Table of Contents

Advertisement

Quick Links

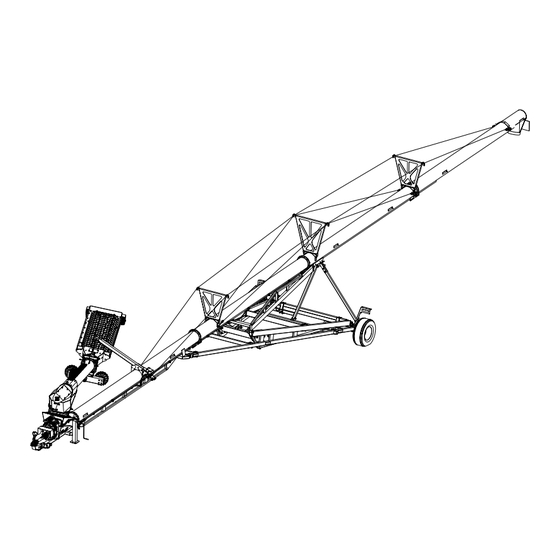

7400 Series

Portable Grain Auger

Operator's Manual

This manual applies to:

AGI GrainMaxx: GMX 7485, GMX 7495, GMX 74105

Read this manual before using product. Failure to

follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

LOOKING FOR PARTS?

Check out our online

Parts Catalog!

Part Number: 8210-00024 R1

Revised: May 2023

Original Instructions

Advertisement

Table of Contents

Summary of Contents for AGI GRAINMAXX 7400 Series

- Page 1 7400 Series Portable Grain Auger Operator’s Manual This manual applies to: AGI GrainMaxx: GMX 7485, GMX 7495, GMX 74105 LOOKING FOR PARTS? Check out our online Parts Catalog! Read this manual before using product. Failure to Part Number: 8210-00024 R1...

- Page 2 This product has been designed and manufactured to meet general engineering standards. Other local regulations may apply and must be followed by the operator. All personnel must be trained in the correct operational and safety procedures for this product. Use the sign-off sheet below to record initial and periodic reviews of this manual with all personnel.

-

Page 3: Table Of Contents

7400 SERIES – PORTABLE GRAIN AUGER CONTENTS 1. Introduction ............................5 1.1 Serial Number Location......................5 1.2 Intended Use ..........................6 1.2.1 Misuse ........................6 2. Safety............................... 7 2.1 Safety Alert Symbol and Signal Words..................7 2.2 General Safety Information....................... 7 2.3 Rotating Flighting Safety ...................... - Page 4 7.10 Clean and Wash the Equipment ................... 48 7.11 Repack the Wheel Bearings with Grease................48 7.12 Check/Adjust the Truss Cables....................49 7.13 Replace the Shear Bolt ......................51 8. Troubleshooting............................ 52 9. Specifications ............................55 10. AGI GrainMaxx Limited Warranty ..................... 57 8210-00024 R1...

-

Page 5: Introduction

Keep this manual handy for frequent reference and to review with new personnel. A sign-off form is provided on the inside front cover for your convenience. If any information in this manual is not understood or if you need additional information, please contact AGI or your representative for assistance. -

Page 6: Intended Use

1. INTRODUCTION 7400 SERIES – PORTABLE GRAIN AUGER 1.2. Intended Use The auger is intended for use as listed below and described throughout this manual. Use in any other way is considered contrary to the intended use and is not covered by the warranty. Intended use for the auger •... -

Page 7: Safety

7400 SERIES – PORTABLE GRAIN AUGER 2. SAFETY 2. Safety 2.1. Safety Alert Symbol and Signal Words This safety alert symbol indicates important safety messages in this manual. When you see this symbol, be alert to the possibility of injury or death, carefully read the message that follows, and inform others. -

Page 8: Rotating Flighting Safety

2. SAFETY 7400 SERIES – PORTABLE GRAIN AUGER 2.3. Rotating Flighting Safety • KEEP AWAY from rotating flighting. • DO NOT remove or modify flighting guards, doors, or covers. Keep in good working order. Have replaced if damaged. • DO NOT operate the auger without all guards, doors, and covers in place. -

Page 9: Work Area Safety

7400 SERIES – PORTABLE GRAIN AUGER 2. SAFETY 2.7. Work Area Safety • Have another trained person nearby who can shut down the auger in case of accident. • Do not allow any unauthorized persons in the work area. • Keep the work area clean and free of debris. Figure 1. -

