Summary of Contents for SEW-Eurodrive MOVIMOT DRN DSI Series

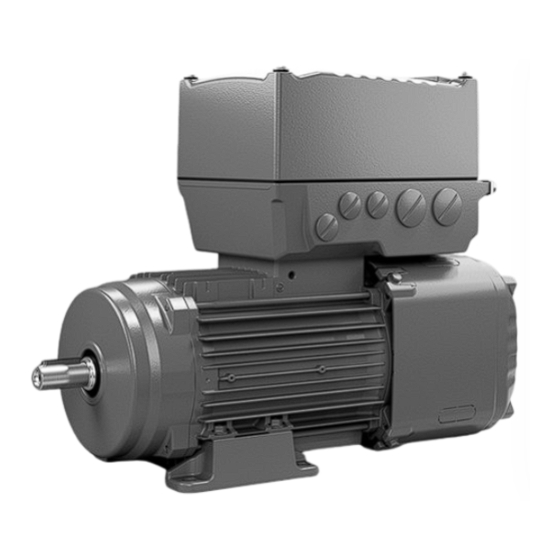

- Page 1 *27803899_0223* Drive Technology \ Drive Automation \ System Integration \ Services Operating Instructions Mechatronic Drive Unit ® MOVIMOT advanced ® DRN..DSI.., DR2C..DSI.. (EtherCAT /SBusPLUS) Edition 02/2023 27803899/EN...

- Page 2 SEW-EURODRIVE—Driving the world...

-

Page 3: Table Of Contents

Table of Contents Table of Contents General information........................ 5 Structure of the safety notes ................... 5 ® Safety notes for MOVIMOT advanced ................... 6 Target group ........................ 6 Designated use ....................... 6 Functional safety technology .................. 7 Transportation......................... 8 Creating a safe working environment ................ 9 Installation/assembly..................... 11 Protective separation .................... 11 Electrical installation ..................... 12... - Page 4 Table of Contents Failures of the mechanical drive ................... 71 Resetting fault messages.................... 73 Description of status and operating displays .............. 73 Device replacement ...................... 81 Shutdown ........................ 85 Waste disposal...................... 86 Inspection and maintenance .................... 87 Inspection and maintenance intervals................ 87 Inspection and maintenance work ................ 88 ®...

-

Page 5: General Information

General information Structure of the safety notes General information Structure of the safety notes 1.1.1 Meaning of signal words The following table shows the graduation and meaning of the signal words in the warnings: Signal word Meaning Consequences if not observed Imminent danger Death or severe injuries DANGER... -

Page 6: Safety Notes For Movimot Advanced

® Safety notes for MOVIMOT advanced Target group ® Safety notes for MOVIMOT advanced Target group Specialist for me- Any mechanical work may be performed only by adequately qualified specialists. Spe- chanical work cialists in the context of this documentation are persons who are familiar with the design, mechanical installation, troubleshooting, and maintenance of the product, and who possess the following qualifications: •... -

Page 7: Functional Safety Technology

® Safety notes for MOVIMOT advanced Functional safety technology 2.2.1 Hoist applications To avoid danger of fatal injury by falling hoists, observe the following points when us- ing the product in lifting applications: • The product is not designed for use as a safety device in lifting applications. •... -

Page 8: Transportation

® Safety notes for MOVIMOT advanced Transportation Transportation Inspect the shipment for damage as soon as you receive the delivery. Inform the ship- ping company immediately about any damage. If the product or the packaging is dam- aged, do not assemble, install, connect, or start up the product. If the packaging is damaged, the product itself may also be damaged. -

Page 9: Creating A Safe Working Environment

® Safety notes for MOVIMOT advanced Creating a safe working environment Creating a safe working environment Before you work on the product, ensure a safe working environment. Observe the fol- lowing basic safety note: 2.5.1 Performing work on the product safely Defective or dam- Never install defective or damaged products. - Page 10 ® Safety notes for MOVIMOT advanced Creating a safe working environment 2.5.2 Performing electrical work safely Observe the following information to perform electrical work safely: Electrical work may only be performed by a qualified electrician or an electronically in- structed person under the supervision of an electrician. Observe the 5 safety rules in the specified sequence when working on electrical com- ponents, unless there are important reasons to deviate from them (observe the specifi- cations of DIN EN 50110-1 (VDE 0115-1)):...

