Subscribe to Our Youtube Channel

Summary of Contents for Krautzberger HS-25/2K

- Page 1 Operating instructions Hand-held spray gun HS-25/2K T-Dok-044-GB-Rev.0 200-0358 Translation of the original operating instructions...

- Page 2 Thank you for selecting a Krautzberger product. This product has been manufactured following state-of-the-art manufacturing procedures and extensive quality assurance measures. We promise you a product of the highest quality. If you have questions, requests or suggestions, please contact us. We are always glad to assist you.

-

Page 3: Table Of Contents

ENGLISH Hand-held spray gun HS-25/2K Table of contents Information about the operating manual................5 Function and identification....................6 Function........................6 Identification......................... 6 Safety and responsibility....................7 Symbols in this manual....................7 Personnel requirements....................8 Personal safety equipment and clothing..............9 Responsibility of the owner.................. - Page 4 Safety........................48 10.2 Order........................48 10.3 Spare parts......................48 Dismantling........................49 11.1 Safety........................49 11.2 Dismantling......................50 Disposal..........................51 12.1 Safety........................51 12.2 Disposal........................52 Technical data........................53 13.1 Technical data......................53 Declaration of conformity....................54 Index..........................55 GB–4 mail@krautzberger.com, www.krautzberger.com...

-

Page 5: Information About The Operating Manual

ENGLISH Hand-held spray gun HS-25/2K 1 Information about the operating manual This manual provides important information about the safe and efficient operation of the machine. The manual is part of the machine and must be kept in immediate proximity to the machine so that it is accessible for the personnel at all times. -

Page 6: Function And Identification

Hand-held spray gun - HS-25/2K 090-0828 Operating instructions T-Dok-044 Ä Chapter 13.1 ‘Technical data’ on page 53) Further information: ( Serial number A model plate is mounted on the device below the Krautzberger logo for clear identification. GB–6 mail@krautzberger.com, www.krautzberger.com... -

Page 7: Safety And Responsibility

ENGLISH Hand-held spray gun HS-25/2K 3 Safety and responsibility Symbols in this manual Safety information This manual uses symbols to identify safety information. The safety information is preceded by signal words that indicate the severity of the hazard. DANGER! This combination of symbol and signal word indicates an immediate dangerous situation, which will cause death or severe injuries if it is not averted. -

Page 8: Personnel Requirements

References to sections in this manual and other applicable docu- ments Lists without specified sequence [Pushbutton] Operating elements (e.g. buttons, switches), display elements (e.g. signal lights) ‘Display’ Screen elements (e.g. buttons, assignment of function keys) Personnel requirements GB–8 mail@krautzberger.com, www.krautzberger.com... -

Page 9: Personal Safety Equipment And Clothing

ENGLISH Hand-held spray gun HS-25/2K This manual identifies the qualifications of the personnel for the different scopes of work as listed below: Operator The operator has been instructed by the system owner in an orientation session on the assigned tasks and possible dangers in case of improper behaviour. Tasks that go beyond the operation in standard mode must only be carried out by the operator if such is indicated in this manual and the operate has explicitly been tasked to do so. -

Page 10: Responsibility Of The Owner

Furthermore, the owner is responsible for making sure that the machine is always in perfect tech- nical condition. Therefore, the following applies: GB–10 mail@krautzberger.com, www.krautzberger.com... -

Page 11: Intended Use

ENGLISH Hand-held spray gun HS-25/2K The owner must ensure that the maintenance intervals described in this operating manual are adhered to. The owner must have all safety equipment checked regularly for functionality and complete- ness. Intended use The hand-held spray gun is designed for the processing of 2-component materials. - Page 12 A sufficient fresh air supply must be provided on the system owner's side. If necessary, utilise suitable extraction systems. – Ensure sufficient earth connection, e.g. connection to the building earth connection! Heating systems and water lines do not provide sufficient earth connection! GB–12 mail@krautzberger.com, www.krautzberger.com...

-

Page 13: General Safety Instructions

ENGLISH Hand-held spray gun HS-25/2K – When mixing different components and/or during the simultaneous use of solvents or thinners in order to produce coating materials, take measures to prevent the creation of materials with inherent increased risk potential (e.g. flammability, explosiveness, increased propensity for explosions through spraying with air, toxicity, increased toxicity through chemical reaction with air, etc.)! Avoid increasing the risk potential due as it... - Page 14 The system owner is responsible for the presence and the up-to-date status of the safety data sheet and the associated generation of the risk assessment of the effected workstations. GB–14 mail@krautzberger.com, www.krautzberger.com...

