Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Winco DE30F4-XX/4

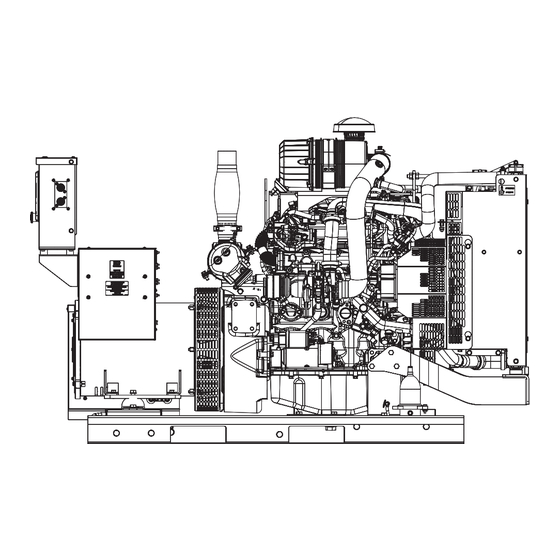

- Page 1 DE30F4-XX/4 GENERATOR INSTALLATION AND OPERATORS MANUAL www.wincogen.com...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SAVE THESE INSTRUCTIONS ENGINE CODES SAFETY INFORMATION WIRING SIZE TABLE SAFETY DEFINITIONS ENGINE HARNESS SPECIFICATIONS PANEL WIRING DIAGRAM DE30F4 DSE7310 WIRING DIAGRAM INTRODUCTION GENERATOR CONNECTIONS TESTING POLICY CA EMISSION CONTROL STATEMENT 35 Rated output of generator is based on engineering tests US ENVIRONMENTAL STATEMENT of typical units, and is subject to, and limited by, the REVALIDATION OF WARRANTY... -

Page 3: Save These Instructions

COPY YOUR MODEL AND SERIAL NUMBER HERE No other WINCO generator has the same serial number as yours. If you should ever need to contact us on this unit, it will help us to respond to your needs faster. -

Page 4: Safety Information

SAFETY INFORMATION IMPORTANT SAFETY INSTRUCTIONS This engine generator set has been designed and DANGER: FIRE HAZARD manufactured to allow safe, reliable performance. Poor Gasoline and other fuels present a hazard of possible maintenance, improper or careless use can result in explosion and/or fire. -

Page 5: Specifications

SPECIFICATIONS DE30F4 STANDBY PRIME VOLTS WATTS AMPS WATTS AMPS 120/240 1-PH 30,000 30.0 30,000 30.0 120/208 3-PH 30,000 37.5 30,000 37.5 120/240 3-PH 30,000 37.5 30,000 37.5 277/480 3-PH 30,000 37.5 30,000 37.5 346/600 3-PH 30,000 37.5 30,000 37.5 GENERATOR RESISTANCE (all value at 22°C) Model Stamford S1L2-K1... -

Page 6: Testing Policy

Go to the WINCO website for a list of engine dealers temperature, altitude, fuel, and other conditions specified (wincogen.com) or contact the WINCO Service Department. -

Page 7: Preparing The Unit

This must be completed and NOT PLACE FUEL IN THE TANK PRIOR TO LIFTING. returned to WINCO Inc. within 180 days of the factory invoice date. If this form is not returned, the Warranty may be voided. -

Page 8: Installation

When installing, ensure that the radiator is at least 0.75” from a solid surface such as a wall or duct. The radiator The WINCO installation manual OPM-112 contains is mounted on rubber vibration isolators that allow it to additional information on indoor installations and move. -

Page 9: Exhaust Installation

EXHAUST INSTALLATION INSTALLING THE FUEL LINE WARNING: PERSONAL INJURY Engine-generator sets are properly adjusted before they leave the factory. Connecting a fuel supply with adequate Improper exhaust installation will allow dangerous gases supply volume is critical to reliable operation. Diesel units to seep into enclosed spaces causing a hazard to your with optional base mounted fuel tanks are pre-plumbed to health and/or death. -

Page 10: Load Balancing

Code ANSI/NFPA 70. to properly size the wire to meet or full capacity can be drawn from C by connecting the load at exceed the amperage rating of the circuit breaker installed. 240V from L1 to L2. Remember that power from C equally reduces the amount of power available at both A and B and vice versa. -

Page 11: Transfer Switch

DC WIRING VEHICLE-MOUNTED GENERATOR Your WINCO generator ships with a bonded neutral. All communication and DC wiring should be run in separate When mounted to a vehicle to safely distribute power it is conduit from AC wiring. To install the wires, reference necessary that the generator frame is bonded to the vehicle the following picture. - Page 12 RS485. The ports are wired onto the back of the DSE7310. In order to finalize communication the program will need to be adjusted using the free DSE configuration software to enable the commutation. Contact Winco service for a list of register values. OPM-158/D...