-

Page 11: Installation/Assembly

® Safety notes for MOVIMOT advanced Installation/assembly Installation/assembly Ensure that the product is installed and cooled in accordance with the regulations in the documentation. Protect the product from excessive mechanical strain. The product and its mounted components must not protrude into the path of persons or vehicles. Ensure that no components are deformed or no insulation spaces are modified, particularly during transportation. -

Page 12: Electrical Installation

® Safety notes for MOVIMOT advanced Electrical installation Electrical installation The preventive measures and protection devices must comply with the applicable reg- ulations (e.g. EN 60204-1 or EN 61800-5-1). 2.8.1 Stationary application The necessary preventive measure for the product is: Type of energy transfer Preventive measure Direct power supply Ground connection... -

Page 13: Device Structure

Device structure Example nameplate and type designation of the drive unit Device structure Example nameplate and type designation of the drive unit ® 3.1.1 MOVIMOT advanced nameplates ® The MOVIMOT advanced drive unit is always equipped with 2 nameplates: • Nameplate 1: Data of the drive unit. - Page 14 Device structure Example nameplate and type designation of the drive unit Nameplate 2 (..DR2C.. motor) The following image shows an example of a nameplate of the WA..DR2C.. gearmotor [1] [2] [3] [4] 76646 Bruchsal/Germany [15] WA20 DR2C71MSA4/TF 01.01234567890.0001.22 [14] 3~IEC60034 Inverter duty only VPWM 400 V Y...

- Page 15 Device structure Example nameplate and type designation of the drive unit Nameplate 2 (DRN.. motor) The following image shows an example of a nameplate of the DRN.. motor 76646 Bruchsal / Germany [17] DRN80M4/FF/DI/DFC/BW1 [16] 01.1774473607.0001.00 VPWM 3~IEC60034 Inverter duty [15] Hz 60 r/min 1751...

- Page 16 Device structure Example nameplate and type designation of the drive unit ® 3.1.2 Type designation of the MOVIMOT advanced DSI The following table shows the type designation of the drive unit. Gear unit series R = Primary gear unit Gear unit size DRN Product family DRN = Asynchronous motor of the DRN..

-

Page 17: Electronics

Device structure Electronics EI8Z Option EI8Z = Single-turn encoder with DDI connection AK8Z = Multi-turn absolute encoder with DDI connection IV = Plug connector TF = Motor protection D11 = Switch disconnector with feedback contact BW1 = Integrated BW 1 braking resistor BW2 = Integrated BW 2 braking resistor PE = Electronics pressure compensation fitting AL = Metal fan... - Page 18 Device structure Electronics 3.2.2 Connection configuration of the electronics cover The electronics covers are available in several connection configurations with M12 plug connectors. If the M12 plug connectors X4233_1 and X4233_2 for fieldbus connection are not available at the electronics cover, fieldbus connection is realized via the mini I/O plug connectors X42 and X43 of the connection unit.

-

Page 19: Example Nameplate And Type Designation Of Electronics

Device structure Example nameplate and type designation of electronics Example nameplate and type designation of electronics 3.3.1 Inner nameplate of DSI.. electronics cover The following figure gives an example of a nameplate of the electronics cover. For the structure of the type designation, refer to chapter "Type designation of the electronics cover". - Page 20 Device structure Example nameplate and type designation of electronics 3.3.3 Type designation DSI.. electronics cover The following table shows the type designation of the electronics cover: Product family DSI = Electronics cover Direct System bus Installation Type communication ® PLUS 1 = EtherCAT /SBus Connection configuration...

