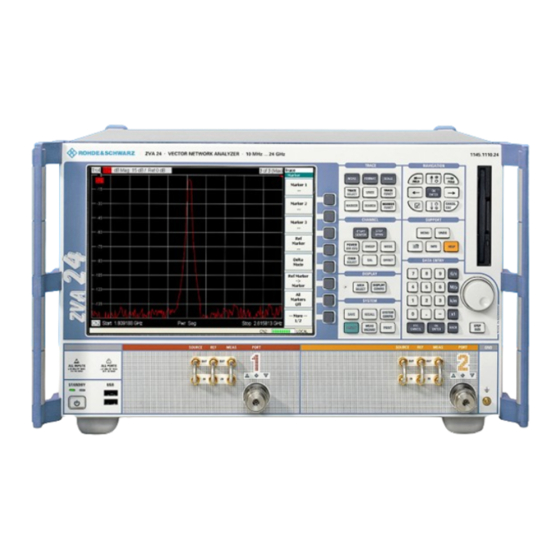

Summary of Contents for Rohde & Schwarz ZVA 24

- Page 1 Service Manual Instrument Vector Network Analyzers ® R&S ZVA 8 / ZVA 24 1145.1110.08 / 24/26 Printed in Germany Test and Measurement Division 1145.1155.82-01...

- Page 2 ® R&S is a registered trademark of Rohde & Schwarz GmbH & Co. KG. Trade names are trademarks of the owners. This product includes software developed by the OpenSSL Project for use in the OpenSSL Toolkit (http://www.openssl.org).

- Page 3 R&S ZVA Chapter Overview Chapter Overview Safety Instructions Spare Parts Express Service List of R&S Representatives Contents of Manuals for Vector Network Analyzers R&S ZVA Service and Repair Chapter 1: Performance Test Chapter 2: Alignment Chapter 3: Repair Chapter 4: Software Update / Installation of Options Chapter 5: Documents...

- Page 5 Before putting the product into operation for the first time, make sure to read the following S a f e t y I n s t r u c t i o n s Rohde & Schwarz makes every effort to keep the safety standard of its products up to date and to offer its customers the highest possible degree of safety.

- Page 6 Safety Instructions Observing the safety instructions will help prevent personal injury or damage of any kind caused by dangerous situations. Therefore, carefully read through and adhere to the following safety instructions before putting the product into operation. It is also absolutely essential to observe the additional safety instructions on personal safety that appear in other parts of the documentation.

- Page 7 Safety Instructions 5. Operating the products requires special 12. Do not insert the plug into sockets that are training and intense concentration. dusty or dirty. Insert the plug firmly and all Disabled persons should not use the the way into the socket. Otherwise this can products unless it is made certain that their result in sparks, fire and/or injuries.

- Page 8 Safety Instructions 21. Rohde & Schwarz products are not 26. Please be aware that in the event of a fire, protected against penetration of water, toxic gases that may be hazardous to your unless otherwise specified (see also safety health may escape from the product. instruction 1.).

- Page 9 Informaciones de seguridad Por favor lea imprescindiblemente antes de la primera puesta en funcionamiento las siguientes informaciones de seguridad Informaciones de seguridad Es el principio de Rohde&Schwarz de tener a sus productos siempre al día con los estandards de seguridad y de ofrecer a sus clientes el máximo grado de seguridad. Nuestros productos y todos los equipos adicionales son siempre fabricados y examinados según las normas de seguridad vigentes.

- Page 10 Informaciones de seguridad Tener en cuenta las informaciones de seguridad sirve para tratar de evitar daños y peligros de toda clase. Es necesario de que se lean las siguientes informaciones de seguridad concienzudamente y se tengan en cuenta debidamente antes de la puesta en funcionamiento del producto. También deberán ser tenidas en cuenta las informaciones para la protección de personas que encontrarán en otro capítulo de esta documentación y que también son obligatorias de seguir.

- Page 11 Informaciones de seguridad 4. Ciertos productos, como por ejemplo las de función o electrónicos no son aptos instalaciones de radiación HF, pueden a para la el corte de la red eléctrica. Si los causa de su función natural, emitir una productos sin interruptor están radiación electromagnética aumentada.

- Page 12 Informaciones de seguridad 18. En caso de que los productos que son celulas de Litio). Cambiar las baterías o instalados fijamente en un lugar sean sin los acumuladores solamente por los del protector implementado, autointerruptor tipo R&S correspondiente (ver lista de o similares objetos de protección, deberá...

- Page 13 Safety Instructions WARNING Danger of injuries When removing the rear feet, the unit can slip out of the cabinet. Put the unit onto the front handles, before removing the rear feet and taking off the cabinet. Thus the risk of personal injuries and damages to the unit is avoided. When mounting the cabinet take care not to pen in the fingers.

- Page 14 R&S ZVA Index Index Front unit ................3.11 Frontend Repelcement............3.43 Alignment................. 2.3 Function description ............3.1 Frequency accuracy ..........2.6 Frequency response correction......2.7, 2.9 Level accuracy ............2.9 Manual............... 2.4 Reference frequency ..........2.6 Instrument construction ............3.1 Test equipment............2.4 Keyboard Battery Function ..............3.11 Replacement ............

- Page 15 Index R&S ZVA Synthesizer Replacement............3.47 Refurbished Modules ............2 Repairs ................3.1 Replacement Boards ..............3.14 Test equipment Replacing Alignment ..............2.4 Performance test............1.2 Boards ..............3.14 Test equpment Troubleshooting ............3.49 Tracking generator Shipping Function ..............3 . 1 4 Instrument ..............1 Troubbleshooting Module................

-

Page 16: Table Of Contents

FSQ FVREF "Überschrift 2" \* MERGEFORMAT Fehler! Formatvorlage nicht definiert. R&S ZVA Contents Table of Contents - Chapter 1 "Performance Test" 1 Performance Test ....................1.1 Preliminary Remarks........................1.1 Test Equipment and Accessories....................1.2 Performance Test ..........................1.3 Checking the Frequency Uncertainty..................1.3 Checking the Harmonics......................1.4 Checking the Maximum Output Power ..................1.5 Checking the Accuracy of Output Power .................1.6 Checking the Output Linearity....................1.7... -

Page 18: Preliminary Remarks

R&S ZVA Preliminary Remarks 1 Performance Test Preliminary Remarks • The required characteristics of the network analyzer are checked after a warm-up time of at least 60 minutes; this ensures that the guaranteed data is met. • The values stated in the following sections are not guaranteed data; only the specifications in the data sheet are binding. -

Page 19: Test Equipment And Accessories

Performance Test R&S ZVA Test Equipment and Accessories Item Type of Recommended characteristics or Recommended R&S Application equipment features model Order No. Spectrum a) Counter mode: FSU 26 1129.9003.26 Frequency uncertainty analyzer Min. resolution: 100 Hz Harmonics Max. rel. frequency deviation: 10 Output linearity b) Linearity Input linearity... -

Page 20: Performance Test

R&S ZVA Performance Test Performance Test Compare with data sheet Checking the Frequency Uncertainty Instrument: Spectrum analyzer (see Chapter “Test Equipment“, Item1) Test cable (see Chapter “Test Equipment“, Item7) Test setup: Connect the spectrum analyzer to port 1 Spectrum analyzer settings: - [ PRESET ] - [ FREQ : 1 GHz ] - [ SPAN : 50 kHz ]... -

Page 21: Checking The Harmonics

Performance Test R&S ZVA Checking the Harmonics Instrument: Spectrum analyzer (see Chapter "Test Equipment", Item1) Test cable (see Chapter “Test Equipment", Item7) Test setup: Connect the spectrum analyzer to port1 (port 2 to port 4) Spectrum analyzer settings: Note: Synchronize the reference oscillators in the spectrum analyzer and in the ®... -

