Summary of Contents for Landoll 6231

- Page 1 ‘ Model 6231 Disc Operators Manual LANDOLL COMPANY, LLC 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM F-832-2307...

- Page 2 The identification plate, which lists the model number and serial number, is located on the front of the frame. SERIAL NUMBER The serial number is located on the identification plate. The Following information will help decode the 6231 Disc serial number 62H23100100 = xxmyysssss QR CODE DECAL...

- Page 3 DANGER DO NOT operate or perform any maintenance tasks on this equipment until you have completed the following: 1. Receive proper training to operate this equipment safely. 2. Read and understand the operator’s manual. 3. Be thoroughly trained on inspection and repair procedures. Failure to comply with this warning may result in serious injury or possibly death.

- Page 5 Center Frame Walker Assembly........3-2 6231 Disc Frame and Hitch Assembly ....... . 3-4 Leveler Assembly .

- Page 6 TABLE OF CONTENTS Rear Tow Hitch Short (Option)........3-63 Rear Tow Hitch Short Drop (Option) .

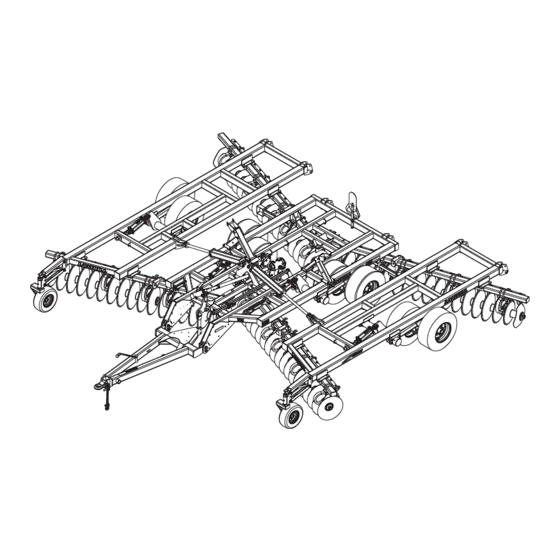

- Page 7 TABLE OF CONTENTS Introduction and Safety Information The Landoll Model 6231 Disc is a quality product designed to give years of trouble free performance. By following each section of this manual, your system will perform as designed for you and your operation.

- Page 8 5. Use a locking-style hitch pin that properly fits the The safety statements contained in this manual relate to tractor drawbar and the implement hitch. Lock the the operation of the Model 6231 Disc. tractor drawbar in the center position to prevent loss of steering control.

- Page 9 TABLE OF CONTENTS High Pressure Fluid Safety 6. Attach the safety chain to the tractor recommended drawbar support. Provide only enough slack in the 1. Escaping fluid under pressure can be nearly invisible chain for turning. Do not attach the safety chain to an and have enough force to penetrate the skin causing intermediate support.

- Page 10 TABLE OF CONTENTS Tire Safety Safety Chain 1. Tire changing can be dangerous and should be 1. Use a chain with a strength rating equal to or greater performed by trained personnel using correct tools than the gross weight of towed machinery, which is and equipment.

- Page 11 Safety Decals and Reflectors New safety signs may be ordered from your Landoll dealer. Refer to this section for parts and proper safety The 6231 Disc is equipped with all safety signs installed sign placement. for safe operation. To Install new safety signs: For you safety: 1.

- Page 12 TABLE OF CONTENTS P/N 144193 SIS 20MPH Front of center frame, middle QTY. 1 P/N 2-573-010037 Danger: Folding wing Front side, center frame both sides QTY. 2 P/N 2-573-010037 Danger: Folding wing Back side, rear hinge plate, center frame, both sides QTY.

- Page 13 QTY. 2 P/N 528934 Yellow Reflector Left rear, center frame, both sides QTY. 2 P/N 528938 Orange Reflector Back side, light brackets, top, both sides QTY. 2 P/N 528938 Orange Reflector Back side, center frame, top, 6231-21’-29’ both sides QTY. 2...

- Page 14 TABLE OF CONTENTS P/N 528938 Orange Reflector Back side, center frame, top, 6231-30’-36’ both sides QTY. 2 P/N 528933 Red Reflector Back side, light brackets, bottom, both sides QTY. 2 P/N 528933 Red Reflector Back side, center frame, bottom, 6231-21’-29’ both sides QTY.

- Page 15 TABLE OF CONTENTS P/N 224589 SIS 20 mile/h Back side of SIS 20MPH mount plate QTY. 1 P/N 70260977 SMV Emblem Back side, SMV mount plate QTY. 1 P/N 528934 Yellow Reflector Right side, rear tow hitch, both sides QTY. 2...

- Page 16 TABLE OF CONTENTS Table provided for general use. NOTES: 1-10 F-832-2307...

- Page 17 This manual is compiled as a guide for owners and Be certain to register the machine Online registration at operators of the 6231 Disc. Read it carefully so as to be www.landoll.com within 10 days of purchase or lease, in able to follow the suggestions made.

- Page 18 1) subjected to or operated in a manner which, at any time, have exceeded the product design limits: 2) repaired or altered outside our factory in any way so as, in the judgment of Landoll Company, LLC , to affect its stability or reliability: 3) subject to misuse, negligence, accident, or has been operated in a manner expressly prohibited in the instructions;...

- Page 19 This exclusive remedy shall not be deemed to have failed of its essential purpose so long as Landoll Company, LLC is willing and able to repair or replace defective parts in the prescribed manner.

- Page 20 TABLE OF CONTENTS General Torque Specifications (rev. 4/97) TORQUE SPECIFIED IN FOOT POUNDS This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and cap-screws assembled without supplemental lubrication (as received condition).

- Page 21 TABLE OF CONTENTS Hydraulic Fitting Torque Specifications TORQUE IS SPECIFIED IN FOOT POUNDS- 37 JIC, ORS, & ORB (REV. 10/97) This chart provides tightening torques for general purpose applications when special torques are not specified on process or drawing. Assembly torques apply to plated nuts and capscrews assembled without supplemental lubrication (as received condition).

- Page 22 TABLE OF CONTENTS Model Specifications 6231 Disc Spindle Wheel Model Working Transport Transport Blade No. of No. of Tire Size & Ply & Bolt Estimated Number Width Width Height Diamaeter Blades Bearings Size Pattern 6231-21 20’-7” 14’-0” 9’-11” 24” 28/30 12.5L x 15 LRF...

- Page 23 TABLE OF CONTENTS Table provided for general use. NOTES:...

- Page 24 TABLE OF CONTENTS Wing Stabilizer & Light Bracket Placement 16-1/4 Figure 2-2: Wing Stabilizer and Light Bracket Placement - 21' - 29' (Left Half) F-832-2307...