-

Page 21: Markings

Device structure Markings Application level 0 = Application level 0 (standard) ® 1 = Application level 1 (required for MOVIKIT Positioning Drive) 2 = Application level 2 – ® MOVIKIT version ® 000 = No MOVIKIT module loaded ex works (controller with freely configur- able process data interface) ®... - Page 22 Device structure Markings The UKCA mark states compliance with the following British directives • Low Voltage Directive S. I. 2016/1101 • EMC S. I. 2016/1091 • The Supply of Machinery (Safety) Regulations S. I. 2008/1597 • Directive S. I. 2012/3032 for limiting the use of certain hazardous sub- stances in electrical and electronic equipment •...

-

Page 23: Mechanical Installation

Mechanical installation Installation notes Mechanical installation Installation notes Perform the following steps before installation: WARNING! Electric shock caused by dangerous voltages in the connection box. Severe or fatal injuries. De-energize the device. Pay attention to the 5 safety rules in chapter “Carrying out electrical work safely”. -

Page 24: Installation Requirements

Mechanical installation Installation requirements Installation requirements Check that the following conditions have been met: • The information on the drive unit's nameplate must match the voltage supply sys- tem. • The drive unit is undamaged (no damage caused by shipping or storage). •... -

Page 25: Setting Up The Drive Unit

Mechanical installation Setting up the drive unit Setting up the drive unit 4.4.1 Notes Pay attention to the following information when installing the drive unit: • Perform the steps described in chapter "Installation notes" (→ 2 23) before in- stalling the drive unit: •... - Page 26 Mechanical installation Setting up the drive unit 4.4.3 Electronics cover Installing the electronics cover Install the electronics cover as follows: WARNING! Risk of burns due to hot surfaces. Severe injuries. Let the device cool sufficiently before touching it. 2. NOTICE! Loss of the guaranteed degree of protection. Possible damage to prop- erty.

- Page 27 Mechanical installation Setting up the drive unit Removing the electronics cover Remove the electronics cover as follows: WARNING! Risk of burns due to hot surfaces. Severe injuries. Let the device cool sufficiently before touching it. 2. Undo the screws of the electronics cover. 3.

- Page 28 Mechanical installation Setting up the drive unit 4.4.7 Pressure compensation on electronics (option /PE) Fitting the provided pressure compensation fitting (option/PE) For designs with an included pressure compensation fitting (option /PE), install the fit- ting depending on the mounting position used. The tightening torque is 4.0 Nm. Pressure compensation fitting installation positions The following table shows the installation location-dependent mounting positions of the pressure compensation fitting (option/PE):...

-

Page 29: Tightening Torques

Mechanical installation Tightening torques Tightening torques ® 4.5.1 Examples of MOVIMOT advanced The following figure shows an example of the installation of the threaded blanking plugs, cable glands and electronics cover. The number and position of threaded blank- ing plugs and cable bushings depend on the ordered variant. 38411578379 Tighten the screws in diametrically opposite sequence with a tightening torque of 6.0 Nm (for size 1) or 9.5 Nm (for size 2). - Page 30 Mechanical installation Tightening torques 4.5.2 Tightening torque for cable gland Tighten cable glands optionally included delivery SEW‑EURODRIVE with the following torques: Screw fitting Part Contents Size Outer di- Tighten- number (pieces) ameter of cable torque (mm) (Nm) EMC cable glands 18204783 10 M16 ×...

-

Page 31: Electrical Installation

Electrical installation Installation instructions Electrical installation Installation instructions 5.1.1 Permitted voltage systems Information on voltage supply sys- Information on permissibility tems TN and TT systems – voltage sys- Use is possible without restrictions. tems with directly grounded star point IT systems – voltage systems with Use is only permitted with electronics cover in non-grounded star point IT system design (...-513-..). - Page 32 Electrical installation Installation instructions 4. Screw the screw [1] with the insulating bushing [2] into the electronics cover. Tighten the screw with a tightening torque of 1.4 to 1.6 Nm. 9007233821379851 5. Place the electronics cover onto the connection box and fasten the electronics cover.

- Page 33 Electrical installation Installation instructions 5.1.3 Permitted cable cross section of terminals Line terminals X1 Observe the permitted cable cross sections for installation: Line terminals X1 Without conductor end With conductor end sleeve sleeves (with or without plastic collar) Connection cross sec- 0.5 mm –...