Page 22: Checking The Maximum Output Power

R&S ZVA Performance Test Checking the Maximum Output Power Instrument: Power sensor or Power meter with power sensor (see Chapter “Test Equipment“, Item2) Test setup: Connect power sensor to port1 (port 2 to port 4) Power sensor settings: For measurement frequencies, see Performance Test Report {f ®... -

Page 23: Checking The Accuracy Of Output Power

Performance Test R&S ZVA Checking the Accuracy of Output Power Instrument: Power sensor or Power meter with power sensor (see Chapter “Test Equipment“, Item2) Test setup: Connect the power sensor to port 1 (port 2 to port 4) Power sensor settings: For measurement frequencies, see Performance Test Report {f ®... -

Page 24: Checking The Output Linearity

R&S ZVA Performance Test Checking the Output Linearity Instrument: Spectrum analyzer (see Chapter “Test Equipment“, Item1) Test cable (see Chapter “Test Equipment“, Item7) Test setup: Connect the spectrum analyzer to port 1(port 2 to port 4) Spectrum analyzer settings: Note: Synchronize the reference oscillators in the spectrum analyzer and in the ®... -

Page 25: Checking The Power Measurement Uncertainty

Performance Test R&S ZVA Checking the Power Measurement Uncertainty Instrument: Power sensor or Power meter with power sensor (see Chapter “Test Equipment“, Item2) Signal generator (see Chapter “Test Equipment“, Item5) Power splitter (see Chapter “Test Equipment“, Item6) Calibration kit (see Chapter “Test Equipment“, Item4) Test cable (see Chapter “Test Equipment“, Item7) Preparation/ Connect the signal generator to the power-splitter input using the test... -

Page 26: Checking The Input Linearity

R&S ZVA Performance Test Checking the Input Linearity Instrument: Calibration kit (see Chapter “Test Equipment“, Item4) ® R&S ZVA settings: - [ Preset ] - [ Meas : Ratios: b1/a1 Src Port 1] [ Meas : Ratios: b2/a2 Src Port 2] [ Meas : Ratios: b3/a3 Src Port 3] [ Meas : Ratios: b4/a4 Src Port 4] - [ Meas Bandwidth : 10 Hz ]... -

Page 27: Checking The Input Noise Level

Performance Test R&S ZVA Checking the Input Noise Level Test equipment Calibration kit (see Chapter “Test Equipment“, Item4) Test setup: Connect the Match Male from the calibration kit to port 1 (port 2 to port 4) ® R&S ZVA settings: - [ Preset ] - [ Meas : Wave Quantities: b1 Src Port 1 (b2 Src Port 2, b3 Src Port 3, b4 Src Port 4)]... -

Page 28: Checking The Matching (Raw)

R&S ZVA Performance Test Checking the Matching (raw) Instrument: Calibration kit (see Chapter “Test Equipment“, Item4) Test cable (see Chapter “Test Equipment“, Item7) ® 1. Preparation/ Connect the test cable to port 1 on the R&S ZVA and perform a 1-port test setup: calibration at the end of the cable. -

Page 29: Checking The Dynamic Range

Performance Test R&S ZVA Checking the Dynamic Range Test equipment: Calibration kit N (see Chapter “Test Equipment“, Item4) Test setup: Connect Short Male to port1 and port 2 (port 3 and port 4) (use Short Female with Through Male as a second Short Male) ®... -

Page 30: Checking The Receiver Attenuator (Only With Option Receiver Attenuator)

R&S ZVA Performance Test Checking the Receiver Attenuator (only with Option Receiver Attenuator) Test equipment: Calibration kit N (see Chapter “Test Equipment“, Item4) Test setup: Connect Short Male to port1 (port to port 4) ® R&S ZVA settings: - [ Preset ] - [ Meas : Wave Quantities : b1/ Src Port 1] [ Meas : Wave Quantities : b2/ Src Port 2] [ Meas : Wave Quantities : b3/ Src Port 3]... -

Page 31: Checking The Dc Measurement Inputs

Performance Test R&S ZVA Checking the DC Measurement Inputs Test equipment: DC Power Supply NGSM 32/10 (see Chapter “Test Equipment“, Item9) Multimeter URE3 (see Chapter “Test Equipment“, Item10) DC cable (see Chapter “Test Equipment“, Item11) Test setup: Connect the Power Supply to the Input DC MEAS 1V (DC MEAS 10V) of the ZVA using the DC cable ®... -

Page 32: Performance Test Report

R&S ZVA Performance Test Report Performance Test Report Table 1-1: Performance Test Report ROHDE & SCHWARZ Performance Test Report Version 18.11.05 Model (ZVA8/ZVA24) Item number: 1145.1110. Serial number Tested by: Date: Signature: General: All Tables apply to port1; values for ports 2 to 4 are identical. Parameter Covered on Min. - Page 33 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.5 1 dB Harmonics Source power +8dBm Freq. Harmonics 50 MHz 100 MHz ________ 150 MHz ________ 100 MHz 200 MHz ________ 300 MHz ________...

- Page 34 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.5 2 dB Harmonics Source power +8 dBm Freq. Harmonics 4.1 GHz 8.2 GHz ________ 12.3 GHz ________ 5.0 GHz 10.0 GHz ________ 15.0 GHz ________...

- Page 35 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.6 0.5 dB Max. output power Test frequency ZVA8: 300 kHz ________ 1 MHz ________ 2 MHz ________ 5 MHz ________ ZVA8, (ZVA24): 10 MHz...

- Page 36 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Page 1.6 0.5 dB 17.0 GHz ________ 18.0 GHz ________ 19.0 GHz ________ 20.0 GHz ________ 21.0 GHz ________ 22.0 GHz ________ 23.0 GHz ________ 24.0 GHz ________...

- Page 37 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.7 0.2 dB Power Uncertainty output power -10 dBm Test frequency ZVA8: 300 kHz ________ 1 MHz ________ 2 MHz ________ 5 MHz ________...

- Page 38 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Page 1.7 0.2 dB 15.0 GHz - 0.8 ________ 16.0 GHz - 0.8 ________ 16.1 GHz - 0.8 ________ 17.0 GHz - 0.8 ________ 18.0 GHz - 0.8...

- Page 39 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (without Opt. Gen Att) Reference –10 dBm Freq. Level ZVA8 only: 300 kHz 20 dB ________ 15 dB ________...

- Page 40 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (without Opt. Gen Att) Reference –10 dBm Freq. Level 51 MHz 20 dB - 0.8 ________ 15 dB - 0.8...

- Page 41 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (without Opt. Gen Att) Reference –10 dBm Freq. Level - 0.8 ________ 2.1 GHz 20 dB - 0.8 ________ 15 dB...

- Page 42 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (without Opt. Gen Att) Reference –10 dBm ZVA8, ZVA24: Freq. Level 6 GHz 20 dB - 0.8 ________ 15 dB...

- Page 43 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (without Opt. Gen Att) Reference –10 dBm Freq. Level 16 GHz 20 dB - 0.8 ________ 15 dB - 0.8...

- Page 44 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (with Opt. Gen Atten) Reference –10 dBm Freq. Level 51 MHz 20 dB - 0.8 ________ 15 dB - 0.8...

- Page 45 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (with Opt. Gen Atten) Reference –10 dBm Freq. Level - 0.8 ________ 1 GHz 20 dB - 0.8 ________ 15 dB...

- Page 46 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (without Opt. Gen Atten) Reference –10 dBm Freq. Level 2.1 GHz 20 dB - 0.8 ________ 15 dB - 0.8...

- Page 47 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (with Opt. Gen Atten) Reference –10 dBm Freq. Level 4 GHz 20 dB - 0.8 ________ 15 dB - 0.8...