- Page 25 TABLE OF CONTENTS 64-1/2 16-1/4 Figure 2-3: Wing Stabilizer and Light Bracket Placement - 21' - 29' (Right Half)

- Page 26 TABLE OF CONTENTS Figure 2-4: Wing Stabilizer and Light Bracket Placement - 30’-36' (Left Half) 2-10 F-832-2307...

- Page 27 TABLE OF CONTENTS 64-1/2 Figure 2-5: Wing Stabilizer and Light Bracket Placement - 30’-36' (Right Half) 2-11...

- Page 28 TABLE OF CONTENTS 3 Row Coil Tine Harrow Placement 2-3/16 2-3/8 4-13/16 4-5/16 4-7/16 4-15/16 Figure 2-6: 3 Row Coil Tine Harrow Placement - 21' 2-12 F-832-2307...

- Page 29 TABLE OF CONTENTS 5-11/16 6-3/16 2-1/32 4-23/32 4-1/4 2-9/16 Figure 2-7: 3 Row Coil Tine Harrow Placement - 23' 2-13...

- Page 30 TABLE OF CONTENTS 5-11/16 6-3/16 4-5/16 15-13/16 15-1/16 Figure 2-8: 3 Row Coil Tine Harrow Placement - 26' 2-14 F-832-2307...

- Page 31 TABLE OF CONTENTS Table provided for general use. NOTES: 2-15...

- Page 32 TABLE OF CONTENTS 6-3/16 16-13/16 Figure 2-9: 3 Row Coil Tine Harrow Placement - 29' (Left Half) 2-16 F-832-2307...

- Page 33 TABLE OF CONTENTS 5-11/16 4-5/16 17-9/16 Figure 2-10: 3 Row Coil Tine Harrow Placement - 29' (Right Half) 2-17...

- Page 34 TABLE OF CONTENTS 2-1/2 16-9/16 3-1/2 Figure 2-11: 3 Row Coil Tine Harrow Placement - 30' (Left Half) 2-18 F-832-2307...

- Page 35 TABLE OF CONTENTS 2-5/16 3-1/16 Figure 2-12: 3 Row Coil Tine Harrow Placement - 30' (Right Half) 2-19...

- Page 36 TABLE OF CONTENTS 2-1/2 18-5/16 3-1/2 Figure 2-13: 3 Row Coil Tine Harrow Placement - 33' (Left Half) 2-20 F-832-2307...

- Page 37 TABLE OF CONTENTS 2-5/16 3-1/16 18-3/4 Figure 2-14: 3 Row Coil Tine Harrow Placement - 33' (Right Half) 2-21...

- Page 38 TABLE OF CONTENTS 1-3/16 2-1/2 19-9/16 Figure 2-15: 3 Row Coil Tine Harrow Placement - 36' (Left Half) 2-22 F-832-2307...

- Page 39 TABLE OF CONTENTS 1-3/8 2-1/16 Figure 2-16: 3 Row Coil Tine Harrow Placement - 36' (Right Half) 2-23...

- Page 40 TABLE OF CONTENTS Conditioner Reel Placement 24-11/16 82” REEL ASSEMBLY 114” REEL ASSEMBLY 82” REEL ASSEMBLY Figure 2-17: Conditioner Reel Placement - 21' 2-24 F-832-2307...

- Page 41 TABLE OF CONTENTS 24-11/16 91” REEL ASSEMBLY 114” REEL ASSEMBLY 91” REEL ASSEMBLY Figure 2-18: Conditioner Reel Placement - 23' 2-25...

- Page 42 TABLE OF CONTENTS 24-11/16 30-1/2 30-1/2 114” REEL ASSEMBLY 114” REEL ASSEMBLY 114” REEL ASSEMBLY Figure 2-19: Conditioner Reel Placement - 26' 2-26 F-832-2307...

- Page 43 TABLE OF CONTENTS 24-11/16 129” REEL ASSEMBLY 114” REEL ASSEMBLY 129” REEL ASSEMBLY Figure 2-20: Conditioner Reel Placement - 29' 2-27...

- Page 44 TABLE OF CONTENTS 25-1/8 114” REEL ASSEMBLY 156” REEL ASSEMBLY 114” REEL ASSEMBLY Figure 2-21: Conditioner Reel Placement - 30' 2-28 F-832-2307...

- Page 45 TABLE OF CONTENTS 25-1/8 138” REEL ASSEMBLY 156” REEL ASSEMBLY 138” REEL ASSEMBLY Figure 2-22: Conditioner Reel Placement - 33' 2-29...

- Page 46 TABLE OF CONTENTS Figure 2-23: Conditioner Reel Placement - 36' 2-30 F-832-2307...

- Page 47 TABLE OF CONTENTS Chevron Flat Bar Reel Placement 24-5/8” 27” 27” 91” CHEVRON 114” CHEVRON 91” CHEVRON REEL/GANGBAR REEL/GANGBAR REEL/GANGBAR ASSEMBLY ASSEMBLY ASSEMBLY Figure 2-24: Chevron Flat Bar Reel Placement - 23 2-31...

- Page 48 TABLE OF CONTENTS 24-5/8” 30-1/2” 30-1/2” 114” CHEVRON 114” CHEVRON 114” CHEVRON REEL/GANGBAR REEL/GANGBAR REEL/GANGBAR ASSEMBLY ASSEMBLY ASSEMBLY Figure 2-25: Chevron Flat Bar Reel Placement - 26' 2-32 F-832-2307...

- Page 49 TABLE OF CONTENTS 24-5/8” 30” 30” 129” CHEVRON 114” CHEVRON 129” CHEVRON REEL/GANGBAR REEL/GANGBAR REEL/GANGBAR ASSEMBLY ASSEMBLY ASSEMBLY Figure 2-26: Chevron Flat Bar Reel Placement - 29' 2-33...

- Page 50 TABLE OF CONTENTS 19” 25-1/8” 33-1/8” 33-1/8” 114” CHEVRON 156” CHEVRON 114” CHEVRON REEL/GANGBAR REEL/GANGBAR REEL/GANGBAR ASSEMBLY ASSEMBLY ASSEMBLY Figure 2-27: Chevron Flat Bar Reel Placement - 30' 2-34 F-832-2307...

- Page 51 TABLE OF CONTENTS 19” 25-1/8” 32” 32” 138” CHEVRON 156” CHEVRON 138” CHEVRON REEL/GANGBAR REEL/GANGBAR REEL/GANGBAR ASSEMBLY ASSEMBLY ASSEMBLY Figure 2-28: Chevron Flat Bar Reel Placement - 33' 2-35...

