELEASE IN THE EVENT FASTENER OR COMPONENT FAILURE. A. TIGHTENING ____________________________________________________________ Fit Pneutorque®...

- Page 13 PAGE 11 OF 16 B. RELEASING _____________________________________________________________ NOTE: ONLY FOR BI-DIRECTIONAL TOOLS Fit the Pneutorque® with the correct size impact or high quality socket to suit the fastener to be released. Ensure the clockwise/counter-clockwise selector is correctly set. Rotate the handle into a convenient position relative to the reaction arm. Fit the tool onto the fastener to be released with the reaction arm adjacent to the reaction point.

- Page 14 PAGE 12 OF 16 MAINTENANCE To maintain optimum performance and safety, regular maintenance needs to be carried out. The only user maintenance required on these tools is the replacement of drive squares and the silencer. Any other maintenance or repairs should be carried out by Norbar or a Norbar approved agent and should form part of a service.

- Page 15 PAGE 13 OF 16 DRIVE SQUARE:- ____________________________________________________________ To avoid internal damage (especially due to torque overload), the output drive square has been designed to shear first. This saves major internal damage and allows easy square removal. Figure 10 The drive square can be replaced with either a ¾” drive square (#18544), or a 1” drive square (#18545). A new retaining screw (#25351.30) is supplied with the square.

- Page 16 PAGE 14 OF 16 SPECIFICATIONS RANGE MAXIMUM TOOL SPEED MODEL OVERLOAD (FREE RUNNING AT MAX. AIR PRESSURE) 18039 & 18041 120 N.m 600 N.m 660 N.m 200 r/min 18040 & 18042 200 N.m 1000 N.m 1100 N.m 125 r/min ± 5% Repeatability: Maximum pressure –...

- Page 17 PAGE 15 OF 16 Declaration of Conformity Manufactured by Norbar Torque Tools Ltd., Beaumont Road, Banbury, Oxon, OX16 1XJ The Directives covered by this Declaration Safety of Machinery Directive, 98/37/EEC The Equipment Covered by this Declaration Equipment: 52mm Stall Tool. Model No.(s): 18039.F06, 18039.B06, 18040.F06, 18040.B06,...

- Page 18 PAGE 16 OF 16 TROUBLE SHOOTING The following is only a guide, for more complex faults please contact your local Norbar distributor or Norbar directly. PROBLEM LIKELY SOLUTIONS Tool output does not rotate when trigger pulled. Check air supply is functioning & connected. Check air pressure setting (at least 1 bar).

- Page 20 Corporate Headquarters AIMCO Corporation De Mexico Sa De Cv 10000 S.E. Pine St. Ave. Cristóbal Colon 14529 Portland, OR 97216 Chihuahua, Chihuahua. 31125 Mexico (800) 852-1368 +52-(614) 380-1010 FAX (800) 582-9015 FAX +52 (614) 380-1019 www.aimco-global.com LIT-MAN300, Rev.07/2020 Printed in USA...

Need help?

Do you have a question about the DynaTorque PT 52 Series and is the answer not in the manual?

Questions and answers