- Page 34 Electrical installation Installation instructions 5.1.4 Activating line terminals X1 Adhere to the following sequence when actuating the line terminals X1: 25649924107 5.1.5 Actuating line terminals X1a Adhere to the following sequence when actuating the line terminals X1a: 34682210443 5.1.6 Activating terminals X3 for the braking resistor Adhere to the following sequence when actuating the X3 terminals for the braking re- sistor: 25650172171...

- Page 35 Electrical installation Installation instructions 5.1.7 Activating control terminals X9 Observe the following sequence when actuating the X9 control terminals: 25657187979 5.1.8 Selecting the residual current device The inverter can cause a direct current in the protective earthing conductor. Proceed as follows when selecting the residual current device: 1.

- Page 36 Electrical installation Installation instructions 5.1.10 Notes on PE connection PE connection to devices with a lifting eye The handle is only used to transport the unit. The handle is not required for operation. 1. Remove the lifting eye. Store the lifting eye for future service work. WARNING! Electric shock due to faulty PE connection.

- Page 37 Electrical installation Installation instructions PE connection to devices with hoop guard The optional hoop guard is used to protect the connectors on the electronics cover. Do not remove the guard bracket. 1. Connect the PE cable to the guard bracket according to the following figure. 2.0 –...

- Page 38 Electrical installation Installation instructions Leakage currents Earth-leakage currents ≥ 3.5 mA can occur during normal operation. In order to fulfill EN 61800-5-1, observe the following notes: • The protective earth (PE) connection must meet the requirements for systems with high earth-leakage currents. • This usually means –...

- Page 39 Electrical installation Installation instructions • If safe protective separation is required, then this must be implemented outside the device at heights of 2000 m above sea level or greater (safe electrical separation as per EN 61800-5-1). • At installation altitudes between 2000 and 3800 m above sea level, measures must be taken that reduce the line side overvoltage from category III to category II for the entire system.

- Page 40 Electrical installation Installation instructions Branch Circuit Protection Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection must be provided in accordance with the National Electrical Code and any additional local codes. For maximum branch circuit protection see table below. SCCR: 65 kA /500 V 5 kA /500 V (devices with maintenance switch)

-

Page 41: Terminal Assignment Of Movimot Advanced Dsi

Electrical installation Terminal assignment of MOVIMOT® advanced DSI Terminal assignment of MOVIMOT® advanced ® Terminal assignment of MOVIMOT advanced DSI Attach units without a plug connector to the terminals as follows: WARNING! Electric shock caused by dangerous voltages in the connection box. - Page 42 Electrical installation Terminal assignment of MOVIMOT® advanced DSI 5.2.2 Connection box size 2 ® The following image shows the terminals of MOVIMOT advanced DSI, size 2: 11 12 13 14 21 22 23 24 11 12 13 34443089803 5.2.3 Assignment ® The following table shows the terminal assignment of MOVIMOT advanced DSI: Terminal...

- Page 43 Electrical installation Terminal assignment of MOVIMOT® advanced DSI Terminal Marking Function – – Protective earth connection – Braking resistor connection braking re- – Braking resistor connection sistor termi- nals yellow F_STO_P1 Input STO+ control termi- yellow F_STO_P1 Input STO+ nals (to loop through) –...

- Page 44 Electrical installation Terminal assignment of MOVIMOT® advanced DSI The following figure shows the factory-installed jumpers at the X9 terminals: 11 12 13 14 21 22 23 24 9007221264582283 These jumpers are not present in the following designs: • Designs with plug connectors with STO function •...

-

Page 45: Movimot Advanced Dsi Connection Diagram

Electrical installation MOVIMOT® advanced DSI connection diagram MOVIMOT® advanced connection diagram ® MOVIMOT advanced DSI connection diagram The following figure shows the connections of the device: F11/F12/F13 F11/F12/F13 ® MOVIMOT® advanced DSI Line terminals Engineering Line terminals interface Load disconnector ®... -

Page 46: Cable Routing And Cable Shielding

Electrical installation Cable routing and cable shielding The plug connector positions can be found in the "Plug connector positions, size 1" (→ 2 53), "Plug connector positions, size 2" (→ 2 56) chapters. Cable routing and cable shielding 5.4.1 Accessory bag with installation equipment (part number 18241395) INFORMATION For some installation variants, you do not need all the parts of the accessory kit. - Page 47 Electrical installation Cable routing and cable shielding 5.4.2 General installation options The following chapters show common examples and contain important notes on cable selection and cable routing. Assembly of installation materials The following image illustrates the assembly of the installation material: Size 2 Size 1 ®...

