Subscribe to Our Youtube Channel

Summary of Contents for Woodward ELA 21

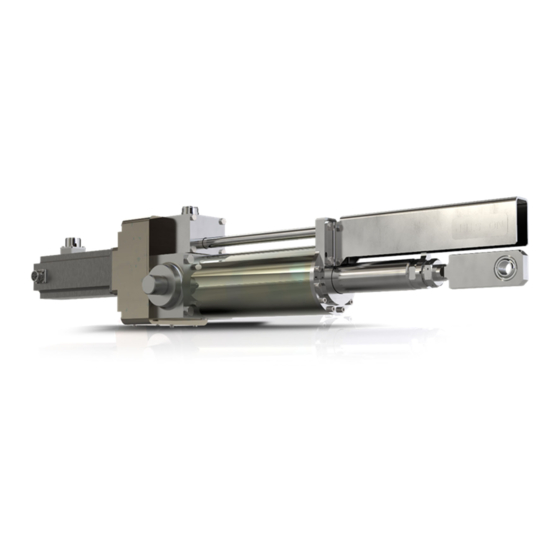

- Page 1 Released Product Manual 35128 (Revision A, 8/2023) Original Instructions Electric Large Actuator (ELA) 21 and ELA 28 Lubrication Procedure Installation and Operation Manual...

- Page 2 Revisions— A bold, black line alongside the text identifies changes in this publication since the last revision. Woodward reserves the right to update any portion of this publication at any time. Information provided by Woodward is believed to be correct and reliable. However, no responsibility is assumed by Woodward unless otherwise expressly undertaken.

-

Page 3: Table Of Contents

Contacting Woodward’s Support Organization ................... 11 Technical Assistance ..........................12 ........................13 EVISION ISTORY The following are trademarks of Woodward, Inc.: Woodward Illustrations and Tables Figure 1-1. Grease Port Locations ........................ 6 Figure 1-2. Greasing Technique ........................7 ... -

Page 4: Warnings And Notices

Be prepared to make an emergency shutdown when starting the engine, turbine, or other type of prime mover, to protect against runaway or overspeed with possible personal injury, loss of life, or property damage. Start-up Woodward... -

Page 5: Electrostatic Discharge Awareness

Do not touch the components or conductors on a printed circuit board with your hands or with conductive devices. To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715 , Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules. -

Page 6: Regulatory Compliance

Released Manual 35128 ELA21/28 Lubrication Procedure Regulatory Compliance Regulatory Compliance and Declaration information is contained in Manual 35033 for the ELA 28 and Manual 35107 for the ELA 21. Woodward... -

Page 7: Chapter 1. Lubrication Procedure

Temperature ratings are included in the specification section of this manual. Use only Woodward-approved grease to lubricate the roller screw, gears and bearing in this actuator. Use of any other grease will reduce performance and reliability. Woodward lubrication kits are available. -

Page 8: Grease Kit Contents

Each kit contains multiple syringes with a premeasured amount of grease. Do not refill the syringes. Please refer to the product manual for the correct grease kit part number or contact your Woodward service provider to confirm the recommended grease kit. The correct grease kit should be used for each corresponding actuator, ensuring that grease is not cross contaminated. -

Page 9: Gear And Bearing Lubrication Procedure (Ports 1-5)

4. Attach the thread connector of the grease syringe to the threaded bearing grease port. Fully seat the fitting. 5. Inject 4 cm³ of Woodward approved grease into the bearing grease port. 6. Remove the grease syringe from the bearing port and install the port plug. Torque to 2.5–3.2 Nꞏm / 22–28 lb.-in. -

Page 10: Roller Screw Lubrication Procedure (Port 6)

5. Attach the thread connector of the grease syringe to the threaded grease port of the roller screw. Fully seat the fitting. 6. Inject 4 cm³ of Woodward approved grease (3901-1003) into the roller screw grease port. 7. Remove the grease syringe from the roller screw grease port and install the roller screw port plug and torque the port plug to 2.5–3.2 Nꞏm / 22–28 lb.-in (Figure 7-1). -

Page 11: Chapter 2. Product Support And Service Options

An Authorized Independent Service Facility (AISF) provides authorized service that includes repairs, repair parts, and warranty service on Woodward's behalf. Service (not new unit sales) is an AISF's primary mission. A current list of Woodward Business Partners is available at www.woodward.com/local-partner... -

Page 12: Returning Equipment For Repair

All repair work carries the standard Woodward service warranty (Woodward Product and Service Warranty 5-01-1205) on replaced parts and labor. -

Page 13: Replacement Parts

The unit serial number, which is also on the nameplate Engineering Services Woodward offers various Engineering Services for our products. For these services, you can contact us by telephone, by email, or through the Woodward website. Technical Support ... -

Page 14: Technical Assistance

ELA21/28 Lubrication Procedure Technical Assistance If you need to contact technical assistance, you will need to provide the following information. Please write it down here before contacting the Engine OEM, the Packager, a Woodward Business Partner, or the Woodward factory: General... -

Page 15: Revision History

Released Manual 35128 ELA21/28 Lubrication Procedure Revision History Revision A— Replaced Table 1-1 with new content about grease kit Revised regreasing adapter from 1249-1301 to 1249-1338 New Manual— Woodward... - Page 16 Released Manual 35128 ELA21/28 Lubrication Procedure THIS PAGE INTENTIONALLY LEFT BLANK Woodward...

- Page 17 Released Manual 35128 ELA21/28 Lubrication Procedure THIS PAGE INTENTIONALLY LEFT BLANK Woodward...

- Page 18 Released Manual 35128 ELA21/28 Lubrication Procedure THIS PAGE INTENTIONALLY LEFT BLANK Woodward...

- Page 19 Released Manual 35128 ELA21/28 Lubrication Procedure THIS PAGE INTENTIONALLY LEFT BLANK Woodward...

- Page 20 Email and Website—www.woodward.com Woodward has company-owned plants, subsidiaries, and branches, as well as authorized distributors and other authorized service and sales facilities throughout the world. Complete address / phone / fax / email information for all locations is available on our website.

Need help?

Do you have a question about the ELA 21 and is the answer not in the manual?

Questions and answers