Summary of Contents for Landoll 6250 Disc

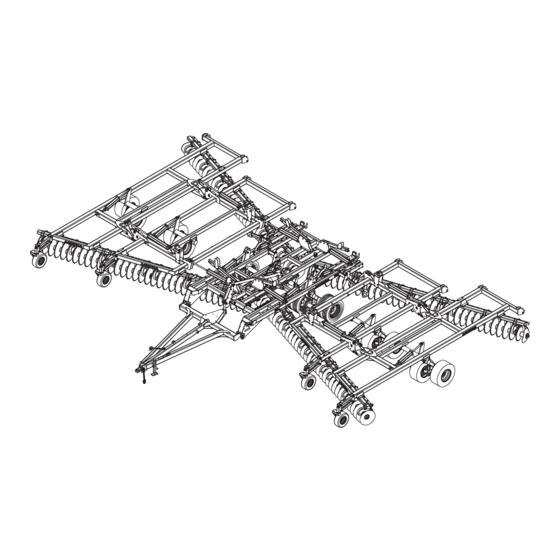

- Page 1 Model 6250 Disc Operators Manual LANDOLL COMPANY, LLC 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM F-733-1120 11/2020-Present...

- Page 2 Manuals for the 6250 Disc MANUAL NUMBER MANUAL NAME F-733 6250 Disc Operator’s Manual F-734 6250 Disc Parts Manual...

-

Page 3: Table Of Contents

6250 Disc Frame and Hitch Assembly ........ - Page 4 6250 Disc Wheel Bearing Maintenance ........

-

Page 5: Introduction And Safety Information

Introduction and Safety Information Introduction The Landoll Model 6250 Disc is a quality product designed to give years of trouble free performance. By following each section of this manual, your system will perform as designed for you and your operation. -

Page 6: Understanding Safety Statements

1.5 times the weight of the towing vehicle. vehicle. The safety statements contained in this manual relate to 3. Carry reflectors or flags to mark the tractor and the operation of the Model 6250 Disc. implement in case of breakdown on the road. F-733-1120... -

Page 7: Attaching, Detaching, And Storage

INTRODUCTION AND SAFETY INFORMATION Protective Equipment 4. Do not transport at speeds over 20 MPH under good conditions. Never travel at a speed which does not 1. Wear protective clothing and equipment. allow adequate control of steering and stopping. Reduce speed if towed load is not equipped with 2. -

Page 8: Safety Chain

INTRODUCTION AND SAFETY INFORMATION Safety Chain 2. A second chain should be used between each implement. 1. Use a chain with a strength rating equal to or greater 3. Attach the chain to the tractor drawbar support or than the gross weight of towed machinery, which is specified anchor location. -

Page 9: Standard Specifications

Chapter 2 Standard Specifications Model Specifications 6250 Disc Model Number 6250-40 6250-45 6250-50 Working Width 40'-0” 45'-0” 50'-0” Transport Width 17'-6” 17'-6” 17'-6” Transport Height 11'-0” 12'-3” 13'-6” Blade Diameter 24” 24” 24” Number of Blades (W/8-3/4” Spacing) 56/58 62/64 69/71 Number of Blades (W/7”... - Page 10 STANDARD SPECIFICATIONS Tire Inflation Tire Size Tire Manufacturer Ply/Load Rating Inflation Pressure (Psi) (Max.) 235/75R17.5 Double Coin 16 Ply (Load Range H)/6,005 lbs. 125 psi 320/70R15 Firestone Load Index 144/6,150 lbs @ 40 mph. 70 psi 32/1550 X R16.5 Galaxy G Load/8,000 lbs.

-

Page 11: General Torque Specifications (Rev. 4/97)

STANDARD SPECIFICATIONS General Torque Specifications (rev. 4/97) TORQUE SPECIFIED IN FOOT POUNDS - This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition). -

Page 12: Hydraulic Fitting Torque Specifications

STANDARD SPECIFICATIONS Hydraulic Fitting Torque Specifications TORQUE IS SPECIFIED IN FOOT POUNDS- 37 JIC, ORS, & ORB (REV. 10/97) This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition). - Page 13 STANDARD SPECIFICATIONS Table provided for general use. NOTES:...