- Page 48 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (with Opt. Gen Atten) Reference –10 dBm Freq. Level 6 GHz 20 dB - 0.8 ________ 15 dB - 0.8...

- Page 49 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (with Opt. Gen Atten) Reference –10 dBm Freq. Level ZVA24 only: 10 GHz 20 dB - 0.8 ________ 15 dB...

- Page 50 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (with Opt. Gen Atten) Reference –10 dBm Freq. Level 16 GHz 20 dB - 0.8 ________ 15 dB - 0.8...

- Page 51 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.8 0.1 dB Power linearity (with Opt. Gen Atten) Reference –10 dBm Freq. Level 24 GHz 20 dB - 0.8 ________ 15 dB - 0.8...

- Page 52 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Page 1.9 0.3 dB Port __ Power measurement uncertainty Test frequency 10 MHz ________ 20 MHz ________ 50 MHz ________ 100 MHz ________ 200 MHz ________ 500 MHz...

- Page 53 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Page 1.9 0.3 dB 21.0 GHz ________ 22.0 GHz ________ 23.0 GHz ________ 24.0 GHz ________ 1145.1155.82 1.36...

- Page 54 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.10 0.01 dB Input linearity Reference –10 dBm 50 MHz 20 dB -0.1 ________ 15 dB -0.1 ________ 10 dB -0.1 ________ 5 dB...

- Page 55 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.10 0.01 dB Input linearity Reference –10 dBm 4 GHz 20 dB (ZVA24) -0.3 ________ 20 dB (ZVA8) -0.1 ________ 15 dB -0.1 ________...

- Page 56 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.10 0.01 dB Input linearity Reference –10 dBm ZVA24: 10.6 GHz 20 dB -0.3 ________ 15 dB -0.1 ________ 10 dB -0.1 ________ 5 dB...

- Page 57 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.11 Input noise level Test frequency ZVA8: 303 kHz ________ –100 1.12 MHz ________ –100 2.12 MHz ________ –100 5.12 MHz ________ –100 ZVA8, (ZVA24):...

- Page 58 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Page 1.11 16.00012 GHz ________ –110 16.10012 GHz ________ –110 18.00012 GHz ________ –110 19.00012 GHz ________ –110 20.00012 GHz ________ –110 21.00012 GHz ________ –110 22.00012 GHz...

- Page 59 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.12 1 dB Matching (raw) Test frequency ZVA8: 300 kHz ________ 1 MHz ________ 2 MHz ________ 5 MHz ________ ZVA8, (ZVA24): 10 MHz 16 (10)

- Page 60 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ to Port __ Page 1.13 Dynamic range ZVA8 (without options step attenuator and direct generator/receiver access) Test frequency 303 kHz ________ 1.12 MHz ________ 2.12 MHz...

- Page 61 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ to Port __ Page 1.13 Dynamic range ZVA8 (with option step attenuator and without option direct generator/receiver access) Test frequency 303 kHz ________ 1.12 MHz ________...

- Page 62 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ to Port ___ Page 1.13 Dynamic range ZVA24 (without options step attenuator and direct generator/receiver access) Test frequency 10.12 MHz ________ 20.12 MHz ________ 50.12 MHz...

- Page 63 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Page 1.13 20.00012 GHz ________ 21.00012 GHz ________ 22.00012 GHz ________ 23.00012 GHz ________ 23.99988 GHz ________ 1145.1155.82 1.46...

- Page 64 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ to Port ___ Page 1.13 Dynamic range ZVA24 (with option step attenuator and without option direct generator/receiver access) Test frequency 10.12 MHz ________ 20.12 MHz ________...

- Page 65 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Page 1.13 19.00012 GHz ________ 20.00012 GHz ________ 21.00012 GHz ________ 22.00012 GHz ________ 23.00012 GHz ________ 23.99988 GHz ________ 1145.1155.82 1.48...

- Page 66 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Port __ Page 1.14 0.1 dB Receiver Step Atten. Attenuation Accuracy Reference 0 dB Atten. Frequ. 5 dB 10 MHz ________ 1.0 GHz ________ 2.0 GHz ________...

- Page 67 Performance Test Report R&S ZVA Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Page 1.14 0.1 dB ZVA24 only: 10.0 GHz ________ 12.0 GHz ________ 14.0 GHz ________ 16.0 GHz ________ 18.0 GHz ________ 20.0 GHz ________ 22.0 GHz ________...

- Page 68 R&S ZVA Performance Test Report Parameter Covered on Min. value Actual value Max. value Unit Measurement tolerance Accuracy Page 1.15 1 mV DC meas 1 V Pos. Input -1000 m V - 27.5 ________ + 27.5 -300 mV - 10.0 ________ + 10.0 -10 mV...

- Page 70 R&S ZVA Table of Contents - Alignment Table of Contents - Chapter 2 "Alignment" 2 Alignment......................2.3 Service Menu ...........................2.3 Manual Alignment and Recording Correction Values ..............2.4 Test Equipment ........................2.4 Aligning the Frequency Accuracy ........Fehler! Textmarke nicht definiert. Aligning the DC Inputs ............Fehler! Textmarke nicht definiert. Correction Value Recording.....................2.9 Installation of the Alignment Program ..................2.9 Factory System Error Calibration.....................2.9...

- Page 71 Table of Contents - Alignment R&S ZVA This page has been left blank intentionally. 1145.1155.82 I-2.2...

-

Page 72: Alignment

R&S ZVA Manual Alignment and Recording Correction Values 2 Alignment This chapter describes the alignment of the frequency reference and the recording of correction data after a board has been replaced. The following manual alignments or corrections can be performed on the ZVA: •... -

Page 73: Manual Alignment And Recording Correction Values

Manual Alignment and Recording Correction Values R&S ZVA Manual Alignment and Recording Correction Values In the sequel, the test equipment and the instrument preparations required to manually align the ZVA and each of the alignments are described. Preliminary remarks The analyzer must be allowed to warm up for at least 30 minutes before alignment. This is the only way of ensuring that the guaranteed data are met. - Page 74 R&S ZVA Manual Alignment and Recording Correction Values Item Type of equipment Recommended specifications Recommend R&S Order No. Application ed model Calibration kit N calibration kit ZV-Z21 1085.7099.02 Recording correction values on ZVA8 Calibration kit 3.5mm calibration kit ZV-Z32 1128.3501.02 Recording correction values on ZVA24 Test cable...

-

Page 75: Aligning The Frequency Accuracy

Manual Alignment and Recording Correction Values R&S ZVA Aligning the Frequency Accuracy Test equipment Spectrum analyzer (section "Test Equipment", item 1): Error <1x10 Test setup: Connect the spectrum analyzer to the 10-MHz reference output at the rear of the ZVA. ZVA settings: Select internal reference MENU : System: Reference Internal... -

Page 76: Aligning The Dc Inputs

R&S ZVA Manual Alignment and Recording Correction Values Aligning the DC Inputs At the outset, ensure that the correction parameters "Multiplier" M and "Offset" F have been preset to M=1 and F=0 for both inputs. This can be done using the Service Functions 3.1.2.5 and 3.1.2.2 which are described below under Service Functions. - Page 77 Manual Alignment and Recording Correction Values R&S ZVA Example illustrating DC Meas 1 V: When +1 V is applied, V 1 = 1.023 V is displayed by the ZVA; when -1 V is applied, V2 = -1.011 V is displayed. The results of the calculation are M = 1.017 and F = 0.0059. The following entries are, therefore, made: Select Service Level 2 (see Service Functions).

