Subscribe to Our Youtube Channel

Summary of Contents for Danfoss H1 115

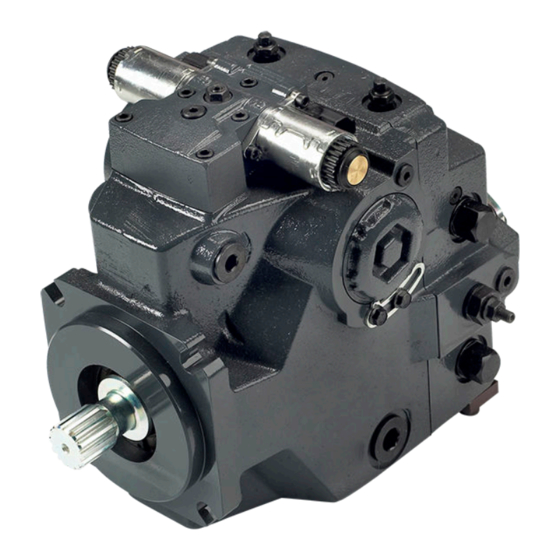

- Page 1 Technical Information H1 Axial Piston Single Pumps Size 115/130 powersolutions.danfoss.com...

- Page 2 Model code – Charge pumps size, the graphs for charge pumps change September 2014 MDC, CCO, and Swash Angle Sensor options added Mar 2014 Converted to Danfoss layout - DITA CMS Apr 2013 FDC option added mar 2013 AC section updated...

-

Page 3: Table Of Contents

H1P input shaft - Option G2 (SAE D, 27 teeth)........................39 H1P input shaft - Option F3, Code 44-3..........................40 Tapered shaft customer acknowledgement........................41 H1P 115/130 Auxiliary mounting - Option H2 (SAE A, 9 teeth)..................42 11063346 | BC00000198en-US0801 | 3 © Danfoss | May 2017... - Page 4 Non Feedback Proportional Electric control (NFPE), with manual override, option A8 (12 V) / B8 (24 V)..59 Automotive Control (AC) Dimensions............................60 Forward-Neutral-Reverse (FNR) with manual override, options A9 (12 V) / B1 (24 V)...........61 Filtration H1P 115/130 suction filtration, option L..........................62 H1P 115/130 filtration, option M..............................63 11063346 | BC00000198en-US0801 © Danfoss | May 2017...

-

Page 5: Technical Specifications

The housing must always be filled with hydraulic fluid. Recommended mounting for a multiple pump stack is to arrange the highest power flow towards the input source. Consult Danfoss for nonconformance to these guidelines. Will be inlet pressure with internal charge pump. For reference see H1P 115/130 Operating Parameters. -

Page 6: H1P 115/130 Operating Parameters

Intermittent = Short term t < 1min per incident and not exceeding 2 % of duty cycle based load-life At the hottest point, normally case drain port Cold start = Short term t < 3 min, p ≤ 50 bar [725 psi], n ≤ 1000 min (rpm) 11063346 | BC00000198en-US0801 © Danfoss | May 2017... -

Page 7: External Radial Shaft Loads

= shaft moment L = flange distance = external force to the shaft Thrust loads should be avoided. Contact your Danfoss representative in the event thrust loads are anticipated. H1P 115/130 Bearing Life Maximum external shaft load based on shaft deflection... -

Page 8: H1P 115/130 Mounting Flange Loads

= 5933 N•m [52 510 lbf•in] Shock load moment = 12 640 N•m [ 111 870 lbf•in] For more information, see H1 Axial Piston Pumps, Basic Information, BC00000057, the section “Mounting flange loads”. 11063346 | BC00000198en-US0801 © Danfoss | May 2017... -

Page 9: Charge Pump Selection

Multiple low speed high torque motors • High input shaft speeds Contact your Danfoss representative for application assistance if your application includes any of these conditions. Charge Pump Curves, Size 26/34 cm³ The curves shown below at the following conditions:... -

Page 10: Master Model Code

24 V — NFPE 12 V — NFPE 24 V — NFPE 12 V — — NFPE 24 V — — Align with options: E: Displacement limiters and W: Special hardware. 11063346 | BC00000198en-US0801 10 | © Danfoss | May 2017... - Page 11 D – Controls (continued) — Fan Drive Control (FDC) Code Control type Voltage DEUTSCH Connector 12 V 24 V Align with options: F: Orifices, E: Displacement limiters, M, N: Overpressure protection, and W: Special hardware. 11063346 | BC00000198en-US0801 | 11 © Danfoss | May 2017...