- Page 14 STANDARD SPECIFICATIONS Figure 2-1: Wing Stabilizer and Light Bracket Placement (40' Model) (Left Half) F-733-1120...

- Page 15 STANDARD SPECIFICATIONS Figure 2-2: Wing Stabilizer and Light Bracket Placement (40' Model) (Right Half)

- Page 16 STANDARD SPECIFICATIONS Figure 2-3: Wing Stabilizer and Light Bracket Placement (45' Model) (Left Half) F-733-1120...

- Page 17 STANDARD SPECIFICATIONS Figure 2-4: Wing Stabilizer and Light Bracket Placement (45' Model) (Right Half)

- Page 18 STANDARD SPECIFICATIONS Figure 2-5: Wing Stabilizer and Light Bracket Placement (50' Model) (Left Half) 2-10 F-733-1120...

- Page 19 STANDARD SPECIFICATIONS Figure 2-6: Wing Stabilizer and Light Bracket Placement (50' Model) (Right Half) 2-11...

- Page 20 STANDARD SPECIFICATIONS DETAIL A 31-1/4” 45-1/4” EXTRA SCRAPER PLATE DETAIL A USED ON OUTER TIRES ONLY dual tire scraper installation Figure 2-7: Dual Tire Scraper Installation 2-12 F-733-1120...

- Page 21 STANDARD SPECIFICATIONS Table provided for general use. NOTES: 2-13...

- Page 22 STANDARD SPECIFICATIONS Figure 2-8: Coil Tine Harrow Placement (40’ Model) (1 of 2) 2-14 F-733-1120...

- Page 23 STANDARD SPECIFICATIONS Figure 2-9: Coil Tine Harrow Placement (40’ Model) (2 of 2) 2-15...

- Page 24 STANDARD SPECIFICATIONS Figure 2-10: Coil Tine Harrow Placement (45’ Model) (1 of 2) 2-16 F-733-1120...

- Page 25 STANDARD SPECIFICATIONS Figure 2-11: Coil Tine Harrow Placement (45’ Model) (2 of 2) 2-17...

- Page 26 STANDARD SPECIFICATIONS Figure 2-12: Coil Tine Harrow Placement (50’ Model) (1 of 2) 2-18 F-733-1120...

- Page 27 STANDARD SPECIFICATIONS Figure 2-13: Coil Tine Harrow Placement (50’ Model) (2 of 2) 2-19...

- Page 28 Page Intentionally Blank...

-

Page 29: Assembly Instructions

Chapter 3 Assembly Instructions It is very important that your new 6250 Disc be properly DANGER assembled, adjusted and lubricated before use. Illustrations to assist with the assembly process are Disc blades are extremely sharp. Exercise provided in “Standard Specifications” on page 2-1. - Page 30 ASSEMBLY INSTRUCTIONS Figure 3-1: Center Disc Gang Installation F-733-1120...

-

Page 31: Disc Gangs

ASSEMBLY INSTRUCTIONS Disc Gangs Mounting Center Frame Tires and Wheels DANGER Install the tire and wheel assemblies on the center section. The center frame tires uses 265/70R19.5 tIres Disc blades are extremely sharp. Exercise with 8-bolt walking dual wheels and 4” slip-in spindles. extreme care when working on or near disc blades. - Page 32 ASSEMBLY INSTRUCTIONS RIGHT INNER WING CENTER FRAME LEFT INNER WING 3/4-10 X 2 HEX HEAD CAP SCREW 3/4-10 HEX LOCK SEE DETAIL A TIRE AND WHEEL ASSEMBLY CLAMP PLATE 1-3/4 THRUST WASHER 3/4-10 X 8-1/2 HEX HEAD 1-3/4 X 14-1/8 CAP SCREW HINGE PIN W/ 5/8 X 3 CROSS PIN...

-

Page 33: Dual Tire Scraper Installation

ASSEMBLY INSTRUCTIONS Figure 3-4: Dual Tire Scraper Installation Dual Tire Scraper Installation Inner Wing Frames Refer to Figure 2-7 for dual tire scraper placement. 1. Place the inner wing frames on top of the wing gang assemblies and attach using 3/4-10 x 2 and 3/4-10 x 1. - Page 34 ASSEMBLY INSTRUCTIONS Figure 3-5: Outer Wing Frame Installation F-733-1120...