-

Page 13: Installing The Battery

INSTALLING THE BATTERY CAUTION WARNING In the following battery installation procedure, check to be The electrolyte is diluted sulfuric acid that is harmful to the sure the engine control is in the “stop” position. This should skin and eyes. It is electrically conductive and corrosive. be your last step before initial start-up. - Page 14 Make sure all DC battery connections are tight and clean. Follow battery manufacturer’s recommendations. This charger is mounted under the customer connection on the control side of the generator. The charger will need to be plugged to a customer’s power source, using a customer supplied heavy duty, UL approved extension cord.

-

Page 15: Starting Procedure

We have partnered with a national lubrication oil 1. Remove the dipstick (1) and ensure the oil level is manufacturer to give you access to Winco private branded between the Min and Max limits. premium oil available at comparable prices to conventional oils. -

Page 16: Manual Start Panel

MANUAL START PANEL Low fuel lamp will be steady when fuel level has reached 20% or less. It will flash when the fuel level is 5% or less. (Standard) The engine will shut down if the fuel level is at 5% or less. This generator comes standard with a manual start control In the event that the upper left and upper right icons are panel. -

Page 17: Dse7310 Mkii

DSE7310 MKII WARNINGS Warnings are non-critical alarm conditions. They do not (Optional) affect the operation of the generator system, they serve to draw the operator’s attention to an undesirable CAUTION condition. Warning alarms are self-resetting when the If the DSE7310 is being replaced with a manual start panel, fault condition is removed. -

Page 18: Control Power

With the engine running smoothly check the no load voltage and frequency on the digital display. The voltage should match the nameplate and a frequency of 59.5 to 60.5 hertz (Hz). If you have the proper voltage at the generator the next step is to check the voltage at the generator terminals in the Automatic Transfer Switch. -

Page 19: Operating Conditions

OPERATING CONDITIONS Inspect the CV filters and hoses regularly during cold NORMAL OPERATION operation looking for signs of freezing. If the line freezes it will cause pressure to build in the crankcase and may cause This generator set is designed to be operated under load an engine seal failure. -

Page 20: Maintenance

We have partnered with a national lubrication oil until it is fit up against the gasket (2). manufacturer to give you access to Winco private branded 6. Using the oil filter wrench, further tighten the oil filter. premium oil available at comparable prices to conventional oils. -

Page 21: Checking Water In Pre-Filter

CHECKING WATER IN PRE-FILTER Using Illustration 2: 1. Loosen the nut (2) 2. Disconnect the fittings (1)(4). WARNING: EQUIPMENT DAMAGE 3. Remove the vapor recirculation pipe (3). Clean the exhaust valve prior to checking the pre-filter to reduce the risk for system contamination. Do NOT perform while the engine is running. -

Page 22: Maintenance Schedule

TROUBLE SHOOTING TABLES the engine and run it for approx. 5 min. 3. Drain the fuel from the injection circuit, from the filter and from the injection pump channels. 4. Connect the fuel circuit to a tank containing CFB Problem Possible Causes protective liquid (ISO 4113) and introduce the liquid by Unit will not crank when... -

Page 23: Engine Codes

ENGINE CODES FMI Test Translation The electrical Signal of the EGR Valve position sensor is monitored. In case of defect recognition a replacement value is 1B-3 taken. The electrical Signal of the EGR Valve position sensor is monitored. In case of defect recognition a replacement value is 1B-4 taken. - Page 24 FMI Test Translation The Fuel Rail pressure control is executed with a device: Metering Unit (MeUn) as feeding quantity control and an 9D-12 overpressure valve allocate in the rail (PRV). Dataset Interlock Feature is used to prevent the flashing of unintended datasets on to the ECU during any SW upgrades A6-2 in field.

- Page 25 FMI Test Translation Hardware errors in the injectors and respective ECM power stages are investigated. Diagnostic procedure uses pattern detection to identify specific errors and trigger appropriate substitute reaction. The behavior pattern describes in a 28C-5 bit mask different detected problem (overcurrent, command collision, RAM error,short circuit,..) when the expected combination of errors is detected (measured and reference pattern are matching) a failure is detected.

