Summary of Contents for Evolis Primacy 2 SE

- Page 1 Primacy 2 SE USER GUIDE Company © 2022. All rights reserved. User-Guide_MDD_ENG_20220829_A...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Copyright and Trademarks Warranty Environmental information recycling of end-of-life products icons About your new printer THE PRINTER 1. GETTiNG STArTED Unpacking Description of the printer and its functions installation Connecting the printer power Supply Cable installing the printer Driver Connecting to a Network ribbons Cards... - Page 3 TABLE OF CONTENTS 4. ADVANCED FEATUrES Available options Duplex printing LCD Touchscreen Card Lamination Module THE PRINTER Encoding Options Configuring a Wi-Fi Network Security Options Advanced Features Rewrite (Option) UV Effect With The Overlay panel Color Profile 5. MAiNTENANCE regular Cleaning printer Cleaning print head Cleaning Advanced Cleaning...

- Page 4 TABLE OF CONTENTS 6. hELp Diagnostic help printing a Technical Test Card printing a Graphical Test Card identifying installed Software Versions THE PRINTER Troubleshooting printing problems Jammed Cards replacing the print head Updating the firmware Updating the print driver 7. DECLArATiONS OF CONFOrMiTY General United-Kingdom...

-

Page 5: Copyright And Trademarks

COpYriGhT AND TrADEMArKS Company © 2022. All rights reserved. Users must observe the copyright regulations applicable in their country. This manual must not be photocopied, translated, reproduced or transmitted, in whole or in part, for any reason and by any electronic or mechanical means whatsoever without the express written consent of Company. All the information contained in this document is subject to change without prior notice. -

Page 6: About Your New Printer

This printer uses consumables and accessories available from Company. Certifications and declarations of conformity: CE, UKCA, iCES, VCCi, BiS, CCC, KC, EAC, rOhS, FCC (Evolis contact: Evolis, Rising Sun Mills, 188 Valley St., Suite 421, RI 02909 Providence, evolisnortham@evolis.com) THE PRINTER Icons on the printer label: Evaluation for apparatus only based on altitude not exceeding 2000m, therefore it’s the only operating condition applied for the... -

Page 7: Getting Started Unpacking

1. GETTiNG STArTED UNpACKiNG Your printer is supplied with several accessories that we ask you to look at closely. This list may vary depending on your location. THE PRINTER The printer is shipped in special packaging designed to prevent any damage in transit. if you notice any visible damage, do not hesitate to contact the shipper and immediately inform your Company dealer, who will tell you the procedure to follow. -

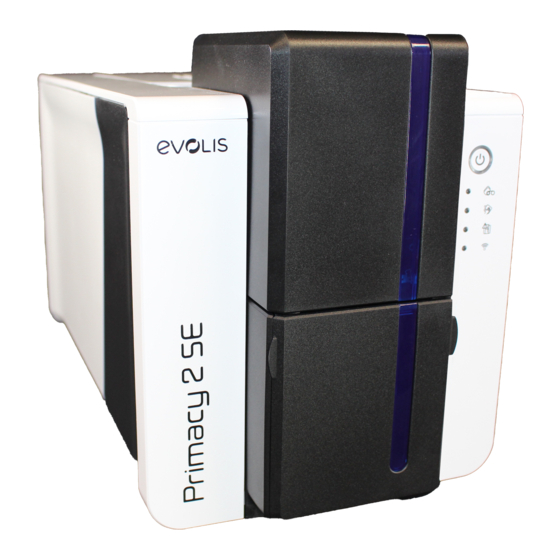

Page 8: Description Of The Printer And Its Functions

DESCripTiON OF ThE priNTEr AND iTS FUNCTiONS Access to the side panels of the machine and the option module fitting/removal areas is restricted to your retailer/installer or to experienced users. Always disconnect the machine from the power supply (unplugged) before performing work on it. if the printer is equipped with an LCD screen, refer to the corresponding user guide for more information. - Page 9 protective cover THE PRINTER F. Place for reject box (See "Managing the rear output hopper", page 16) G. Location for security locking (option) h. power cable socket i. Ethernet connector J. USB socket (type A) K. USB socket (type B) L.

