Danfoss H1 Technical Information

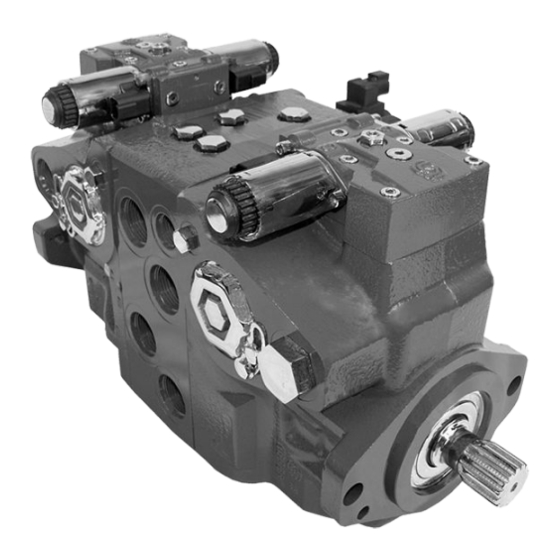

Axial piston pump, size 045/053, single

Hide thumbs

Also See for H1:

- Technical information (144 pages) ,

- Service manual (72 pages) ,

- Basic information (40 pages)

Summary of Contents for Danfoss H1

- Page 1 MAKING MODERN LIVING POSSIBLE Technical Information H1 Axial Piston Pump Size 045/053, Single powersolutions.danfoss.com...

- Page 2 Technical Information H1 Axial Piston Pump Size 045/053, Single Revision History Table of Revisions Date Changed Mar 2014 Converted to Danfoss laylout - DITA CMS Apr 2013 FDC option added Mar 2013 AC section updated Nov 2012 AC added Feb 2011...

-

Page 3: Table Of Contents

H1P input shaft - Option F2, Code 25-3..........................30 Tapered shaft customer acknowledgement........................30 Auxiliary mounting pads................................31 H1P Auxiliary mounting - Option H2 (SAE A, 9 teeth)....................31 H1P Auxiliary mounting - Option H1 (SAE A, 11 Teeth) .....................32 11063344 • Rev HA • Mar 2014... - Page 4 Technical Information H1 Axial Piston Pump Size 045/053, Single Contents H1P Auxiliary mounting - Option H3 (SAE B, 13 Teeth)....................32 H1P Auxiliary mounting - Option H5 (SAE B-B, 15 Teeth)..................33 Charge pump Charge pump sizing/selection..............................34 Charge pump flow and power curves 12 cm³........................ 34 Installation drawings Port description H1P 045/053 Single............................35...

-

Page 5: Technical Specifications

Technical Information H1 Axial Piston Pump Size 045/053, Single Technical specifications Technical specifications For definitions of the following specifications, see Basic Information 11062168, Operating parameters. H1P general specifications Axial piston pump of cradle swashplate design with variable displacement Design Clockwise, counterclockwise... -

Page 6: H1P Fluid Specifications

Technical Information H1 Axial Piston Pump Size 045/053, Single Technical specifications Feature Unit Size 045 Size 053 Minimum for external charge supply at minimum charge pressure. Full performance (pressure and displacement) possible at minimum charge and control pressure supply Minimum for full performance (pressure and displacement) for internal... -

Page 7: General Technical Specifications

0° or 180° as shown in the figure. Danfoss recommends clamp-type couplings for applications with radial shaft loads. Contact your Danfoss representative for an evaluation of unit bearing life if you have continuously applied external loads exceeding 25 % of the maximum allowable radial load (R ) or the pump swashplate is positioned on one side of center all or most of the time. -

Page 8: Mounting Flange Loads H1P 045/053

Shock load moment – M 4110 [36380] 2930 [25935] Control on top Control on side P301 214a P301 214b For calculation details refer to H1 Pump Basic Information Manual 11062168, section Mounting Flange Loads. P301 213 11063344 • Rev HA • Mar 2014... -