- Page 26 FMI Test Translation Engine Starter is controlled by two relays actuators one for Low Side and one for High Side. Both power stages are 2A4-6 monitored by Hardware for electric failures. The Engine Position Management module is responsible for signals from camshaft and crankshaft sensor evaluation: angle and speed determination, signal plausibility and quality are monitored by this module.

- Page 27 FMI Test Translation The Power stage of EGR Valve actuator is monitored by Hardware for electric failures. The Power stage of electric EGR Valve actuator (H-Bridge) is monitored by Hardware for electric failures. The H-Bridge has 2 switches (High side and Low side). Each circuit is monitored separately. The Power stage of electric EGR Valve actuator (H-Bridge) is monitored by Hardware for electric failures.

- Page 28 FMI Test Translation 4009 The Power stage of Fuel Filter heater is monitored by Hardware for electric failures. FA9-5 4009 The Power stage of Fuel Filter heater is monitored by Hardware for electric failures. FA9-6 The electrical Signal of the Oxi Cat temperature upstream sensor is monitored. In case of defect recognition a substitute 4765 129D-3 value is taken.

-

Page 29: Wiring Size Table

WIRING SIZE TABLE The table below is based on Table 310.15 (B) (16) in the National Electric Code 2014 edition. Allowable ampacitier of insulated conductors rated 0 through 2000V, 75°C through 90°C. Not more than three current-carrying conductors in Raceway, Cable, or Earth (direct buried). Adjust for 40°C (104°F) ambient temperature. -

Page 30: Engine Harness

ENGINE HARNESS OPM-158/D... -

Page 31: Panel Wiring Diagram

MANUAL START PANEL WIRING DIAGRAM OPM-158/D... -

Page 32: Dse7310 Wiring Diagram

DSE7310 WIRING DIAGRAM OPM-158/D... -

Page 33: Generator Connections

GENERATOR CONNECTIONS THREE PHASE AC WIRE HIGH AND LOW WYE OPM-158/D... - Page 34 SINGLE PHASE 311 WINDING THREE PHASE AC WIRING- DELTA OPM-158/D...

-

Page 35: Ca Emission Control Statement

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT YOUR WARRANTY RIGHTS AND OBLIGATIONS California Air Recourses Board and FPT Industrial S.p.A. are pleased to explain the emission control system warranty on 2018 to 2020 off-road engines. In California, new heavy-duty off-road engines must be designed, built, and equipped to meet the state’s stringent anti-smog standards. -

Page 36: Environmental Statement

US ENVIRONMENTAL WARRANTY STATEMENT FPT Industrial S.p.A. warrants to the ultimate purchaser and each subsequent purchaser that the engine is designed, built, and equipped so as to conform with US Environmental Protection Agency (EPA) regulations applicable at the time of manufacture and that it is free from defects in workmanship or material which would cause it not to meet these regulations for a period of time: 2 years or 1,500 hours of operation, whichever occurs first, for engines less than 19kW (25HP) 5 Years or 3,000 hours of operation, whichever occurs first, for engines greater than or equal to 19kW (25 HP) -

Page 37: Revalidation Of Warranty

(12) months afterwards for a maximum of 33 months from engine manufacture date for warranty coverage to be available, and provide written confirmation to WINCO Inc that the engine was revalidated. Warranty will be exhausted if the unit is still in the seller’s inventory after revalidation cycle. -

Page 38: Limited Warranty

Air cooled units purchased for stock have 1 year to be sold. The warranty to the original retail customer commences on the date of sale of the product to them. All liquid cooled units have 180 days from the Winco invoice to submit a start up date. If no startup form is submitted, then warranty period starts on the Winco invoice date unit was sold. - Page 39 Note 2: 3rd Year warranty coverage is parts only/no labor. Note 3: Round trip mileage is limited to 200 miles per trip and a total of 2 trips per repair unless authorized in writing by the WINCO Service Dept.

- Page 40 225 S. CORDOVA AVE • LE CENTER, MN 56057 Sales: 507-357-6821• sales@wincogen.com Service: 507-357-6831 • service@wincogen.com www.wincogen.com OPM-158/D...

Need help?

Do you have a question about the DE30F4-XX/4 and is the answer not in the manual?

Questions and answers