Table of Contents

Troubleshooting

Summary of Contents for Winco DE4040

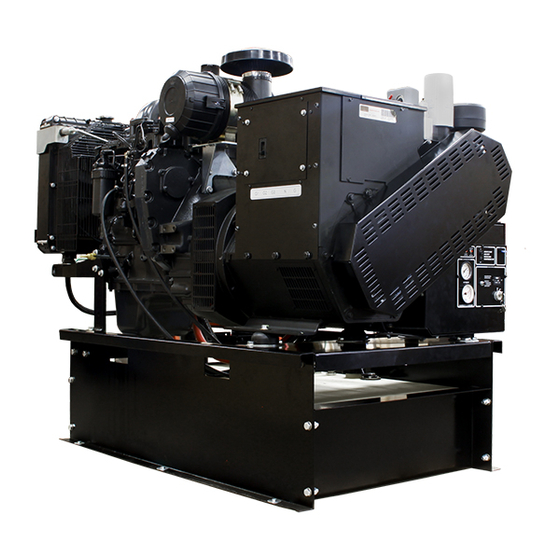

- Page 1 DE4040/2 GENERATOR INSTALLATION AND OPERATORS MANUAL MANUAL KEY START AND DSE4510 ELECTRIC START WINCO INC. 225 S. CORDOVA AVE. LE CENTER, MN 56057 SERVICE DEPT. 507-357-6831 • SALES DEPT. 507-357-6821 www.wincogen.com...

-

Page 2: Table Of Contents

COPY YOUR MODEL AND SERIAL NUMBER HERE the generator. No other WINCO generator has the same serial number as yours. If you should ever need to contact us on this unit, it will help us to USING THIS MANUAL respond to your needs faster. -

Page 3: Safety Information

SAFETY INFORMATION A. Operate only in well ventilated areas. B. Never operate indoors including attached garages This engine generator set has been designed and manufactured to C. Never operate the unit in such a way as to allow exhaust gases allow safe, reliable performance. -

Page 4: Specifications

Model Stamford UC1224D information to document build data for warranty and replacements Winding Group parts. Be sure to have the main WINCO unit data plate information Resistances Ohms recorded inside the front cover of this manual for future reference Rotor 0.59... -

Page 5: Preparing The Unit

1. As you receive your unit, it is critical to check it for any damage. If PRIOR TO LIFTING. any damage is noted, it is always easiest to refuse the shipment and let WINCO take care of the freight claim. If you sign for the unit, the transfer of the ownership requires that you file the freight claim INSTALLATION 2. -

Page 6: Ventilation Requirements

VENTILATION REQUIREMENTS LUBRICATION WARNING: EQUIPMENT DAMAGE: Before starting the engine, check the oil level in the crankcase. If It is the installer’s responsibility to ensure that there is sufficient cooling it is low, refill to the full mark with the proper weight/grade of oil as air available to prevent the engine and generator from over heating. recommended by the engine manufacturer’s maintenance instructions. -

Page 7: Servicing Batteries

SERVICING BATTERIES Installation and servicing of batteries must only be preformed or supervised by personnel knowledgeable of batteries and the required precautions. Keep unauthorized personnel away from batteries. Batteries used on these units may, over time, lose water. This is especially true if you are using a trickle charger to maintain When installing or replacing batteries, use the proper group/size your battery. -

Page 8: Neutral And Ground Lugs

Generator ships from the factory with a bonded neutral. Model Lug AMP Wire Capability Torque DE4040 #4 AWG to 300 MCM 250 in. lbs. WARNING: EQUIPMENT DAMAGE: When installing a three phase 240 Volt system, be sure you know which lead is high voltage ‘wild’ leg (208 Volt to neutral). The generator normally carries the high voltage on the G2 lead. -

Page 9: Initial Start Up

DSE4510 ELECTRONIC START INITIAL START UP Use the following check list to verify correct installation before starting NOTE: See DSE4510 Wiring Schematic in this manual for proper the engine. wiring procedure. □ Engine oil. Fill as required with proper grade/qty. □ Engine coolant. Fill as required with proper mixture. STARTING PROCEDURE □... - Page 10 The editor automatically exits after 5 minutes of inactivity to instrumentation, event log, and configuration screens. ensure security. The PIN number is not set by WINCO when the module leaves the PROTECTIONS factory. If the code has been ‘lost’ or ‘forgotten’, the module must When an alarm is present, the common alarm LED if configures will be returned to the DSE factory to have the module removed.