-

Page 78: Correction Value Recording

R&S ZVA Manual Alignment and Recording Correction Values Correction Value Recording Required test equipment (see Table 2-1): • PC with IEC/IEEE bus interface • ZVAB service program • Power meter with power sensor • Signal generator • Short and match included in the calibration kit •... - Page 79 Manual Alignment and Recording Correction Values R&S ZVA When you click on the CAL button again, CAL MANAGER appears with a dialog in which the "Channel Cal" calibration must be copied to the CAL POOL under the name "Factory". Then, the Windows Explorer is used to copy the file Factory.cal which is now in the directory C:\Rohde&Schwarz\Nwa\Calibration\Data to the directory C:\Documents and Settings\All Users\Application Data\Rohde&Schwarz\Nwa\Data\Eeprom\Mbt.

- Page 80 R&S ZVA Instrument Construction and Function Description Table of Contents - Chapter 3 "Repairs" Repairs......................3.1 Instrument Construction and Function Description..............3.1 Block Diagram ..........................3.2 Description of the Block Diagram ....................3.4 Board Replacement........................3.14 Board Overview ........................3.16 Replacing Front Module Controller A90 .................. 3.17 Replacing the Lithium Battery on the Front Module Controller..........

- Page 81 Instrument Construction and Function Description R&S ZVA 1145.1155.82 I-3.2...

-

Page 82: Repairs

R&S ZVA Instrument Construction and Function Description 3 Repairs This chapter describes the ZVA’s construction, simple procedures for repairs, troubleshooting and board replacement. A selftest which checks the diagnostic voltages of the board and indicates limit violations is provided for troubleshooting and diagnostics. Chapter 4 of this service manual describes the installation of options and firmware updates. -

Page 83: Block Diagram

Instrument Construction and Function Description R&S ZVA Block Diagram See also Chapter 5, Annex and Drawings. BRIDGE PORT 1 (ZVA8) COUPLER PORT 1 (ZVA24) GENERATOR PORT 1 PORT 1 15 to 21 MHz RECEIVER REF PORT 1 RECEIVER MEAS PORT 1 NETCON NETCON ANALOG... - Page 84 R&S ZVA Instrument Construction and Function Description BRIDGE PORT 1 (ZVA8) COUPLER PORT 1 (ZVA24) GENERATOR PORT 1 PORT 1 20.4 MHz RECEIVER REF PORT 1 RECEIVER MEAS PORT 1 NETCON NETCON ANALOG DIGITAL GRAPHICS DISPLAY BRIDGE PORT 2 (ZVA8) COUPLER PORT 2 (ZVA24) OPTION GENERATOR...

-

Page 85: Description Of The Block Diagram

Instrument Construction and Function Description R&S ZVA Description of the Block Diagram The block diagrams shown in Fig. 3-1 and Fig. 3-2 apply to the R&S ZVA8 and the R&S ZVA24 two- ports and four-ports. The ZVA is a vector network analyzer covering 300 kHz to 8 GHz (R&S ZVA8) or 10 MHz to 24 GHz (R&S ZVA24). - Page 86 R&S ZVA Instrument Construction and Function Description Reflectometer Unit ZVA24 A reflectometer unit comprising a coupler unit, a generator section (Generator) and a receiver section (Receiver) is incorporated in every port (Port1 to 4). The Generator and the Receiver are screwed together to form a compact unit.

- Page 87 Instrument Construction and Function Description R&S ZVA Network controller The network controller comprises two boards, the netcon analog and the netcon digital which are screwed together to form a single unit. The boards are four-channel – in other words, one network controller is required for two ports (2 measurement channels + 2 reference channels).

- Page 88 R&S ZVA Instrument Construction and Function Description Frequency reference The frequency reference board generates the highly stable and spectrally pure clock signals, required by the ZVA, which can be phase-locked to external synchronisation signals. The various function blocks are: The 128 MHz VCXO (voltage-controlled crystal oscillator) which generates a stable, low-noise reference frequency for the synthesisers, for the A/D converters and for digital signal processing.

- Page 89 Instrument Construction and Function Description R&S ZVA Synthesizers The source signals for the generator signals associated with each port and the LO signal for the mixers on the receiver boards for each of the reflectometers are generated on the synthesizer board. One or two individual synthesizers are accommodated on a synthesizer board.

- Page 90 R&S ZVA Instrument Construction and Function Description Synthesizer-DS to Reflectometer 1 (GEN) Synthesizer 9 kHz to 8GHz to Reflectometer 2 (GEN) to Reflectometer 3 (GEN) Synthesizer 9 kHz to 8GHz to Reflectometer 4 (GEN) 1145.1155.82...

- Page 91 Instrument Construction and Function Description R&S ZVA Synthesizer-LO to Reflectometer 1 (LO) to Reflectometer 2 (LO) Synthesizer 15.625 MHz to 8025 MHz to Reflectometer 3 (LO) to Reflectometer 4 (LO) The synthesizer models are incorporated as follows in the various ZVA models: Synthesizer- LS 1302.4290.02 LS 1302.4290.24...

- Page 92 R&S ZVA Instrument Construction and Function Description Front unit The front unit comprises a mounting plate on which the LCD, the flexible switch board and key pad, and the tachogenerator are accommodated. The front module controller is mounted in the controller tray in the instrument frame. LC display All results and setting information the user requires is displayed on the colour LCD.

- Page 93 Instrument Construction and Function Description R&S ZVA Power supply The power supply produces all the voltages required to power the ZVA. It can be turned off with a switch on the instrument’s rear panel. The power supply is a primary-switched power supply with power factor correction (PFC) and standby circuit (+12 V standby).

- Page 94 R&S ZVA Instrument Construction and Function Description Motherboard The motherboard supplies power to the boards and connects them to the control and data buses. A number of RF connections are also routed via the motherboard. As well as straight connections, a number of circuits are accommodated on the motherboard: Motherboard controller (MBCON) 28 V supply Preamplifier for the DC measurement inputs...

-

Page 95: Board Replacement

Board Replacement R&S ZVA Board Replacement The following section is a detailed description of board replacement. Chapter 5 tells you how to order spare parts. It contains a list of mechanical parts and their order numbers as well as drawings relating to board replacement. - Page 96 R&S ZVA Board Replacement • Follow the additional safety instructions at the beginning of Caution this manual. • Disconnect the instrument from the mains before removing the enclosure. • To prevent damage to electronic components, only open the instrument on an anti-static workbench. The following methods can be used singly or in any Wrist strap with cord combination...

-

Page 97: Board Overview

Board Replacement R&S ZVA Board Overview Table 3-1 Overview: Board Replacement Board Measures taken after replacement Function test Alignment Other Recording of correction values System error calibration Front module controller Check error log BIOS update Lithium battery Check error log Hard disk Check error log System error calibration... -

Page 98: Replacing Front Module Controller A90

R&S ZVA Board Replacement Replacing Front Module Controller A90 (See Chapter 5, Spare Parts List, Item 580, and drawings 1145.1110, 1145.1310) The front module controller is located behind the front unit. Opening the instrument and removing the front unit Turn off the instrument and disconnect from the mains. Remove termination and 3.5mm connection cables (only with option ZVAx-B16) Remove the 4 screws from the front handles (410), left and right, and take off the front handles. - Page 99 Board Replacement R&S ZVA Installing the new front module controller and putting the instrument back together Carefully insert the new front module controller on the motherboard and screw into place with 10 sems screws (590). Caution: With type FMR6 1091.2520.00, there is a danger of shorting between board components, tracks and screws (590).

- Page 100 R&S ZVA Board Replacement Putting into operation Connect the mains cable and turn on at the power on switch. The instrument is now in standby mode. Prepare a BIOS disk downloading the required file from https://gloris.rohdeschwarz.com (Document link: Firm- \ Software) on a floppy disk. Insert the BIOS disk into the floppy disk drive.

