Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Refer to the "Model Description Chart" to match the pump material

options.

862003 for Air Section repair (see page 7).

862020 for replacement of Diaphragms (see page 4).

862025 for replacement of Balls and Seats (see page 4).

862026 (optional) for replacement of Balls and Seats (see page 4).

PUMP DATA

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . see "Model

Pump Type . . . . . . . . . . . . . . . . . . . . . . . Metallic Air Operated

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . see "Model

Weight

Aluminum . . . . . . . . . . . . . . . . . . . . . . . 19 lbs (8.62 kgs)

Stainless Steel . . . . . . . . . . . . . . . . . . . 28.95 lbs (13.13 kgs)

Maximum Air Inlet Pressure . . . . . . 120 psig (8.3 bar)

Maximum Material Inlet Pressure . 10 psig (0.69 bar)

Maximum Outlet Pressure . . . . . . . 120 psig (8.3 bar)

Maximum Flow Rate

(flooded inlet)

Maximum Particle Size . . . . . . . . . . . 1/8" dia. (3.2 mm)

Dimensional Data . . . . . . . . . . . . . . . . . see page 9 and 10

Noise Level @ 70 psig, 60 cpm

Tested with 873275 muffler installed.

The pump sound pressure levels published here have been updated to an Equivalent Contin-

uous Sound Level (LA

) to meet the intent of ANSI S1.13-1971, CAGI-PNEUROP S5.1 using four

eq

microphone locations.

GENERAL DESCRIPTION

The Bink's Diaphragm Pump offers high volume delivery even

at low air pressure. Bink's pumps feature stall resistant design,

modular air motor / fluid sections.

Air operated double diaphragm pumps utilize a pressure

differential in the air chambers to alternately create suction

and positive fluid pressure in the fluid chambers, Ball checks

ensure a positive flow of fluid. Pump cycling will begin as air

pressure is applied and it will continue to pump and keep up

with the demand. It will build and maintain line pressure and

will stop cycling once maximum line pressure is reached (dis-

pensing device closed) and will resume pumping as needed.

CCN 99866683

1" DIAPHRAGM PUMP

1:1 RATIO (METALLIC)

OPERATING OR SERVICING THIS EQUIPMENT.

Description Chart"

Double Diaphragm

Description Chart"

. . . 35 gpm (133 lpm)

. . 64.5 dB(A)

U.S.A. / Canada Customer Service

195 Internationale Blvd

Glendale Heights, IL 60139

Tel. 630-237-5000

Fax. 630-237-5011

1'' DIAPHRAGM PUMP

MODEL DESCRIPTION CHART

FLUID CAP / MANIFOLD MATERIAL, THREADS

0 - Aluminum, N.P.T.F. - 1

1 - Aluminum, B.S.P.

2 - Stainless Steel, N.P.T.F. - 1

3 - Stainless Steel, B.S.P.

CENTER BODY MATERIAL

SEAT MATERIAL

BALL MATERIAL

DIAPHRAGM MATERIAL

81882X

RELEASED:

8-20-99

REVISED:

11-9-18

(REV: K)

81882X

ALUMINUM PUMP

STAINLESS STEEL

PUMP

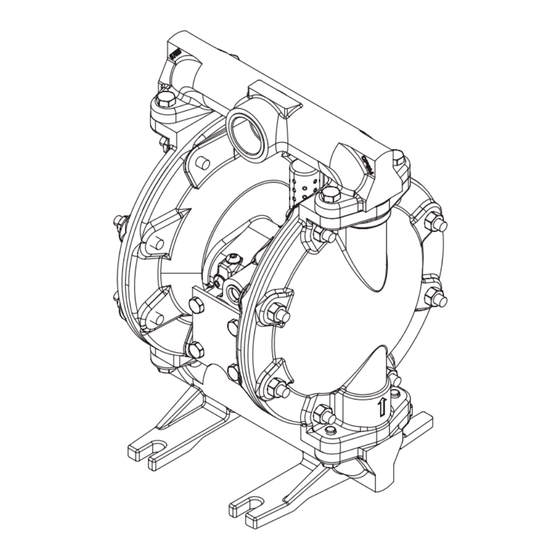

Figure 1

81882

- Aluminum

- 316 Stainless Steel

- Stainless Steel

- PTFE (Optional kit)

®

- PTFE / Santoprene

Toll Free Customer Service

and Technical Support

800-992-4657

Toll Free Fax

888-246-5732

X

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Binks 81882 Series

- Page 1 OPERATOR’S MANUAL 81882X INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE RELEASED: 8-20-99 REVISED: 11-9-18 (REV: K) 1” DIAPHRAGM PUMP 1:1 RATIO (METALLIC) READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT. It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference. SERVICE KITS 81882X 1’’...