- Page 48 Electrical installation Cable routing and cable shielding 5.4.3 Installation with separately routed Ethernet cable Notes on cable routing and shielding – Recommended cable routing Note the following points for cable routing and cable shielding: • Cable selection – When selecting the cable, be mindful of the recommended connection cable in the product manual >...

- Page 49 Electrical installation Cable routing and cable shielding 5.4.4 Installation with PA hybrid cable Notes on cable routing and shielding – Recommended cable routing Note the following points for cable routing and cable shielding: • Cable selection – When selecting the cable, be mindful of the recommended connection cable in the product manual >...

- Page 50 Electrical installation Cable routing and cable shielding 5.4.5 Installation with PAC hybrid cable Notes on cable routing and shielding – Recommended cable routing Note the following points for cable routing and cable shielding: • Cable selection – When selecting the cable, be mindful of the recommended connection cable in the product manual >...

- Page 51 Electrical installation Cable routing and cable shielding 5.4.6 Installation with PSC hybrid cable Notes on cable routing and shielding – Recommended cable routing Note the following points for cable routing and cable shielding: • Cable selection – When selecting the cable, be mindful of the recommended connection cable in the product manual >...

-

Page 52: Emc Cable Glands

Electrical installation EMC cable glands EMC cable glands 5.5.1 Cable shielding (alternative) As an alternative to using shield clamps for shielded cables (e.g. control cables, STO cables, power cables), you can use EMC cable glands, which are available as an op- tion, to connect the shield. -

Page 53: Plug Connectors

Electrical installation Plug connectors Plug connectors ® 5.6.1 Plug connector positions of the MOVIMOT advanced DFC, DSI drive unit size 1 The following figure shows possible plug connector positions: X4142 X1523 X5505 X2313 X5504 X4142 X2313 X1523 X5504 X5505 X2242 X1206 X2326, X2327 X1121, X1216... - Page 54 Electrical installation Plug connectors Plug connectors Not together at a position with the Designation Coding ring/ Function Position plug connector: color • X1121 X1203_1 Black "AC 400 V connection" X, 2 or 3 • X1206 • X1207 • X1216 • X1217 •...

- Page 55 Electrical installation Plug connectors Plug connectors Not together at a position with the Designation Coding ring/ Function Position plug connector: color • X1203_2 X2328 "Hybrid connection PA (OUT)" X, 2 or 3 • X2242 AC 400 V and DC 24 V backup voltage • X2326 •...

- Page 56 Electrical installation Plug connectors ® 5.6.2 Plug connector positions of the MOVIMOT advanced DFC, DSI drive unit size 2 Cable entry M25 The following figure shows possible plug connector positions: X1207 X2326 X1121 X1206 X2327 X1203_2 X1203_1 X1216 X1217 X1206 X1121 X1203_1 X1203_2...

- Page 57 Electrical installation Plug connectors Plug connectors Not together at a position with the Designation Coding ring/ Function Position plug connector: color • X1121 X1203_1 Black "AC 400 V connection" X, 2 or 3 • X1206 • X1207 • X1216 • X1217 •...

- Page 58 Electrical installation Plug connectors Plug connectors Not together at a position with the Designation Coding ring/ Function Position plug connector: color • X1203_2 X2326 Gray/green "Hybrid connection PAC (OUT)" X, 2 or 3 • X2327 AC 400 V, DC 24 V backup voltage and Ethernet 1) Plug connector X1203_1 can also be ordered separately (i.e.

