Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Euroflex MB-flex O aluminum

- Page 1 Quick installation guide Conveyor system MB-flex O aluminium...

- Page 2 Conveyor system MB-flex O aluminium Publisher euroflex GmbH Hohe-Flum-Strasse 62 79650 Schopfheim Germany Tel: + 49 (0) 07622 68 453-30 Fax: + 49 (0) 07622 68 453-01 E-Mail: info@euroflexgmbh.de Internet: www.euroflexgmbh.de The document is protected by copyright. All rights are strictly reserved. Copying,...

-

Page 3: Table Of Contents

Content Content Reader information ....................4 Target group ........................... 4 Customer service ........................4 Copyright protection ........................ 4 Safety ........................5 Owner............................5 Obligations of the owner ......................5 Instruction of the personnel ....................6 Qualification requirements ...................... 6 2.4.1 Specially trained personnel .................. -

Page 4: Reader Information

Our customer service department will be happy to advise you on technical matters. Information on ordering spare parts can be found in the section “Spare parts and their purchase” (Page 8). Customer service Designation Specification Company euroflex GmbH Street no. Hohe-Flum-Straße 62 Postcode, place 79650 Schopfheim Country... -

Page 5: Safety

Safety Safety This chapter provides information on the safe operation of the conveyor system: ▪ Owner (Page 5) ▪ Obligations of the owner (Page 5) ▪ Instruction of the personnel (Page 6) ▪ Qualification requirements (Page 6) ▪ Personal protective equipment (Page 7) ▪... -

Page 6: Instruction Of The Personnel

Safety Instruction of the personnel Each person assigned to carry out work must, before commencing, receive instruction from the owner regarding their delegated activities and potential dangers during work. For instruction, observe the following: ▪ Repeat instruction at regular intervals. ▪... -

Page 7: Electricians

Safety 2.4.5 Electricians Electricians are persons who, as a result of their technical training, knowledge, experience and awareness of pertinent norms and provisions, are capable of correctly carrying out work on electrical systems. Electricians are capable of recognizing potential dangers independently, and consequently avoiding personal injury and property damage caused by electrical currents. -

Page 8: Spare Parts And Their Purchase

Safety Spare parts and their purchase Spare parts and accessories can be ordered directly from the manufacturer via the following contact. Spare parts: Contact Designation Specification Company euroflex GmbH Street no. Hohe-Flum-Straße 62 Postcode, place 79650 Schopfheim Country Germany Telephone... -

Page 9: Assembly

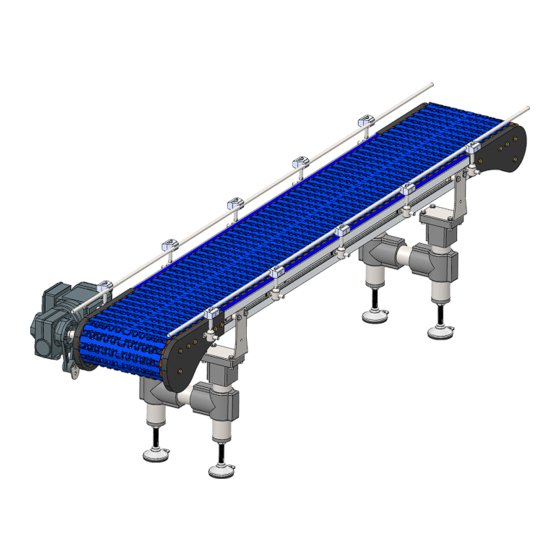

Assembly Assembly This chapter provides information on the assembly of the conveyor system: ▪ Overview of MB-flex O aluminium (Page 9) ▪ Assembly the slide rails and slide profiles on the modular belt conveyor (Page 11) ▪ Assembling the modular chain belt (Page 16) Overview of MB-flex O aluminium Fig. - Page 10 Assembly Information Data Designation or value Personnel Maintenance personnel Personal protective equipment Protective work clothing Protective gloves Safety shoes Tools, aids Mitre cutter Steel pin (Ø 4 mm x approx. 200 mm long) Hammer Carpet knife Open-end wrench Hexagon socket screw key Assembly tool Drill and drill bit Ø...

-

Page 11: Assembly The Slide Rails And Slide Profiles On The Modular Belt Conveyor

Assembly Assembly the slide rails and slide profiles on the modular belt conveyor Observe the following during assembly: ▪ Install the slide rails in a number of continuous lengths where possible. ▪ In areas with high loads, the slide rails must be separated to enable expansion. Separation is required at bending wheels, deflection units and drive units. - Page 12 Assembly 4. Clip slide rail to the chassis profile with the nose on the underside (see Figure). 5. Clip slide rail to the chassis profile in the running direction with the assembly tool. ǃ Avoid the development of “waves” in the slide rail by clipping it on completely (audibly).