Page 10: Guards Safety

2. SAFETY 7400 SERIES – PORTABLE GRAIN AUGER 2.8. Guards Safety • Keep guards in place. Do not operate with guard removed. • Do not walk on, step on, or damage guards. • Lock out power before removing a guard. •... -

Page 11: Positioning The Auger

7400 SERIES – PORTABLE GRAIN AUGER 2. SAFETY 2.11. Positioning the Auger • Transport and place equipment on reasonably level ground when raising, lowering, positioning, or operating. • Move the auger into position slowly. Do not unhitch and attempt to move by hand. •... -

Page 12: Pto Driveline Safety

2. SAFETY 7400 SERIES – PORTABLE GRAIN AUGER 2.13.1 PTO Driveline Safety Drive • Keep body, hair, and clothing away from rotating PTO driveline. • Make certain the driveline shields telescope and rotate freely on driveline before attaching. • Make certain the driveline is securely attached at both ends. •... -

Page 13: Hydraulic Power Safety

7400 SERIES – PORTABLE GRAIN AUGER 2. SAFETY 2.13.2 Hydraulic Power Safety Power Source • Refer to the rules and regulations applicable to the power source operating the hydraulic system. • Do not connect or disconnect hydraulic lines while system is under pressure. -

Page 14: Tire Safety

2. SAFETY 7400 SERIES – PORTABLE GRAIN AUGER 2.14. Tire Safety Failure to follow proper procedures when mounting a tire on a wheel or rim can produce an explosion that may result in serious injury or death. • DO NOT attempt to mount a tire unless you have the proper equipment and experience to do the job. -

Page 15: Safety Equipment

7400 SERIES – PORTABLE GRAIN AUGER 2. SAFETY • Hearing Protection • Hard Hat Wear ear protection to prevent hearing Wear a hard hat to help protect your damage. head. • Dust Mask Wear a dust mask to prevent breathing potentially harmful dust. - Page 16 2. SAFETY 7400 SERIES – PORTABLE GRAIN AUGER Figure 2. Decal Locations 8110-00024 (both sides) P1513052 P1513003 P1513042 P1513001 P1513010 P1513044 (both sides) 4100-50339 (both sides) P1513016 P1513035 P1513038 P1513035 P1513048 P1513008 8110-00048 P1513037 4100-50329 P1513002 P1513008 (inside) 8110-00082 (both sides) 4100-50330 P1513035 P1513008...

- Page 17 7400 SERIES – PORTABLE GRAIN AUGER 2. SAFETY Table 1. Safety Decals P1513016 P1513002 P1513001 DANGER WARNING WARNING ROTATING FLIGHTING HAZARD ENTANGLEMENT HAZARD To prevent serious injury or death: To prevent death or serious injury: • Read and understand the manual before To prevent serious injury or death: •...

- Page 18 2. SAFETY 7400 SERIES – PORTABLE GRAIN AUGER P1513037 P1513052 P1513008 WARNING NOTICE WARNING TRANSPORT HAZARD MISSING GUARD HAZARD To prevent damage, wheels must be To prevent serious injury or death: free to move when raising or lowering To prevent serious injury or •...

-

Page 19: Features

7400 SERIES – PORTABLE GRAIN AUGER 3. FEATURES 3. Features Read this section to familiarize yourself with the basic component names and functions of the auger. Figure 3. Auger Features Table 2. Auger Features Item Item Description Description Spout Boot Tube Trussing Swing-Away Controls... -

Page 20: Transport

4. TRANSPORT 7400 SERIES – PORTABLE GRAIN AUGER 4. Transport Before continuing, ensure you have completely read and understood this manual’s Safety section, in addition to the safety information in the section(s) below. 4.1. Transport Safety • Check with local authorities regarding transport on public roads. Obey all applicable laws and regulations. -

Page 21: Transport Preparation

7400 SERIES – PORTABLE GRAIN AUGER 4. TRANSPORT 4.2. Transport Preparation 1. It is not recommended that the auger be transported faster than 20 mph (32 km/h). Table 3 references the acceptable transport speed as per the ratio of tractor weight versus auger weight. See Specifications (Section 9. - Page 22 4. TRANSPORT 7400 SERIES – PORTABLE GRAIN AUGER Figure 5. Transport Position and Chain Attach 8210-00024 R1...