- Page 59 Electrical installation Plug connectors Plug connectors Not together at a position with the Designation Coding ring/ Function Position plug connector: color • X2313 X5504 Yellow "STO" X, 2 or 3 (3-wire connection) X5505 Yellow "STO" X, 2 or 3 • X1523 •...

- Page 60 Electrical installation Plug connectors 5.6.3 STO bridging plug (3-phase) WARNING Safe disconnection of the device is not possible when the jumper plug is used. Severe or fatal injuries. • Only use the jumper plug if the device is not used to fulfill any safety function. WARNING Disabling of the safety-related disconnection of further devices due to parasitic voltages when using an STO jumper plug.

- Page 61 Electrical installation Plug connectors 5.6.4 Plug connector positions at the DSI.. electronics cover The following figure shows an example of the plug connector positions: X5133_1 X5133_2 X5133_3 X4233_1 X4233_2 18014420217585035 Plug connectors Function X5133_1 "Digital inputs DI01 and DI02" X5133_2 "Digital inputs DI03 and DI04"...

-

Page 62: Pc Connection

Electrical installation PC connection 5.6.5 Plug connector positions of electronics cover DSI with safe digital inputs The following figure shows an example of the plug connector positions: X5133_1 X5133_2 X5133_3 X4233_1 X4233_2 X5601_1 X5601_2 X3301 36623553163 Plug connectors Function X5133_1 "Digital inputs DI01 and DI02"... -

Page 63: Startup

Startup Startup notes Startup Startup notes Perform the following steps before startup: WARNING! Electric shock caused by dangerous voltages in the connection box. Severe or fatal injuries. De-energize the device. Pay attention to the 5 safety rules in chapter “Carrying out electrical work safely”. -

Page 64: Startup Requirements

Startup Startup requirements ® ð Lock the function using the parameter Release brake/deactivate DynaStop with FCB01 – Enable = "0" (Path: Funktionen > Antriebsfunktionen > FCB01 Endstufensperre). [Functions > Drive functions > FCB01 Output stage inhibit] ® 3. In the MOVISUITE engineering software, configure the parameters according to the lifting application requirements and its safety assessment. -

Page 65: Dip Switches

Startup DIP switches DIP switches 6.3.1 Overview NOTICE Damage to the DIP switches caused by unsuitable tools. Damage to property. • Set the DIP switches only using suitable tools, such as a slotted screwdriver with a blade width of ≤ 3 mm. •... - Page 66 Startup DIP switches DIP switch S1 The following table shows the functions of DIP switch S1: DIP switch ® Binary coding EtherCAT device ID Bit 2 Bit 2 Bit 2 Bit 2 DIP switch S2 The following table shows the functions of DIP switch S2: DIP switch ®...

-

Page 67: Startup Procedure

Startup Startup procedure Startup procedure ® Start up the devices using the MOVISUITE Engineering software from SEW‑EURODRIVE. 25882306443 The startup procedure is divided into segments. The following steps show an example of the procedure when starting up a device. Drive train seg- ment Drive train Configuring drive trains. - Page 68 Startup Startup procedure PI configuration • Advanced PI configuration • FCB 05 Speed control Drive functions • FCB 06 Interpolated speed control • FCB 09 Positioning • FCB 10 Interpolated position control • FCB 12 Reference travel • FCB 01 Output stage inhibit Advanced drive functions •...

-

Page 69: Startup With Cbg22A On-Site Keypad

Startup Startup with CBG22A on-site keypad Startup with CBG22A on-site keypad You can intuitively perform startup using the CBG22A on-site keypad using the sym- bols and the functions on the color display. You can find more information in the product manual > chapter "Startup" > "Startup with CBG22A on-site keypad". -

Page 70: Operation

Operation Switch disconnector Operation Switch disconnector NOTICE Increased wear of the switch contacts. Destruction of the switch contacts. • Do not operate the switch disconnector under load. The switch disconnector of the device serves to interrupt the voltage supply of the electronics cover. -

Page 71: Service

Service Failures of the mechanical drive Service NOTICE Improper work on the drive units can result in damage. Damage to property. • Make sure that the drives from SEW‑EURODRIVE are repaired by qualified per- sonnel only. • Consult SEW‑EURODRIVE SERVICE. Failures of the mechanical drive Follow the information in the "DR..71-315, DRN63-315, DR2..56-80 AC motors"... - Page 72 Service Failures of the mechanical drive 8.1.2 Brake malfunctions The following table shows fault diagnostics options for malfunctions of the brake: Fault Possible cause Measure • Contact SEW‑EURODRIVE Brake does not re- Electronics cover defec- Service lease tive • Replace electronics cover Max.

