Advertisement

Quick Links

Owner's Manual & Parts Book

Grouser Products

755 2nd Ave NW - West Fargo, ND 58078

Phone: 1-701-282-7710

Fax: 1-701-282-8131

E-mail: grouser@grouser.com

Website: www.grouser.com

PN: 44616

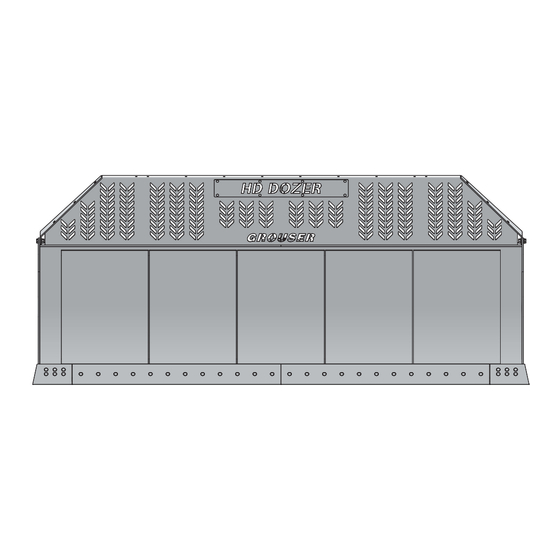

Ag Pro HD

Serial Number: 10208557-Current

Purchase Date

Serial Number

Model Number

Tractor Model

Dealer

Date 9-6-2023

Advertisement

Summary of Contents for Grouser Products Ag Pro HD

- Page 1 Ag Pro HD Owner’s Manual & Parts Book Purchase Date Grouser Products Serial Number 755 2nd Ave NW - West Fargo, ND 58078 Model Number Phone: 1-701-282-7710 Fax: 1-701-282-8131 Tractor Model E-mail: grouser@grouser.com Dealer Website: www.grouser.com PN: 44616 Serial Number: 10208557-Current...

- Page 2 Contact Us, Improvements, & Warranty Thank you for your recent purchase of a Grouser Ag Pro HD Dozer. Welcome to the family of satisfied Grouser blade owners. Grouser Products is committed to offering quality products to help professionals in their daily jobs. We are also committed to providing you the highest level of customer satisfaction possible.

- Page 3 The Ag Pro HD Dozer: 1. The Ag Pro HD Dozer should be operated only by those who are responsible and instructed to do so. 2. Read the owner’s manual carefully before using this equipment. Lack of operating knowledge can lead to accidents.

- Page 4 AG PRO PN: 27-14842-XX PN: 27-14845 PN: 27-18208 XX = Length of Blade PN: 27-2409 Left and Right Side WARNING: This product can expose you to chemicals including lead and lead compounds, mineral oils, and phthalates which are known to the State of California to cause cancer and birth defects or other reproductive harm.

- Page 5 • Inspect all bolts, and tighten any loose bolts to torque specifications on page 3. • Check replaceable cutting edge for wear ensuring there is enough material to prevent permanent damage to the Ag Pro HD Dozer. For cutting edge information, see pages 21 .

- Page 6 Some assembly of Lift System components is necessary. Follow the steps listed below. See diagram below for the correct hardware and orientation of parts. 1. Remove all pins and fasteners on each side of the undercarriage and set aside for later installation. 2.

- Page 7 Note: Refer to Pages 8-9 for the correct hose lengths and hose location. Note: All connections are identified by spiral bands. 2 bands are from the base end of a cylinder and 1 band is from the rod end of a cylinder. Orange = Lift, Green = Tilt and Red = Angle. 1.

- Page 8 QTY. PART NO. DESCRIPTION DETAIL A 11699-10-10 JIC Union SCALE 1 : 7 12631-0780 78” x 1/2" -8JIC/-8JIC Abrasion Resistant Hose 812525 12631-0810 81” x 1/2" -8JIC/-8JIC Abrasion Resistant Hose 12631-3200 320" (26.67”) x 1/2" -8JIC/-8JIC Abrasion Resistant Hose 20740 12637-3000 300"...

- Page 9 QTY. PART NO. DESCRIPTION DETAIL B 12933 11699-10-10 12932 19494-OR 12641-0670 SCALE 1:6 20809 1-1/16" Hex Jam Nut NF CZ 34032 Bulkhead Run Tee JIC 34042 Straight JIC x O-Ring 34051 Straight Thread Elbow 90° JIC x O-Ring 34059 Straight Thread Elbow 90° JIC x O-Ring 34150 Straight Thread Elbow 45°...

-

Page 10: Tilt Function

16. Cycle the left cylinder in and out 5 more times and then the right cylinder in and out 5 more times. 16. Check tractor oil level and fill if necessary. Run the blade through all the functions. If any function does not operate correctly, refer to corresponding section above and re- bleed. If problem still persists, call Grouser Products. - Page 11 To Connect: Note: If necessary, use a spotter to help center the blade on the lift system. 1. If necessary, lift the locking latch and push the quick attach lock handle on the left side of the lift system to open the quick attach system.