Page 9: Model Code

Technical Information H1 Axial Piston Pump Size 045/053, Single Model code Model code H1P 045/053 H1 P N N N Displacement 45 cm³ [2.75 in³] 53.8 cm³ [3.28 in³] A - Rotation Left hand (counter clockwise) Right hand (clockwise) B - Product version... - Page 10 Technical Information H1 Axial Piston Pump Size 045/053, Single Model code H1 P N N N E - Displacement limiters None No limiters, with nested springs (required for NFPE) (align with option Y: Settings for adjustment, if applicable) Adjustable externally (align with option Y: Settings for adjustment, if applicable)

- Page 11 Technical Information H1 Axial Piston Pump Size 045/053, Single Model code H1 P N N N K - Auxiliary mounting pad None ISO 3019-1, flange 82 - 2, outer dia 16 mm - 4 (SAE A, 9 teeth 16/32 coupling)

- Page 12 Technical Information H1 Axial Piston Pump Size 045/053, Single Model code H1 P N N N T - Filtration options (align with option G: Endcap selection) Suction filtration (see basic drawings) Remote full charge flow filtration (see endcap drawings) External charge flow filtation (see endcap drawings), (align with option S: Charge pump, option N)

-

Page 13: Control Options

Technical Information H1 Axial Piston Pump Size 045/053, Single Control options Electrical Displacement Control (EDC) options A2 (12 V)/A3 (24 V) EDC principle The Electrical Displacement Control (EDC) consists of a pair of proportional solenoids on each side of a three-position, four-way porting spool. -

Page 14: Control Signal Requirements

Technical Information H1 Axial Piston Pump Size 045/053, Single Control options EDC-schematic diagram F00B F00A Feedback from Swash plate P003 478E Control signal requirements Control current Voltage a* mA b mA Pin connections 12 V 1640 any order 24 V * Factory test current, for vehicle movement or application actuation expect higher or lower value. -

Page 15: Control Response

* For coil location see installation drawings. Control response H1 controls are available with optional control passage orifices to assist in matching the rate of swashplate response to the application requirements (e.g. in the event of electrical failure). Software ramp or rate limiting should be used to control vehicle response in normal operation. The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to zero (deceleration) is a net function of spool porting, orifices, and charge pressure. -

Page 16: Solenoid Connector

Technical Information H1 Axial Piston Pump Size 045/053, Single Control options P003 193 Pump displacement vs. electrical signal 100 % “0“ Voltage VDC 100 % P003 190E 3-Position electric control, hydraulic schematic F00B F00A P003 189 Control current Voltage Min. current to stroke pump mA... -

Page 17: Control Response

* For coil location see installation drawings. Control response H1 controls are available with optional control passage orifices to assist in matching the rate of swashplate response to the application requirements (e.g. in the event of electrical failure). Software ramp or rate limiting should be used to control vehicle response in normal operation. The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to zero (deceleration) is a net function of spool porting, orifices, and charge pressure. -

Page 18: Response Time, Fnr 045/053

Technical Information H1 Axial Piston Pump Size 045/053, Single Control options Charge pressure = 20 bar [290 psi] Speed = 1800 min (rpm) Response time, FNR 045/053 Stroking direction 0.8 mm [0.03 in] Orifice 1.3 mm [0.05 in] Orifice No orifice Neutral to full flow 1.8 s... -

Page 19: Control Signal Requirements

Technical Information H1 Axial Piston Pump Size 045/053, Single Control options NFPE schematic F00B F00A P003 188 Control signal requirements Control current Voltage a* mA b mA c mA Pin connections 12 V 1290 1540 any order 24 V * Factory test current, for vehicle movement or application actuation expect higher or lower value. -

Page 20: Control Response

* For coil location see installation drawings. Control response H1 controls are available with optional control passage orifices to assist in matching the rate of swashplate response to the application requirements (e.g. in the event of electrical failure). Software ramp or rate limiting should be used to control vehicle response in normal operation. The time required for the pump output flow to change from zero to full flow (acceleration) or full flow to zero (deceleration) is a net function of spool porting, orifices, and charge pressure. -