-

Page 73: Resetting Fault Messages

Service Resetting fault messages Resetting fault messages WARNING Eliminating the cause of the problem or performing a reset may result in the drive re- starting automatically. Severe or fatal injuries. • Prevent unintended startup. Acknowledge fault message by: • Switch the supply system off and on again. •... - Page 74 Service Description of status and operating displays 8.3.2 General LEDs "F-ERR" LED The following table describes the display functions of the "F-ERR" LED: Meaning • Device off. ® • No MOVISAFE CSB51A safety option available. Flashing sequence Device identification for safety key ID query. Green Fault-free operation Steady light...

- Page 75 Service Description of status and operating displays "F-RUN" LED The following table describes the display functions of the "F-RUN" LED: Meaning • Device off. ® • No MOVISAFE CSB51A safety option available. Flashing sequence Device identification for safety key ID query. Green Device in operating state and parameter set approved.

- Page 76 Service Description of status and operating displays "DRIVE" status LED The following table describes the display functions of the "DRIVE" LED: Operating status/ Meaning Measure Fault Subfault code code – Not ready for operation Line voltage absent. Power on the line voltage.

- Page 77 Service Description of status and operating displays Operating status/ Meaning Measure Fault Subfault code code Green/red Ready for operation A displaying fault is present. Please consult product manual > Flashes with The output stage is enabled. "Fault table" chapter changing colors, The motor is in operation.

- Page 78 Service Description of status and operating displays Operating status/ Meaning Measure Fault Subfault code code 1, 2 Output stage monitoring fault Contact SEW‑EURODRIVE Continuous illu- Brake chopper fault Service. mination DC link fault 3, 4, 8 Control mode fault 2, 99 Data Flexibility fault 7, 8 Temperature monitoring fault...

- Page 79 Service Description of status and operating displays LEDs "L/A" IN The following table describes the display functions of the "L/A" IN LED: Meaning ® PLUS Green There is an Ethernet connection to the EtherCAT /SBus interface IN without bus activity. Illuminated ®...

- Page 80 Service Description of status and operating displays ® Plus 8.3.3 Bus-specific LEDs for EtherCAT /SBus "RUN" LED The following table describes the display functions of the "RUN" LED: Meaning "INIT" state The interface is in the "INIT" state. Green "PRE_OPERATIONAL" state Flashing Mailbox communication is possible.

-

Page 81: Device Replacement

Service Device replacement Device replacement 8.4.1 Information WARNING ® Removing the electronics cover will disable DynaStop Severe or fatal injuries. • If it is not permitted to deactivate the system, additional measures are required (e.g. mechanical stake-out) WARNING Electric shock caused by dangerous voltages in the connection box. Dangerous voltages can still be present for up to 5 minutes after disconnection from the power supply system. - Page 82 Service Device replacement 8.4.2 Replacing the electronics cover Replace the electronics cover as follows: 1. Observe the safety notes. 2. Loosen the screws and take off the electronics cover from the connection box. 3. Compare the data on the nameplate of the previous electronics cover with the data on the nameplate of the new electronics cover.

- Page 83 Service Device replacement 8.4.3 Replacing the memory module Replace the memory module as follows: 1. Observe the safety notes. 2. Loosen the screws and take off the electronics cover from the connection box. 3. Remove the memory module from the old electronics cover. 4.

- Page 84 Service Device replacement 8.4.4 Replacing the drive unit Replace the drive unit as follows: 1. Observe the safety notes. 2. Install the lifting eyes to the drive unit, see chapter "Service" > "Device replace- ment" > "Installing the lifting eyes" (→ 2 85). 3.