- Page 13 Assembly 15. Carefully knock in M4 x 8 plastic screw. 16. Cut the screw head carefully and flush. 17. Rework possible supernatants with the file. 18. Mount the slide rail at the end of the profile (seen in the running direction) before intermediate elements or following elements with a spacing of approx.

-

Page 14: Assembly The Slide Profiles On The Modular Belt Conveyor

Assembly 3.2.2 Assembly the slide profiles on the modular belt conveyor 1. Press the slide profiles (1) onto the holding profile. 2. Check the slide profiles for damage. ǃ Only use undamaged slide profiles. 3. Chamfer the slide profiles at the start (viewed in running direction). - Page 15 Assembly 11. Each slide profile piece must be fixed at the beginning (viewed in running direction). 12. Using the drill (drill bit ø 3.4 mm), drill a hole in the slide profile and holding profile. 13. After drilling, deburr and remove all chips. 14.

-

Page 16: Assembling The Modular Chain Belt

Assembly Assembling the modular chain belt Observe the following during assembly: ▪ Select the chain length so that the contraction of the chain ends is done with little effort. ǃ With a tight chain, rattling will be heard at the drive station. 1. -

Page 17: Cleaning

Cleaning Cleaning This chapter provides information on the execution of the operating mode Cleaning: ▪ Personnel and Protective equipment (Page 17) ▪ Selection of the cleaning agent (Page 17) ▪ Preparation (Page 18) ▪ Execution (Page 18) ATTENTION Warning of material damage due to improper cleaning! Improper cleaning leads to damage to the system or its surroundings. -

Page 18: Preparation

Cleaning Preparation Carry out the following work steps: 1. Switch off the conveyor system. ▼ No voltage is present at the conveyor system. 2. Close the pneumatic supply at the main valve and secure it with a personal padlock. 3. Secure the main switch on the control cabinet with a personal padlock. The conveyor system is prepared for cleaning. - Page 19 Take care not to apply too much disinfectant so that the conveyor does not need to be rinsed. ǃ Remove excess disinfectant via the drain. ✓ Ready. Contact euroflex GmbH for instructions on cleaning any further contaminants. Quick installation guide_Conveyor system MB-flex O Al_20221114_EN.docx...

-

Page 20: Maintenance

Maintenance Maintenance This chapter provides information on the maintenance work to be carried out: ▪ Lubrication (Page 20) ▪ Maintenance plan (Page 21) ▪ Maintenance log (Page 23) ▪ Repair (Page 23) Lubrication Incorrect or negligent use of hazardous substances may lead to serious environmental pollution. Observe the following: ▪... -

Page 21: Maintenance Plan

Use of non-original spare parts can lead to defects in the conveyance goods, operational malfunctions, loss of safety functions and damage to or destruction of components. » Only replace components with original spare parts from euroflex GmbH. General Assembly and maintenance work... - Page 22 Maintenance Conveyor system Assembly and maintenance work Interval [Bh] Personnel Remove foreign bodies 8 (per shift) Operating personnel Clean conveyor system surface 8 (per shift) Operating personnel Check gear unit for leakage 8 (per shift) Maintenance personnel Inspect surface for damage Maintenance personnel Conveyor chain check for damage and elongation...

-

Page 23: Maintenance Log

Maintenance Electrical system Assembly and maintenance work Interval [Bh] Personnel Check electrical wiring for visible damage Electricians Electrical connections and distributors: Electricians Check terminal boxes for damage Maintenance log The required maintenance intervals are dependent on the intensity of use of the system at the owner's deployment site and the consequent signs of wear. -

Page 24: Conveyor Chain: Repair Or Adjust The Chain Tension

Maintenance 5.4.1 Conveyor chain: Repair or adjust the chain tension WARNING Danger to life due to moving machine parts! Danger of injury and pulling in due to too long chain sag! Risk of crushing and cutting! Moving machine parts can cause serious personal injury or death. »... - Page 25 Maintenance 5.4.1.1 Adjust modular belt chain Data Designation or value Personnel Maintenance personnel Personal protective equipment Protective work clothing Protective gloves Safety shoes Interval in each case after 50 OH, 250 OH, 500 OH, then check every 500 OH Replace after 4,000 OH Tools, aids Open-end wrench Hexagon socket screw key...

-

Page 26: Table Of Figures

Table of figures Table of figures Fig. 1: Overview of MB-flex O aluminium (example) ................9 Fig. 2: Assembly the slide rails and slide profiles on the modular belt conveyor ......11 Fig. 3: Assembly the slide rails on the modular belt conveyor ............13 Fig.

Need help?

Do you have a question about the MB-flex O aluminum and is the answer not in the manual?

Questions and answers