-

Page 23: Preparing The Auger For Towing

7400 SERIES – PORTABLE GRAIN AUGER 4. TRANSPORT 4.4. Preparing the Auger for Towing Follow all safety precautions when transporting the auger and use a proper towing vehicle. 1. Fully lower the auger. 2. Disconnect the PTO driveline and hydraulics (as applicable) from the tractor. 3. -

Page 24: Placement

5. PLACEMENT 7400 SERIES – PORTABLE GRAIN AUGER 5. Placement Before continuing, ensure you have completely read and understood this manual’s Safety section, in addition to the safety information in the section(s) below. 5.1. Placement Safety • The auger is not insulated, keep away from overhead power lines. Electrocution can occur without direct contact. - Page 25 7400 SERIES – PORTABLE GRAIN AUGER 5. PLACEMENT 8. Move the jack into storage position. 9. Move the auger into working position slowly. Do not unhitch and attempt to move the auger by hand. 10. Back the auger up to the storage facility while it is in its lowered configuration. 11.

-

Page 26: Raising And Lowering

5. PLACEMENT 7400 SERIES – PORTABLE GRAIN AUGER Figure 8. Auger Placement (Direct PTO Drive) Chock Wheels Chock Wheels Chock Wheels Chock Wheels Tractor Apply Parking Brakes 5.2.1 Raising and Lowering The intake hopper must be off the ground when raising and lowering the auger. Before using the hydraulic lift cylinder: •... -

Page 27: Extendable Axle Positioning

7400 SERIES – PORTABLE GRAIN AUGER 5. PLACEMENT Dirt in the hydraulic system can damage the cylinder o-rings and can cause leakage and failure of the system. 2. Connect the hydraulic hoses, ensure the connections are tight. Visually check for leaks, binding, flattening, kinks, or wear. -

Page 28: Auger-To-Tractor Hookup

5. PLACEMENT 7400 SERIES – PORTABLE GRAIN AUGER 4. Remove the axle pin from the axle and position the axle as desired until the holes line up. Reinsert the axle pin and secure with hairpin. Lower the jack. 5. Repeat the process on the opposite side of the axle. Figure 9. - Page 29 7400 SERIES – PORTABLE GRAIN AUGER 5. PLACEMENT Measurements Between Drawbar and PTO Driveline 14" (35.6 cm) 10" – 14" (25.4 cm – 35.6 cm) 46" (116.8 cm) Note Measurements must be taken with auger on level ground and in full down position. Raise tractor drawbar if necessary to maintain (B) dimension of 10"...

-

Page 30: Raising And Lowering The Intake Hopper

5. PLACEMENT 7400 SERIES – PORTABLE GRAIN AUGER 5.5. Raising and Lowering the Intake Hopper 1. Attach the winch cable hook (B) to the appropriate hopper lifting point. 2. Fully raise the hopper. 3. Secure the hopper with the transport chain and hook (A). Do not operate auger with intake hopper in transport position. -

Page 31: Grain Hopper Positioning

7400 SERIES – PORTABLE GRAIN AUGER 5. PLACEMENT Do not continue to supply power to winch when swing-away is fully up. Damage to equipment and/or personal injury could result. 5.6. Grain Hopper Positioning The low-profile grain hopper is designed to be rolled into position to receive grain for transfer through the boot to the auger discharge spout. -

Page 32: Telescoping Swing-Away Operation

5. PLACEMENT 7400 SERIES – PORTABLE GRAIN AUGER 5.6.2 Telescoping Swing-Away Operation The telescoping swing-away has three functions: swing, tip-up and extend. These are controlled with a three handle hydraulic valve located on the swing auger tube above the hopper. The decal on the side of the tube indicates the maximum allowable retraction while the PTO is engaged. - Page 33 7400 SERIES – PORTABLE GRAIN AUGER 5. PLACEMENT Figure 12. Telescoping Swing Away Operating Decal 8210-00024 R1...