-

Page 35: Outer Wing Frames

ASSEMBLY INSTRUCTIONS Outer Wing Frames 1. Install double hinge and locks to inner wing with thrust washer toward rear of the machine using hinge pin and 1-1/4-7 hex lock nut (See Figures 3-5 and 3-7) Install two fold links per hinge, placing them over the bushing of the double hinge. - Page 36 ASSEMBLY INSTRUCTIONS Figure 3-8: Frame and Hitch Assembly Installation F-733-1120...

-

Page 37: 6250 Disc Frame And Hitch Assembly

ASSEMBLY INSTRUCTIONS 6250 Disc Frame and Hitch NOTE Assembly The hitch may be assembled in the upper or lower position depending on matching tractor drawbar height. IMPORTANT See “Hitch Adjustment” on page 4-11 for proper adjustment. Read all safety precautions at the front of the section 2. - Page 38 ASSEMBLY INSTRUCTIONS Figure 3-9: Leveler Assembly Installation 3-10 F-733-1120...

-

Page 39: Leveler Assembly

ASSEMBLY INSTRUCTIONS Leveler Assembly 6. Attach leveler tower to the top of the leveler ball joint link with hitch pin, 1/2 x 2-1/4 grooved alloy pin, (2) 1. Attach rear of leveler assembly to the center left lift 1-1/2” washers, and 1-8 hex lock nut. using the leveler pins through the leveler base/cross. -

Page 40: Depth Stop Tube Installation

ASSEMBLY INSTRUCTIONS Figure 3-10: Depth Stop Tube Installation Depth Stop Tube Installation 3. Insert 90º elbow fitting in the front of the limit valve. 4. Using 5/16-18 x 5 hex head cap screws secure the 1. Attach the depth control mount plate to the lift using front end of the depth stop tube assembly to the top 3/8-16 x 1-1/4 hex head cap screws and hex lock of the frame mount with the depth stop guide, slide... - Page 41 ASSEMBLY INSTRUCTIONS Figure 3-11: Lift Hydraulic Installation (40’ Model) 3-13...

- Page 42 ASSEMBLY INSTRUCTIONS Figure 3-12: Fold Hydraulic Installation (40’ Model) 3-14 F-733-1120...

- Page 43 ASSEMBLY INSTRUCTIONS Figure 3-13: Lift Hydraulic Installation (45’ Model) 3-15...

- Page 44 ASSEMBLY INSTRUCTIONS Figure 3-14: Fold Hydraulic Installation (45’ Model) 3-16 F-733-1120...

- Page 45 ASSEMBLY INSTRUCTIONS Figure 3-15: Lift Hydraulic Installation (50’ Model) 3-17...

- Page 46 ASSEMBLY INSTRUCTIONS Figure 3-16: Fold Hydraulic Installation (50’ Model) 3-18 F-733-1120...

- Page 47 ASSEMBLY INSTRUCTIONS Figure 3-17: Transport Lock and Fold Hydraulic Assembly Details 3-19...

- Page 48 ASSEMBLY INSTRUCTIONS Figure 3-18: Fold Hydraulic Assembly Figure 3-19: Hose Clamp Assembly 3-20 F-733-1120...

-

Page 49: Hydraulic Installation

(See Figure 3-18.) 12. Attach outer wing stops and wing stabilizer to fold 5. The fold cylinders come equippped from Landoll stabilizer mount using 3/4-10 x 5 hex head cap Company, LLC. with a black, 1/16 restricted 90 screws and hex lock nuts (See Figure 3-20.) - Page 50 ASSEMBLY INSTRUCTIONS Figure 3-20: Wing Stabilizer Bracket Mounting Installation 3-22 F-733-1120...

- Page 51 ASSEMBLY INSTRUCTIONS Figure 3-21: Hydraulic Fitting Installation 3-23...

- Page 52 ASSEMBLY INSTRUCTIONS Figure 3-22: Light and SMV Bracket Installation 3-24 F-733-1120...