- Page 12 No limiters, with nested springs, required for NFPE, AC, FDC Adjustable externally Adjustable externally with nested springs, required for NFPE, AC, FDC Align with option Y: Settings for adjustment (if applicable).ima1444887758105 11063346 | BC00000198en-US0801 12 | © Danfoss | May 2017...

- Page 13 Flange 127–4, outer Ø32 mm - 4 (SAE C, 14 teeth 12/24 coupling) Flange 101–2, outer Ø22 mm - 4 (SAE B, 14 teeth 12/24 coupling) Align with option: G – Endcap selection. 11063346 | BC00000198en-US0801 | 13 © Danfoss | May 2017...

- Page 14 420 bar [6090 psi] 450 bar [6526 psi] L, F – with pressure limiter; K – without pressure limiter. Please contact Danfoss Power Solutions for pressures not shown or for applied pressure above max. working pressure (see H1P 115/130 Operating Parameters on page 6).

- Page 15 EDC / FNR / MDC valve plate with speed ring on the cylinder block (Align with options: D and E ) MDC / EDC / FNR valve plate with MDC handle X – Paint and nametag Black paint and Danfoss nametag 11063346 | BC00000198en-US0801 | 15 ©...

- Page 16 – – (12 V AC–2 in/out with Swash Plate in/out – – Angle Sensor (24 V in/out MDC handle standard position None = available option – = not available option 11063346 | BC00000198en-US0801 16 | © Danfoss | May 2017...

-

Page 17: Control Options

Electrical Displacement Control, with hydraulic schematic F00B F00A Feedback from Swash plate P003 478E P003 191 Pump displacement vs. control current 100 % Current mA "0" 100 % P003 479E 11063346 | BC00000198en-US0801 | 17 © Danfoss | May 2017... -

Page 18: Edc Control Signal Requirements

Description Quantity Ordering data Mating connector DEUTSCH DT06-2S Wedge lock DEUTSCH W2S Socket contact (16 and 18 AWG) DEUTSCH 0462-201-16141 Danfoss mating connector kit K29657 EDC Solenoid Data Description 12 V 24 V Maximum current 1800 mA 920 mA Nominal coil resistance @ 20 °C [68 °F]... -

Page 19: Control Response

0.8 mm [0.03 in] orifice 1.3 mm [0.05 in] orifice No orifice Neutral to full flow 4.4 s 1.95 s 1.0 s Full flow to neutral 2.9 s 1.3 s 0.8 s 11063346 | BC00000198en-US0801 | 19 © Danfoss | May 2017... -

Page 20: Manual Displacement Control (Mdc)

Torque required to move handle to maximum displacement 1.4 N•m [12.39 lbf•in ] Torque required to hold handle at given displacement 0.6 N•m [5.31 lbf•in] Maximum allowable input torque 20 N•m [177 lbf•in] 11063346 | BC00000198en-US0801 20 | © Danfoss | May 2017... -

Page 21: Mdc General Information

MDC shaft rotation Port A in (low) out (high) out (high) in (low) Port B out (high) in (low) in (low) out (high) Servo port high pressure As seen from shaft side. 11063346 | BC00000198en-US0801 | 21 © Danfoss | May 2017... -

Page 22: Control Response

The Neutral Start Switch (NSS) contains an electrical switch that provides a signal of whether the control is in neutral. The signal in neutral is Normally Closed (NC). Neutral Start Switch schematic P005 702 11063346 | BC00000198en-US0801 22 | © Danfoss | May 2017... -

Page 23: Connector

Wedge lock DEUTSCH W2S Socket contact (16 and 18 AWG) DEUTSCH 0462-201-16141 Danfoss mating connector kit K29657 Case Gauge Port M14 The drain port should be used when the control is mounted on the unit’s bottom side to flush residual contamination out of the control. -

Page 24: Forward-Neutral-Reverse Electric Control (Fnr), Options: A9 (12 V) And B1 (24 V)

P003 480 Connector ordering data Description Quantity Ordering data Mating connector DEUTSCH DT06-2S Wedge lock DEUTSCH W2S Socket contact (16 and 18 AWG) DEUTSCH 0462-201-16141 Danfoss mating connector kit K29657 11063346 | BC00000198en-US0801 24 | © Danfoss | May 2017... -

