Summary of Contents for Bender ISOMETER iso175

- Page 1 Manual EN ISOMETER® iso175 Insulation monitoring device for unearthed drive systems (IT systems) in road vehicles iso175_D00415_01_M_XXEN/11.2023...

- Page 2 iso175_D00415_01_M_XXEN/11.2023...

-

Page 3: Table Of Contents

Signs and symbols............................5 Service and Support............................5 Training courses and seminars........................6 Delivery conditions............................6 Inspection, transport and storage......................6 Warranty and liability.............................6 Disposal of Bender devices..........................7 1.10 Safety..................................7 List of abbreviations..................8 Device-specific safety instructions..............9 Function......................11 Intended use..............................11 Device features...............................11... - Page 4 Table of contents 4.10.1 Device error..............................18 4.10.2 HV system.................................18 4.10.3 Status output OK ............................20 Dimensions and mounting................21 Wiring........................ 22 Commissioning....................23 Operation......................24 R_iso_corrected / R_iso_original......................24 Interfaces................................24 8.2.1 Status output OK ............................24 8.2.2 High-Speed CAN............................24 Insulation measurement..........................25 Checking the connection of the device....................

-

Page 5: General Information

Protect from dust Temperature range Recycling RoHS directives Service and Support Information and contact details about customer service, repair service or field service for Bender devices are available on the following website: Fast assistance | Bender GmbH & Co. KG. iso175_D00415_01_M_XXEN/11.2023... -

Page 6: Training Courses And Seminars

Regular face-to-face or online seminars for customers and other interested parties: www.bender.de > know-how > seminars. Delivery conditions The conditions of sale and delivery set out by Bender GmbH & Co. KG apply. These can be obtained in printed or electronic format. The following applies to software products: ‘Software clause in respect of the licensing of standard software as part of deliveries,... -

Page 7: Disposal Of Bender Devices

ISOMETER® iso175 Disposal of Bender devices Abide by the national regulations and laws governing the disposal of this device. For more information on the disposal of Bender devices, refer to www.bender.de > service & support. 1.10 Safety If the device is used outside the Federal Republic of Germany, the applicable local standards and regulations must be complied with. -

Page 8: List Of Abbreviations

List of abbreviations List of abbreviations Abbreviation Description High voltage HS-CAN High speed CAN Kl. 15 Terminal 15 Kl. 31 Terminal 31 n.c. not connected Digital status output (LV pin 8, high-side active) Signal not valid to be defined iso175_D00415_01_M_XXEN/11.2023... -

Page 9: Device-Specific Safety Instructions

ISOMETER® iso175 Device-specific safety instructions DANGER High voltage Danger to life The ISOMETER® is galvanically connected to the HV busbar of the vehicle. When it is installed, up to 1000 V are applied to the electronic contacts of the HV+ connector and the adjacent components. This applies also to the switched-off condition, i. - Page 10 Device-specific safety instructions ADVICE As prerequisite for proper monitoring of the chassis ground connection (see chapter “Online self test”, page 14), terminal 31 must be connected to the same potential as LV-pin 3. This connection may not be made directly at the device itself but via chassis ground. Only in this manner can it be ensured that LV-pin 3 is also connected to chassis ground.

-

Page 11: Function

HV system. Depending on the variant, the device communicates with a higher-level location using different CAN protocols (standard Bender, SAEJ1939). Other installation locations in the vehicle or in industry sectors such as e. g. the shipping, railroad or aerospace industries are considered non-compliant with the intended use. -

Page 12: Measured Value Quality

Function The present duration of an individual insulation measurement is output by the measured value Isolation: Time_elapsed_since_last_measurement. At the beginning of each new insulation measurement this value is automatically reset to 0 s. Due to the then following internal statistical filtering and averaging of the individual measured values, the insulation resistance measured value is only available at the device interface with a delay (after up to 12 individual measurements). -

Page 13: Fast Start Measurement

ISOMETER® iso175 Wiring example 4.3.4 Fast start measurement The ISOMETER® includes a fast start measurement that is dependent on the selected profile. After a restart this provides the user with a quick overview over the insulation status of the HV system before the first complete measurement has been carried out. -

Page 14: Self Test

Function However, the interim values (estimated values) are only calculated when the following conditions have been met by the HV system: Condition 1: The voltage of the HV system must be stable for at least 200 ms within the first 3 s after the insulation measurement has been started, i. -