-

Page 53: Led Light And Smv Bracket Installation

ASSEMBLY INSTRUCTIONS LED Light and SMV Bracket IMPORTANT Installation Make sure lights are positioned for maximum visibility from the rear. 1. Attach lights and mounting brackets to the center frames using u-bolts, 3/4-10 x 6 hex head cap 6. Install the rear warning light harness to the frame. screws, hex nuts, and hex lock nuts (See Connect 2 pin and 3 pin ends to each of the warning Figure 3-22.) Refer to pages 2-6 thru 2-11 for light... - Page 54 ASSEMBLY INSTRUCTIONS Figure 3-23: Harrow Installation 3-26 F-733-1120...

-

Page 55: Coil Tine Installation

ASSEMBLY INSTRUCTIONS Coil Tine Installation 5. Assemble 17” heavy spring assembly to tine arm using 1” pivot pin and 5/16 x 1-1/2 spring slotted pins. 1. Assemble 2-1/2” adjustment pin into plates welded Set pin centers to 20-1/2” dimension as shown in onto rear of frame using 2-1/2”... - Page 56 ASSEMBLY INSTRUCTIONS Figure 3-24: Finishing Reel Hydraulic Installation (40’ Model) 3-28 F-733-1120...

- Page 57 ASSEMBLY INSTRUCTIONS Figure 3-25: Finishing Reel Hydraulic Installation (45’ Model) 3-29...

- Page 58 ASSEMBLY INSTRUCTIONS Figure 3-26: Finishing Reel Hydraulic Installation (50’ Model) 3-30 F-733-1120...

- Page 59 ASSEMBLY INSTRUCTIONS Figure 3-27: Finishing Conditioner Reel Installation (Center Arm for the Three Arm Reel) (Option) 3-31...

- Page 60 ASSEMBLY INSTRUCTIONS Figure 3-28: Finishing Conditioner Reel Installation (Outer Arms of Center Reel or Wing Reels) (Option) 3-32 F-733-1120...

-

Page 61: Finishing Hydraulic Conditioner Reel Installation (Option)

ASSEMBLY INSTRUCTIONS Finishing Hydraulic Conditioner 3. Install 1-8 hex nut onto rod of cylinder and install 17” heavy spring assembly onto cylinder rod. Reel Installation (Option) 4. Install 1-1/2” flange bearing into reel arm, and slide in 1-1/2” pivot bushing. NOTES 5. - Page 62 ASSEMBLY INSTRUCTIONS Figure 3-31: Finishing Conditioner Reel Installation Hydraulic Hose Placement (Left Half) Figure 3-32: Finishing Conditioner Reel Installation Hydraulic Hose Placement (Right Half) 3-34 F-733-1120...

- Page 63 ASSEMBLY INSTRUCTIONS 8. Install fittings into manifold according to Figures 3-24 through 3-26. 9. Install bulkhead plates to the inner and outer wings with hose clamps (See Figures 3-33 and 3-34.) Assemble bulkhead tees and 90º swivel adapters onto each of them. 10.

-

Page 64: Final Assembly

ASSEMBLY INSTRUCTIONS Final Assembly WARNING 1. Attach a tractor to the implement and charge the lift Do not attempt to lift heavy parts (such as the system hydraulics as described is “Hydraulic Lift frame, disc gangs, lift, pull hitch, or reel/gang bar System”... -

Page 65: Operation And Maintenance

DANGER DANGER Never allow anyone to ride on the 6250 Disc at When transporting the unit, place cylinder any time. Allowing a person to ride on the lockouts in the transport lock position after fully machine can inflict serious personal injury or extending the cylinders. -

Page 66: Tractor Preparation

OPERATION AND MAINTENANCE Tractor Preparation Disc Preparation The Landoll 6250 Disc is designed to be pulled by tractor equipped with a double lip or clevis type hitch CAT IV or V. If your tractor is not equipped as such, you need to purchase the hitch from your local tractor dealer. -

Page 67: Attaching To The Tractor

OPERATION AND MAINTENANCE Attaching to the Tractor WARNING 1. Align the tractor drawbar with the machine. Raise or Escaping hydraulic fluid can cause serious lower the disc ring hitch, as needed, using the swivel personnel injury. Relieve system pressure before jack. - Page 68 OPERATION AND MAINTENANCE 2. The hydraulic system is not filled with oil and should be purged of air before transporting and field operations. Carefully hitch the disc to the tractor and connect the hydraulic lift hoses. Check to make sure the tractor hydraulic reservoir is full of the manufacturer’s recommended oil.

