Summary of Contents for Parker MI-101

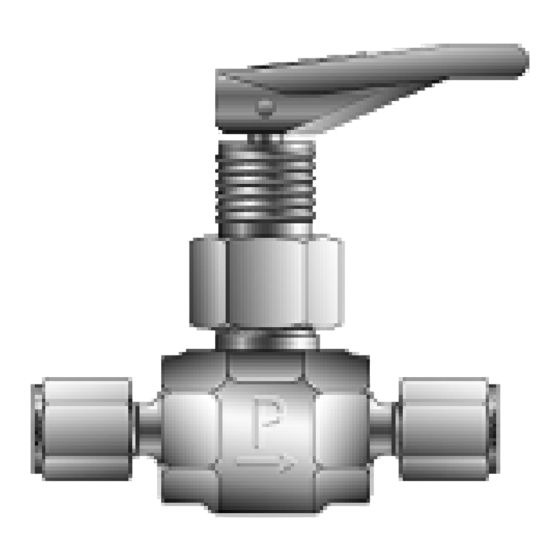

- Page 1 Maintenance Instructions MI-101 Revision - VQ Series Needle Valve MAXIMUM WORKING PRESSURE AND TEMPERATURE Parker Hannifin Corporation Instrumentation Valve Division Jacksonville, Alabama...

- Page 2 MI-101 PANEL MOUNTED VALVES USE OF THE (OPTIONAL) HANDLE POSITIONER Parker Hannifin Corporation Instrumentation Valve Division Jacksonville, Alabama...

- Page 3 OF ALL PRESSURE BEFORE STARTING VALVE REMOVAL OR DISASSEMBLY. FAILURE TO DO SO CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE. REASSEMBLY NOTE: Valve Size Brass Valve Bodies Stainless Steel Bodies NOTE: Parker Hannifin Corporation Instrumentation Valve Division Jacksonville, Alabama...

- Page 4 WALL THICKNESS, AND THE LUBRICITY OF NUT LUBRICANTS CAN RESULT IN AN IMPROPERLY ASSEMBLED TUBE FITTING CONNECTION. -Two ferrule A-LOK ® -Single ferrule CPI -ANSI/ASME B1.20.1 compression port compression port Internal pipe threads -VacuSeal face -UltraSeal face -ANSI/ASME B1.20.1 seal port seal port External pipe threads Parker Hannifin Corporation Instrumentation Valve Division Jacksonville, Alabama...

- Page 5 HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE. ALL PARKER VALVES MUST PASS A RIGID OPERATIONAL AND LEAKAGE TEST BEFORE LEAVING THE FAC- TORY. IT IS RECOMMENDED AFTER ANY REASSEMBLY, THE VALVE SHOULD BE TESTED BY THE USER FOR OPERATION AND LEAKAGE.

Need help?

Do you have a question about the MI-101 and is the answer not in the manual?

Questions and answers