Page 25: Control Response

Stroking direction 0.8 [0.03] orifice 1.3 [0.05] orifice No orifice Neutral to full flow 4.2 s 1.9 s 1.2 s Full flow to neutral 5.2 s 2.2 s 1.1 s 11063346 | BC00000198en-US0801 | 25 © Danfoss | May 2017... -

Page 26: Non Feedback Proportional Electric Control (Nfpe)

A typical response characteristic is shown in the accompanying graph. Under some circumstances, such as contamination, the control spool could stick and cause the pump to stay at some displacement. 11063346 | BC00000198en-US0801 26 | © Danfoss | May 2017... -

Page 27: Nfpe Control Signal Requirements

Description Quantity Ordering data Mating connector DEUTSCH DT06-2S Wedge lock DEUTSCH W2S Socket contact (16 and 18 AWG) DEUTSCH 0462-201-16141 Danfoss mating connector kit K29657 Description 12 V 24 V Maximum current 1800 mA 920 mA Nominal coil resistance @ 20 °C [68 °F] 3.66 Ω... -

Page 28: Control Response

Stroking direction 0.8 [0.03] orifice 1.3 [0.05] orifice No orifice Neutral to full flow 5.0 s 2.4 s 0.9 s Full flow to neutral 2.5 s 1.2 s 0.4 s 11063346 | BC00000198en-US0801 28 | © Danfoss | May 2017... -

Page 29: Automotive Control (Ac)

Individual settings for forward and reverse driving direction (4 x 2 curves). • Independent pump and hydraulic-motor profiling and ramping for each mode. • Electric drive pedal connection • Electronic inching function without separate control valve • Electric creep mode potentiometer 11063346 | BC00000198en-US0801 | 29 © Danfoss | May 2017... -

Page 30: Performance Functions

Factory calibration for hysteresis compensation. • Starting current adjustment in the factory • Pre-installed application software and parameter files For more information, see Automotive Control for H1 SIngle Pumps Technical Information, BC00000213. 11063346 | BC00000198en-US0801 30 | © Danfoss | May 2017... -

Page 31: Fan Drive Control (Fdc)

Use in other systems could result in unintended movement of the machine or it’s elements. Loss of the input signal to this control will cause the pump to produce maximum flow. The FDC is for Fan Drive systems only! 11063346 | BC00000198en-US0801 | 31 © Danfoss | May 2017... - Page 32 Pump displacement vs. control current Forward 100% H1 FDC control Max Current a = Forward Threshold b = Reverse Threshold N = Neutral Override Current 100% Signal Current (mA(DC Reverse P301 443 11063346 | BC00000198en-US0801 32 | © Danfoss | May 2017...

-

Page 33: Manual Override (Mor)

45 N to engage the plunger. Additional actuations typically require less force to engage the MOR plunger. Proportional control of the pump using the MOR should not be expected. Refer to control flow table for the relationship of solenoid to direction of flow. 11063346 | BC00000198en-US0801 | 33 © Danfoss | May 2017... -

Page 34: Swash Plate Angle Sensor For Nfpe And Ac2 Controls

Working range (swashplate angle) 475 mV 500 mV 525 mV Correlation between signals 1 and 2 Up to duration of 2.5 seconds at 25°C Signal 1 (nominal) is lower than signal 2 (redundant) 11063346 | BC00000198en-US0801 34 | © Danfoss | May 2017... -

Page 35: Swash Plate Angle Sensor Connector

K02325 Interface with ECU Interface with ECU schematic 0.1uF 340R 340R Sig1 Out 1 5.6 nF 340R 340R Sig2 Out 2 5.6 nF Minimum recommended load resistance is 100 kΩ. 11063346 | BC00000198en-US0801 | 35 © Danfoss | May 2017... -

Page 36: Control-Cut-Off Valve (Cco Valve)

CCO schematic (MDC shown) P005 703 CCO connector Connector ordering data Description Quantity Ordering number Mating connector DEUTSCH DT06-2S Wedge lock DEUTSCH W2S Socket contact (16 and 18 AWG) DEUTSCH 0462-201-16141 11063346 | BC00000198en-US0801 36 | © Danfoss | May 2017... -

Page 37: Cco Solenoid Data

External wrench size 80 N•m [708 lbf•in] Torque for external hex seal lock nut For more information, see H1 Axial Piston Pumps, Service Manual, AX00000087, the section “Displacement Limiter Adjustment”. 11063346 | BC00000198en-US0801 | 37 © Danfoss | May 2017... -