-

Page 69: Hydraulic Fold System

Disc when it is fully unfolded. The tractor should be stopped and not moving with the unit fully raised. See “Folding the 6250 Disc” on page 4-6 and “Unfolding the 6250 Disc” on page 4-6 for further instructions on folding and... -

Page 70: Folding The 6250 Disc

OPERATION AND MAINTENANCE Folding the 6250 Disc Fully raise machine. 2. Begin folding the machine. Transport locks will engage on the center lift as the outer wings are folding, fully fold all inner and outer wings (See Figures 4-6 and 4-7). -

Page 71: General Operation

OPERATION AND MAINTENANCE General Operation Field Operation 1. The horsepower requirements are typically 8-10 1. Raise the unit to take the weight off of the transport horsepower per foot of cut. This will vary widely due locks. to speed, depth, moisture, residue and types of soils. 2. -

Page 72: Leveling (Side To Side)

OPERATION AND MAINTENANCE Leveling (Side to Side) 2. To level the center frame: a. Verify that all of the tires are properly inflated. 1. An adjustable radius rod connects the center frame b. With the unit unfolded, raise it to fully extend the lifts together to keep them operating in unison. - Page 73 OPERATION AND MAINTENANCE 3. After adjusting the cylinder rod or rods, the radius rod needs to be adjusted back to a neutral position. This is accomplished by fully retracting the lift cylinders and adjusting the radius rod until there is no load on it, reinstall the 1”...

-

Page 74: Leveling (Front-To-Rear)

OPERATION AND MAINTENANCE Leveling (Front-to-Rear) 3. Implements with the hydraulic leveler, can make adjustments on-the-go from the tractor. A reference 1. The leveling feature on the Disc is used to keep the gauge is provided on the implement for a guide. machine level when raising the unit from a working 4. -

Page 75: Hitch Adjustment

OPERATION AND MAINTENANCE Hitch Adjustment 4. To adjust the hitch (See Figure 4-14.): a. Lower the Disc to the ground. 1. It is important for the Disc to maintain a proper draft b. Adjust the hydraulic leveler in or out until the line with the tractor to do a level job of discing. -

Page 76: Scraper Adjustment

OPERATION AND MAINTENANCE Scraper Adjustment 1. Rigid scrapers should be set initially as close to the disc blade as possible without rubbing The Disc is equipped with rigid scrapers at regular spools (approximately 1/8”) (See Figure 4-15.) A slotted with dual scrapers at the disc bearings. hole at the top of each scraper is provided for individual adjustment. -

Page 77: Coil Tine Harrow

OPERATION AND MAINTENANCE Coil Tine Harrow CAUTION The coil tine harrow is an optional attachment used for The coil tine harrow adds significant amount of additional soil and residue leveling. It features 3 rows of weight to the rear of implement and can create 1/2”... - Page 78 OPERATION AND MAINTENANCE Figure 4-17: Harrow Adjustment and Settings 4-14 F-733-1120...

-

Page 79: Operation/Adjustment

OPERATION AND MAINTENANCE Operation/Adjustment IMPORTANT In some conditions it may be desirable to run the tine NOTE rows at slightly different tine angles. In general, the harrow should run level front to rear behind the disc. Example: Lower tine angle on the front row may help 1. -

Page 80: Front Gauge Wheels

OPERATION AND MAINTENANCE Front Gauge Wheels IMPORTANT 1. The Disc is equipped with castering gauge wheels at Excessive down pressure can cause the implement the outer front corners of each wing. These gauge to throw a center ridge. wheels are used to limit depth of the wings, and 3. -

Page 81: Disc Blades

3. Sharpening – In some cases there is a desire to sharpen disc blades for improved cutting. There are 1. The 6250 disc is equipped with full concavity disc several people who roll-sharpen disc blades. Most blades on both front and rear. This is 3” concavity for disc blades used today are made of chrome-boron 24”... -