- Page 52 TABLE OF CONTENTS 19” 35-1/4” 35-1/4” 25-1/8” 39-1/8” 39-1/8” 156” CHEVRON 156” CHEVRON 156” CHEVRON REEL/GANGBAR REEL/GANGBAR REEL/GANGBAR ASSEMBLY ASSEMBLY ASSEMBLY Figure 2-29: Chevron Flat Bar Reel Placement - 36' 2-36 F-832-2307...

- Page 53 IN ASSEMBLY INSTRUCTIONS SECTION FOR ARM ASSEMLY 21-3/8” NOTE: LOCATION OF TUBE CLAMPS 204413 DOUBLE REEL ASSEMBLY 105/120 17-5/8” 17-5/8” 6231-21’ 204416 DOUBLE REEL 204422 DOUBLE REEL ASSEMBLY 75/75 ASSEMBLY 75/75 21-3/4" NOTE: LOCATION OF TUBE CLAMPS 204413 DOUBLE REEL 22-1/2"...

- Page 54 IN ASSEMBLY INSTRUCTIONS SECTION FOR ARM ASSEMLY 21-3/8" NOTE: LOCATION OF TUBE CLAMPS 204413 DOUBLE REEL 23-3/8" 23-3/8" ASSEMBLY 105/120 6231-26’ 204418 DOUBLE REEL 204424 DOUBLE REEL ASSEMBLY 105/105 ASSEMBLY 105/105 21-3/8" NOTE: LOCATION OF TUBE CLAMPS 204413 DOUBLE REEL 23-3/8"...

- Page 55 4” REAR JACK MOUNT ASSEMBLY 19” 26-5/8” NOTE: LOCATION OF TUBE CLAMPS 20-1/2” 20-1/2” 204427 DOUBLE REEL ASSEMBLY 6231-30’ 204418 DOUBLE REEL 204424 DOUBLE REEL ASSEMBLY 105/105 ASSEMBLY 105/105 NOTE: LOCATION OF 4” 19” REAR JACK MOUNT ASSEMBLY 26-5/8” NOTE: LOCATION OF TUBE CLAMPS 23-3/8”...

- Page 56 REAR JACK MOUNT ASSEMBLY 19” 43” 43” 26-5/8” NOTE: LOCATION OF TUBE CLAMPS 204427 DOUBLE REEL 26” 26” ASSEMBLY 6231-36’ 232462 DOUBLE REEL 232461 DOUBLE REEL ASSEMBLY 135/135 ASSEMBLY 135/135 Figure 2-33: Double Round Reel Placement - 36’ 2-40 F-832-2307...

- Page 57 TABLE OF CONTENTS Double Flat Reel Placement 21-3/8” NOTE: LOCATION OF TUBE CLAMPS 209626 DOUBLE REEL ASSEMBLY 105/120 17-3/8” 17-3/8” 6231-21’ 209629 DOUBLE REEL 209635 DOUBLE REEL ASSEMBLY 75/75 ASSEMBLY 75/75 21-3/8" NOTE: LOCATION OF TUBE CLAMPS 209626 DOUBLE REEL 23"...

- Page 58 TABLE OF CONTENTS 21-3/8" NOTE: LOCATION OF TUBE CLAMPS 209626 DOUBLE REEL 23" 23" ASSEMBLY 105/120 6231-26’ 209631 DOUBLE REEL 209637 DOUBLE REEL ASSEMBLY 105/105 ASSEMBLY 105/105 21-3/8" NOTE: LOCATION OF TUBE CLAMPS 204511 DOUBLE REEL 23" 23" ASSEMBLY 105/120 6231-29’...

- Page 59 4” REAR JACK MOUNT ASSEMBLY 19” 26-5/8 ” NOTE: LOCATION OF TUBE CLAMPS 20-1/4” 20-1/4” 209639 DOUBLE REEL ASSEMBLY 150/165 6231-30’ 209631 DOUBLE REEL 209637 DOUBLE REEL ASSEMBLY 105/105 ASSEMBLY 105/105 19” 26-5/8” NOTE: LOCATION OF TUBE CLAMPS 23-1/8” 23-1/8”...

- Page 60 REAR JACK MOUNT ASSEMBLY 19” 43-3/4” 43-3/4” 26-5/8” NOTE: LOCATION OF TUBE CLAMPS 209639 DOUBLE REEL 25-1/8” 25-1/8” ASSEMBLY 150/165 6231-36’ 236791 DOUBLE REEL 236790 DOUBLE REEL ASSEMBLY 135/135 ASSEMBLY 135/135 Figure 2-37: Double Flat Reel Placement - 36’ 2-44 F-832-2307...

- Page 61 Chapter 3 TABLE OF CONTENTS Assembly Instructions It is very important that your new 6231 Disc be properly WARNING assembled, adjusted and lubricated before use. Illustrations to assist with the assembly process are Do not attempt to lift heavy parts (such as the provided in “Specifications”...

- Page 62 6. Place walker under the lift leg and carefully hold a thrust washer on each side while lifting the walker up 1. On Models 6231-30’, 33’-36’, units will be shipped into line with the pin hole on the axle leg.

- Page 63 TABLE OF CONTENTS NOTE: WALKER ORIENTATION NOTE: WALKER ORIENTATION Figure 3-1: Center Frame Walker Assembly 6231-30’-36’...

- Page 64 TABLE OF CONTENTS 6231 Disc Frame and Hitch 3. Move the jack to the forward mounting tube and rotate to parking position to support the front of the Assembly hitch. 4. Insert a 3/4 x 7 bolt into the hose holder tube on the...

- Page 65 TABLE OF CONTENTS 1/2 X 11 BOLTS 3/8 X 2 BOLTS, HOSE HOLDER CLAMP DOUBLE PILOT CHECK VALVE 3/8 LOCK NUTS DETAIL A 1/2 LOCK NUTS 3/8 X 3 BOLT, 3/8 FLAT WASHER, HOSE CLAMPS, 3/8 LOCK NUT 3/8 X 3-1/2 ALL THREAD, 3/8 NUT, HOSE HOLDER CLAMP, WING NUTS DETAIL A...

- Page 66 TABLE OF CONTENTS Leveler Assembly 6. Slide a 1-1/2 Thrust Washer over each side of trunnion of the leveler spring tube assembly. 1. Install a 1-5/8 x 1-1/4 x 1 bushing in the leveler L link 7. Slide a leveler spring mount over each side Trunnion See Figure 3-3.