Page 15: Offline Self Test

ISOMETER® iso175 4.4.2 Offline self test The offline self test checks the following device functions: • Electrical connection from connector HV+ to connection cable HV_pos (L+) • Electrical connection from connector HV- to connection cable HV_neg (L-) ADVICE During the test only the electrical connection is checked, the polarity of the connection, however, is not checked. -

Page 16: Measurement Profiles

Function Measurement profiles The ISOMETER® offers users different measurement profiles which they can use to better adapt their device to the respective HV system. This adaptation can be performed in 2 ways: Temporarily: If sudden disturbances occur in an HV system, e. g. significant HV voltage fluctuations, users can change the active profile in the operating mode “normal insulation measurement“... -

Page 17: Chassis-Ground Connection

ISOMETER® iso175 Chassis-ground connection The device can use a CAN command (Earthlift: Status) to separate the chassis-ground connection. The chassis-ground connection must always be disconnected when a further isometer monitors the HV system. If the chassis-ground connection were not separated, a further isometer would measure also the internal resistance of the ISOMETER®... -

Page 18: Measuring The System Leakage Capacitance

Function R_iso_neg = 1220 k R_iso_pos = 780 k In this case the measured value “Unbalance“ is 39 [%]. Evaluation of the unbalance-alarm status: 39 % →the value falls hence short of the threshold value “Unbalance Threshold“ and an “Unbalance Alarm“ is triggered. The hysteresis for resetting the alarm status is 5 %, i. - Page 19 ISOMETER® iso175 holding Iso-Alarm = 0x01 users can reset all active alarm bits, provided that the corresponding alarm condition is no longer met. HV+ to chassis-ground error The ISOMETER® offers the possibility of checking the electrical connection between HV+ and chassis ground. For this purpose the offline self test must be carried out (see chapter “Offline self test”, page 15).

-

Page 20: Status Output Ok Hs

Function Insulation resistance measured value no longer up to date The ISOMETER® offers the possibility of monitoring automatically whether the insulation resistance measured value is updated within a defined time period (parameter Isolation: Threshold_Timeout_Measurement). If the measured value has not been updated within the defined time period, the corresponding alarm bit (Status: Warnings_and_Alarms, bit 6) is set. -

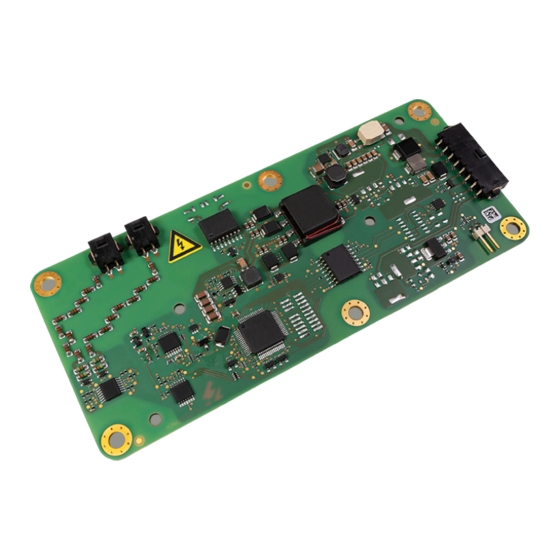

Page 21: Dimensions And Mounting

ISOMETER® iso175 Dimensions and mounting Dimensions Dimension diagram 78.25 ø 4.2 Dimensions in mm (L x W x H) 140 x 60 x 15 mm LV: protrudes 1 mm from the printed circuit board edge Red markings: fastening positions Mounting Mounting and connector kits are not part of the scope of delivery (see chapter ordering information “Accessories”, page 34). -

Page 22: Wiring

Wiring Wiring Wiring diagram HV-System DC 0 V…1000 V Kl.31 Kl.15 CAN H CAN L OK HS Connector* Pin no. Description Mains voltage (L+) Mains voltage (L-) Supply voltage - (terminal 31) Supply voltage - (terminal 15) Earth connection (E) n.c. -

Page 23: Commissioning

ISOMETER® iso175 Commissioning Once the ISOMETER® has been mounted and connected, the supply voltage and the HV system must be connected. It can be checked for proper functioning in the following manner: For appropriate functionality of the CAN-bus interface, a correctly installed termination is necessary. After the supply voltage has been switched on, the device automatically sends the message IMD_Info_General at 100 ms intervals. -

