Summary of Contents for Krautzberger KS 5F

- Page 1 Operating instructions Hand-held Spray Gun KS 5F T-Dok-666-GB-Rev.1 ■ 200-0380 Translation of the original operating instructions...

- Page 2 Thank you for selecting a Krautzberger product. This product has been manufactured following state-of-the-art manufacturing procedures and extensive quality assurance measures. We promise you a product of the highest quality. If you have questions, requests or suggestions, please contact us. We are always glad to assist you.

-

Page 3: Table Of Contents

ENGLISH Hand-held Spray Gun KS 5F Table of contents Function and identification....................5 Function........................5 Identification......................... 5 Using this operating manual..................... 7 Symbols in this manual....................7 Personnel requirements....................8 Personal protective equipment..................9 Safety and responsibility....................12 Responsibility of the owner..................12 Intended use...................... - Page 4 Accessories........................40 Disassembly and disposal....................41 11.1 Safety........................41 11.2 Disassembly......................41 11.3 Disposal........................41 Technical data........................42 12.1 Dimensions and weight.................... 42 12.2 General specifications..................... 42 12.3 Dimensions......................43 Declaration of conformity....................44 Notes..........................45 Index..........................46 GB–4 mail@krautzberger.com, www.krautzberger.com...

-

Page 5: Function And Identification

1 Function and identification Function The material squeeze spray gun KS 5F with thread nozzle is especially well-suited for the pro- cessing of highly viscose coating materials such as glue, adhesives, sealing agents or grease. The hand-held spray gun operates based on the airless principle, which means the spray jet is exclusively generated by the fluid pressure, which presses the fluid through a nozzle. - Page 6 Operating instructions T-Dok-666-GB-Rev.1 Serial number The serial number of the hand-held spray gun is located on the main element. It serves as a unique identifier. GB–6 mail@krautzberger.com, www.krautzberger.com...

-

Page 7: Using This Operating Manual

ENGLISH Hand-held Spray Gun KS 5F 2 Using this operating manual Symbols in this manual Safety instructions This manual uses symbols to identify safety instructions. The safety instructions are preceded by signal words that indicate the severity of the hazard. -

Page 8: Personnel Requirements

Tasks that go beyond the operation in standard mode must only be carried out by the operator if such is indicated in this manual and the operate has explicitly been tasked to do so. GB–8 mail@krautzberger.com, www.krautzberger.com... -

Page 9: Personal Protective Equipment

Description of the personal protective equipment recommended by Krautzberger The personal protective equipment is described below: Protective work clothing Protective work clothing are tight fitting work clothes with low tear resistance, with tight sleeves, and without any protruding parts. - Page 10 Safety goggles are used to protect the eyes from flying parts and splashes of liquid. Protective gloves Protective gloves protect hands from friction, abrasion, puncture wounds, or deeper injuries, as well as from contact with hot surfaces. Safety shoes GB–10 mail@krautzberger.com, www.krautzberger.com...

- Page 11 ENGLISH Hand-held Spray Gun KS 5F Safety shoes protect the feet against crushing, falling parts or slipping on slippery ground. Safety helmet The helmet protects the head against injuries from falling parts and oscillating loads as well as in tight spaces.

-

Page 12: Safety And Responsibility

The owner must have all safety equipment checked regularly for functionality and complete- ness. Intended use The hand-held spray gun KS 5F is used for the processing of highly viscose coating materials. The intended use also includes the compliance with all the information in this operating manual. Predictable misuse Any use beyond the intended use or any other use constitutes misuse. -

Page 13: General Safety Instructions

ENGLISH Hand-held Spray Gun KS 5F Unauthorized persons must be prevented from entering the hazard zone. Always securely store the hand-held spray gun away from children. Especially during work breaks and in particular during the processing of hazardous materials, preventative measures must be taken against the improper use through unauthorised persons! Clean thoroughly prior to storage and/or transport. - Page 14 Never point the fluid outlet opening or the spray jet toward people. – Check the material hose lines for damage and to make sure that they are firmly in place before each operation. – Adhere to the spray media manufacturer's specifications in the safety data sheet. GB–14 mail@krautzberger.com, www.krautzberger.com...