Page 38: Dimensions

2206 N•m [19 500 lbf•in] Maximum For definitions of maximum and rated torque values, refer to H1 Axial Piston Pumps Basic Information, BC00000057, the section “Shaft Torque Ratings and Spline Lubrication”. 11063346 | BC00000198en-US0801 38 | © Danfoss | May 2017... -

Page 39: H1P Input Shaft - Option G2 (Sae D, 27 Teeth)

3000 N•m [26 550 lbf•in] Maximum For definitions of maximum and rated torque values, refer to H1 Axial Piston Pumps Basic Information, BC00000057, the section “Shaft Torque Ratings and Spline Lubrication”. 11063346 | BC00000198en-US0801 | 39 © Danfoss | May 2017... -

Page 40: H1P Input Shaft - Option F3, Code 44-3

Rated torque includes just the capability of the press-fit in accordance with an assumed fastener grade 5. For definitions of maximum and rated torque values, refer to H1 Axial Piston Pumps Basic Information, BC00000057, the section “Shaft Torque Ratings and Spline Lubrication”. 11063346 | BC00000198en-US0801 40 | © Danfoss | May 2017... -

Page 41: Tapered Shaft Customer Acknowledgement

The Danfoss H1 tapered shaft has been designed using the industry standard ISO 3019-1, minus the through-hole in the end of the shaft. Danfoss recommends a self-locking nut instead of a castle nut and pin. The nut and mating square-cut key are customer supplied. The specified torque rating of the tapered shaft is based on the cross-sectional diameter of the shaft, through the keyway, and assumes the proper clamp and fit between shaft and coupling. -

Page 42: H1P 115/130 Auxiliary Mounting - Option H2 (Sae A, 9 Teeth)

BC00000057, the section “Shaft Torque Ratings and Spline Lubrication”. Caution Standard pad cover is installed only to retain coupling during shipping. Do not operate pump without an auxiliary pump or running cover installed. 11063346 | BC00000198en-US0801 42 | © Danfoss | May 2017... -

Page 43: H1P 115/130 Auxiliary Mounting - Option H1 (Sae A, 11 Teeth)

BC00000057, the section “Shaft Torque Ratings and Spline Lubrication”. Caution Standard pad cover is installed only to retain coupling during shipping. Do not operate pump without an auxiliary pump or running cover installed. 11063346 | BC00000198en-US0801 | 43 © Danfoss | May 2017... -

Page 44: H1P 115/130 Auxiliary Mounting - Option H3 (Sae B, 13 Teeth)

BC00000057, the section “Shaft Torque Ratings and Spline Lubrication”. Caution Standard pad cover is installed only to retain coupling during shipping. Do not operate pump without an auxiliary pump or running cover installed. 11063346 | BC00000198en-US0801 44 | © Danfoss | May 2017... -

Page 45: H1P 115/130 Auxiliary Mounting - Option H5 (Sae B-B, 15 Teeth)

PRESSURE ANGLE : 30° SHAFT LENGHT : ∅29.633 [∅1.167] PITCH-Ø TYP OF FIT : FILLETT ROOT, SIDE FIT : ANSI B92.1-1996 CLASS 6 MIN ACTIVE SPLINE LENGTH 17.8MM P301 301 11063346 | BC00000198en-US0801 | 45 © Danfoss | May 2017... -

Page 46: H1P 115/130 Auxiliary Mounting - Option H6 (Sae C, 14 Teeth)

BC00000057, the section “Shaft Torque Ratings and Spline Lubrication”. Caution Standard pad cover is installed only to retain coupling during shipping. Do not operate pump without an auxiliary pump or running cover installed. 11063346 | BC00000198en-US0801 46 | © Danfoss | May 2017... -

Page 47: H1P 115/130 Auxiliary Mounting - Option H4 (Sae D, 13 Teeth)

BC00000057, the section “Shaft Torque Ratings and Spline Lubrication”. Caution Standard pad cover is installed only to retain coupling during shipping. Do not operate pump without an auxiliary pump or running cover installed. © Danfoss | May 2017 11063346 | BC00000198en-US0801 | 47... -

Page 48: H1P 115/130 Displacement Limiters, Option B And D

167.0 ± 2.0 [5.546 ± 0.039] [6.575 ± 0.079] [6.575 ± 0.079] Wrench size 22 (external hex) Wrench size 6 (internal hex) P003 401E Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 48 | © Danfoss | May 2017... -

Page 49: Installation Drawings

Servo gauge port ∕ –20; Ø24.5 max clearance dia for fitting Charge inlet port ∕ –12; Ø69 max clearance dia for fitting Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 | 49 © Danfoss | May 2017... - Page 50 –18; Ø28 max clearance dia for fitting Servo / Case gauge port ∕ –20; Ø21 M5 / M14 max clearance dia for fitting Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 50 | © Danfoss | May 2017...