- Page 67 TABLE OF CONTENTS NOTE: 1-1/2 NUT USED ON HYDRAULIC LEVELER ONLY 1-1/2 NUT 71” LEVELER TUBE WELDMENT 1-5/8 X 1 X 1-1/4 X 1 BUSHING, LEVLER L LINK DETAIL A LEVELER SPRING TUBE ASSEMBLY LEVELER SPRING MOUNTS, 1-1/2 FLANGE BEARINGS, 1-1/2 THRUST WASHERS 1-1/4 X 6 BOLTS, 1 X 2-1/2 BOLTS,...

- Page 68 TABLE OF CONTENTS Manual Leveler 10. With a 1/2 x 2 bolt and 1/2 lock nut, attach the leveler indicator gauge to the leveler cross. Do not over 1. Using the manual leveler, screw the 71” leveler tube tighten this screw, as the indicator gauge must be onto the leveler screw assembly See Figure 3-3.

- Page 69 TABLE OF CONTENTS 140525 MANUAL 5/16 X 2-1/2 71” LEVELER LEVELER ASSEMBLY SPRING PIN TUBE FLANGE BEARING 1/4 ZERK 5/8 LOCK NUTS, 5/8 X 3-1/2 BOLTS LEVELER L LINK 1N FLAT WASHER 5/16 X 2-1/2 1-1/2 FLAT SPRING PIN WASHER, LEVELER CROSS 1-1/2 FLANGE 71”...

- Page 70 TABLE OF CONTENTS Fold Cylinder Mount 3. For 30’ models, install the fold cylinder mount over the middle center frame cross bar over the leveler 1. For 21’- 26’ models, assemble the fold cylinder spring assembly See Figure 3-6. Attach using 5/8 x mount to the middle cross bar of the center frame 4 x 7-3/4 u-bolts and hex lock nuts.

- Page 71 TABLE OF CONTENTS LOCATION ON 21’-29’ MODELS LOCATION ON 29’ MODELS 5/8-11 HEX LOCK NUT 5/8 X 4 X 6-1/2 U-BOLT FOLD CYLINDER MOUNT 21’ - 29’ MODELS LOCATION ON 30’-36’ MODELS LOCATION ON 33’-36’ MODELS FOLD CYLINDER MOUNT 5/8-11 HEX LOCK NUT 30’...

- Page 72 TABLE OF CONTENTS Center Frame Tires Disc Gangs Install the tire and wheel assemblies on the center DANGER DANGER section. Disc blades are extremely sharp. Exercise extreme care when working on or near disc blades. Do not allow discs to roll over or fall onto any bodily part.

- Page 73 TABLE OF CONTENTS NOTE: MOST RIGHT DISC GANG 3/4-10 X 2 HEX ASSEMBLIES NOT SHOWN FOR HEAD CAP SCREW CLARITY. LEFT REAR CENTER FRAME DISC GANG CONNECTION RIGHT REAR CENTER FRAME DISC GANG ASSEMBLY 3/4-10 HEX LOCK LEFT REAR CENTER FRAME DISC GANG ASSEMBLY 1/2 X 2-1/4 SLOTTED...

- Page 74 TABLE OF CONTENTS Wing Frames 1. Place the wing frames on top of the wing gang 3. Attach the front gauge wheel assemblies to the wing assemblies and attach using 3/4-10 x 2 hex head cap frames using 1-8 x 6 hex head cap screws, gauge screws and hex lock nuts See Figure 3-8.

- Page 75 4. Install 90 degree regular adapter fittings in the base the pins and roll pins provided. Position the cylinders end of the 4-1/2” x 30” cylinders and both ends of all so the hydraulic ports point forward. Model 6231-29’ lift cylinders. rear fold cylinders, the ports point rearward.

- Page 76 TABLE OF CONTENTS Lift Hydraulic Installation 90° #8 ADAPTER 1/2” X 210” LIMIT VALVE 3/4-16 MALE COUPLER #8 ADAPTER 3/8” X 120” 1/2” X 36” #8 ADAPTER 90° #8 ADAPTER 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT BLUE HOSE 90° #8 WRAP ADAPTER 3/8”...

- Page 77 TABLE OF CONTENTS 90° #8 ADAPTER 1/2” X 210” LIMIT VALVE 3/4-16 MALE COUPLER #8 ADAPTER 3/8” X 136” 1/2” X 36” #8 ADAPTER 90° #8 ADAPTER 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT BLUE HOSE 90° #8 WRAP ADAPTER 3/8”...

- Page 78 TABLE OF CONTENTS 90° #8 ADAPTER 1/2” X 210” LIMIT VALVE 3/4-16 MALE COUPLER #8 ADAPTER 3/8” X 150” 1/2” X 36” #8 ADAPTER 90° #8 ADAPTER 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT BLUE HOSE 90° #8 WRAP ADAPTER 3/8”...

- Page 79 TABLE OF CONTENTS 90° #8 ADAPTER 1/2” X 210” LIMIT VALVE 3/4-16 MALE COUPLER #8 ADAPTER 3/8” X 165” 1/2” X 36” #8 ADAPTER 90° #8 ADAPTER 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT BLUE HOSE 90° #8 WRAP ADAPTER 3/8”...

- Page 80 TABLE OF CONTENTS 90° #8 ADAPTER 1/2” X 210” LIMIT VALVE 3/4-16 MALE COUPLER #8 ADAPTER 3/8” X 182” 1/2” X 36” #8 ADAPTER 90° #8 ADAPTER 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT BLUE HOSE 90° #8 WRAP ADAPTER 3/8”...

- Page 81 TABLE OF CONTENTS 90° #8 ADAPTER 1/2” X 210” LIMIT VALVE 3/4-16 MALE COUPLER #8 ADAPTER 3/8” X 196” 1/2” X 36” #8 ADAPTER 90° #8 ADAPTER 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT BLUE HOSE 90° #8 WRAP ADAPTER 3/8”...

- Page 82 TABLE OF CONTENTS 90° #8 ADAPTER 1/2” X 210” LIMIT VALVE 3/4-16 MALE COUPLER #8 ADAPTER 3/8” X 212” 1/2” X 36” #8 ADAPTER 90° #8 ADAPTER 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT BLUE HOSE 90° #8 WRAP ADAPTER 3/8”...

- Page 83 TABLE OF CONTENTS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS Figure 3-16: Lift Hydraulic Layout 6231-21’-29’ 3-23...

- Page 84 TABLE OF CONTENTS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS Figure 3-17: Lift Hydraulic Layout 6231-30’-36’ 3-24 F-832-2307...

- Page 85 TABLE OF CONTENTS Fold Hydraulic Installation 90° #8 1/16” RES ADAPTER 4-1/2 X 30 CYLINDER 90° #8 ADAPTER 3/8” X 50” 90° #8 ADAPTER 3/8” X 33” 5/16 X 2-1/2 SLOTTED PIN 1/2 X 3-1/2 BOLT, 3/4-16 PLUG 1/2 LOCK NUT 1-1/4 FLAT WASHER 3/8”...