-

Page 15: Residual Risks

Take breaks between spray processes. Residual risks The hand-held spray gun made by Krautzberger GmbH has been manufactured based on state-of- the-art technology and generally accepted technical safety regulations. Nonetheless, its use can pose a threat to the life or health of users or third parties, damage the hand-held spray gun itself or cause other property damage. -

Page 16: Transport, Storage, And Packaging

Packaging The hand-held spray gun is packaged in accordance with the anticipated transport conditions and the packaging needs to protect it against transport damage, corrosion, and other damage. Remove packaging material. Remove potentially present transport safety restraints. GB–16 mail@krautzberger.com, www.krautzberger.com... -

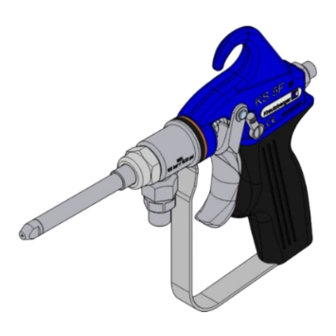

Page 17: Overview

ENGLISH Hand-held Spray Gun KS 5F 5 Overview Fig. 1: Overview KS 5F Material outlet Head piece Locking lever Main element Plastic grip Pull lever Protection hoop pivotable / rigid fluid connection ■ 200-0380 GB–17... -

Page 18: Operation

The system owner is responsible for the presence and the up-to-date status of the safety data sheet and the associated generation of the risk assessment of the effected workstations. GB–18 mail@krautzberger.com, www.krautzberger.com... -

Page 19: General Information About Commissioning/Start-Up

To ensure that there are no particles clogging the nozzles, we recommend to clean the coating material with a material filter positioned in front of the fluid connection (high pressure material filters can be purchased from Krautzberger GmbH). In contrast to compressed air-operated hand-held spray guns, the spray pattern for airless devices can by default not be changed through settings on the nozzle. -

Page 20: Function Test And Start-Up

This presents the risk of causing a fatal embolism. In addition, there is a risk of poisoning in case of toxic coating or cleaning material. – The pull lever must be locked with the locking lever every time the spray gun is put down! GB–20 mail@krautzberger.com, www.krautzberger.com... - Page 21 ENGLISH Hand-held Spray Gun KS 5F Point the hand-held spray gun at a test surface. Fig. 2: Release the locking lever Release the locking lever ( Fig. 2/2). DANGER! Risk of death due to high pressure! WARNING! Risk of injury due to recoil forces during the activation of the hand-held spray gun! Start the spraying process by activating the pull lever ( Fig.

-

Page 22: Shutting Down

Close the material supply and switch off the fluid pressure pump if necessary. Release the residual energy by activating the pull lever ( Fig. 3/1). Flip the locking lever ( Fig. 3/2). 6.4.2 Long-term shut-down Fig. 4: Long-term shut-down GB–22 mail@krautzberger.com, www.krautzberger.com... - Page 23 ENGLISH Hand-held Spray Gun KS 5F Disrupt the spraying process by releasing the pull lever ( Fig. 4/1). Close the material supply and switch off the fluid pressure pump if necessary. Release the residual energy by activating the pull lever ( Fig. 4/1).

-

Page 24: Maintenance

Do not clean fluid nozzle with hard, sharp-hedged objects. A special flat brush as well as var- ious nozzle cleaning needles made by Krautzberger GmbH are recommended for cleaning purposes. In case of prolonged operational interruptions, allow the hand-held spray gun to air-dry after flushing it with cleaning product and store it at a suitable location until it will be used again. -

Page 25: Clean Hand-Held Spray Gun

Clean the outside of the hand-held spray gun with a cloth soaked in cleaning product. Replace threaded needle and needle pack General Information about the replacement of parts Slightly grease sliding parts with special Krautzberger grease. The special grease can be purchased from Krautzberger GmbH (contact data see last page). ■ 200-0380 GB–25... - Page 26 163.5 mm as exactly as possible. A deviation of up to +0.1mm is possible. A shorter length leads to an insufficient valve seat. Occasionally check the moving parts for free range of motion and relubricate when necessary. GB–26 mail@krautzberger.com, www.krautzberger.com...

- Page 27 ENGLISH Hand-held Spray Gun KS 5F Replace threaded needle Fig. 5: Unscrew valve lock screw Unscrew the valve lock screw ( Fig. 5/1). Fig. 6: Remove pressure spring Remove the pressure spring ( Fig. 6/1). Fig. 7: Unscrew nozzle nut Unscrew nozzle nut ( Fig.

- Page 28 Fig. 9: Unscrew the threaded needle from the needle bolt Loosen the needle pusher ( Fig. 9/1) and unscrew the threaded needle ( Fig. 9/3) from the needle bolt ( Fig. 9/2). Fig. 10: Screw the needle pusher onto the new threaded needle GB–28 mail@krautzberger.com, www.krautzberger.com...

- Page 29 ENGLISH Hand-held Spray Gun KS 5F Screw the needle pusher ( Fig. 10/2) onto the new threaded needle ( Fig. 10/1). Fig. 11: Length measure Set specified length exactly. Fig. 12: Screw needle bolt onto the threaded needle Screw the needle bolt ( Fig. 12/2) onto the threaded needle ( Fig. 12/4) and counter against the needle pusher ( Fig.

- Page 30 Pull the head piece ( Fig. 15/1) towards the front and out of the main element. Fig. 16: Pull off insulating washer from seal screw Pull off the insulating washer ( Fig. 16/2) from the seal screw ( Fig. 16/1). GB–30 mail@krautzberger.com, www.krautzberger.com...