- Page 10 THE PRINTER p. printer serial number label Q. Dust filter r. Location for double-sided printing activation key (option) S. Side panel opening mechanism...

-

Page 11: Connecting The Printer Power Supply Cable

iNSTALLATiON Connecting the printer power Supply Cable The printer must be connected to a properly protected and earthed electrical installation. Fi: Laite on liitettävä suojamaadoitus koskettimilla varustettuun pistorasiaan. THE PRINTER NO: Apparatet må tilkoples jordet stikkontakt. SE: Apparaten skall anslutas till jordat uttag. DK: printeren skal tilsluttes til en korrekt beskyttet og jordforbundet el-installtion. -

Page 12: Installing The Printer Driver

installing the printer Driver Do not connect the USB data cable before the installation of the printer driver is complete. Follow the instructions of the wizard carefully. the Card printer premium Suite is an all-in-one driver software solution, which enhances the user experience by making interactions between printer and computer more intuitive. -

Page 13: Connecting To A Network

Connecting to a Network Changing the printer’s basic settings without prior knowledge of the layout of the LAN in question or without genuine technical knowledge may result in a malfunction of the printer, and may even extend to more widespread failure of all or part of the LAN. Contact your System and Network Administrator before connecting to or changing the settings for your local area network. -

Page 14: Ribbons

ribbons The use of recommended ribbons optimizes your printer’s operation and avoid causing damage to it. The use of ribbons from other suppliers may damage the printer and voids the manufacturer’s warranty for the printer. For optimum print quality, it is recommended to clean the printer is fully cleaned every time the ribbon is changed. See "printer Cleaning", page 46. Fitting the ribbon THE PRINTER The printer automatically recognizes the ribbon inserted. -

Page 15: Cards

Cards Inserting Cards For optimum quality, the cards used must be ISO 7810 certified. NOTE Use only the card types recommended by Company. Do not touch the printable surface of the cards to preserve print quality. THE PRINTER Do not use cards that are damaged, folded, embossed or dropped on the floor. Keep your cards protected from dust. -

Page 16: Managing The Rear Output Hopper

Adjusting Card Thickness The printer is equipped with a manual card thickness adjustment mechanism which can be reached through the card feeder when open. The printer accepts cards between 0.25mm and 1.25mm thick (10 to 50mil). The factory setting is 0.76mm. THE PRINTER Open the card feeder and remove cards if Adjust the thickness of the cards used by Close the feeder... -

Page 17: Managing Print Settings

2. MANAGiNG priNT SETTiNGS the Card Printer Premium Suite enables changes of specific predefined settings through its user-friendly interface on Windows platforms. Contact your Company dealer for advice and assistance before making any change of setting. NOTE THE PRINTER To access this application: Double-click on the Card printer premium Suite shortcut or, from the Start button on the bottom left of your screen in the Windows task bar, select All programs >... -

Page 18: Printing And Interacting With The Printer

3. priNTiNG AND iNTErACTiNG WiTh ThE priNTEr priNTiNG A CArD A large number of applications allow documents to be printed (for example MS Word, MS Access, MS Excel, MS PowerPoint). On Microsoft Word ® THE PRINTER After having set the printer as the default: •... -

Page 19: Using The Control Panels

USiNG ThE CONTrOL pANELS LED Control panel push button Cards and ribbon THE PRINTER FLAShiNG Cleaning printer STEADY LiGhT Wi-Fi PRINTER READY PROCESSING • The printer is ready to receive data. • The printer is receiving data. RIBBON CARDS • No ribbon in the printer. •... - Page 20 REGULAR CLEANING CLEANING (after 1,000 cards have been inserted) (after 1,200 cards have been inserted) • The printer must be cleaned. • The printer must be cleaned to avoid the risk of the warranty being voided. (See "Regular Cleaning", page 45) ADVANCED CLEANING •...