- Page 86 TABLE OF CONTENTS 90° #8 1/16” RES ADAPTER 4-1/2 X 30 CYLINDER 90° #8 ADAPTER 3/8” X 70” 90° #8 1/2 X 3-1/2 BOLT, ADAPTER 1/2 LOCK NUT 5/16 X 2-1/2 SLOTTED PIN 3/4-16 PLUG 3/8” X 40” 1-1/4 FLAT WASHER 3/8”...

- Page 87 TABLE OF CONTENTS 90° #8 1/16” RES ADAPTER 90° #8 ADAPTER 3/8” X 42” 3/8” X 22” 4-1/2 X 30 CYLINDER 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT 8 PORT 3/8” X 33” 3/8” X 50” MANIFOLD 1/2 X 3-1/2 BOLT, 1/2 LOCK NUT #8 ADAPTER 3/8”...

- Page 88 TABLE OF CONTENTS 90° #8 1/16” RES ADAPTER 90° #8 ADAPTER 3/8” X 67” 3/8” X 36” 4-1/2 X 30 CYLINDER 8 PORT MANIFOLD 3/8” X 70” 3/8” X 40” 1/2 X 3-1/2 BOLT, #8 ADAPTER 3/8” X 67” 1/2 LOCK NUT 3/8”...

- Page 89 TABLE OF CONTENTS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS Figure 3-22: Fold Hydraulic Layout 6231-21’, 23’, 26’, 30’ Single 3-29...

- Page 90 TABLE OF CONTENTS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS NOTE: 6231-29’ REAR FOLD CYLINDER PORTS FACE REARWARD Figure 3-23: Fold Hydraulic Layout 6231-29’ Double 3-30 F-832-2307...

- Page 91 TABLE OF CONTENTS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS NOTE: RUN HOSES THROUGH ALL HOSE CLAMPS & LOOPS NOTE: 6231-33’-36’ REAR FOLD CYLINDER PORTS FACE FORWARD Figure 3-24: Fold Hydraulic Layout 6231-33’, 36’ Double 3-31...

- Page 92 TABLE OF CONTENTS 7-PIN 4-PIN CIRCUIT WIRE COLOR CONN. TOWER GROUND WHITE – WORK LAMPS BLACK LEFT FLASHING YELLOW & TURN – STOP LAMPS RIGHT FLASHING GREEN & TURN TAIL LAMPS BROWN SWITCHED – BLUE POWER (12 V) MAIN WARNING LIGHT HARNESS - WIRING CHART RIGHT RIGHT LEFT...

- Page 93 TABLE OF CONTENTS LED Light and SMV Bracket IMPORTANT Installation Make sure lights are positioned for maximum visibility from the rear. NOTE 5. Install the rear warning light harness to the frame. Connect 2 pin and 3 pin ends to each of the warning See Figure 3-27 for light bracket, smv mounting bracket lights.

- Page 94 TABLE OF CONTENTS NOTE: LED LIGHTS, HARNESS, AND MODULE DO NOT INTERCHANGE WITH PREVIOUS FRONT SIS DECAL MOUNT, LIGHTING SYSTEM SIS 20 MPH DECAL, NOTE: LIGHT BRACKET WELDMENTS SMV EMBLEM NOT SOLD W/O REFLECTORS 1/4 X 1 BOLTS, 1/4 X 1-1/4 1/4 LOCK NUTS BOLTS &...

- Page 95 NOTE: RUN REAR HARNESS THROUGH TUBE OF LIGHT NOTE: RUN REAR BRACKETS HARNESS THROUGH TUBE OF LIGHT BRACKETS 37" 6231-21’-29’ 40" 6231-30’-36’ 25" 6231-21’-29’ 28" 6231-30’-36’ 16-1/4" 6231-21’-29’ 16-1/4" 6231-21’-29’ 15" 6231-30’-36’ 15" 6231-30’-36’ 47" 6231-21’-29’ 60" 6231-30’-36’ Figure 3-27: LED Light Layout...

- Page 96 TABLE OF CONTENTS 6231 Coil Tine Assembly 6. Connect the other end of the spring assembly to the reel arm using 1” pivot pins, 1” machine bushings, See Figure 2-6 through 2-16 for harrow placement and 5/16 x 1-1/2 spring pins.

- Page 97 TABLE OF CONTENTS 1 X 9 ADJUSTMENT PLASTIC WEAR BUSHINGS, BOLT, 2-1/2 PIVOT BUSHING 1” PIVOT PINS, ADJUSTMENT PIN 1” MACHINE BUSHINGS, 5/16 X 1-1/2 SPRING PINS 1 X 6-1/2 BOLT, 1” LOCK NUT REEL ARM 3/4 LOCK NUTS SNAP RING 1”...

- Page 98 See Figure 2-30 through 2-31 double reel gang bar placement locations. 10. Models 6231-30’-36’ 6” coil tine mount on rear tube of center and wing frames with 5/8 x 6-11/16 x 5-1/2 21” u-bolts and 5/8 lock nuts. Attach double reel/gang bar...

- Page 99 TABLE OF CONTENTS 12. Attach flat bar reels with angled blades as shown 14. Models 6231-30’-33’-36’ attach the rear jack mount See Figures 3-32. to the rear tube of center frame with 3/4 x 4 bolts, 3/4 flat washers, rear jack plate and 3/4 lock nuts Figure 3-33.

- Page 100 TABLE OF CONTENTS MODEL 6231-36’ SHOWN 5/8 X 6-11/16 X 5-1/2 U-BOLTS, 5/8 LOCK NUTS COIL TINE MOUNT 1-1/2 FLANGE BEARINGS, REEL ARM 1-1/2 PIVOT BUSHING REEL ARM COND REEL/BANBAR ROUND ASSEMBLY PIVOT PIN, MACHINERY BUSHINGS, 1 X 6-1/2 BOLT,...

- Page 101 ASSEMBLY 3 X 3 CLAMP TUBES, 1/2 X 5-1/2 BOLTS, 1/2 LOCK NUTS DOUBLE REEL ASSEMBLY CLAMP TUBE, 1-3/4 RUBBER SPRING TORSION GANGBAR MOUNT PLATE, 3/4 X 8-1/2 BOLTS, 3/4 LOCK NUTS Figure 3-35: Conditioner Double Reel Installation 6231-21’-29’ 3-41...

- Page 102 PIN, 1 X 9 ADJ BOLT 1/2 LOCK NUTS DOUBLE REEL REEL ARM ASSEMBLY 17” SPRING ASSEMBLY CLAMP TUBE, 1-3/4 RUBBER SPRING TORSION GANGBAR MOUNT PLATE, 3/4 X 8-1/2 BOLTS, 3/4 LOCK NUTS Figure 3-36: Conditioner Double Reel Installation 6231-30’-36’ 3-42 F-832-2307...