-

Page 101: Replacing The Lithium Battery On The Front Module Controller

Board Replacement R&S ZVA Replacing the Lithium Battery on the Front Module Controller (See Chapter 5, Spare Parts List, Item (582), and drawings 1145.1110, 1145.1290) The lithium battery is located on the front module controller behind the front unit. Caution Do not expose lithium batteries to high temperatures or naked flames. - Page 102 R&S ZVA Board Replacement Removing the lithium battery Carefully lift up and pull out the battery. Note: Lithium battery 3.4 V (dia. 20 mm * 3 mm) R&S Item No. 0858.2049.00 Front Module Controller Typ FMR6 Connector for rotary pulse generator Contact side of switching foil (keyboard) up Battery LAN 1 LAN 2...

- Page 103 Board Replacement R&S ZVA Putting into operation Connect the mains cable and turn on at the power switch. The instrument is now in standby mode. Select Service Level 2 (see Service Functions). When the instrument has been started, check the protocol file for errors: [ INFO : Error Log ] 1145.1155.82 3.22...

-

Page 104: Replacing Hard Disk A60

R&S ZVA Board Replacement Replacing Hard Disk A60 (See Chapter 5, Spare Parts List, Item 710, and drawings 1145.1110 and 1145.1310) The hard disk is located between the controller tray and the boards. The spare disk is delivered with the software pre-installed. -

Page 105: Replacing Lcd A70 And The Dc/Ac Converter

Board Replacement R&S ZVA Replacing LCD A70 and the DC/AC Converter (See Chapter 5, Spare Parts List Items 910, 930 and drawings 1145.1110, 1145.1390) The LCD and the associated DC/AC converter are accommodated on a mounting plate. The connection to the front module controller is made with cables which should also be replaced individually. The replacement procedure is as follows: Opening the instrument and removing the front unit Turn off the instrument and disconnect from the mains. - Page 106 R&S ZVA Board Replacement Installing and putting into operation a new LCD or DC/AC converter Reinstall the new LCD or new DC/AC converter by reversing the disassembly procedure, refit all screws and reconnect the cables that have been disconnected (drawing 1145.1390). When replacing the display (921) or display cable (945), use a new adhesive label (946) to secure the cabling.

-

Page 107: Replacing Flexible Switch Board (Keyboard) A16 / Key Pad A15

Board Replacement R&S ZVA Replacing Flexible switch board (Keyboard) A16 / Key Pad A15 (See Chapter 5, Spare Parts List, Items 860, 870 and drawings 1145.1110, 1145.1390) The flexible switch board (keyboard) and key pad are located behind the front cover and the keyboard frame Opening the instrument and removing the front unit Turn off the instrument and disconnect from the mains. - Page 108 R&S ZVA Board Replacement Installing a new flexible switch board / key pad and reassembling the instrument Insert the new flexible switch board (860) into the keyboard frame (800, 805) from behind. N.B.: The positioning pins must be inserted in the holes in the keyboard frame. Place the new key pad (870) on the rear of the flexible switch board (860).

-

Page 109: Replacing The Front Cover

Board Replacement R&S ZVA Replacing the Front Cover (See Chapter 5, Spare Parts List, Items 300, 303, 306, 310, 313, 316 and drawing 1145.1110) The front cover is the outermost front panel with lettering. Each instrument type has its own front cover. Turn off the instrument and disconnect from the mains. -

Page 110: Replacing Disk Drive A30

R&S ZVA Board Replacement Replacing Disk Drive A30 (See Chapter 5, Spare Parts List, Item 670 and drawings 1145.1110 and 1145.1310) Opening the instrument and removing the disk drive Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 111: Replacing Usb Board A40

Board Replacement R&S ZVA Replacing USB Board A40 (See Chapter 5, Spare Parts List, Item 1050 and drawings 1145.1110 and 1145.1390) The USB board is located behind the front cover and the keyboard frame next to the ON key. Opening the instrument and removing the USB-board Turn off the instrument and disconnect from the mains. -

Page 112: Replacing Power Supply A20

R&S ZVA Board Replacement Replacing Power Supply A20 (See Chapter 5, Spare Parts List, Items 790 and drawings 1145.1110, 1145.1310) The power supply is installed at the rear of the instrument frame. Removing the power supply Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) towards the rear. -

Page 113: Replacing Fuse Board A21

Board Replacement R&S ZVA Replacing Fuse board A21 (See Chapter 5, Spare Parts List, Item 735, and drawings 1145.1110, 1145.1290) The fuse board is installed on the left-hand side of the power supply. Removing the power supply and the fuse board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 114: Replacing A Fan

R&S ZVA Board Replacement Replacing a Fan (See Chapter 5, Spare Parts List, Item 15 and drawings 1145.1110, 1145.1310) The fans, three in all, are located behind the right-hand side panel. Opening the instrument and removing the fan Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 115: Replacing Motherboard A10

Board Replacement R&S ZVA Replacing Motherboard A10 (See Chapter 5, Spare Parts List, Item 510 and drawings 1145.1110, 1145.1310) The motherboard is located on the base of the instrument. N.B.: The motherboard can only be replaced at R&S service centers. Opening the instrument and removing the motherboard Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. - Page 116 R&S ZVA Board Replacement Place the instrument on its top and remove the instrument’s base cover (297) by undoing the screws (299). Undo the RF cabling from the reflectometers (165, 170, 175) to the LO divider (125) and to the motherboard.

- Page 117 Board Replacement R&S ZVA Installing the motherboard and reassembling the instrument N.B.: The motherboard is the passport of the instrument and unique for every unit. The Eprom on the motherboard contains the serial No. of the instrument. Pre-configured motherboards are not available. Install the new motherboard by reversing the removal procedure.

-

Page 118: Replacing A Reflectometer Rm8 A510 To 540

R&S ZVA Board Replacement Replacing a Reflectometer RM8 A510 to 540 (See Chapter 5, Spare Parts List, Items 150, 160 and drawing 1145.1110) The boards are located under the motherboard. Opening the instrument and removing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 119: Replacing Generator Board (Zva8 Only)

Board Replacement R&S ZVA Replacing Generator Board (ZVA8 only) (See Chapter 5, Spare Parts List, Item 110 and drawing 1302.4960.08) Opening the instrument and removing the board Remove the reflectometer (see chapter Replacing Reflectometer Board A510 to A540) Remove the cover (130) Remove the fan cable Pull off the generator board (110) Installing the board and reassembling the instrument... -

Page 120: Replacing Receiver Board (Zva8 Only)

R&S ZVA Board Replacement Replacing Receiver Board (ZVA8 only) (See Chapter 5, Spare Parts List, Item 120, 125 and drawing 1302.4960.08) Opening the instrument and removing the board Remove the reflectometer (see chapter Replacing Reflectometer Board A510 to A540) Remove the cover (150) Pull off the receiver board (120, 125) Installing the board and reassembling the instrument Fit the new receiver board (120, 125) -

Page 121: Replacing Generator And Receiver Cover (Zva8 Only)

Board Replacement R&S ZVA Replacing Generator and Receiver Cover (ZVA8 only) (See Service Circular 10028 and Chapter 5, Spare Parts List, Items 130, 150 and drawing 1302.4960.08) Opening the instrument and removing the cover Remove the reflectometer (see chapter Replacing Reflectometer Board A510 to A540) Remove the RM mount (200), 4 screws (210) Remove the covers (130, 150) Installing the cover and reassembling the instrument... -

Page 122: Replacing The Inner Conductor Of A Port Connector (Zva8 Only)

R&S ZVA Board Replacement Replacing the Inner Conductor of a Port Connector (ZVA8 only) (See Chapter 5, Spare Parts List, Item 110, and drawings 1145.1110, 1145.4177, 1145.3593) Opening the instrument and removing the reflectometer Remove the Reflectometer (see chapter Replacing Reflectometer Board A510 to A540) Replacing the inner conductor Unscrew the N outer conductor with a spanner (narrow, SW 14mm) and take out inner conductor unit. -