Page 24: Operation

Operation Operation R_iso_corrected / R_iso_original The insulation resistance measured value R_iso_original is the insulation resistance (raw value) actually measured by the device. In accordance with automotive standard LV 123, a measured insulation resistance must never be higher than the actually present insulation fault. For this reason the tolerance* applicable in each case is subtracted from the measured value R_iso_original, and the measured value R_iso_corrected is output additionally. -

Page 25: Insulation Measurement

R_iso_status = 0xFE. The selection of the connection cable used is decisive for a properly functioning connection. For information on validated cable types and cable lengths recommended by Bender, see chapter “Tabular data”, page 29, HV connection. - Page 26 Operation case users can switch to the profile Disturbed. This profile is more robust with respect to varying HV voltages, however it also means longer measurement times. In light of the many factors influencing the HV system, a general recommendation for the profile to be selected or for changing the profile cannot be given.

-

Page 27: Maintenance And Trouble-Shooting

ISOMETER® iso175 Maintenance and trouble-shooting Unsafe to start is always active If the fast start measurement always signals an unsafe condition (true), the following issues may be the cause: The HV system has a lower insulation resistance than twice the configured alarm threshold value “Warning“... - Page 28 Maintenance and trouble-shooting ADVICE Please not that the presence of an insulation fault in the system can then be detected only later and the vehicle has then already started off. When a customised profile is needed, Customer Service (see chapter “Service and Support”, page 5) must be contacted. The “Service“...

-

Page 29: Technical Data

ISOMETER® iso175 Technical data 10.1 Factory settings Sending the CAN command Status: Factory_reset = 1 resets all parameters to the factory settings. This requires that the device function “write enable parameter“ is active (Status: Lock = 0xFC). ADVICE For all the factory settings to become active, a power cycle (reset) must be carried out. Name Index Default value... - Page 30 Technical data Supply / monitored IT system Supply voltage U DC 12…24 V Tolerance Supply voltage U -17…+50 % ≤0.55 W Self consumption, no load at output Max. operating current I 300 mA HV voltage range (L+/L-) U DC 0…1000 V Recommended back-up-fuse M 630 mA Response values...

- Page 31 ISOMETER® iso175 Tolerance ‘R_iso_corrected’ Measuring range Abs. fault (R_iso_status = 0xFD) 0…50 k 0…-50 k Rel. fault 50 k …1.2 M 0…-120 % to 0…-48 % 1.2…5 M 0…-48 % to 0…-76 % 5…10 M 0…-76 % > 10 M not specified Tolerance ‘R_iso_corrected’...

- Page 32 Technical data CAN interface Data transmission rate 125, 250, 500, 666, 800, 1000 kBaud Terminating resistor 120 * via jumper: Recommended: Weitronictw Jumper series 165. Manufacturer ordering no.: 165-101-10-10 Load-dump protection ≤ 58 V ESD protection Contact discharge – directly at the terminals ≤...

-

Page 33: Standards And Approvals

B91068202 Response value: D00415 iso175C-32-SB TYCO B91068203 100 k (error) HS-CAN 500 k (warning) Bender iso175C-42-SB Samtec/Molex B91068204 HV+ / HV- connections • Manufacturer: TE Connectivity / AMP • Series: Micro Mate-N-Lok™ • Article number: 1445022-2 LV connection • Manufacturer: TE Connectivity / AMP •... - Page 34 HS-CAN According to customer B91068200 variants Samtec/Molex (top) (SAE J1939 or Bender) specifications For sales contact data and further information see ‘https://www.bender.de/loesungen/emobility/’ . Accessories Description Suitable for type Art. No. IR155 / iso175 fastening kit B91068500 IR155 / iso175 connection kit (TYCO)

- Page 35 Alle Rechte vorbehalten. 35305 Grünberg Nachdruck und Vervielfältigung nur mit Germany Genehmigung des Herausgebers. © Bender GmbH & Co. KG, Germany Subject to change! The specified Tel.: +49 6401 807-707 All rights reserved. standards take into account the edition emobility@bender.de Reprinting and duplicating only with valid until 11.2023 unless otherwise...

Need help?

Do you have a question about the ISOMETER iso175 and is the answer not in the manual?

Questions and answers