- Page 103 Installation See Figure 3-40 See Figure 3-41 Models 6. Models 6231-30’-36’ attach 6” coil tine mount to rear 6231-30’-36’Hydraulic Conditioner Double Reel tube of center and wing frames with 5/8 x 6-11/16 x Installation. 5-1/2 u-bolts and 5/8 lock nuts See Figure 3-41.

- Page 104 8. Models 6231-30’-33’-36’ attach the rear jack mount to the rear tube of center frame with 3/4 x 4 bolts, 3/4 flat washers, rear jack plate and 3/4 lock nuts Figure 3-38.

- Page 105 TABLE OF CONTENTS REEL ARM 1-1/2 FLANGE BEARINGS, 1-1/2 PIVOT BUSHING REEL ARM PIVOT PIN, MACHINERY BUSHINGS, 1 X 6-1/2 BOLT, 5/16 X 1-1/2 SPRING 1 LOCK NUT PINS TRUNION MOUNT ASSEMBLY, 1/2 X 2 2-1/2 X 2-1/2 BOLTS, 1/2 LOCK CYLINDER, WASHERS 1-1/8 NUT...

- Page 106 3/8 X 3/4 NYLON SET SCREW CLAMP TUBE, 1-3/4 RUBBER SPRING TORSION DOUBLE REEL ASSEMBLY CLAMP TUBE, 1-3/4 RUBBER SPRING TORSION GANGBAR MOUNT PLATE, 3/4 X 8-1/2 BOLTS, 3/4 LOCK NUTS Figure 3-40: Hydraulic Conditioner Double Reel Installation 6231-21’-29’ 3-46 F-832-2307...

- Page 107 CLAMP TUBE, 1-3/4 RUBBER 2-1/2 X 2-1/2 17” SPRING SPRING TORSION CYLINDER, ASSEMBLY 1-1/8 NUT 3/8 X 3/4 NYLON SET SCREW GANGBAR MOUNT PLATE, 3/4 X 8-1/2 BOLTS, 3/4 LOCK NUTS Figure 3-41: Hydraulic Conditioner Double Reel Installation 6231-30’-36’ 3-47...

- Page 108 3/8 X 1-1/2 BOLT Figure 3-42: 8 Port Manifold Installation 21’-26’, 30’ SCRAPER 10. Models 6231-26’, 33, 36’ install the 8 port manifold See Figure 3-43 to the manifold bracket on the rear 1/2 X 1-3/4 of center frame with 1/2 x 3-1/2 bolts and 1/2 lock SQUARE nuts.

- Page 109 TABLE OF CONTENTS CLAMP BRACKET, 1/2 X 1-3/4 SQUARE HEAD BOLT, 2-1/2 - 8-1/2 HOSE CLAMP 1/2 FLANGE LOCK NUT, RED HOSE 4-1/2 - 6-1/2 HOSE CLAMP HOSE CLAMP, 3/8 X 1-1/2 BOLT, WRAP 3/8 FLANGE LOCK NUT HOSE CLAMP 90°...

- Page 110 TABLE OF CONTENTS CLAMP BRACKET, 1/2 X 1-3/4 SQUARE HEAD BOLT, 2-1/2 - 8-1/2 HOSE CLAMP 1/2 FLANGE LOCK NUT, RED HOSE 4-1/2 - 6-1/2 HOSE CLAMP HOSE CLAMP, 3/8 X 1-1/2 BOLT, WRAP 3/8 FLANGE LOCK NUT HOSE CLAMP 90°...

- Page 111 TABLE OF CONTENTS CLAMP BRACKET, 1/2 X 1-3/4 SQUARE HEAD BOLT, 2-1/2 - 8-1/2 HOSE CLAMP 1/2 FLANGE LOCK NUT, RED HOSE 4-1/2 - 6-1/2 HOSE CLAMP HOSE CLAMP, 3/8 X 1-1/2 BOLT, WRAP 3/8 FLANGE LOCK NUT HOSE CLAMP 90°...

- Page 112 TABLE OF CONTENTS CLAMP BRACKET, 1/2 X 1-3/4 SQUARE HEAD BOLT, 1/2 FLANGE LOCK NUT, RED HOSE HOSE CLAMP, 3/8 X 1-1/2 BOLT, 2-1/2 - 8-1/2 HOSE CLAMP WRAP 3/8 FLANGE LOCK NUT 4-1/2 - 6-1/2 HOSE CLAMP 3/4-16 MALE 90°...

- Page 113 TABLE OF CONTENTS CLAMP BRACKET, 1/2 X 1-3/4 SQUARE HEAD BOLT, 2-1/2 - 8-1/2 HOSE CLAMP 1/2 FLANGE LOCK NUT, RED HOSE 4-1/2 - 6-1/2 HOSE CLAMP HOSE CLAMP, 3/8 X 1-1/2 BOLT, WRAP 3/8 FLANGE LOCK NUT HOSE CLAMP 90°...

- Page 114 TABLE OF CONTENTS CLAMP BRACKET, 1/2 X 1-3/4 SQUARE HEAD BOLT, 1/2 FLANGE LOCK NUT, RED HOSE HOSE CLAMP, 3/8 X 1-1/2 BOLT, 2-1/2 - 8-1/2 HOSE CLAMP WRAP 3/8 FLANGE LOCK NUT 4-1/2 - 6-1/2 HOSE CLAMP 3/4-16 MALE 90°...

- Page 115 TABLE OF CONTENTS CLAMP BRACKET, 1/2 X 1-3/4 SQUARE HEAD BOLT, 1/2 FLANGE LOCK NUT, RED HOSE HOSE CLAMP, 3/8 X 1-1/2 BOLT, 2-1/2 - 8-1/2 HOSE CLAMP WRAP 3/8 FLANGE LOCK NUT 4-1/2 - 6-1/2 HOSE CLAMP 3/4-16 MALE 90°...

- Page 116 HOSE CLAMP 1/4 X 80” HOSE (6231-29’) 1/4 X 38” HOSE (6231-21’) 1/4 X 68” HOSE (6231-26’) 1/4 X 84” HOSE (6231-29’) BULKHEAD PLATE DETAIL B #6 BULKHEAD MODELS 6231-26’-29’ Figure 3-52: Hydraulic Double Reel Assembly 6231-21’, 26’, 29’ 3-56 F-832-2307...