-

Page 15: Residual Risks

Wear protective gloves, if in doubt. Residual risks Devices, machines or systems made by Krautzberger GmbH have been manufactured based on state-of-the-art technology and in compliance with technical safety regulations. Nonetheless, their use may pose a threat to the life or health of users or third parties, or harm the device, the machine, the system or other material assets. -

Page 16: Transport, Delivery Condition, Storage, And Packaging

Remove packaging material. Remove potentially present transport safety restraints. Disposal of packaging Dispose of the packaging material in accordance with the respectively applicable legal regulations and ordinances. GB–16 mail@krautzberger.com, www.krautzberger.com... -

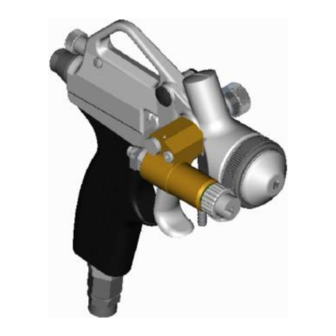

Page 17: Menu

ENGLISH Hand-held spray gun HS-25/2K 5 Menu Fig. 1: Menu Air regulator Suspension bracket Jet regulator Air nozzle - main nozzle system (HVLP) Fluid connection - component A Air nozzle - additional system Fluid connection - component B Pull lever... -

Page 18: Installation

Secure components against tipping or falling. – Ensure that the utilised hose lines meet the requirements for pressure, chemical and mechanical loads. At the same time, adhere to the spray media manufacturer's specifica- tions in the safety data sheet. GB–18 mail@krautzberger.com, www.krautzberger.com... - Page 19 ENGLISH Hand-held spray gun HS-25/2K WARNING! Risk of death, risk of injury or property damage due to hazardous media! Potential consequences: The application of hazardous media can lead to death, severe inju- ries or property damage. When handling hazardous substances, ensure that the current safety data sheets of the haz- ardous substance manufacturer are available.

-

Page 20: General Installation Information

Operate the spray gun with processed, dried compressed air (air quality pursuant to DIN ISO 8573-1: quality class 4). Never point the compressed air at living beings. During the work with flammable materials, the maximum coating material throughput must be calculated. Dimensions All dimensions are approximate measurements in millimetres (mm) GB–20 mail@krautzberger.com, www.krautzberger.com... -

Page 21: Connections

ENGLISH Hand-held spray gun HS-25/2K Fig. 2: Dimensions Connections Fig. 3: Connections Establish material supply - component A ( Fig. 3/2) and material supply - component B ( Fig. 3/1). Connect quick coupling of the compressed-air hose supplied by the system owner to the plug nipple ( Fig. -

Page 22: Operation

Always wait until the pressure is released. – Never point the hand-held spray gun at living beings. – Only trained personnel is permitted to perform cleaning and maintenance work. GB–22 mail@krautzberger.com, www.krautzberger.com... - Page 23 ENGLISH Hand-held spray gun HS-25/2K WARNING! Explosion hazard due to escaping material vapours! Depending on the medium, escaping material vapours may create explosive mixtures and may thereby lead to serious injuries and property damage. – Do not smoke in the hazard zone –...

- Page 24 Risk of injury due to recoil forces during the activation of the spray gun! During long-term use, the recoil forces created when the spraying process is activated can damage the central nervous system. Note: – Take breaks between spray processes. GB–24 mail@krautzberger.com, www.krautzberger.com...

- Page 25 ENGLISH Hand-held spray gun HS-25/2K WARNING! Hearing damage due to excessive noise exposure! Depending on the operating conditions, the sound pressure of the device/machine may cause hearing damage. Note: – Take suitable action to reduce the impact of the existing sound pressure level. The owner is responsible for the type and implementation of suitable measures, which may depend on the local conditions.

-

Page 26: General Information About The Start-Up

Do not use sharply abrasive, chemically aggressive, very hot or very cold spray media without first consulting with and receiving approval from Krautzberger GmbH. Adhere to the spray media manufacturer's safety data sheets. Ä Chapter Only operate the hand-held spray gun in compliance with the values specified in ( 13.1 ‘Technical data’... -

Page 27: Start Operation

ENGLISH Hand-held spray gun HS-25/2K Start operation 7.4.1 Initial start-up Switch on compressed-air supply provided by the system owner. Fig. 4: Pull lever In order to remove dirt particles from the air ducts, operate the pull lever ( Fig. 4/1 ) of the hand-held spray gun multiple times. -