- Page 31 ENGLISH Hand-held Spray Gun KS 5F Fig. 17: Unscrew seal screw from the head piece Unscrew the seal screw ( Fig. 17/1) from the head piece. Fig. 18: Remove needle pack Remove parts of the needle pack ( Fig. 18/1, 2) comprised respectively of two O-rings ( Fig.

- Page 32 – Do not use any sharp objects during the installation of the needle pack. – Ideally, use an O-ring picker for that. Fig. 20: Screw the seal screw into the head piece GB–32 mail@krautzberger.com, www.krautzberger.com...

- Page 33 ENGLISH Hand-held Spray Gun KS 5F Screw the seal screw ( Fig. 20/1) only slightly into the head piece. Fig. 21: Slide insulating washer over the seal screw Slide insulating washer ( Fig. 21/2) over the seal screw ( Fig. 21/1).

- Page 34 Risk of injury due to threaded needles! Re-insert threaded needle ( Fig. 24/1) from the rear into the main element and - to prevent damage - carefully push through the head piece to the end stop position. GB–34 mail@krautzberger.com, www.krautzberger.com...

- Page 35 ENGLISH Hand-held Spray Gun KS 5F Fig. 25: Push compression spring over the needle bolt into the main element Push compression spring ( Fig. 25/1) over the needle bolt into the main element. Fig. 26: Screw in valve lock screw Tightly screw in valve lock screw ( Fig.

-

Page 36: Replace Fluid Nozzle

The tightness must be checked with a set sealing pre-tensioning! ð Replace fluid nozzle Fig. 29: Replace fluid nozzle Unscrew the fluid nozzle ( Fig. 29/1) from the extension ( Fig. 29/2). Screw the new fluid nozzle into the extension ( Fig. 29/2). GB–36 mail@krautzberger.com, www.krautzberger.com... -

Page 37: Replace Extension

ENGLISH Hand-held Spray Gun KS 5F Replace extension Fig. 30: Remove nozzle nut Unscrew nozzle nut ( Fig. 30/1) and pull off extension ( Fig. 30/2) and seal ( Fig. 30/3) from the threaded needle ( Fig. 30/4). Fig. 31: Unscrew the fluid nozzle from the extension Unscrew the fluid nozzle ( Fig. -

Page 38: Troubleshooting

If the fault is not included in the following tables or if it cannot be eliminated with the measures described, contact Krautzberger Customer Care. Error Cause... -

Page 39: Spare Parts

Designation – Item number according to spare parts list – Quantity – Desired shipping method (post, freight, sea, air, express) – Delivery address A complete spare part overview is available on the website of Krautzberger GmbH: www.krautzberger.de ■ 200-0380 GB–39... -

Page 40: Accessories

Operating instructions T-Dok-666-GB-Rev.1 Accessories A wide range of accessories are available for the hand-held spray gun KS 5F. For further informa- tion, visit us on the Internet (www.krautzberger.com) or contact your Krautzberger dealer, consul- tant or our office staff. Here are a few examples:... -

Page 41: Disassembly And Disposal

ENGLISH Hand-held Spray Gun KS 5F Disassembly and disposal 11.1 Safety Personnel: Qualified personnel Protective equipment: The selection of the protective equipment depends on the installation conditions on site and the medium utilized by the system owner. The applicable country-specific safety, accident prevention,... -

Page 42: Technical Data

The following dimensions impact the hand-held spray gun function (closing of the fluid needle): – Reduction of fluid outlet opening – Use of extensions – Selection of compression spring (spring force) – Coating material (viscosity) – Flow rate of the used fluid pressure pump – Length of supply line GB–42 mail@krautzberger.com, www.krautzberger.com... -

Page 43: Dimensions

ENGLISH Hand-held Spray Gun KS 5F 12.3 Dimensions Fig. 33: Dimensions ■ 200-0380 GB–43... -

Page 44: Declaration Of Conformity

Operating instructions T-Dok-666-GB-Rev.1 Declaration of conformity Fig. 34: Declaration of conformity GB–44 mail@krautzberger.com, www.krautzberger.com... -

Page 45: Notes

ENGLISH Hand-held Spray Gun KS 5F Notes ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ■ 200-0380... -

Page 46: Index

Wear parts ........... . 25 GB–46 mail@krautzberger.com, www.krautzberger.com... - Page 47 ENGLISH Hand-held Spray Gun KS 5F Weight ............42 ■...

- Page 49 Krautzberger GmbH Stockbornstrasse 13 65343 Eltville am Rhein, Germany Hotline: +49 (0) 6123 698-222 Reception: +49 (0) 6123 698-0 Fax: +49 (0) 6123 698-200 Email: mail@krautzberger.com Internet: www.krautzberger.com © Krautzberger GmbH 2017 © Krautzberger GmbH 2017...

Need help?

Do you have a question about the KS 5F and is the answer not in the manual?

Questions and answers