-

Page 34: Operation

6. OPERATION 7400 SERIES – PORTABLE GRAIN AUGER 6. Operation Before continuing, ensure you have completely read and understood this manual’s Safety section, in addition to the safety information in the section(s) below. 6.1. Operation Safety • Keep away from rotating and moving parts, including the flighting, drive components, shafts, and bearings. -

Page 35: Operation - Pto Drive

7400 SERIES – PORTABLE GRAIN AUGER 6. OPERATION 6.3. Operation - PTO Drive 1. Attach the PTO driveline securely to the tractor and confirm the connection to the auger shaft is secure. 2. Confirm the PTO driveline rotating shield and other shields/guards are in place and in good working order. 3. -

Page 36: Emergency Shutdown

6. OPERATION 7400 SERIES – PORTABLE GRAIN AUGER Figure 13. Reverse Position 6.4. Emergency Shutdown In an emergency situation: 1. Stop or shut down the power source immediately and lock out all power. 2. Stop the flow of material (if applicable). 3. -

Page 37: Shutdown

7400 SERIES – PORTABLE GRAIN AUGER 6. OPERATION 6.6. Shutdown When operation has been completed: 1. Once auger is clear of grain, lock out the power source. 2. Clean out any remaining grain from the auger with a vacuum or sweep out. 3. - Page 38 6. OPERATION 7400 SERIES – PORTABLE GRAIN AUGER 12. Connect the winch cable and safety chain as shown to place the swing-away hopper in storage position. This position ensures there will be adequate drainage of any moisture. Figure 14. Swing-Away Hopper Storage Position Power Swing When Equipped: 1.

-

Page 39: Maintenance

7400 SERIES – PORTABLE GRAIN AUGER 7. MAINTENANCE 7. Maintenance Before continuing, ensure you have completely read and understood this manual’s Safety section, in addition to the safety information in the section(s) below. 7.1. Maintenance Safety • Keep components in good condition. Follow the maintenance procedures. -

Page 40: Visually Inspect The Equipment

7. MAINTENANCE 7400 SERIES – PORTABLE GRAIN AUGER Section 7.8 – Check the Gearbox Oil Level on page 47 Annually: Section 7.4 – Lubricate the Equipment on page 41 Section 7.7 – Oil and Adjust the Chain Drives on page 45 Section 7.10 –... -

Page 41: Lubricate The Equipment

7400 SERIES – PORTABLE GRAIN AUGER 7. MAINTENANCE 7.4. Lubricate the Equipment Your equipment can operate at top efficiency only if clean fluids and lubricants are used. Use clean containers to handle all fluids and lubricants. Store them in an area protected from dust, moisture, and other contaminants. -

Page 42: Periodic Grease Locations

7. MAINTENANCE 7400 SERIES – PORTABLE GRAIN AUGER 7.4.2 Periodic Grease Locations Figure 15. Frame Grease Locations 8210-00024 R1... - Page 43 7400 SERIES – PORTABLE GRAIN AUGER 7. MAINTENANCE Figure 16. Lift Cylinder and Upper/Lower Bearing Grease Locations 8210-00024 R1...

-

Page 44: Inspect Hydraulic Hoses And Fittings

7. MAINTENANCE 7400 SERIES – PORTABLE GRAIN AUGER Figure 17. Swing-Away Grease Locations 7.5. Inspect Hydraulic Hoses and Fittings When equipped: 1. Pressurize the system. 2. Using a piece of cardboard or wood, run it along the length of the hose and around all fittings. Escaping hydraulic fluid under pressure will cause serious injury if it penetrates the skin surface. -

Page 45: Inspect And Service The Hydraulic Winch And Lift Cable

7400 SERIES – PORTABLE GRAIN AUGER 7. MAINTENANCE 7.6. Inspect and Service the Hydraulic Winch and Lift Cable When equipped: Place the auger in the fully lowered position with the cable slack. To Inspect the Lift Cable: 1. Inspect the cable for damage such as fraying, kinking, or unwinding. Replace if damaged (see below). 2. - Page 46 7. MAINTENANCE 7400 SERIES – PORTABLE GRAIN AUGER Note The hopper has two chains, one for each flighting. 3. Oil the roller chain. Figure 19. Hopper Chain Mover Chain 1. Remove the cover plate. 2. Check the chain slack at the middle of the longest span does not move more than 1/4”. To tighten, loosen the 4 bolts on the motor side of the housing and tighten the draw bolt on the end of the housing as required.