-

Page 21: Lcd Touchscreen

LCD Touchscreen Permanent Status of Consumables and Cleaning THE PRINTER Lamination film ribbon Cards Cleaning Wi-Fi Color status The ribbon, cards, and cleaning statuses are always displayed in different colors to indicate the printer status: • Green: ready/OK for printing •... -

Page 22: Pop-Ups

pop-ups the Card Printer Premium Suite offers a service allowing the printer to communicate with the user through notifications. There are several types of notifications: • Messages about the maintenance of the printer. • Messages and alerts associated with the ribbons, their compatibility with your printer or the nature of your print requests. •... -

Page 23: Advanced Features Available Options

4. ADVAnCeD FeATUreS AVAiLABLe OpTiOnS Options can be factory-installed or provided separately. NOTE When options are provided separately, the shipping kit contains all the installation information. THE PRINTER The following options are compatible with this printer: • Double-sided printing (Duplex activation key) •... -

Page 24: Duplex Printing

Duplex printing Activation Key A wizard is available to activate duplex printing in the Card Printer Premium Suite > Assistance & Maintenance > Installable options. NOTE To obtain the activation key for that upgrade, contact your Company dealer. THE PRINTER Turn the printer on insert the key as shown The Push button flashes until the end of... -

Page 25: Lcd Touchscreen

Double-Side Printing With a Simplex Printer in case the double-side printing feature is not activated on the printer, proceed manually as follows: THE PRINTER LCD Touchscreen Unplug the printer before performing the installation. Open the printer cover, remove the ribbon Disconnect the panel cable. - Page 26 THE PRINTER Unclip the LeD panel. pivot the LeD panel downward. remove the LeD panel. CLIC Clip the LCD panel in the slot on the right A click sound confirms that the LCD panel is in Close the printer side, put the ribbon back in of the output hopper.

-

Page 27: Card Lamination Module

Card Lamination Module Access to the side panels of the machine and the option module fitting/removal areas is restricted to your retailer/installer or to experienced users. Always disconnect the machine from the power supply (unplugged) before performing any work on it. Description of the Card Lamination Module THE PRINTER i. - Page 28 THE PRINTER e. Location of the reject box F. Location for security locking G. platform for lamination module installation h. heating head i. Axles J. Jam-clearing wheel K. Card leveler L. Dust filter M. power cable socket n. Serial number label...

- Page 29 Installation of the Card Lamination Module Install the printer and the Card Lamination Module on a flat surface. To save energy, the printer and the Card Lamination Module automatically switch to standby mode after 10 minutes of inactivity. NOTE They switch to hibernation mode after 30 minutes in standby mode. THE PRINTER The standby settings can be configured in the Card Printer Premium Suite.

- Page 30 Once the printer and Card Lamination Module are connected, plug the lamination module in an earthed power socket plug the printer in an earthed power socket Connect the printer USB cable to the computer The system is powered on: the control panel lights up. The machine is working properly. Make sure the card thickness gauge is well adjusted on the printer.

- Page 31 THE PRINTER Open the door of the lamination module. Depending on the type of card and film Tighten the two wheels and close the door used, place the block support on position A of the lamination module. Loosen the two wheels as shown. or B (see the table below).

- Page 32 Interacting With the Card Lamination Module Although the lamination module was designed to operate independently and keep user involvement to a minimum, it may prove useful to be aware of the main warning messages. LEGEND THE PRINTER Control button Cards and ribbon Cards and film printing module Lamination module...

- Page 33 RIBBON PRINTER COVER OPEN • no ribbon in the printer. • The printer cover is open. • end of ribbon. Close the cover again. The printer restarts. • The ribbon is not correctly fitted. MECHANICAL ERROR • The ribbon is torn. •...