-

Page 2: Operating And Safety Precautions

Keep containers closed when not in use. CAUTION Use only genuine Binks replacement parts to assure compatible pressure rating and longest service life. WARNING PUMP EXHAUST may contain ontaminants. Can cause severe injury. Pipe exhaust away from work area Hazards or unsafe practices which could and personnel. -

Page 3: Air And Lube Requirements

AIR AND LUBE REQUIREMENTS FLUID SECTION DISASSEMBLY EXCESSIVE AIR PRESSURE. Can cause per- 1. Remove (16) manifolds for aluminum pump and (60, 61) WARNING sonal injury, pump damage or property damage. inlet and outlet manifold for stainless steel pump. A filter capable of filtering out particles larger than 50 2. - Page 4 PARTS LIST /81882X FLUID SECTION FLUID SECTION SERVICE KITS 862020 Diaphragms Kits include: Items 7 and 8 Diaphragms, plus “O” ring items: 2, 3, 19 and Key-Lube grease packet. Items # 19 862025 Ball and Seat Repair Kits include: □...

- Page 5 PARTS LIST / 818820, 818821 FLUID SECTION ASSEMBLY TORQUE REQUIREMENTS COLOR CODE NOTE: DO NOT OVERTIGHTEN FASTENERS. Material Diaphragm Ball Color Color ALL FASTENERS ARE METRIC. Santoprene® Green (14) Bolt, 25 - 30 ft lbs (33.9 - 40.7 Nm), apply Loctite 271 to threads. (26) Bolts and (29) Nuts, 120 - 140 in.

- Page 6 PARTS LIST / 818822, 818823 FLUID SECTION FOR THE AIR MOTOR SECTION SEE PAGES 7 AND 8 Air Inlet 1’’ OUTLET Fluid Side Side 1’’ INLET Torque Sequence Cross Section View of Diaphragms Figure 3 ASSEMBLY TORQUE REQUIREMENTS COLOR CODE NOTE: DO NOT OVERTIGHTEN FASTENERS.

-

Page 7: Air Motor Section Service

PARTS LIST / 81882X AIR MOTOR SECTION Indicates parts included in 862003 Air Section Service Kit. SERVICE KIT NOTE: Service Kit 862003 is a general repair kit for all 1” and larger Bink’s diaphragm pump air motors. It contains extra “O” Rings and other- parts that may not be needed to service this model. - Page 8 PARTS LIST / 81882X AIR MOTOR SECTION IMPORTANT BE CERTAIN TO ORIENT (115) SPACER LEGS AWAY FROM BLOCKING INTERNAL PORTS WHEN REASSEMBLING AIR SECTION. MAJOR VALVE See cross section detail, gure 5. Figure 4 195A 195A 195B PILOT VALVE MAJOR VALVE CROSS SECTION DETAIL 109 110 112 114 111 116 LUBRICATION / SEALANTS...

-

Page 9: Troubleshooting

TROUBLE SHOOTING Product discharged from exhaust outlet. Low output volume, erratic flow, or no flow. Check for diaphragm rupture. Check air supply. Check tightness of diaphragm nut. Check for plugged outlet hose. Check for kinked (restrictive) outlet material hose. Air bubbles in product discharge. Check for kinked (restrictive) or collapsed inlet material Check connections of suction plumbing. - Page 10 DIMENSIONAL DATA - 818822, 818823 (Dimensions shown are for reference only, they are displayed in inches and millimeters (mm). 8-9/16” Material Outlet 8” (203 mm) (217.5 mm) 1 - 11 1/2 NPTF -1 (818822) 1 - 11 BSP (818823) Outlet 12-7/16”...

- Page 11 81882X (en) Page 11 of 12...

- Page 12 PN 876007 Page 12 of 12 81882X (en)

Need help?

Do you have a question about the 81882 Series and is the answer not in the manual?

Questions and answers