Advertisement

Quick Links

Order #XXXXX -

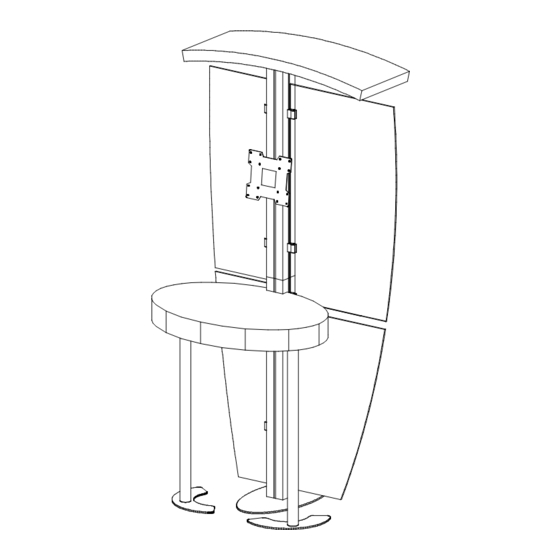

MOD-1524 - General Layout

Canopy

*

*

Q914

Use thumbscrew & washer

Connector

to attach to vertical extrusion.

3

Thumbscrew

*

Silde extrusion

over connector;

secure with screws.

2

**To prevent product loss,

Keep all screws attached

to connector piece after

disassembling

1

w w w . c l a s s i c e x h i b i t s . c o m

Item

Qty.

Description

1

1

Oval Base Plate

1A

2

Curved Base Plates

2

1

41"h Square Vertical Extrusion

3

1

41"h Square Vertical Extrusion

4

2

38" Round Vertical Extrusion

*

Counter Attachment

Counter Support

Leg Attachment

Insert screws located

on underside of counter

into holes on flange plate

and secure with wing nuts.

Washer

*

Counter Top

*

*

4

4

1A

1A

WHEN DISASSEMBLING ALUMINUM EXTRUSION, TIGHTEN ALL

SETSCREWS AND LOCKS TO PREVENT LOSS DURING SHIPPING

All manuals and user guides at all-guidesbox.com

Steps:

1) Connect verticals [2] & [3] together.

See

Q125 Connector

2) Attach base plate [1] to assembly [2/3].

3) Connect curved base plates [1A] to verticals [4].

4) Attach assemblies [1A/4] to the bottom side of counter top.

See

Counter Support Leg Attachment

5) Secure counter top to vertical [3].

See

Counter Attachment

6) Connect Monitor Mount to vertical [3].

See

Monitor Mount Attachment

7) Install Graphic Wings to A10 clips on vertical extrusions.

See

A10 Clamp

Wing Nut

A10 Clamp Detail

1) Slide Connector of A10

into extrusion groove.

2) Tighten setscrew when

A10 is in desired location.

3) Insert Infill into Clamp

4) Tighten knob on A10 to

secure wing in place.

Setscrew

Knob to attach graphics

detail.

detail.

detail.

detail.

detail

*

*

Attach monitor mount to vertical

Slide Mount

into Groove of

Vertical Extrusion.

Step 1

866.652.2100

When assembled

Monitor Mount Attachment

extrusions after assembly.

Tighten

Attach top

Setscrew

Plate and

tighten screws

© 2015

Page 1 of X

Advertisement

Summary of Contents for Classic Exhibits visionary design MOD-1524

- Page 1 All manuals and user guides at all-guidesbox.com Step 1 Order #XXXXX - MOD-1524 - General Layout 866.652.2100 Steps: Item Qty. Description 1) Connect verticals [2] & [3] together. Oval Base Plate Q125 Connector detail. Curved Base Plates 2) Attach base plate [1] to assembly [2/3]. 41”h Square Vertical Extrusion 3) Connect curved base plates [1A] to verticals [4].

- Page 2 All manuals and user guides at all-guidesbox.com Step 2 Order #XXXXX - MOD-1524 - General Information 866.652.2100 Using Your Setup Instructions The Visionary Designs Setup Instructions are created specifically for your Detail A configuration. They are laid out sequentially, including an exploded view of the entire display, and then a logical series of detailed steps to assemble the main structure and components.

Need help?

Do you have a question about the visionary design MOD-1524 and is the answer not in the manual?

Questions and answers