-

Page 11: Dse4510 Default Codes

DSE4510 DEFAULT CODES Low Fuel Level - The level detected by the fuel level Auxiliary Inputs - Auxiliary inputs can be be user sensor is below the low fuel level pre-set alarm setting. configured and will display the message as written by the user. High Fuel Level - The level detected by the fuel level Fail to Start -The engine has not fired after the preset number of start attempts. -

Page 12: De4040 Troubleshooting Table

DE4040 TROUBLESHOOTING TABLE AIR COMPRESSOR Problem Possible Causes This unit has been equipped with an air compressor that uses an Engine won’t crank Low/dead battery auxiliary shaft from the generator to provide counter-clockwise 120 PSI Blown DC fuses @ 40 CFM Defective DSE4510... -

Page 13: Adjusting The Belt

AIR COMPRESSOR MAINTENANCE There is an approximate 30PSI difference between the cutout pressure and the point at which the switch loads the compressor again. In order to reach the adjustment nut, unscrew the acorn nut on the top of the All maintenance, assembly, and repair work should be carried out by gray switch housing and lift the housing off of the switch. -

Page 14: Checking The Oil Level

ated every 100 operating hours.. over 80°C/176°F; danger of burns! Wear personal safety equipment! – With hot oil, the oil level can be approx. 10 mm evel check can only be carried out higher than with cold oil shortly after discharg- opening. -

Page 15: Replacing The Air Intake Filter

ule designed for installation in a compressed-air generating station. pressor module and/or its components– Installation and operating manual - NK 31 The sole intended use of the system is the compression of atmospheric air. The NK 31 may 1.7 Nameplate only be used to compress gases or other media 7.5 Fine separator cartridge 7.5.2 Replacing fine separator cartridge... -

Page 16: Air Compressor Troubleshooting Table

AIR COMPRESSOR TROUBLESHOOTING TABLE PROBLEM POSSIBLE CAUSES REMEDY Incorrect direction of rotation Phase reversed Reconnect 2 supply line System does not start No electricity Check electrical connections Combistat switches off due to excessively high temp Check oil level, cooling, thermo-bypass System difficult to start Motor output insufficient Check... -

Page 17: Dse4510 Wiring Schematic

DSE4510 WIRING SCHEMATIC REV B OPM-106... -

Page 18: Key Start Panel Schematic

KEY START PANEL SCHEMATIC ENGINE HARNESS SCHEMATIC NOTE: LOW COOLANT SWITCH IS OPTIONAL. OIL PRESSURE AND COOLANT TEMPERATURE SENDERS INCLUDED ON MODELS WITH ELECTRONIC ENGINE IS FOR UNITS WITH TANKS AND LEAK DETECTION FOR CONTROLS. FUEL LEVEL UNITS WITH SECONDARY CONTAINMENT. OPM-106 REV B... -

Page 19: Three Phase Ac Wiring- Delta

THREE PHASE AC WIRE HIGH AND LOW WYE THREE PHASE AC WIRING- DELTA SINGLE PHASE 311 WINDING REV B OPM-106... -

Page 20: 12 Month Limited Warranty

WINCO written instructions. WINCO’s sole liability, and Purchaser’s sole remedy for a failure under this warranty, shall be limited to the repair of the product. At WINCO’s option, material found to be defective in material or workmanship under normal use and service will be repaired or replaced.

Need help?

Do you have a question about the DE4040 and is the answer not in the manual?

Questions and answers