VAT 590 Series Installation, Operating, & Maintenance Instructions

Variable leak valve with manual actuator

Hide thumbs

Also See for 590 Series:

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for VAT 590 Series

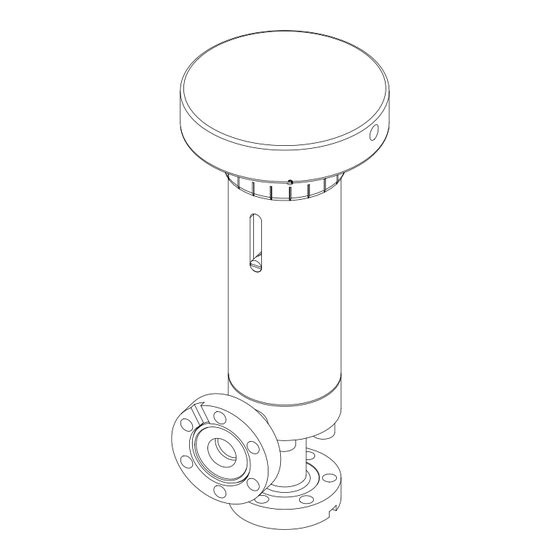

- Page 1 Installation, Operating & Maintenance Instructions Variable leak valve with manual actuator Series 590 DN 16 mm (I. D. ⅝") This manual is valid for the following product ordering numbers: 59024- . E01 - ..Sample picture 299498EA Edition 2013-07-03...

- Page 2 VAT. Offenders are liable to pay damages. The original VAT firmware and updated state of the art versions of the VAT firmware are intended for use with VAT products. The VAT firmware contains a limited, time unlimited user license.

-

Page 3: Table Of Contents

Series 590 Contents Description of product ................ 4 Identification of product ..................4 Use of product ..................... 4 Related documents ..................... 4 Important information ..................4 Technical data ..................... 4 Safety ....................5 Compulsory reading material ................5 Danger levels ...................... 5 Personnel qualifications .................. -

Page 4: Description Of Product

The fabrication number is lasered directly on the product. Fabrication number Use of product Use product for clean and dry vacuum applications only. Other applications are only allowed with the written permission of VAT. Suitable for XHV applications. Related documents Product data sheet Dimensional drawing... -

Page 5: Safety

Series 590 SAFETY Safety Compulsory reading material Read this chapter prior to performing any work with or on the product. It contains important information that is significant for your own personal safety. This chapter must have been read and understood by all persons who perform any kind of work with or on the product during any stage of its serviceable life. -

Page 6: Personnel Qualifications

SAFETY Series 590 Personnel qualifications WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. 6/23 Edition 2013-07-03 299498EA... -

Page 7: Design And Function

Series 590 DESIGN AND FUNCTION Design and Function Design With handwheel: Type 590 … - . E01 - …. Handwheel Valve body Connecting flange Sealing surface Position indication side scale and scale ring Figure 3-1 299498EA Edition 2013-07-03 7/23... -

Page 8: Function

DESIGN AND FUNCTION Series 590 Function Valve is closed and opened manually. Figure 3-2 Diaphragm Scale Pressure spring Rotary flange / seat port Spindle Rotary flange / side port Handwheel Valve seat side Further function definitions see chapter «5.1 Normal operation». 8/23 Edition 2013-07-03 299498EA... -

Page 9: Installation

Make sure that the supplied products are in accordance with your order. Inspect the quality of the supplied products visually. If it does not meet your requirements, please contact VAT immediately. Store the original packaging material. It may be useful if products must be returned to VAT. -

Page 10: Installation Into The System

INSTALLATION Series 590 Installation into the system NOTICE Contamination Product may get contaminated. Always wear cleanroom gloves when handling the product. NOTICE Force effect from other components of the system Valve body may get deformed and/or malfunctions may occur. – Do not use valve to support other components. –... - Page 11 Series 590 INSTALLATION Remove plastic bag. Remove protective covers (1); see «Figure 4-1». 1 Protective covers Figure 4-1 Store protective covers. They may be useful when valve needs to be repacked. Clean sealing surfaces; see «Figure 3-1» on page 7, with cleanroom wiper soaked with pure alcohol (Isopropanol).

-

Page 12: Mounting To The System

INSTALLATION Series 590 4.2.2 Mounting to the system Mount valve to your system by using appropriate flange screws. Mount screws evenly in crosswise order until the seal touches the sealing surface. Tighten all screws with the torques appropriate for the property classes of the screws. 1 Flange A (valve seat side) 2 Flange B 3 Screw holes... -

Page 13: Operation

Series 590 OPERATION Operation WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. Normal operation Valve is closed and opened manually. Closing: turn handwheel clockwise to the zero on the scale. The valve is completely closed when the stop is reached. -

Page 14: Operation Under Increased Temperature

30 °C. Bake-out Bake-out temperature see product data sheet. Trouble shooting Failure Check Action Leak at gate Condition of gate Please contact VAT www.vatvalve.com seal Condition of Please contact VAT www.vatvalve.com valve gate Leak at body Condition of bonnet seal and Please contact VAT www.vatvalve.com... -

Page 15: Maintenance

When the valve has reached the specified lifetime; see product data sheet, we recommend to have it serviced by VAT. Please contact your nearest VAT service center to get recommendations and an offer. You will find the addresses on our website www.vatvalve.com. -

Page 16: Repairs

REPAIRS Series 590 Repairs WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. WARNING Danger of injury in case of insufficient skills Inappropriate handling may cause serious injury or property damage. Make sure that the valve does not topple or fall down while removing the protective covers from the flanges. -

Page 17: Replacement Of Diaphragm

In case of a seat seal leak caused by environmental influences and no visible damage of the sealing surface at the seat, the diaphragm seal can be replaced. VAT offers a range of components; see «Table 11-1 » on page 23. The seal exchange can be carried out by the user. - Page 18 REPAIRS Series 590 Required material: Diaphragm Ordering information: See chapter «11 Spare parts» on page 23 and «Figure 7-1» on page 17. NOTICE Inappropriate mounting position of valve Maintenance may be troublesome and parts may drop down. Ideally dismount valve from the system and put it on a clean workbench with the actuator upwards.

-

Page 19: Dismounting And Storage

Series 590 DISMOUNTING AND STORAGE Dismounting and Storage WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. NOTICE Contamination Product may get contaminated. Always wear cleanroom gloves when handling the product. Dismounting Dismount valve according chapter «4 Installation», however in reverse order. -

Page 20: Packaging And Transport

Always use the original packaging material and handle product with care. When returning products to VAT, please fill out the VAT form «Declaration of Chemical Contamination» and send it to VAT in advance. The form can be downloaded from our website www.vatvalve.com. -

Page 21: Packaging

PACKAGING AND TRANSPORT Packaging Cover all valve openings with protective covers; see chapter «4.2.1 Preparation for installation». Pack valve appropriately, by using the original packaging material. VAT disclaims any liability for damages resulting from inappropriate packaging. Transport NOTICE Inappropriate packaging Product may get damaged if inappropriate packaging material is used. -

Page 22: Disposal

DISPOSAL Series 590 Disposal WARNING Harmful substances Environmental pollution. Discard products and parts according to the local regulations. 22/23 Edition 2013-07-03 299498EA... -

Page 23: Spare Parts

Please contact one of our service centers and specify the fabrication number of the product; see chapter «1.1 Identification of product». You will find the addresses on our website www.vatvalve.com. Parts may only be replaced by the VAT service staff. Quantity Repair procedure...

Need help?

Do you have a question about the 590 Series and is the answer not in the manual?

Questions and answers