Page 28: Start-Up

Begin spraying process by pulling the pull lever ( Fig. 5/1). Ä Chapter 7.5 ‘Adjusting the spray pattern’ If necessary, adjust the spray pattern ( on page 29). End spraying process by releasing the pull lever ( Fig. 5/1). GB–28 mail@krautzberger.com, www.krautzberger.com... -

Page 29: Adjusting The Spray Pattern

ENGLISH Hand-held spray gun HS-25/2K Adjusting the spray pattern 7.5.1 Air regulation Fig. 6: Air regulation The spray gun is equipped with an installed air controller with which the airflow can be fine-tuned directly on the machine. 7.5.2 Jet regulation Fig. -

Page 30: Fluid Pressure

If too much fluid is being sprayed, the fluid output can be reduced with the needle stroke adjusting screw ( Fig. 8/1). If the flow needs to be restricted significantly, you should select a smaller nozzle if possible. The graphic shows the hand-held spray gun with a closing piece ( Fig. 8/1). GB–30 mail@krautzberger.com, www.krautzberger.com... -

Page 31: Shut Down Spray Booth

ENGLISH Hand-held spray gun HS-25/2K Shut down spray booth 7.6.1 Temporary shut-down Fig. 9: Pull lever Disrupt the spraying process by releasing the pull lever ( Fig. 9/1). 7.6.2 Long-term shut-down Fig. 10: Pull lever Disrupt the spraying process by releasing the pull lever ( Fig. 9/1). -

Page 32: Maintenance

Always wait until the pressure is released. – Never point the hand-held spray gun at living beings. – Only trained personnel is permitted to perform cleaning and maintenance work. GB–32 mail@krautzberger.com, www.krautzberger.com... - Page 33 The use of incorrect or defective spare parts can cause risks for the personnel as well as damage, malfunctions or complete failure. Note: – Only use original spare parts from Krautzberger or Krautzberger-approved spare parts. – If in doubt, always contact our service department (contact information on last page). WARNING! Risk of injury due to improper maintenance! Improper maintenance can cause severe injury or property damage.

- Page 34 Risk of injury due to sharp edges! Sharp edges and pointed corners can cause abrasions and cuts on the skin. Note: – Proceed cautiously when working on or near sharp edges and pointed corners. – Wear protective gloves, if in doubt. GB–34 mail@krautzberger.com, www.krautzberger.com...

-

Page 35: Work After Completed Maintenance

ENGLISH Hand-held spray gun HS-25/2K ENVIRONMENT! Danger to the environment due to incorrect disposal! Incorrect disposal may cause dangers to the environment. Note: – At the end of its useful life, dispose of the device via industrial waste disposal. –... -

Page 36: Maintenance Schedule

If increased wear becomes noticeable during regular checks, the necessary maintenance intervals must be shortened based on the actual wear signs. In case of questions about maintenance work and intervals, contact the Krautzberger customer service (see contact information on the last page). - Page 37 ENGLISH Hand-held spray gun HS-25/2K Ä Chapter 7.6.1 ‘Temporary shut-down’ on page 31). Interrupt the operation ( Disrupt the material supply for component A and component B provided by the system owner. Release the residual energy by pulling the pull lever.

- Page 38 Operating instructions T-Dok-044-GB-Rev.0 Actuator (7) on the press button Fluid needle (2) in front of the screw (3) Needle actuator (1) GB–38 mail@krautzberger.com, www.krautzberger.com...

-

Page 39: Change Nozzle Set

ENGLISH Hand-held spray gun HS-25/2K Change nozzle set 8.6.1 Main nozzle system (component A) Fluid needle Disassembly Ä Chapter 7.6.2 ‘Long-term shut-down’ on page 31). Shut down hand-held spray gun ( CAUTION! Preload! Closing piece/needle stroke setting are preloaded. –... - Page 40 Installation Insert the fluid needle including needle spring and tighten the lock screw of the valve axis. Insert valve spring and valve axis with fluid needle. Unscrew the closing piece/needle stroke setting with a suitable tool. GB–40 mail@krautzberger.com, www.krautzberger.com...

- Page 41 ENGLISH Hand-held spray gun HS-25/2K Air and fluid nozzle Disassembly Fig. 15: Air and fluid nozzle Loosen nut ( Fig. 15/1) by hand. Remove seal ( Fig. 15/2) and air nozzle ( Fig. 15/3). Unscrew the fluid nozzle ( Fig. 15/4).