-

Page 47: Check The Gearbox Oil Level

7400 SERIES – PORTABLE GRAIN AUGER 7. MAINTENANCE 2. Check the chain slack at the middle of the longest span. It should move no more than 1/4”. Adjust the chain roller as required. 3. Oil the roller chain. Figure 21. Collector Chain 7.8. -

Page 48: Change The Gearbox Oil

7. MAINTENANCE 7400 SERIES – PORTABLE GRAIN AUGER 7.9. Change the Gearbox Oil For gearbox locations, refer to Section 7.8 – Check the Gearbox Oil Level on page 1. Place a pan under the drain plug. 2. Use a wrench and remove the drain plug. 3. -

Page 49: Check/Adjust The Truss Cables

7400 SERIES – PORTABLE GRAIN AUGER 7. MAINTENANCE Figure 22. Diagonal Pattern for 4-bolt and 6-bolt Tires 7.12. Check/Adjust the Truss Cables Check the auger tube for side-to-side straightness, no slack in the cables, and a just noticeable upward deflection of the discharge end. During operation, it is normal for the tube to deflect downward. Follow the procedure below to keep cables tight and the tube in the correct position. - Page 50 7. MAINTENANCE 7400 SERIES – PORTABLE GRAIN AUGER Figure 24. Eyebolt Anchor 4. Tighten cable eyebolts evenly on both sides (use eyebolt nuts to tighten eyebolts) until the discharge end just starts to angle upward. • The tube should not deflect to the left or right if tightened evenly. •...

-

Page 51: Replace The Shear Bolt

7400 SERIES – PORTABLE GRAIN AUGER 7. MAINTENANCE 7.13. Replace the Shear Bolt The PTO is equipped with a shear bolt to protect against overloads. To replace shear bolt: 1. Remove yoke from the shaft on the lower gearbox or the tractor. 2. -

Page 52: Troubleshooting

The following section covers some causes and solutions to some of the problems that may be encountered. If there is a problem that is difficult to solve, even after having read through this section, please contact your representative or AGI. Have this manual and the serial number available. Auger Cause... - Page 53 7400 SERIES – PORTABLE GRAIN AUGER 8. TROUBLESHOOTING Flighting shaft is bent. Repair or replace flighting shaft. Flighting is damaged. Repair or replace flighting. Worn bearing. Repair or replace bearing. Low gear oil level. Inspect the gearbox, replace if damaged or add oil if not damaged.

- Page 54 8. TROUBLESHOOTING 7400 SERIES – PORTABLE GRAIN AUGER Lower auger to transport position and If auger will not lift, seal in hydraulic cylinder is damaged. repair hydraulic cylinder as required. 8210-00024 R1...

-

Page 55: Specifications

7400 SERIES – PORTABLE GRAIN AUGER 9. SPECIFICATIONS 9. Specifications 7485 7495 74105 Capacity 14,100 – 15,000 Bu/Hr Tube Size 14” (36 cm) Transport Length 90’ 100’ 110’ (27.4 m) (30.5 m) (33.5 m) Width (axles in 12’4” 12’4” 12’4” transport) (3.76 m) (3.76 m) - Page 56 9. SPECIFICATIONS 7400 SERIES – PORTABLE GRAIN AUGER 7485 7495 74105 Hitch Jack 10,000 lb PTO Drive Power Require- 160–180 HP 180 HP 180–200 HP ments PTO Speed 1000 RPM PTO Shaft Weasler 1-3/8” diameter, 21 spline Max. Operating 25° Angle 37 oz (1.1 L) Capacity...

-

Page 57: Agi Grainmaxx Limited Warranty

Warranty This warranty relates to AGI GrainMaxx augers (the “Product”) sold by Ag Growth International Inc., (referred to herein as the “Seller”) and applies only to the first user of the Product (meaning a purchaser directly from the Seller or from an authorized dealer or distributor of the Product, referred to herein as the “Buyer”). - Page 58 GrainMaxx is an AGI Brand. AGI is a leading provider of equipment solutions for agriculture bulk commodities including seed, fertilizer, grain, and feed systems with a growing platform in providing equipment and solutions for food processing facilities. AGI has manufacturing facilities in Canada, the United States, the United Kingdom, Brazil, South Africa, India and Italy and distributes its products globally.

Need help?

Do you have a question about the GRAINMAXX 7400 Series and is the answer not in the manual?

Questions and answers