Lincoln B Series Service & Operating Manual

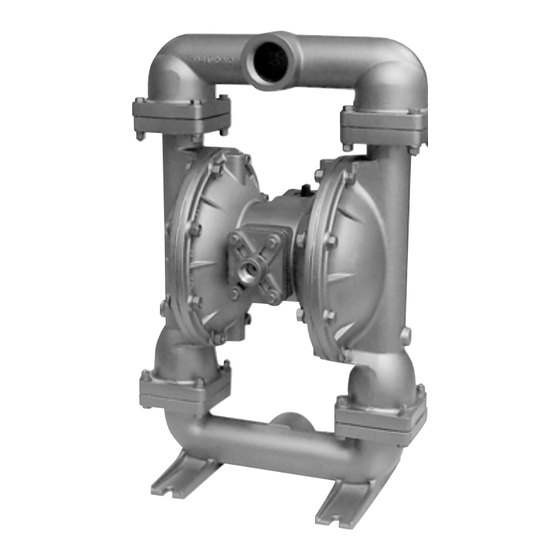

2" alumlnum air-powered diaphragm pump

Hide thumbs

Also See for B Series:

- Manual (58 pages) ,

- Service & operating manual (25 pages) ,

- Quick start manual (7 pages)

Table of Contents

Advertisement

SERVICE & OPERATING MANUAL

Model 85624 Series B

Model 85624 Series B

Model 85624 Series B

Model 85624 Series B

Model 85624 Series B

2" Aluminum Air-Powered Diaphragm Pump

2" Aluminum Air-P

2" Aluminum Air-P

2" Aluminum Air-P

2" Aluminum Air-P

Table of Contents

Engineering Data and Temperature Limitations .................................................. 1

Performance Curve ............................................................................................... 2

Dimensions ........................................................................................................... 3

Metric Dimensions ................................................................................................ 4

Principle of Pump Operation ................................................................................ 5

Installation and Start-Up ....................................................................................... 5

Air Supply ............................................................................................................. 5

Air Valve Lubrication ............................................................................................. 5

Air Line Moisture .................................................................................................. 5

Air Inlet and Priming ............................................................................................. 5

Between Uses ...................................................................................................... 5

Installation Guide .................................................................................................. 6

Troubleshooting .................................................................................................... 7

Warranty ............................................................................................................... 7

Recycling .............................................................................................................. 8

Important Safety Information ................................................................................ 8

520-359-000

7/03 Revision A

owered Diaphragm Pump

owered Diaphragm Pump

owered Diaphragm Pump

owered Diaphragm Pump

LINCOLN

®

• One Lincoln Way, St. Louis, MO 63120-1578 • Customer Service (314) 679-4200

Composite Repair Parts Drawing ...................................................................... 10

Available Service and Conversion Kits .............................................................. 10

Composite Repair Parts List .............................................................................. 11

Air Distribution Valve Assembly Drawing, Parts List and Servicing ................... 12

Actuator Plunger Servicing ................................................................................. 13

Diaphragm Service Drawing .............................................................................. 14

Diaphragm Servicing .......................................................................................... 15

Check Valve Servicing ........................................................................................ 16

Check Valve Drawing ......................................................................................... 16

Pumping Hazardous Liquids .............................................................................. 17

Converting Pump for Piping Exhaust Air ............................................................ 17

Converted Exhaust Illustration ........................................................................... 17

Grounding the Pump .......................................................................................... 18

ATEX Declaration of Conformity ......................................................................... 19

II 2GD b T5

CE

U.S. Patent #

5,996,627 &

6,241,487

Other U.S. Patents

Applied for

Section - B5

Section - B5

Section - B5

Section - B5

Section - B5

Page - 27A

Page - 27A

Page - 27A

Page - 27A

Page - 27A

Form # 403291

Advertisement

Table of Contents

Need help?

Do you have a question about the B Series and is the answer not in the manual?

Questions and answers