Page 123: Replacing The Bridge Unit (Zva8 Only)

Board Replacement R&S ZVA Replacing the Bridge Unit (ZVA8 only) (See Chapter 5, Spare Parts List, drawings 1145.1110, 1145.4177, Item 100) Opening the instrument and removing the reflectometer Remove the Reflectometer (see chapter Replacing Reflectometer Board A510 to A540) Removing the bridge unit Loosen the MEAS, REF and GEN cables (310, 320, 300) at both ends and disconnect at the bridge unit. -

Page 124: Replacing A Reflectometer Rm24 A510 To 540

R&S ZVA Board Replacement Replacing a Reflectometer RM24 A510 to 540 (See Chapter 5, Spare Parts List, Items 180, 185, 190 and drawings 1145.1110, 1302.4425) The boards are located under the motherboard. Opening the instrument and removing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 125: Replacing The Coupler Unit (Zva24 Only)

Board Replacement R&S ZVA Replacing the Coupler Unit (ZVA24 only) (See Chapter 5, Spare Parts List, drawing 1145.1110, item 230) Opening the instrument and removing the coupler Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 126: Replacing The Reflectometer Fan

R&S ZVA Board Replacement Replacing the Reflectometer Fan (See Chapter 5, Spare Parts List, Item 100, 190 and drawings 1145.1110, 1145.4177, 1145.4283) Remove the Reflectometer (see chapter Replacing a Reflectometer RMxx A510 to A540) Replacing the fan Disconnect the fan cable at the reflectometer. Undo the 4 holding screws (110,194) and remove the fan. -

Page 127: Replacing Network Controller Board A130, A140

Board Replacement R&S ZVA Replacing Network Controller Board A130, A140 (See Chapter 5, Spare Parts List, Items 100, 105 and drawing1145.1110) The board is in the upper section of the instrument. Opening the instrument and removing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 128: Replacing Synthesizer Board A150, A160

R&S ZVA Board Replacement Replacing Synthesizer Board A150, A160 (See Chapter 5, Spare Parts List, Items 110, 112, 113, 115 and drawing 1145.1110) The board is located in the upper section of the instrument. Opening the instrument and removing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 129: Replacing Frequency Reference Board A100

Board Replacement R&S ZVA Replacing Frequency Reference Board A100 (See Chapter 5, Spare Parts List, Item 120 and drawings 1145.1110, 1164.1770) Opening the instrument and replacing the board Turn off the instrument and disconnect from the mains, screw off the 4 rear-panel feet (460) and pull off the enclosure (400) backwards. -

Page 130: Troubleshooting

R&S ZVA Troubleshooting Troubleshooting The instructions in this manual describe troubleshooting down to the board level. Any defective boards can then be replaced and the instrument put back into operation. A selftest which checks the board diagnostic voltages and displays limit violations is provided to facilitate troubleshooting and diagnosis. We recommend that you return your instrument to the technical specialists at an R&S service facility for board replacement and any further repairs that may be needed (see the address list at the beginning of this manual). -

Page 131: Troubleshooting - Power-Up Problems

Troubleshooting R&S ZVA Troubleshooting - Power-up Problems • Fault: It is not possible to turn on the ZVA. Action Cause of fault / remedy Check mains switch on the rear panel Mains switch OFF: Turn on at mains switch. ⇓ Check LED is yellow (standby) LED does not come on: Measure voltage at X92.C23... -

Page 132: Troubleshooting Boot Problems

R&S ZVA Troubleshooting Troubleshooting Boot Problems • Fault: ZVA does not start the measurement application. The first action the ZVA performs after power-up is booting BIOS for the processor. When the processor has been successfully initialised, the Windows XP start-up procedure begins. Then, the measurement application is loaded as an autostart program. -

Page 133: Troubleshooting - Boot Error

Troubleshooting R&S ZVA Troubleshooting - Boot Error If the message below appears on the screen when the boot procedure has been completed, Warning: Boot error occurred. For details browse Error Log file. the cause of the error can be found in the Error-Log file. Setup INFO Info... -

Page 134: Troubleshooting With The Selftest

R&S ZVA Troubleshooting Troubleshooting with the Selftest The selftest is used to check supply voltages to the boards, including voltages generated on the boards themselves. On the frequency reference board, two clock signals (128 MHz and ADC-CLK) are also measured. Starting the selftest: •... - Page 135 Troubleshooting R&S ZVA Total selftest status: user mode ---PASSED--- Instrument Type: ZVA8 with 4 Ports Part Number: 1145.1110k10 Product ID: 01.00 Serial Number: 100124 IP Addresses IP Address: 0.0.0.0&nbs; Subnet Mask: 0.0.0.0 IP Address: 0.0.0.0 Subnet Mask: 0.0.0.0 IP Address: 127.0.0.1 (Localhost) Subnet Mask: 255.0.0.0 SyMapping: ZVA8_P4 LO Divider: is not active...

- Page 136 R&S ZVA Troubleshooting Test description Result State +5VA_ADC 2.250V 2.750V 2.484V PASSED +2.5VD_MDD1 1.125V 1.375V 1.260V PASSED +2.5VD_MDD2 1.125V 1.375V 1.260V PASSED +1.5VD_FCON 0.675V 0.825V 0.752V PASSED -5VA_ADC 2.250V 2.750V 2.460V PASSED DGND1 0.000V 0.200V 0.000V PASSED DGND2 0.000V 0.200V 0.000V PASSED AGND...

- Page 137 Troubleshooting R&S ZVA +10.5VA SUPPLY 2.300V 2.800V 2.576V PASSED +10.5VB SUPPLY 2.300V 2.800V 2.592V PASSED +12V FAN 2.000V 2.600V 2.204V PASSED +12V SUPPLY 2.000V 2.600V 2.204V PASSED -12V SUPPLY 1.600V 2.000V 1.796V PASSED Voltages Rm3 Test description Result State 0.000V 0.200V 0.000V PASSED...

- Page 138 R&S ZVA Troubleshooting Interpreting the Results of the Selftest Negative voltages are transformed into positive voltages by means of a positive voltage and a resistor network because the A/D converters that are used can handle only positive voltages. This is why an acceptable negative voltage may elicit a FAIL because the associated positive voltage is out of tolerance.

-

Page 139: Checking The Temperature Sensors

Troubleshooting R&S ZVA Checking the Temperature Sensors Select Service Level 2 (see Service Functions). Setup INFO Info When the Hardware Info softkey is pressed information about the installed hardware, the results of temperature measurements and … are displayed. Hardware Info Selftest Error Log…... -

Page 140: Service Functions

R&S ZVA Troubleshooting Service Functions The service functions allow you to examine particular circuit sections on specific boards or to make well-defined settings that would normally change automatically according to the state of the instrument (e.g. the IF). There are a number of service functions which, if used incorrectly, could cause the instrument to malfunction. - Page 141 Troubleshooting R&S ZVA Service Function Structure Group Main ID Sub ID Function Address Data Group Applies to HW (boards) Boards Boards Main ID Sub ID 0: All boards 1: Network controller1 0: All board 1: PCI 2: ND 3: NA 2: Network controller2 5: Motherboard 9: Frequency reference...

- Page 142 R&S ZVA Troubleshooting Group 1: General Functions Functions Service Data Serv. Lev. function Enables/disables the peak detector and RMS 1.0.0.1.X 0 → Use disabled detector independently of the model 1 → Use enabled Enable/disables the arbitrary mode settings in 1.0.0.5.X 0 →...

- Page 143 Troubleshooting R&S ZVA Motherboard Functions Service function Data Serv. lev. MB: Fan manual 2.5.0.11.1.X X= 0 to 5 MB: Fan automatic 2.5.0.11.0 MB:Read Temp 2.5.0.3.1 Front (NC) (addr.:205) MB: Read Temp 2.5.0.3.2 Rear (SY) (addr.: 204) MB: Read Temp 2.5.0.3.3 Back (PS) (addr.: 202) Frequency reference Functions...