-

Page 85: Shutdown

Service Shutdown 8.4.5 Installing the lifting eye for motors without gear units Install the lifting eye as follows: 1. Remove the PE connection cable. 2. Install the lifting eye for transportation as depicted in the following image: 2.0 – 2.4 Nm 9007231640809611 Shutdown WARNING... - Page 86 Service Waste disposal Waste disposal Dispose of the product and all parts separately in accordance with their material struc- ture and the national regulations. Put the product through a recycling process or con- tact a specialist waste disposal company. If possible, divide the product into the follow- ing categories: •...

-

Page 87: Inspection And Maintenance

Inspection and maintenance Inspection and maintenance intervals Inspection and maintenance Inspection and maintenance intervals The following table shows the inspection intervals: Time interval What to do? Who is permitted to perform the work? When the electronics When the electronics cover is Specialists at cus- cover is opened after an opened after an operating period of... -

Page 88: Inspection And Maintenance Work

Inspection and maintenance Inspection and maintenance work Inspection and maintenance work 9.2.1 Preliminary work regarding inspection and maintenance Please carry out the following steps before all inspection and maintenance work: WARNING! Electric shock caused by dangerous voltages in the connection box. - Page 89 Inspection and maintenance Inspection and maintenance work Work steps with electronics cover size 1 NOTICE Loss of the guaranteed degree of protection. Damage to property. • When the cover is removed from the connection box, the cover and the wiring space must be protected from humidity, dust or foreign particles.

- Page 90 Inspection and maintenance Inspection and maintenance work 3. NOTICE! Loss of the guaranteed degree of protection. Damage to property. Make sure not to damage the sealing surfaces when removing the gasket. Loosen the used gasket by levering it off the retaining cams. ð...

- Page 91 Inspection and maintenance Inspection and maintenance work CAUTION! Risk of injury due to sharp edges. Cutting injuries. Use protective gloves when cleaning. Ensure that work is carried out by trained specialists only. Carefully clean the sealing surfaces of the connection box and electronics cover. 9007228456900619 6.

- Page 92 Inspection and maintenance Inspection and maintenance work 7. Check the installation and startup of the unit using the corresponding, applicable operating instructions. 8. Place the electronics cover back onto the connection box and secure it. ð Pay attention to the following procedure when screwing on the electronics cover: Insert/screw in the screws and tighten them in diametrically opposite se- quence step by step with a tightening torque of 6.0 Nm.

- Page 93 Inspection and maintenance Inspection and maintenance work Work steps with electronics cover size 2 NOTICE Loss of the guaranteed degree of protection. Damage to property. • When the cover is removed from the connection box, the cover and the wiring space must be protected from humidity, dust or foreign particles.

- Page 94 Inspection and maintenance Inspection and maintenance work 3. NOTICE! Loss of the guaranteed degree of protection. Damage to property. Make sure not to damage the sealing surfaces when removing the gasket. Loosen the used gasket by levering it off the retaining cams. ð...

- Page 95 Inspection and maintenance Inspection and maintenance work CAUTION! Risk of injury due to sharp edges. Cutting injuries. Use protective gloves when cleaning. Ensure that work is carried out by trained specialists only. Carefully clean the sealing surfaces of the connection box and electronics cover. 34406743819 6.

- Page 96 Inspection and maintenance Inspection and maintenance work 7. Check the installation and startup of the unit using the corresponding, applicable operating instructions. 8. Place the electronics cover back onto the connection box and secure it. ð Pay attention to the following procedure when screwing on the electronics cover: Insert/screw in the screws and tighten them in diametrically opposite se- quence step by step with a tightening torque of 9.5 Nm.

- Page 100 SEW-EURODRIVE—Driving the world SEW-EURODRIVE GmbH & Co KG Ernst-Blickle-Str. 42 76646 BRUCHSAL GERMANY Tel. +49 7251 75-0 Fax +49 7251 75-1970 sew@sew-eurodrive.com www.sew-eurodrive.com...

Need help?

Do you have a question about the MOVIMOT DRN DSI Series and is the answer not in the manual?

Questions and answers