- Page 34 WAITING FOR CARD INSERTION OR REMOVAL COOLING MODE • The printer is waiting for a card to be inserted • The cooling system has been activated. or removed. The printer pauses for a few seconds and restarts once it Insert a card or remove the card from the is back at its normal operating temperature.

-

Page 35: Encoding Options

encoding Options it is possible to install up to three types of encoder in the printer (magnetic stripe, contact and contactless smartcards) on your premises. The encoders can be factory mounted or installed on-site by your Company dealer. NOTE Magnetic Stripe Encoding THE PRINTER Use only magnetic stripe cards that comply with iSO 7810 and iSO 7811 standards. - Page 36 Cleaning the Magnetic Encoder The magnetic encoder head requires regular maintenance in order to ensure the integrity of the data encoded onto cards. Cleaning of the magnetic encoder is performed when the printer runs an advanced cleaning sequence with T-cards. repeatedly running the cleaning card through the printer cleans the card feed rollers, the cleaning rollers, the print head and the magnetic encoder read-write head.

- Page 37 DB-9 connector pins Smartcard contact points C1 (V c.c.) C2 (reset) C3 (clock) C4 (reserved) THE PRINTER C5 (ground) C6 (Vpp) C7 (I/O) C8 (reserved) Card present signal Contactless Smartcard Encoding Company printers may be equipped with an encoding device for contactless smartcards (RFID). This consists of an encoding module and a built-in antenna. A module such as this must be installed by a specialist.

-

Page 38: Configuring A Wi-Fi Network

Computer Connection Contact your Company dealer for more information on programming a smartcard and configuration of the card present signal. NOTE A smartcard can be encoded with the Cardpresso software, the printer SDK or the SDK of the encoder. If your encoder is supplied with an USB interface, it will either be connected to the printer’s internal USB Hub, or equipped with a USB cable to connect to your computer directly. -

Page 39: Advanced Features

ADVAnCeD FeATUreS rewrite (Option) The feature is manageable from the Card printer premium Suite. Activate Display advanced settings in the three dots menu. NOTE rewritable cards can be blank or pre-printed. THE PRINTER The rewrite feature enables to erase and print, on rewritable cards only. Thanks to the inner color layer of the rewritable card, there is no need to use the ribbon for the rewrite feature. -

Page 40: Color Profile

UV effect bitmap file rendering on the card. THE PRINTER Overlay Settings Overlay settings can be adjusted in the Card printer premium Suite. The overlay can be: • Applied on the whole surface of the card • Applied only on some areas of the card •... -

Page 41: Maintenance

5. MAinTenAnCe Comply with the instructions given below to ensure a good functioning of the printer. The manufacturer’s warranty is subject to a strict compliance with the routine servicing and maintenance instructions, and in particular the printer cleaning cycles. Any failure to follow the maintenance and servicing procedures described in this section voids the print head warranty. THE PRINTER Company declines any liability where there has been a failure to perform required maintenance on the printer. -

Page 42: Regular Cleaning

reGULAr CLeAninG recommended cleaning cycle: whenever the ribbon is changed. NOTE Mandatory cleaning cycle: when the cleaning warning is triggered. Servicing accessory: Adhesive cleaning card and cleaning swab impregnated with isopropyl alcohol. When the cleaning cycle is over, wait 2 minutes before using the printer to let the isopropyl alcohol evaporate. THE PRINTER Cleaning cycles can also be launched from the Card printer premium Suite by clicking on the Cleaning icon on the home page. -

Page 43: Printer Cleaning

printer Cleaning When a YMCKOO ribbon is used, in addition to the regular cleaning cycle, it is recommended to use a T-card every 1000 cards. NOTE Open the printer cover, remove the ribbon and close the cover. Open the card feeder and remove the cards present in it. THE PRINTER Set the card thickness gauge to MAX. -