Page 21: Mode Types

Control options P003 544 The H1 Automotive Control is divided into 2 systems, AC-1 and AC-2. AC-2 is an extension of AC-1 that features an integrated pump swash plate angle sensor and software enabled functions such as Swash Plate Control and Flow Limiter. -

Page 22: Performance Functions

• Pre-installed application software and parameter files Refer to the “Technical Information – H1 Automotive Control” L1223856 for more details. Fan Drive Control (FDC) option F1 (12V)/F2 (24V) The Fan Drive Control (FDC) is a non-feedback control in which an electrical input signal activates the proportional solenoid that ports charge pressure to either side of the pump servo cylinder. -

Page 23: Control Signal Requirements

P301 441 H1 pumps with FDC will be delivered from factory with nominal PL setting of 150 bar [2175 psi]. The PL must be re-adjusted to ensure that the fan reaches the desired fan speed to satisfy the cooling needs of the system. -

Page 24: Connector

Technical Information H1 Axial Piston Pump Size 045/053, Single Control options Connector P003 480 Pump displacement vs. control current Forward 100% H1 FDC control Max Current a = Forward Threshold b = Reverse Threshold N = Neutral Override Current 100%... -

Page 25: Control Response

*Warning: Loss of input signal to this control will cause the pump to produce maximum flow. Control response H1 Fan Drive Control is available only with 0.8 mm [0.03 in] control passage orifice to limit the rate of swashplate response (e.g. in the event of electrical failure). Software ramp or rate limiting should be used to control system response in normal operation. -

Page 26: Displacement Limiter

Swash plate P003 205E Displacement limiter H1 pumps are designed with optional mechanical displacement (stroke) limiters factory set to max. displacement. The maximum displacement of the pump can be set independently for forward and reverse using the two adjustment screws to mechanically limit the travel of the servo piston down to 50 % displacement. -

Page 27: Displacement Change (Approximately) H1P 045/053 S

5.1 cm³ [0.31 in³] 4 mm 13 mm 23 Nm [204 lbf•in] 6.0 cm³ [0.37 in³] For more information refer to H1 pumps Service Manual 520L0848, section Displacement Limiter Adjustment. 11063344 • Rev HA • Mar 2014... -

Page 28: Dimensions

Technical Information H1 Axial Piston Pump Size 045/053, Single Dimensions Input shafts H1P input shaft - Option G4 (SAE B, 13 Teeth) Option G4, ISO 3019-1, Flange Outer dia 22 mm-4 (SAE B, 13 Teeth) Spline data Number of teeth : 13... -

Page 29: H1P Input Shaft - Option G1 (Sae B, 14 Teeth)

Technical Information H1 Axial Piston Pump Size 045/053, Single Dimensions Specifications Option Spline Min active spline Torque rating length Rated torque Nm Maximum torque mm [in] [lbf•in] Nm [lbf•in] 15 teeth, 16/32 pitch 22.0 [0.866] 277 [2450] 370 [3270] For definitions of maximum and rated torque values, refer to: Basic Information Manual 11062168, section Shaft Torque Ratings and Spline Lubrication. -

Page 30: H1P Input Shaft - Option F2, Code 25-3

The Danfoss H1 tapered shaft has been designed using the industry standard ISO 3019-1, minus the through-hole in the end of the shaft. Danfoss recommends a self-locking nut instead of a castle nut and pin. The nut and mating square-cut key are customer supplied. -

Page 31: Auxiliary Mounting Pads

Technical Information H1 Axial Piston Pump Size 045/053, Single Dimensions Auxiliary mounting pads H1P Auxiliary mounting - Option H2 (SAE A, 9 teeth) Option H2, ISO 3019-1, flange 82-2 (SAE A, 9 teeth) 239.6 ±2.5 Auxiliary mounting pad For mating flange 82-2... -

Page 32: H1P Auxiliary Mounting - Option H1 (Sae A, 11 Teeth)