Page 82: Depth Stop Adjustment (Manual)

OPERATION AND MAINTENANCE Depth Stop Adjustment (Manual) The operating depth of the Disc is controlled by a single-point depth stop. The stop is located at the center front of the machine. 1. Adjust the depth stop by turning the handle out (counter-clockwise) to increase operating depth (See Figure 4-20.) Turn the handle in (clockwise) to decrease operating depth. -

Page 83: 6250 Disc Wheel Bearing Maintenance

HUB CAP HEX HEAD CAP 6250 CENTER FRAME WHEELS SCREW Figure 4-21: Wheel Bearing Maintenance 6250 Disc Wheel Bearing Center Frame Maintenance Center frame wheel bearing maintenance should be performed at the beginning of every season. Check periodically for excessive endplay. If needed, adjust or replace hub and components using the following procedure (See Figure 4-21.) -

Page 84: Wing Frame

OPERATION AND MAINTENANCE 1. Lower machine until tires are off the ground, the Wing Frame depth stop may have to be adjusted to allow cylinders Wheel bearing maintenance should be performed at the to retract far enough. beginning of every season of use. Check the wheel 2. -

Page 85: Hydraulic Maintenance

Maximum transport speed for the 6250 is 20 mph for Seal kits are available from your Landoll dealer. the implement and is designated on the speed identification symbol located on the front of the 3. - Page 86 OPERATION AND MAINTENANCE 6. A safety chain is provided with the implement to 8. Know the transport heights and widths of the unit insure safe transport. before transporting. Attachments such as leveling harrows can increase the transport dimensions of the a.

- Page 87 OPERATION AND MAINTENANCE Figure 4-25: Lubrication Schedule LUBRICATION TABLE INTERVAL ITEM DESCRIPTION NO. OF LUBE POINTS (Hours Unless Stated) Disc Gang Bearings 1 each Conditioner Reel Bearings (Not Shown) 1 each Walking Tandem Hubs 1 each (Top) Wing Wheel Hubs 1 each Front Gauge 6 Bolt Wheel Hubs 1 each...

-

Page 88: Lubrication Maintenance

1. Table 4-1 specifies the number and the period of harm the seal. Regular lubrication will maintain a full lubrication points on the 6250 Disc. Proper grease cavity and help purge any contaminants. maintenance of your machine will, under normal... -

Page 89: Storage

OPERATION AND MAINTENANCE Storage 1. The service life of the Disc will be extended by proper off-season storage practices. Prior to storing the unit, complete the following procedures: a. Completely clean the unit. b. Inspect the machine for worn or defective parts. Replace as needed. - Page 90 NOTES:...

-

Page 91: Troubleshooting Guide

Chapter 5 Troubleshooting Guide The Troubleshooting Guide, shown below, is included to help you quickly locate problems that can happen using your 6250 Disc. Follow all safety precautions stated in the previous sections when making any adjustments to your machine. PROBLEM... - Page 92 TROUBLESHOOTING GUIDE PROBLEM PROBABLE CAUSE SOLUTION WHEEL BEARING FAILURE Seals not installed correctly Install seals with the lips pointing outward away from the hub. HYDRAULIC - LIFT CYLINDERS NOT Lift cylinders not in phase Fully extend cylinders and hold hydraulic FULLY EXTENDING lever until all cylinders are fully extended.

- Page 93 Document Control Revision Log: Date Form # Improvement(s): Description and Comments 01/26/2014 F-733 Initial Release 11/05/2018 F-733-1118 Galaxy tire/wheel revision, wheel/hub lubrication revision. 11/04/2020 F-733-1120 Updated model specs with new Firestone tire.Updated new dual tire scraper layout drawing.

- Page 94 Equipment from Landoll Company, LLC is built to exacting standards ensured by ISO 9001 registration at all Landoll manufacturing facilities. Model 6250 Disc Operators Manual Re-Order Part Number F-733-1120 LANDOLL COMPANY, LLC 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM...

Need help?

Do you have a question about the 6250 Disc and is the answer not in the manual?

Questions and answers