Subscribe to Our Youtube Channel

Summary of Contents for Maxon GPC 22 X1 10 Series

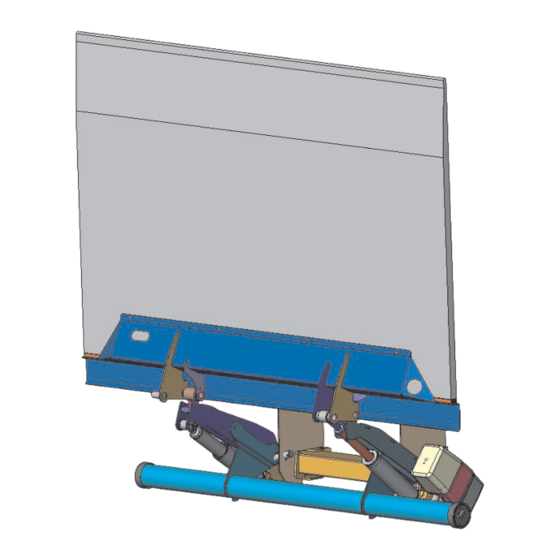

- Page 1 Cantilever GPC X1 Operator`s Manual Liftgate GPC 22 X1 Series 10 Lift CORP. 11921 Slauson Avenue. Document no.: S 20 910 967 Santa Fe Springs, CA 90670 Version 2014 (800) 227 - 4116 © Sörensen Hydraulik GmbH...

- Page 2 Lift CORP. General You have chosen a lift gate of the highest quality. The lift gate is a low maintenance unit. It is equipped with maintenance-free, grease-free bearings and does not require greasing throughout its entire lifetime. The lift gate may only be used for the raising and lowering of loads, which must be loaded in accordance with the load diagram.

-

Page 3: The Electric Motor

Lift CORP. Yearly check The lift gate must be checked for damages at least once a year by trained personnel. The results of this verification must be written down in the maintenance book. Battery capacity Lift capacity Up to 2200 lbs 12V : 1 x 12V 88 Ah 24V : 2 x 12V 66 Ah Battery size... - Page 4 Lift CORP. Switching on the lift gate Switch the lift gate on with the push button located in the cabin. When the red lamp lits, the lift is ready for operation Control panel To drive the different functions on the control panel, you must always activate two different keys simultaneously.

- Page 5 Lift CORP. Hand control box 3 Buttons Open / tilt down Close / tilt up Foot Controls (Optional version) The foot controls are connected so that they only work when pushed in a specific order. To lift and tilt up Step 1 - activate foot control button for lowering Step 2 - activate foot control button for lifting To lower and tilt down...

- Page 6 Lift CORP. General Information Standing on the platform when it is moving As it is only allowed for the operator to stand on the platform, he must ensure that no other person (especially children) are standing inside the danger zone. Hazard information for unsecured loads Under certain circumstances, there is a possibility that the front axle of the vehicle lifts while unloading.

- Page 7 Lift CORP. Description of the Safety Installations Hose Rupture Valves If a hose, a pipe or a screw connection should burst, the lift gate lowers or inclines in a controlled manner at the permitted speed, as long as a function is connected via one of the control units (hand held remote controls, foot controls or hand control box).

- Page 8 Lift CORP. Standing on the platform when it is moving When loading the platform, please ensure that you leave enough space for the operator to securely operate the lift gate. Securing of Loads Rolling and sliding loads must be secured on the platform. Lift gates come optionally equipped with cart stops, securing rolling loads with the maximum efficiency (wheels with maximum diameter 4”...

- Page 9 Lift CORP. Safety guide for the operation of the lift gate Secure the load against toppling over and sliding Operator`s handbook GPC 22 X1, Series 10 Document no.: S 20 910 967 Version: 2014...

- Page 10 Lift CORP. Permissible Loading Apart from being included in these operating instructions, the load diagram is also shown on the lift gate identification plate. All loads must be placed as close to the edge of the Platform nearest to the vehicle floor as possible, with the heaviest part of the load toward the vehicle. No part of any load should be allowed to extend over the edges of the Platform.