Technical Information H1 Axial Piston Pump Size 045/053, Single Dimensions H1P Auxiliary mounting - Option H1 (SAE A, 11 Teeth) Option H1, ISO 3019-1, Flange 82-2 (SAE A, 11 Teeth) 239.6 ±2.5 Auxiliary mounting pad For mating flange 82-2 Per ISO 3019-1 (SAE A) Paint free 4x M10x1.5-6H THD... -

Page 33: H1P Auxiliary Mounting - Option H5 (Sae B-B, 15 Teeth)

Technical Information H1 Axial Piston Pump Size 045/053, Single Dimensions Specifications Option Spline Torque rating maximum torque Nm [lbf•in] 13 teeth, 16/32 pitch 395 [3500] For definitions of maximum torque values, refer to: Basic Information Manual 11062168, section Shaft Torque Ratings and Spline Lubrication. -

Page 34: Charge Pump

High flushing flow requirements • Multiple Low Speed High Torque motors • High input shaft speeds Contact your Danfoss representative for application assistance if your application includes any of these conditions. Charge pump flow and power curves 12 cm³ Charge pressure: 20 bar... -

Page 35: Installation Drawings

Technical Information H1 Axial Piston Pump Size 045/053, Single Installation drawings Port description H1P 045/053 Single Control solenoid connector "C2" Deutsch DT04-2P To be paint free Case drain port "L4" Servo gauge port "M4" Port ISO 11926-1 - 1 1/16-12 Port ISO 11926-1 - 7/16-20 ∅29 max clearance dia for fitting... - Page 36 Technical Information H1 Axial Piston Pump Size 045/053, Single Installation drawings Port description (continued) Port Description Sizes System “B” gauge port 9/16 -18 Charge gauge port 9/16 -18 Alternate charge pressure port 9/16 -18 Servo gauge port 7/16 -20 Servo gauge port...

-

Page 37: Dimensions H1P 045/053 Single

Technical Information H1 Axial Piston Pump Size 045/053, Single Installation drawings Dimensions H1P 045/053 Single Twin Port, ORB, Remote Filter 238 ±2.5 186.3 ±1.2 177.3 ±1.2 2x 136.2 ±1.2 2x 120 ±1.2 Servo gauge port "M4" Port ISO 11926-1 - 7/16-20 Control solenoid connector "C2"... - Page 38 Technical Information H1 Axial Piston Pump Size 045/053, Single Installation drawings Please contact Danfoss for specific installation drawings Twin Port, ORB, Remote Filter 206 ±2.5 Control solenoid connector "C1" 2x 64.2 ±0.8 Deutsch DT04-2P Paint free Servo gauge port "M5"...

- Page 39 Technical Information H1 Axial Piston Pump Size 045/053, Single Installation drawings Please contact Danfoss for specific installation drawings 189.3 ±1.2 System A gauge port "MA" Port ISO 11926-1 - 9/16-18 2x ∅14.3 +0.25 -0.13 2x 73 ±0.25 P700 33 051-1-3 Please contact Danfoss for specific installation drawings 11063344 •...

-

Page 40: Controls

Technical Information H1 Axial Piston Pump Size 045/053, Single Controls Electric Displacement Control (EDC), option A2 (12V) / A3 (24V) Case gauge port "M14" Port ISO 1926-1 - 7/16-20 ∅21 max clearance dia for fitting Control solenoid connector "C1" Shaft... -

Page 41: Electric Displacement Control (Edc) With Manual Override, Option A4 (12 V) / A5 (24 V)

Technical Information H1 Axial Piston Pump Size 045/053, Single Controls Electric Displacement Control (EDC) with manual override, option A4 (12 V) / A5 (24 V) Control manual override "C1" Depressing the plunger mechanically moves the control spool. Actuation allows full stroke pump response as... -

Page 42: Forward-Neutral-Reverse (Fnr) With Manual Override, Option A9 (12 V) B1 (24 V)