- Page 117 2-1/2 - 8-1/2 #128 4-1/2 - 6-1/2 #096 HOSE CLAMP HOSE CLAMP HOSE CLAMP 90° #6 45° #6 X #6 ADAPTER ADAPTER 1/4 X 60” HOSE BULKHEAD PLATE #6 BULKHEAD DETAIL B Figure 3-53: Hydraulic Double Reel Assembly 6231-30’ 3-57...

- Page 118 2-1/2 - 8-1/2 #128 4-1/2 - 6-1/2 #096 HOSE CLAMP HOSE CLAMP HOSE CLAMP 90° #6 45° #6 X #6 ADAPTER ADAPTER 1/4 X 84” HOSE BULKHEAD PLATE #6 BULKHEAD DETAIL B Figure 3-54: Hydraulic Double Reel Assembly 6231-33’ 3-58 F-832-2307...

- Page 119 4-1/2 - 6-1/2 #096 2-1/2 - 8-1/2 #128 90° #6 HOSE CLAMP HOSE CLAMP 45° #6 X #6 ADAPTER ADAPTER HOSE CLAMP 1/4 X 44” HOSE BULKHEAD PLATE #6 BULKHEAD DETAIL B Figure 3-55: Hydraulic Double Reel Assembly 6231-36’ 3-59...

- Page 120 LEVELER CROSS 1/2 X 2 3/8 LOCK NUT BOLTS 3/8 WASHER The spare tire for the 6231-21’-29’ is mounted on the right front corner of the center frame to leave access the depth control, owner’s manual and wrenches See Figure 3-57.

- Page 121 TABLE OF CONTENTS 320/70R15 SPARE TIRE ASSEMBLY (6231-21’-23’), 380/55R 16.5 IMP SPARE TIRE ASSEMBLY (6231-26’-29’), 5/8 FLANGE LOCK NUTS SPARE TIRE MOUNT, 5/8 X 3 X 2-1/2 THD BOLTS, 5/8 FLANGE LOCK NUTS 5/8 X 4-11/16 X 7-3/4 U-BOLTS, 5/8 FLANGE LOCK NUTS Figure 3-57: Spare Tire Installation 6231-21’-29’...

- Page 122 VF410/50R 16.5 IMP SPARE TIRE ASSEMBLY, 5/8 FLANGE LOCK NUTS SPARE TIRE MOUNT, 5/8 X 3 X 2-1/2 THD BOLTS, 5/8 FLANGE LOCK NUTS 3/4 X 5-25/32 X 7-1/4 U-BOLTS, 3/4 LOCK NUTS Figure 3-58: Spare Tire Installation 6231-30’-36’ 3-62 F-832-2307...

- Page 123 TABLE OF CONTENTS Rear Tow Hitch Short (Option) Rear Tow Hitch Long (Option) 1. Attach the rear tow hitch assembly to the rear bar of 1. Models 26’, 33’, 36’ unfold and unpin the rear fold the center frame using rear tow hitch mounting cylinders.

- Page 124 TABLE OF CONTENTS REAR TOW HITCH REAR TOW HITCH MOUNTING PLATES MOUNTING PLATES REAR TOW HITCH ASSEMBLY 3/4 X 6-1/2 BOLTS, 3/4 X 6-1/2 BOLTS, REAR TOW 3/4 LOCK NUTS 3/4 LOCK NUTS HITCH ASSEMBLY 198266 REAR TOW HITCH - SHORT 199314 REAR TOW HITCH DROP WITH HYDRAULICS WITH OUT HYDRAULICS...

- Page 125 TABLE OF CONTENTS 3/8 X 270” 3/4-16 HOSE MALE COUPLER 37° UNION FITTING 3/8 X 120” DUST COUPLER PLUG COUPLER TANDEM ADAPTER HARNESS PLATE 3/8 X 2-1/2 5/16 HEX LOCK NUT BOLT 3/8 LOCK NUT 3/4-16 FEMALE COUPLER 1/2 FLANGE LOCK NUT 1/2 X 5-1/2 X 4-1/4 U-BOLT COUPLER MOUNT BRACKET...

- Page 126 TABLE OF CONTENTS Rear Jack Installation Final Assembly A rear jack assembly is available for use on the rear of 1. Attach a tractor to the implement and charge the lift the disc. system hydraulics as described in “Hydraulic Lift System”...

- Page 127 DANGER DANGER DANGER DANGER Never allow anyone to ride on the 6231 Disc at Always lock the tractor drawbar in the center any time. Allowing a person to ride on the position when transporting the unit. Failure to do machine can inflict serious personal injury or so can result in serious injury or death and cause death to that person.

- Page 128 TABLE OF CONTENTS Tractor Preparation Disc Preparation The Landoll 6231 Disc is designed to be pulled by tractor 1. Prior to operating the 6231 Disc, inspect it thoroughly equipped with a double lip or clevis type hitch. If your for good operating condition.

- Page 129 TABLE OF CONTENTS Attaching To The Tractor Hydraulic Lift System 1. Align the tractor drawbar with the machine. Raise or The disc is equipped with a rephasing hydraulic lift lower the disc ring hitch, as needed, using the swivel system to raise and lower the unit in the field. jack.

- Page 130 TABLE OF CONTENTS 2. The hydraulic system is not filled with oil and should 1-3/8 X 10 TRANSPORT be purged of air before transporting and field LOCKOUT operations. Carefully hitch the disc to the tractor and connect the hydraulic lift hoses. 3.

- Page 131 TABLE OF CONTENTS Hydraulic Fold System IMPORTANT 1. The disc is equipped with a hydraulic fold system to Failure to remove the lock pins when unfolding will raise and lower the wing frames for narrow transport. result in serious damage to the implement. Be sure other people and pets are a safe distance away.

- Page 132 TABLE OF CONTENTS General Operation Field Operation 1. The horsepower requirements are typically 8-10 1. Raise the unit to take the weight off of the transport horsepower per foot of cut. This will vary widely due locks. Remove the transport locks from the lift to speed, depth, moisture, residue and types of soils.

- Page 133 TABLE OF CONTENTS Leveling (Side To Side) APPROX 21” Leveling the disc from side-to-side, involves leveling the center section side-to-side, then leveling the wings to the center section. This will insure that all sections are operating evenly and consistent depth. The unit should be level side-to-side when operating in the field.

- Page 134 TABLE OF CONTENTS Leveling (Front-to-Rear) NOTE 1. The leveling feature on the disc is used to keep the If the tire size is different on the center than the disc level when raising the unit from a working wing, the cylinders will need to be adjusted position to a transport position.

- Page 135 TABLE OF CONTENTS Hydraulic Leveler Gauge 4. Screw the leveler tube in or out. Insert the indicator rod to check if the reference gauge is centered. Adjustment Adjust as required to center the reference gauge. If a unit is equipped with an optional hydraulic leveler, and Make sure the hole for the indicator rod is horizontal the unit is level in the field, but the reference gauge is not and tighten the locking nut on the leveler screw.