-

Page 144: Determining Which Boards Are Defective

R&S ZVA Troubleshooting Determining which Boards are defective The table below lists boards that are probably defective based on the faults that occurred during the performance test. Defective board Problem with: Probable Also possible Frequency accuracy Frequency reference SSB phase-noise Only one port Synthesizer1 All ports... -

Page 145: Board Test

Troubleshooting R&S ZVA Board Test When boards are being tested, internal sources are used whenever possible. This means that it is always assumed that the downstream board in the signal path is OK. If a clear fault is not present, the order of the board tests given below should always be followed. - Page 146 R&S ZVA Troubleshooting Testing the frequency reference board (see Test Equipment) Remove the board from the instrument. Reinsert board and extension card. Connect the output to be tested to the spectrum analyzer using an adapter cable and adapter SMA-N. Set the frequencies listed in the table. Check signals according to following table.

- Page 147 Troubleshooting R&S ZVA Testing the Synthesizer Board N.B.: Synthesizers with part numbers 1145.xxxx or 1300.xxxx are no longer available. In case of defect please contact the Central Service in Munich. Disconnect source (or local) cable at the reflectometer (1 to 4, depending on which synthesizer section is to be tested).

- Page 148 R&S ZVA Troubleshooting 4 GHz 4017.512345 +3 dBm to -3 < -25 dBc < -30 dBc 5.2 GHz 5217.512345 +2 dBm to -4 < -25 dBc < -30 dBc 5.3 GHz 5317.512345 +7 dBm to +2 < -25 dBc < -30 dBc 7.2 GHz 7217.512345 +7 dBm to +2...

- Page 149 Troubleshooting R&S ZVA Synthesizer-DS 1302.5180.xx Source 1 to 4 (set port1 to 4 active) Frequency Source Level 2nd harmonic 3rd harmonic (ZVA setting) 300 kHz +3 dBm to -5 dBm < -27 dBc < -30 dBc 100 MHz +3 dBm to -5 dBm <...

- Page 150 R&S ZVA Troubleshooting Synthesizer-LO 1302.4248.02 Local 1 to 4 (set port1 to 4 active) Frequency LO-Frequency Local Level 2nd harmonic 3rd harmonic (ZVA setting) (Spec analyzer setting) 300 kHz 17.812345 MHz -3 dBm to -6 < -28 dBc < -5 dBc 100 MHz 117.512345 -3 dBm to -6...

- Page 151 Troubleshooting R&S ZVA Testing the Reflectometer RM8 Generator levels It is assumed that the synthesizer section (synthesizer1) associated with the reflectometer to be tested is OK. Loosen cable W514 (GEN -> Bridge unit) at both ends and screw off at the generator output GEN. Note: When loosening, support the cable with a 7mm spanner Connect the generator output to the spectrum analyzer using the SMA cables () and adapter SMA- Set the power to 8 dBm...

- Page 152 R&S ZVA Troubleshooting Frequency Output level Displayed level ax or bx 300 kHz -20 dBm 0 dBm 50 MHz -20 dBm 0 dBm 1 GHz -20 dBm 0 dBm 3 GHz -20 dBm 0 dBm 6 GHz -20 dBm 0 dBm 8 GHz -20 dBm 0 dBm...

- Page 153 Troubleshooting R&S ZVA Frequency Level Output level MEAS Output level REF 300 kHz 0 dBm -18 dBm -32 dBm 50 MHz 0 dBm -18 dBm -32 dBm 1 GHz 0 dBm -18 dBm -32 dBm 3 GHz 0 dBm -18 dBm -32 dBm 6 GHz 0 dBm...

- Page 154 R&S ZVA Troubleshooting Bridge Directivity The following is assumed: • The generator and receiver sections of the reflectometer associated with the bridge unit are OK. Screw the SHORT from an N calibration kit to the port connector. Perform a sweep from 300 kHz to 8 GHz, measure S11, save measured values (Data -> Mem : Math = Data/Mem).

- Page 155 Troubleshooting R&S ZVA Testing the Reflectometer RM24 Generator levels It is assumed that the synthesizer section (synthesizer1) associated with the reflectometer to be tested is OK. Loosen cable W514 (GEN -> coupler unit) at both ends and screw off at the generator output GEN. Connect the generator output to the spectrum analyzer using the SMA cable ().

- Page 156 R&S ZVA Troubleshooting Frequency Output level Displayed level ax or bx +20 dBm ± 3 dB 10 MHz -30 dBm 100 MHz -30 dBm +5 dBm ± 3 dB -5 dBm ± 3 dB 1 GHz -20 dBm 2.5 GHz -20 dBm -10 dBm ±...

- Page 157 Troubleshooting R&S ZVA Frequency Level Output level MEAS Output level REF -50 dBm ± 3 dB -47 dBm ± 3 dB 10 MHz 0 dBm 100 MHz 0 dBm -35 dBm ± 3 dB -32 dBm ± 3 dB 1 GHz 0 dBm -15 dBm ±...

- Page 158 R&S ZVA Troubleshooting Coupler Directivity The following is assumed: • The generator and receiver sections of the reflectometer associated with the coupler unit are OK. Screw the SHORT from the calibration kit to the port connector. Perform a sweep from 10 MHz to 20 GHz, measure S11, save measured values (Data -> Mem : Math = Data/Mem).

- Page 159 Troubleshooting R&S ZVA Testing the Network Controller Board Testing the IF inputs It is assumed that there is one functioning reflectometer in the instrument. Disconnect the IF-MEAS and IF-REF cable from each of the reflectometers. Connect the input to be tested at the end of the appropriate IF cable (W136, W137, W138, W139, and W146, W147, W148, W149) to a functioning port using the adapter cable and SMA-N adapter .

- Page 160 R&S ZVA Troubleshooting Testing the Motherboard 28 V supply Using a multimeter, measure the voltage at X 100.B5 (wrt ground). Permissible deviation: ± 0.5 V Preamplifier for DC measurement inputs Apply the DC voltages listed in the table using the 4-pin Mini-DIN connector at the DC measurement input.

- Page 161 R&S ZVA Table of Contents - Software Update / Installation of Options Table of Contents- Chapter 4 "Software Update / Installation of Options" 4 Software Update / Installation of Options ............4.1 Installing new ZVA Software ......................4.1 Installing Options ..........................4.2 1145.1155.82 I-4.1...

- Page 162 Table of Contents - Software Update / Installation of Options R&S ZVA This page has been left blank intentionally. 1145.1155.82 I-4.2...

- Page 163 R&S ZVA Installing new ZVA Software Software Update / Installation of Options Chapter 4 provides information on updating software, restoring the operating system installation and installing options. Descriptions accompanying the software update or the options can be included in this folder as part of Chapter 4.

- Page 164 R&S ZVA Installing Options Installing Options The following options can be fitted to the ZVA: Direct Generator/Receiver Access for ZVA8 R&S ZVA8-B16 1164.0209.08 for ZVA24 with two ports R&S ZVA24-B16 1164.0209.24 for ZVA24 with four ports R&S ZVA24-B16 1164.0209.26 Generator Step Attenuator Port 1 for ZVA8 R&S ZVA8-B21 1164.0009.02...

- Page 165 R&S ZVA Installing new ZVA Software The OCXO option is permanently integrated on the frequency reference board (mod. 03, mod. 05) and, as a rule, it is specified when the instrument is ordered. When it is retrofitted, the frequency reference board must be replaced (replace mod.