Technical Information H1 Axial Piston Pump Size 045/053, Single Controls Forward-Neutral-Reverse (FNR) with manual override, option A9 (12 V) B1 (24 V) Control manual override "C1" Depressing the plunger mechanically moves the control spool. Actuation allows full stroke pump response as... -

Page 43: Non Feedback Proportional Electric Control (Nfpe) With Manual Override, Option A8 (12 V) B8 (24V)

Technical Information H1 Axial Piston Pump Size 045/053, Single Controls Non Feedback Proportional Electric Control (NFPE) with manual override, option A8 (12 V) B8 (24V) Control manual override "C1" Depressing the plunger mechanically moves the control spool. Actuation allows full stroke pump response as... -

Page 44: Automotive Control (Ac I) With Manual Override, Option A7 (12 V)/C2 (24 V)Automotive Control (Ac Ii) With Manual Override, Option B7 (12V)/C3 (24V)

Technical Information H1 Axial Piston Pump Size 045/053, Single Controls Automotive control (AC I) with manual override, option A7 (12 V)/C2 (24 V)Automotive control (AC II) with manual override, option B7 (12V)/C3 (24V) Control manual override ”C1” Depressing the plunger mechanically moves the control spool. - Page 45 Technical Information H1 Axial Piston Pump Size 045/053, Single Controls Control solenoid Connector “C1” & “C2” Supply Ground Ground Supply Please contact Danfoss for specific installation drawings 11063344 • Rev HA • Mar 2014...

-

Page 46: Displacement Limiters

Technical Information H1 Axial Piston Pump Size 045/053, Single Displacement limiters H1P 045/053 Single displacement limiter, option B and D 2x (116.1) 2x 106.3 ±0.8 2x displacement limiter screw Wrench size 4 internal hex 2x displacement limiter seal nut Wrench size 13 external hex Torque to 23.0 nm... -

Page 47: Endcap

Technical Information H1 Axial Piston Pump Size 045/053, Single Endcap H1P 045/053, endcap, Twin Port, Code 62 Metric 4 Bold FLG, Option D6, D8, F2, and F3 4x 25.4 ±0.25 186.32 ±1.2 System port "B" ∅19-450 bar Split flange boss Per ISO 6162 M10x1.5... -

Page 48: Filtration

Technical Information H1 Axial Piston Pump Size 045/053, Single Filtration H1P 045/053 Single, suction filtration, option L 89.5 ±0.8 177.3 ±1.2 Shaft Charge inlet port "S" Port ISO 1926-1 - 1 5/16-12 P700 33 466 Please contact Danfoss for specific installation drawings... -

Page 49: H1P 045/053 Single, Remote Full Flow Charge Pressure Filtration, Option P For Endcap Option F

Technical Information H1 Axial Piston Pump Size 045/053, Single Filtration H1P 045/053 Single, remote full flow charge pressure filtration, Option P for endcap Option F 199.8 ±1.2 (199.8) (199.8) 177.3 ±1.2 89.5 ±0.8 Shaft Charge inlet port "S" Port ISO 11926-1 - 1 5/16-12... -

Page 50: H1P 045/053 Single External Full Flow Charge Pressure Filtration, Option E

Technical Information H1 Axial Piston Pump Size 045/053, Single Filtration H1P 045/053 Single external full flow charge pressure filtration, Option E 199.8 ±1.2 (199.8) P700 45 735 Please contact Danfoss for specific installation drawings 11063344 • Rev HA • Mar 2014... -

Page 51: Speed And Temperature Sensor

Technical Information H1 Axial Piston Pump Size 045/053, Single Speed and temperature sensor Speed and temperature sensor, Option H for mounting flange, Option K 19.8 ±2.1 Mounting flange Flange 101-2 Per ISO 3019-1 (SAE B) -0.5 1 ±0.5 R0.8 max 2x ∅14.3... - Page 52 Phone: +86 21 3418 5200 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without changes being necessary in specifications already agreed..

Need help?

Do you have a question about the H1 and is the answer not in the manual?

Questions and answers