- Page 136 TABLE OF CONTENTS Variable Ratio Adjustment 1. To change the variable ratio adjustment, lower the implement to the ground and relieve the load on the The leveler is also equipped with a variable ratio lift system. adjustment. This is located at the rear of the leveler and 2.

- Page 137 TABLE OF CONTENTS Hitch Adjustment IMPORTANT 1. It is important for the disc to maintain a proper draft When the hitch is in the lower position, the leveler line with the tractor to do a level job of discing. The ball joint link will be in the upper mounting hole at draft line will vary depending on soil conditions and the rear of the tongue.

- Page 138 TABLE OF CONTENTS Scraper Adjustment Disc Gang Assembly The disc is equipped with rigid scrapers at regular spools with dual scrapers at the disc bearings. 1. The disc gangs are assembled using 1-3/4” diameter 1. Rigid scrapers should be set initially as close to the gang shaft.

- Page 139 Operation/Adjustment The coil tine harrow is an optional attachment used for 1. When adding an attachment to the rear of the Landoll additional soil and residue leveling. It features 3 rows of disc, the leveler linkage on the disc may need to be 1/2”...

- Page 140 TABLE OF CONTENTS 1-8 HEX NUT HEAVY SPRING ASSEMBLY RECOMMENDED HARROW (1 X 9 ADJ SPRING BOLTS SETTINGS RUNS THROUGH CENTER) HARROW ADJUSTMENT HOLES ANGLE ADJUSTMENT PLATE HARROW GANGBAR PLATE Figure 4-16: Harrow Adjustment and Settings 4-14 F-832-2307...

- Page 141 See Figure 4-18. The 6231 may be equipped with optional chevron flat bar reels. Chevron flat bar reels consist of 6 large 5/16 x 3” NOTE blades, formed in a chevron shape. The chevron shape helps to provide a smooth consistent roll.

- Page 142 TABLE OF CONTENTS REEL ARM ASSEMBLY 3/4-16 LOCK NUT GANGBAR MOUNT PLATE 3/4-16 X 5-1/2 BOLT REEL ASSEMBLY Figure 4-18: Conditioner Single Reel Installation 4-16 F-832-2307...

- Page 143 See Figures 4-21. The front reel typically The 6231 disc may be equipped with optional double reel has the blades angled forward to mix and chop the attachment . The double reels will help to firm the soil soil.

- Page 144 An optional hydraulic controlled single or double reel the outer front corners of each wing. These gauge option is available for the 6231 disc. The hydraulic reel wheels are used to limit depth of the wings, and functions similar to the non-hydraulic reel.

- Page 145 Disc Blades DANGER DANGER 1. Standard disc blades for the 6231 are 24” diameter, 4ga, and 3” concavity disc blades on both front and Disc blades are extremely sharp. Exercise rear. The 6231 disc has a variety of disc blade extreme care when working on or near disc options, for particular operations.

- Page 146 TABLE OF CONTENTS Depth Stop Adjustment (Manual) 2. The gauge on the side of the depth stop tube gives a reference for depth setting. The “A“ setting refers to The operating depth of the disc is controlled by a maximum operating depth. single-point depth stop.

- Page 147 TABLE OF CONTENTS Transport 1. Check and follow all federal, state, and local requirements before transporting the disc. 2. The disc should be transported only by tractor HITCH required for field operation. The implement weight WELDMENT should not exceed more than 1.5 times the tractor weight.

- Page 148 TABLE OF CONTENTS 9. Raise the unit to full transport height. WARNING 10. Install transport locks on both lift and fold systems. Do not depend solely on implement hydraulics for Failure to use transport lock pins during transport See Figure 4-25.

- Page 149 TABLE OF CONTENTS Chapter 5 Maintenance and Lubrication Wheel Bearing Maintenance – Wheel Bearing Maintenance -- Non Triple-Lip Triple-Lip Wheel bearing maintenance should be performed at the Transport tires use a self-contained seal with multiple lips. beginning of every season of use. Check the wheel The seal fits tight on both the spindle and wheel hub.

- Page 150 Before servicing any replace all seals. Seal kits are available from your hydraulic component, lower the implement to the Landoll dealer. ground and relieve all system pressure. If a hydraulic component is disconnected, repaired, or replaced, it 3.

- Page 151 TABLE OF CONTENTS Lubrication 1. A proper maintenance schedule will insure a long 3. Wheel seals, when properly installed, will allow operating life and peak performance. Performing the grease to pass without harm to seals. Regular following lubrication will ensure maximum operating lubrication will extend service life, particularly in life of the Disc See Figure 5-3...

- Page 152 TABLE OF CONTENTS Storage 1. The service life of the Field Cultivator will be extended by proper off-season storage practices. Prior to storing the unit, complete the following procedures: a. Completely clean the unit. b. Inspect the machine for worn or defective parts. Replace as needed.

- Page 153 Troubleshooting Guide The Troubleshooting Guide, shown below, is included to help you quickly locate problems that can happen using your 6231 Disc. Follow all safety precautions stated in the previous when making any adjustments to your machine. PROBLEM PROBABLE CAUSE...

- Page 154 TABLE OF CONTENTS PROBLEM PROBABLE CAUSE SOLUTION HYDRAULIC - UNIT SETTLING, ONE Center frame cylinder leaking internally on Repair center master cylinder WING RAISING side of unit that wing is raising HYDRAULIC - WING SETTLING Wing cylinder leaking Repair cylinder DISC GANG PLUGGING Scrapers set too far from disc blade Adjust scrapers to meet disc blade closer...

- Page 155 Document Control Revision Log: Date Form # Improvement(s): Description and Comments 02/05/2016 F-832-0116 Initial Release 11/09/2018 F-832-1118 Lubrication table update 05/27/2020 F-832-0520 Updated tire/wheel assembly in TOC, hydraulic reel manifolds. 03/23/2022 F-832-0322 Added QR decal, SIS 20mph to rear of machine, updated tire in specs. 07/18/2023 F-832-2307 Updated frame, lift, hitch and hydraulic pages, added new electrical drawing with...

- Page 156 Equipment from Landoll Company, LLC is built to exacting standards ensured by ISO 9001 registration at all Landoll manufacturing facilities. Model 6231 Disc Re-order Part Number F-832 LANDOLL COMPANY, LLC 1900 North Street Marysville, Kansas 66508 (785) 562-5381 800-428-5655 ~ WWW.LANDOLL.COM Copyright 2023.

Need help?

Do you have a question about the 6231 and is the answer not in the manual?

Questions and answers