- Page 167 R&S ZVA Contents - Documents Contents - Chapter 5 "Documents" 5 Documents......................1 Shipping of Instrument and Ordering of Spare Parts..............1 Shipping of Instrument ........................1 Shipping of a Module ........................1 Ordering Spare Parts ........................2 Refurbished Modules ........................2 Return of Defective Replaced Modules ..................2 Spare Parts............................3 Available Power Cables ......................3 Spare Parts List ...........................4...

- Page 168 R&S ZVA Contents - Documents This page is left blank intentionally. 1145.1078.82...

-

Page 169: Shipping Of Instrument And Ordering Of Spare Parts

ZVAA Shipping of Instrument and Ordering of Spare Parts 5 Documents This chapter provides information on the ordering of spare parts and contains the spare parts list and the documents for the complete ZVA unit. Shipping of Instrument and Ordering of Spare Parts Please contact your Rohde &... -

Page 170: Ordering Spare Parts

Shipping of Instrument and Ordering of Spare Parts Ordering Spare Parts To deliver replacement parts promptly and correctly, we need the following information: • Stock No. (see component lists in this chapter) • Designation • Component number according to component list •... -

Page 171: Spare Parts

Spare Parts Spare Parts The Stock Nos. necessary for ordering replacement parts and modules can be found in the component lists provided later in this chapter. Important! When replacing a module, please observe the safety instructions and repair instructions provided in chapter 3 and at the beginning of this service manual When shipping a module, be sure to provide sufficient mechanical and antistatic protection. -

Page 172: Spare Parts List

Spare Parts List Mechanical Drawings 1145.1078.02... - Page 173 This page is left blank intentionally. 1145.1078.02...

- Page 174 List of ZVB parts including spare parts List of ZVA parts including spare parts The ZVA is constructed in accordance with R&S Design 2000. Rackmount: 6E 1/1 T350 MOD. 22 Overall dimensions: B x H x T: 465.1 x 286.2 x 417.0 Accessories: 19'' Adapter ZZA-611, Stock No.

- Page 175 MZ EXT. ANALYZER MOUNT 1145.3058.00 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 ZN MOTHERB. RAIL 2 ZVA 1145.2051.00 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 VS 6900/ISR-M2.5X8-A2 0041.1653.00 ZE RM UNIT ZVA 24 GHz 1145.4302.02 A510 A520 VS 965/ISR-M3X8-A4-PA 1148.2798.00 ZM CABLE SET ZVA24 2PORT 1302.5050.24 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 A510 A520 ZE RM UNIT ZVA 24 GHz 1145.4302.02...

- Page 176 Designation spare parts VS 965/ISR-M3X8-A4-PA 1148.2798.00 ZM CABLE SET ZVA 1145.2551.25 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 A510 A520 ZE RM UNIT ZVA 24 GHz 1145.4302.02 A530 A540 VS 965/ISR-M3X8-A4-PA 1148.2798.00 ZM CABLE SET ZVA 1145.2551.26 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 KB COVER PLATE ZVA 1145.3029.00...

- Page 177 1145.1549.00 KB FRONT COVER ZVA 8 4PORT 1145.1503.00 KB FRONT COVER ZVA24 2PORT 1145.2380.00 KB FRONT COVER ZVA24 3PORT 1145.2397.00 KB FRONT COVER ZVA 24 4PORT 1145.1510.00 KB COUNTERSUNK SCREW M1.6X3 LIGHT-GREY 0396.1070.00 KR CASING 6E1/1T450N-ZV 1145.1832.00 KR HOLDING HOOK 1096.4796.00...

- Page 178 List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts GR FRONT MOD. CONTROLLER 6/5+ 1091.2908.00 LITHIUM BATTERY CR2032 0858.2049.00 VS 6900/ISR-M2.5X6-A2 1148.3059.00 DF CABLE 4X2 AND SHIELDING 630 1145.5115.00 DZ FEED THROUGH 0062.1146.00 DZ HOLDER 0794.5214.00...

- Page 179 List of ZVA parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts VS DIN137-A3-A2 0005.0296.00 VS DIN137-A4-A2 0005.0315.00 FN POWER FILTER WITH SWITCH 1145.5067.00 X200 VS 965/ISR-M3X8-A4-PA 1148.2798.00 W200 ZE POWER UNIT ZVAB 1145.3893.00 DZ GROMMET 7X12X16 0099.3520.00 VS 965/ISR-M3X8-A4-PA 1148.2798.00...

- Page 180 List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts VS 965/ISR-M2.5X5-A4-PA 1148.2752.00 MZ SUPPORT PLATE 2 ZVA 1145.2474.00 VS 965/ISR-M2.5X5-A4-PA 1148.2752.00 MZ DUST PROOFING ZVA 1145.1649.00 BP TFT 800X600X3 10.4INCH 1145.5367.00 MZ DISPLAY COVER 1302.5215.00 VS 6900/ISR-M2.5X6-A2 1148.3059.00...

- Page 181 MN COVER B-SIDE GEN 8GHZ 1145.3670.00 MN COVER A-SIDE GEN 8GHZ 1302.5096.00 MN COVER B-SIDE REC 8GHZ 1302.5109.00 OS BARCODE LABEL FOR PCB 0071.7714.00 DRAWING 1145.4302.01 (RM UNIT ZVA 24) ZE REFLECTOMETER 24 1145.4283.02 A500 FJ ADAPTER PC3.5 MALE/MALE 1127.9493.00 ZE COUPLER 24 1162.0701.02...

- Page 182 List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts MZ PLATE RM24 1145.4490.00 VS 965/ISR-M2.5X6-A4-PA 1148.3288.00 DW RF CABLE W518 REF 1300.0351.00 W518 DW RF CABLE W515 MEAS 1300.0368.00 W515 W514 DW RF CABLE W514 GEN 1300.0374.00 DV RF CABLE W541 1145.4931.00...

- Page 183 List of ZVA parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts DW RF CABLE W501 REF IN 1145.2951.00 W501 DW RF CABLE W513 SRC OUT 1164.0321.00 W513 DW RF CABLE W513 SRC OUT 1164.0321.00 W513 DW RF CABLE W513 SRC OUT 1164.0321.00...

- Page 184 List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts DW RF CABLE W503 REF OUT 1300.0380.00 W503 DW RF CABLE W503 REF OUT 1300.0380.00 W503 DW RF CABLE W503 REF OUT 1300.0380.00 W503 DW RF CABLE W501 REF IN 1300.0397.00...

- Page 185 List of ZVA parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts PD INSTALLATION INSTRUCTION 1164.0267.00 Zeichnung 1164.0215.00 (OPTION ZVA8-B21 GEN.ATTENUATOR PORT 1 1164.0009.02) (OPTION ZVA8-B22 GEN.ATTENUATOR PORT 2 1164.0015.02) (OPTION ZVA8-B23 GEN.ATTENUATOR PORT 3 1164.0021.02) (OPTION ZVA8-B24 GEN.ATTENUATOR PORT 4 1164.0038.02) A550 ZE ATTENUATOR COMB 8...

- Page 186 List of ZVB parts including spare parts Position. Designation Stock No. Number Electrical Recommended Designation spare parts Zeichnung 1164.0221.00 (OPTION ZVA24-B31 REC.ATTENUATOR PORT 1 1164.0144.02) (OPTION ZVA24-B32 REC.ATTENUATOR PORT 2 1164.0150.02) (OPTION ZVA24-B33 REC.ATTENUATOR PORT 3 1164.0167.02) (OPTION ZVA24-B34 REC.ATTENUATOR PORT 4 1164.0173.02) ZE ATTENUATOR REC24 1046.5082.05 A550...

- Page 187 List of ZVA parts including spare parts This page is left blank intentionally. 1145.1078.02...

-

Page 221: Circuit Diagram

Circuit Diagram 1145.1078.02...

Need help?

Do you have a question about the ZVA 24 and is the answer not in the manual?

Questions and answers