Page 44: Advanced Cleaning

ADVAnCeD CLeAninG When cleaning the print head: • Unplug the printer from its power supply. • Avoid any contact between the print head and any metal or sharp objects. This could permanently damage the print head. • Avoid touching the print head directly with your fingers, as this could affect print quality or permanently damage the print head. THE PRINTER recommended cleaning cycle: every 5 regular cleaning cycles. -

Page 45: Dust Filter Cleaning

Dust filter cleaning The dust filter is located behind the print head fan. NOTE Open the printer cover and pull the dust filter upward using its groove to remove it from its compartment. Clean the filter by rubbing the wipe over both sides. THE PRINTER With its groove at the top and facing you, slide the dust filter back into its compartment until a click is heard. -

Page 46: Lamination Dust Filter Cleaning

Lamination Dust Filter Cleaning THE PRINTER Unplug the lamination module and disconnect it from the printer. Clean the filter by rubbing the wipe over both sides. The dust filter is located below the lamination unit. Remove the filter by pulling it and slide it out to release it fully. Put the filter back. -

Page 47: Help

6. heLp DiAGnOSTiC heLp printing a Technical Test Card THE PRINTER Technical test cards can be printed from the Card Printer Premium Suite (three-dot menu). NOTE Technical test cards can be printer from the LCD touchscreen. The technical test card must be printed when the machine is received to ensure your printer operates correctly. This card shows various items of technical information concerning the machine (serial number, firmware, cleaning operations, print head, etc.). -

Page 48: Troubleshooting

TrOUBLeShOOTinG printing problems Nothing prints Check the print driver THE PRINTER • Make sure that there is a print driver for your printer in the Windows configuration. • Make sure that the printer is selected as the default printer. Check the printer’s power supply •... - Page 49 Poor print quality Small blemishes on the card • The card surface may be dirty. • Check that your cards are perfectly clean. • Use new cards. • Cleaning roller or print head clogged. THE PRINTER • run a cleaning cycle. Horizontal white lines •...

- Page 50 Partial or incorrect printing We recommend buying cards from your Company dealer. NOTE Use of non-recommended cards may affect print quality and may damage the print head. Check the interface cable • if irregular characters are printed, make sure the USB cable supplied with the printer is being used. THE PRINTER •...

-

Page 51: Jammed Cards

Jammed Cards Do not turn your printer off, as this cancels pending print jobs in the printer’s memory. Freeing a Jammed Card THE PRINTER The mechanical error signal is On and printing is interrupted. Open the printer cover and remove the ribbon. press the power button to activate the card feed rollers. -

Page 52: Replacing The Print Head

replacing the print head The print head is a sensitive component of the printer. it determines the print quality. A regular cleaning and an environment free from dust or other particles ensure a lengthy useful life. See “print head Cleaning”, page 43. Before replacing the print head, contact your Company dealer. - Page 53 Step 2: Installing the new print head THE PRINTER Note the code (PKN number) on the white Insert the new print head vertically (white Connect the cable into its socket, making label of the print head. This code is needed connector upwards), raising it in the two sure it is the right way round.

-

Page 54: Updating The Firmware

Updating the firmware An update of the firmware that is not properly performed may result in a malfunctioning printer. Before updating the firmware, contact your Company dealer. Firmware updates are only required in case of an issue or a malfunction clearly identified by your Company dealer. Interrupting the transfer between computer and printer during the download phase (powering off the printer or computer, unplugging a cable) would make it impossible to restart the printer. -

Page 55: Declarations Of Conformity

EN50364: 2010 Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to this equipment not expressly approved by evolis may cause, harmful interference and void the FCC authorization to Article 3.1 b: (electromagnetic compatibility protection requirements) operate this equipment. -

Page 56: United-Kingdom

BS-EN50364:2010 Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to this equipment not expressly approved by evolis may cause, harmful interference and void the FCC authorization to Article 3.1 b: (electromagnetic compatibility protection requirements) operate this equipment.

Need help?

Do you have a question about the Primacy 2 SE and is the answer not in the manual?

Questions and answers