- Page 11 Lift CORP. Platform, bridge and ramp Never sit the ramp on the platform, always use the platform as a ramp ! Operator`s handbook GPC 22 X1, Series 10 Document no.: S 20 910 967 Version: 2014...

- Page 12 Lift CORP. Load and unload at a ramp Loading and unloading at a ramp is only possible if the platform tip sits firmly on the dock. Please note that the vehicle might lift while unloading, and that the platform will lift from the ground.

- Page 13 Lift CORP. Transferring Loads from Vehicle to Vehicle When transferring loads, it should be ensured that only one of the two platforms is being used as a dock. The platform being used as a dock must lie firmly on the vehicle opposite, or it may lead to the lift gate becoming overloaded.

- Page 14 Lift CORP. Loading with a Fork-Lift Truck Driving over the platform with a fork-lift truck is not allowed if the weight of the fork-lift plus the weight of the load to be transported is greater than the carrying capacity of the lift gate. The platform must lie firmly on the floor.

- Page 15 Lift CORP. Securing of Load The use of the platform or any other parts of the lift gate as a means of securing a load is not permitted. Only close the platform after the lift arms have moved firmly against the bodywork. Under no circumstances close the platform on the floor or in an intermediate position.

- Page 16 Lift CORP. Lift gate as lifting device Do not hand any loads on the platform Lift gate as pushing device Do not use the lift gate as a pushing device Operator`s handbook GPC 22 X1, Series 10 Document no.: S 20 910 967 Version: 2014...

- Page 17 Lift CORP. Care, Maintenance, Testing and Repairs Before the start of maintenance work, the lift gate must be secured against unforeseen movement. The lift gate is very undemanding. It should, however, be included in the regular servicing work on the vehicle. Check that all screw connections are tight.

- Page 18 Free replacement are available from: MAXON Lift Corp., Parts Department. max. bed hight GPC 22 X1 - max. bed hight 46” 7/16 - Liftarm 26” 9/16...

- Page 19 Control Station. SENSE. If load appears to be unsafe, do not lift or lower it. PART NO. MAXON LIFT CORP. 264081 Note: The main liftgate Control Station is normally mounted on right rear corner of the truck body.

- Page 22 Lift CORP. Diagnosis diode Explanation of the diagnosis diode on the control unit Control-Unit Series 10 diode lights constantly. If: Cabin switch is on platform position 60° till ca. 90 ° Control-Unit platform position 0° till -10° Explanation: platform closed (vertical) 90° platform open (horizontal) 0°...

- Page 23 Lift CORP. control panel Test of the sensor-switch in the platform: platform closed and lift on: LED lights. Power supply Ok. platform position 0 ° till ca. 60 °: LED out Sensor-switch S1 is Ok. platform lights are aktivated. platform position 0°...

- Page 24 Lift CORP. Repairs to load bearing components Repairs to load bearing components are only to be carried out in an authorized repair shop, and are to be inspected by a competent person and entered in inspection records. Possible cause Problem 1.

- Page 25 Lift CORP. 5. Tilt down function Pressure switch S4 doesn’t switch doesn’t work by operating foot control or handheld remote Cable defect Mechanical damage on lift cylinder 6. The platform tilts Solenoid on tilt cylinder defect down without operating any functions 7.

-

Page 26: Customer Service

Type of Warranty: Full Parts and Labor MAXON agrees to replace any components which are found to be defective during the first 2 years of service, and will reimburse for labor based on Maxon’s Liftgate Warranty Flat Rate Labor Schedule. - Page 27 Number” received. Major repairs would generally be considered repairs made to the structural assembly of the liftgate and/or repairs not outlined in the Maxon liftgate Waranty Flat Rate Schedule. Major components (i.e. hydraulic pumps, cylinders, valves, or failed structural parts) must be returned, freight pre-paid, prior to the claim being processed.

Need help?

Do you have a question about the GPC 22 X1 10 Series and is the answer not in the manual?

Questions and answers