Table of Contents

Advertisement

Quick Links

Parts

Contents

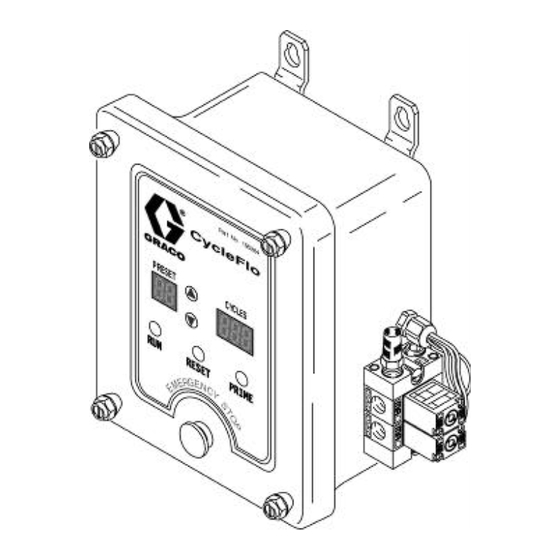

CycleFlo Pneumatic Pump Controller

ü ü

Integrated Air Valves with Silenced Exhaust

ü ü

32 Pump Cycle Presets

ü ü

1-999 Pump Cycles per Preset

ü ü

x10 Cycle Multiplier for High Volume

Applications (10 – 9,990 Cycles)

ü ü

16 Pump Cycle Rates (10 CPM to 200 CPM)

ü ü

Easy Field Programming

ü ü

Self-Test Function for Easy Troubleshooting

ü ü

Standard 120/240 VAC Power

ü ü

120 psi (.8 MPa, 8 bar) Air

Part No. 195264

GRACO INC

P.O. BOX 1441

COPYRIGHT 1999, GRACO INC

Graco Inc. Is registered to I.S. EN ISO 9001

MINNEAPOLIS, MN 55440-1441

309003

Rev A

Advertisement

Table of Contents

Summary of Contents for Graco CycleFlo 195264

- Page 1 Self-Test Function for Easy Troubleshooting ü ü Standard 120/240 VAC Power ü ü 120 psi (.8 MPa, 8 bar) Air GRACO INC P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 COPYRIGHT 1999, GRACO INC Graco Inc. Is registered to I.S. EN ISO 9001...

-

Page 2: Table Of Contents

SETUP & PROGRAMMING..................................8 (CPM) R ................................8 YCLES INUTE .........................................9 RESETS OPERATION........................................10 ....................................10 RIMING THE ..................................10 RONT ANEL PERATION ....................................10 EMOTE PERATION TROUBLESHOOTING.....................................11 SELF-TEST MODE....................................12 PARTS ..........................................13 TYPICAL INSTALLATION DIAGRAM............................14 SPECIFICATIONS.....................................15 MOUNTING INFORMATION................................17 GRACO STANDARD WARRANTY..............................18 GRACO PHONE NUMBER ..................................18 309003... -

Page 3: Warnings

Do not exceed the maximum working pressure of the lowest rated system component. • Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose Graco hoses to temperatures above 200 degrees F (93 degrees C) or below 0 degrees F (-18 degrees C). •... - Page 4 Fire, Explosion, and Electric Shock Hazard Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and resulting fire or explosion and serious injury. • Ground the pumping equipment. • Proper grounding dissipates static electricity. • This equipment is not intended for intrinsically safe areas.

-

Page 5: General Description

Failure to use the proper strain relief, wire type, wire size, can cause damage to internal components or personal injury. The 24 volt DC air supply valve signal is used to control a 3 way valve (Graco part Fire, Explosion, and Electric Shock Hazard number 115605) on the main air supply of pumps larger than the Husky 205. -

Page 6: 120 Volts To 240 Volts Conversion

24VDC, 100mA. The AIR SUPPLY VALVE signal is a 24VDC output signal. This signal is drives the external 6W solenoid valve (Graco part number 115605) controlling the main air supply. (Required for pumps larger than the Husky 205). -

Page 7: Pneumatic Connections

Pneumatic Connections The integrated air valves, located on the right side of the CycleFlo enclosure, have a common air inlet (1/4"NPT) port at the bottom and two outlet ports (1/8”NPT) towards the front of the unit. The exhaust is silenced with a muffler. -

Page 8: Setup & Programming

Setup & Programming An 8 position DIP switch (SW1) (see figure 1 for location) is used to set the cycle rate and cycles multiplier. It is also used to invoke various test modes. Before the CycleFlo can be put into operation, the following (See figure 4) parameters must be programmed for each particular application: Fig.3 –... -

Page 9: Presets

Presets The CycleFlo has 32 programmable Presets to easily switch between amounts of fluid delivered by the pump during a RUN cycle. Each preset is programmed with the number of times the pump will be cycled. Use the ù and ü buttons on the front panel to step through the presets. The PRESET display will indicate the selected PRESET program number and the CYCLES display will show the associated number of pump cycles. -

Page 10: Operation

Operation Priming the Pump A priming feature allows for the temporary operation of the pump for priming purposes. The pump cycle rate during priming is controlled by the 8 position DIP switch (SW1). Pressing the PRIME button on the front panel will start the pump cycling while the button is held. Once primed, release the button to stop pump operation. -

Page 11: Troubleshooting

Troubleshooting The following is a list of possible problems and their causes. The CycleFlo also has a built-in self-test mode that allows dynamic testing of all components. Troubleshooting Guide Problem Possible Cause & Remedy No operation at all 1. Blown fuse – check fuse & replace with 250V 1/4A type 2. -

Page 12: Self-Test Mode

Self-Test Mode During this test the solenoid valves may be activated.This will activate a connected pump. To prevent inadvertent pumping, disconnect the air supply to the solenoid valves or remove the air lines to the pump. The CycleFlo has a built-in test program that allows for dynamic testing of all internal and external components. Once activated, the self-test mode will do the following continuously until the test mode is de-activated: •... -

Page 13: Parts

Parts Main Board Air Valve Display Board Enclosure Enclosure Ribbon Cable Part No. Description 195264 CycleFlo Pneumatic Pump Controller Unit 115416 Enclosure 115384 Emblem (Not shown – located on front of unit) 115381 Main Board 115380 Display Board 115382 Ribbon Cable 115383 Air Valve (Note: two valves are required per controller) 309003... -

Page 14: Typical Installation Diagram

Typical Installation Diagram Controller Diaphragm Pump (Husky 205 shown) PH Controller, Flow Controller, Timer, etc. 309003... -

Page 15: Specifications

Specifications Power Requirements: 120/240 Vac, 50/60 Hz, ¼ to ½ Amp Air Supply: 120 psi Max 309003... - Page 16 309003...

-

Page 17: Mounting Information

Mounting Information 4” 102 mm 8 7/8” 225 mm 309003... -

Page 18: Graco Standard Warranty

Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco's written recommendations.

Need help?

Do you have a question about the CycleFlo 195264 and is the answer not in the manual?

Questions and answers