-

Page 12: Skid Shoe Adjustment

Skid Shoe Adjustment: 1. Remove the handle from the ratchet keeper by pulling the hitch clip pin and insert it into the handle receiver on the ratchet jack. 2. Loosen the locking nut on the ratchet jack. Storage 3. Hold the body of the ratchet jack and rotate the ratchet jack Location handle to raise or lower the skid shoes. - Page 13 PART NO. Qty. DESCRIPTION 21064 21064 3/8" x 1" Carriage Bolt Gr 5 NC CZ 15150 or 14830 14830* Custom Name Plate 20622 15150 Ag Pro Dozer Name Plate 20622 3/8" Flange Hex Nut Gr 5 NC CZ * Part Not Shown 15150-A DWG.

- Page 14 PART NO. 12'/QTY. 14'/QTY. 16'/QTY. 18'/QTY. 20'/QTY. DESCRIPTION 12380 Center Tilt Way Cover 14842-12 12' Decal 14842-14 14' Decal 14842-16 16' Decal 14842-18 18' Decal 14842-20 20' Decal 14845 Ag Pro Blade Decal 43735-12 HD Blade Weld 43735-14 HD Blade Weld 43735-16 HD Blade Weld 43735-18...

- Page 15 9506 40962 40917 18498-R 20749 18299 20749 20562 12380 20568 * Part Not Shown PART NO. PART NO. 12'/QTY. 12'/QTY. 14'/QTY. 14'/QTY. 16'/QTY. 16'/QTY. 18'/QTY. 18'/QTY. 20'/QTY. DESCRIPTION 20'/QTY. DESCRIPTION 18498-L 18498-L Ratchet Keeper - Left Ratchet Keeper - Left 18498-R 18498-R Ratchet Keeper - Right...

- Page 16 P P A A R R T T N N O O . . Q Q T T Y Y . . D D E E S S C C R R I I P P T T I I O O N N 20125 1/2"...

- Page 17 2409 9503 42140 20604 20744 19219 42100 18486 21126 18480 20130 8490 20604 20744 18485 20604 20607 21126 8490 20744 20604 18527 20604 20744 8490 18526 21126 20607 42133 20747 DWG. NO.: 43845 20214...

- Page 18 DETAIL A P P A A R R T T N N O O . . Q Q T T Y Y . D D E E S S C C R R I I P P T T I I O O N N SCALE 1 : 10 11492-8-8 Male JIC x Female JIC Swivel Nut Elbow 45°...

- Page 19 34728 20607 34050 41638 13515 44614 20219 41638 20794 20747 20747 20220 20125 44613 13515 18490 See Detail B 34953 44608 44609 19312-03 20037 44303 See Detail D See Detail A 44328 34750 12631-0280 16695 See Detail C 20607 13515 42138 20747 DETAIL D...

- Page 20 P P A A R R T T N N O O . . Q Q T T Y Y . . D D E E S S C C R R I I P P T T I I O O N N 13933-2-2 1/8”...

- Page 22 Hydraulic Multi-Couplers Left Right Lift Cylinder Lift Cylinder Green Spiral Green Spiral Red Spiral Red Spiral Orange Spiral Orange Spiral Bands (x2) Bands (x1) Bands (x2) Bands (x1) Bands (x2) Bands (x1) Tilt Left Tilt Right Right Right Lift Down Lift Up Side Up Side Up...

- Page 23 Before Each Use: Fixed Half Mobile Half Disconnect the mobile half from the parking station and the cap from the fixed half. Check that there is no contamination (salt, sand, dirt, etc.): On the pins. Inside the cam. In the locking mechanism area. On the face of the plates and couplings.

- Page 24 Cleaning The Female Bushing: Cleaning The Male Interface Seal Make sure the coupling is securely fastened Make sure the coupling is securely fastened into the plate or place in a vice. into the plate or place in a vice. Using a blunt, non-marring tool, depress the Using a non-marring tool, depress the valve face until the seal is exposed.

- Page 25 Leaking When Connected: 1. Male Coupler is the issue despite leakage visually appearing from either top or bottom of female coupler sleeve, the seal between the two halves is made from the male interface seal. 2. Root cause typically is contamination. Can be identified by pushing in piston on male and exposing male seal. If dirty, can be wiped clean and reconnected to test seal.

- Page 26 Page Left Blank Intentionally...

- Page 27 Page Left Blank Intentionally...

-

Page 28: Warranty

Warranty Grouser Products warrants to the original purchaser of each item that the product be free from defects in material and workmanship under normal use and service for a period of two (2) years for Agriculture Series Blades and one (1) year for Heavy Duty Series from date of original retail delivery.

Need help?

Do you have a question about the Ag Pro HD and is the answer not in the manual?

Questions and answers