-

Page 51: Dimensions H1P 115/130

110.9 ± 0.2 Shaft L Shaft L 106.5 ± 0.2 Shaft L [2.559 ± 0.008] [4.366 ± 0.008] [4.193 ± 0.008] P003 394E Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 | 51 © Danfoss | May 2017... - Page 52 ∅ 42.0 max. clearance dia for fitting [10.123 ± 0.039] from filter Shaft L 106.5 ± 0.2 [4.193 ± 0.008] P003 395E Shaft L Shaft L Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 52 | © Danfoss | May 2017...

- Page 53 System A gauge port “MA” Port ISO 11926-1 – P003 396E ∅28.0 max. clearance dia for fitting Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 | 53 © Danfoss | May 2017...

-

Page 54: Controls

[3.13 ± 0.039] Mounting flange Connector : Deutsch DT04-2P to be paint free 2x 141.5 ± 1.0 [5.571 ± 0.039] P003 398E Shaft L Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 54 | © Danfoss | May 2017... -

Page 55: H1P 115/130 Manual Displacement Control (Mdc), Option M1

4x M6x1-6H thd. 9 min. full thd. depth paint free Control handle shaft Shaft 52.9±0.8 Mounting flange 70.7±0.8 75.9±0.8 103.3±0.8 Shaft 70111500-D10 Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 | 55 © Danfoss | May 2017... -

Page 56: H1P 115/130 Manual Displacement Control (Mdc) With Nss, Option M2

75.9±0.8 103.3±0.8 Neutral Start Switch connector: Deutsch DT04-2P paint free Shaft 70111500-D11 Neutral Start Switch connector: Assignment Assignment Supply Ground Ground Supply Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 56 | © Danfoss | May 2017... -

Page 57: H1P 115/130 Manual Displacement Control (Mdc) With Cco, Option M3, M4

Control Cut Off connector C4: Deutsch DT04-2P paint free 102.97 ±0.8 Shaft 70111500-D12 Control Cut Off connector C4: Assignment Assignment Supply Ground Ground Supply Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 | 57 © Danfoss | May 2017... -

Page 58: H1P 115/130 Manual Displacement Control (Mdc) With Nss And Cco, Option M5, M6

102.97 ±0.8 Shaft 70111500-D13 Neutral Start Switch connector / Control Cut Off connector C4: Assignment Assignment Supply Ground Ground Supply Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 58 | © Danfoss | May 2017... -

Page 59: Non Feedback Proportional Electric Control (Nfpe), With Manual Override, Option A8 (12 V) / B8 (24 V)

[3.13 ± 0.039] Mounting flange Connector : Deutsch DT04-2P to be paint free 2x 141.5 ± 1.0 [5.571 ± 0.039] P003 397E Shaft L Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 | 59 © Danfoss | May 2017... -

Page 60: Automotive Control (Ac) Dimensions

Control connector Deutsch DT06-2S; Paint free; For using connector the plug may be CCC3 removed. Control connector Deutsch DTM04-3P; Paint free; For using connector the plug may be removed. Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 60 | © Danfoss | May 2017... -

Page 61: Forward-Neutral-Reverse (Fnr) With Manual Override, Options A9 (12 V) / B1 (24 V)

[3.13 ± 0.039] Mounting flange Connector : Deutsch DT04-2P to be paint free 2x 141.5 ± 1.0 [5.571 ± 0.039] P003 400E Shaft L Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 | 61 © Danfoss | May 2017... -

Page 62: Filtration

∅ 69 max. clearance dia for fitting per ISO 6162 M12 x 1.75 M12 x 1.75 20 min. 20 min. full thread depth full thread depth P003 403E Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 62 | © Danfoss | May 2017... -

Page 63: H1P 115/130 Filtration, Option M

[11.739 ± 0.039] [1.639 ± 0.039] 306.916 ± 1.0 77.749 ± 1.0 [12.083 ± 0.039] [3.061 ± 0.039] P003 404E Please contact Danfoss representative for specific installation drawings. 11063346 | BC00000198en-US0801 | 63 © Danfoss | May 2017... - Page 64 Phone: +86 21 3418 5200 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

Need help?

Do you have a question about the H1 115 and is the answer not in the manual?

Questions and answers