-

Page 42: Add-On Nozzle System (Component B)

Fig. 17: Fluid needle and fluid nozzle Unscrew screw ( Fig. 17/1) and pull out needle with spring ( Fig. 17/2). Loosen nut ( Fig. 17/5), remove air nozzle ( Fig. 17/4) and unscrew fluid nozzle ( Fig. 17/3). GB–42 mail@krautzberger.com, www.krautzberger.com... - Page 43 ENGLISH Hand-held spray gun HS-25/2K Installation Lightly grease the threads of the parts that need to be installed for the first time with special grease from Krautzberger. Tighten fluid nozzle. Prior to installing a new fluid needle, slide the spring and screw onto the threaded side of the needle.

-

Page 44: Troubleshooting

There is a risk of unauthorised start of the electric power supply during the troubleshooting. This presents a risk of fatal injury for all people in the hazard zone. Note: – Before starting any work, shut off all energy supplies and secure against restart. GB–44 mail@krautzberger.com, www.krautzberger.com... - Page 45 Only loosen blockages after it has been ensured that the loosening will not induce any hazardous movement of machine parts. – If in doubt, call in experienced colleagues or the Krautzberger Customer Care. – Ensure ample of space for the installation prior to starting any work.

-

Page 46: Customer Care

Depending on the type of malfunction, eliminate the malfunction or have it eliminated by an authorized specialist. If the error is not included in the following tables or if it cannot be eliminated with the measures described, contact Customer Care at Krautzberger GmbH. Customer Care Krautzberger GmbH Customer service Stockbornstr. -

Page 47: Troubleshooting Table

ENGLISH Hand-held spray gun HS-25/2K Troubleshooting table Troubleshooting table Spray pattern Error Cause Remedy Normal flat jet spray pattern Spray pattern too Dirty air nozzle Clean nozzles heavy towards the top Dirty fluid nozzle and towards the bottom Spray pattern concen-... -

Page 48: Spare Parts

Item number according to spare parts list – Quantity – Desired shipping method (post, freight, sea, air, express) – Delivery address 10.3 Spare parts A complete spare part overview is available on the website of Krautzberger GmbH: www.krautzberger.de GB–48 mail@krautzberger.com, www.krautzberger.com... -

Page 49: Dismantling

If necessary, use hoisting equipment. – Secure components so that they cannot fall or tip over. – If in doubt, always contact Krautzberger Customer Care. WARNING! Life threatening risk of injury or property damage through the application of hazardous media! The contact with hazardous media can lead to death, most severe injuries or property damage. -

Page 50: Dismantling

Remove and dispose of operating and auxiliary material as well as remaining processing materials in an environmentally friendly manner. Afterwards, properly clean components and modules and take them apart in compliance with appli- cable local occupational health & safety regulations as well as environmental protection regula- tions. GB–50 mail@krautzberger.com, www.krautzberger.com... -

Page 51: Disposal

Properly dismantle components. Pay attention to very high individual weight of some of the components. If necessary, use hoisting equipment. – Secure components so that they cannot fall or tip over. – If in doubt, always contact Krautzberger Customer Care. 200-0358 GB–51... -

Page 52: Disposal

Sort remaining components based on the respective material and dispose of them accord- ingly. Properly dispose of potential spray fluid residue separately from the device. If necessary, obtain information about environmentally-appropriate disposal with the local munici- palities or specialised disposal companies. GB–52 mail@krautzberger.com, www.krautzberger.com... -

Page 53: Technical Data

ENGLISH Hand-held spray gun HS-25/2K Technical data 13.1 Technical data Specification Value Unit Maximum fluid pressure 0.6 / 6 MPa / bar Maximum fluid temperature (8 hours of contin- °C uous use) Maximum atomiser air pressure 1.2 / 12 MPa / bar Maximum air temperature °C... -

Page 54: Declaration Of Conformity

Operating instructions T-Dok-044-GB-Rev.0 Declaration of conformity Fig. 19: Declaration of conformity GB–54 mail@krautzberger.com, www.krautzberger.com... -

Page 55: Index

ENGLISH Hand-held spray gun HS-25/2K 15 Index Connection ........... . 21 Continuous sound pressure level . - Page 57 Krautzberger GmbH Stockbornstrasse 13 65343 Eltville am Rhein, Germany Hotline: +49 (0) 6123 698-222 Reception: +49 (0) 6123 698-0 Fax: +49 (0) 6123 698-200 Email: mail@krautzberger.com Internet: www.krautzberger.com © Krautzberger GmbH 2016 © Krautzberger GmbH 2016...

Need help?

Do you have a question about the HS-25/2K and is the answer not in the manual?

Questions and answers