Summary of Contents for Emerson Rosemount Analytical Oxymitter 4000

- Page 1 Instruction Manual IB-106-340C Rev. 4.1 July 2004 OXYMITTER 4000 HAZARDOUS AREA OXYGEN TRANSMITTER http://www.processanalytic.com...

- Page 2 Model 275/375 may require modification. If a software modification is required, please contact your local Fisher-Rosemount Service Group or National Response Center at 1-800- 433-6076 or 1-888-433-6829. Emerson Process Management Rosemount Analytical Inc. Process Analytic Division 1201 N. Main St.

- Page 3 HIGHLIGHTS OF CHANGES Effective April, 2004 Rev. 4.0 Page Summary Cover Updated revision number and date. Deleted certification data. P-3 through P-14 Added foreign language versions of “Safety Instructions for the Wiring and Installation of this Apparatus”. Revised Warning. Revised para. 1-2a to include LOI and Model 375 communicator.

- Page 4 HIGHLIGHTS OF CHANGES (Continued) Effective April, 2004 Rev. 4.0 Page Summary Revised para. 3-3a to correct mA signal level values. Moved power up and remaining procedures to Section 5, Startup and Operation. 4-1 through 4-5 Added new Section 4 to discuss system configuration instructions for instruments with an LOI.

-

Page 5: Table Of Contents

CONFIGURATION OF HAZARDOUS AREA OXYMITTER 4000 WITH LOI ....4-1 General ..........................4-1 Logic I/O .......................... 4-4 Recommended Configuration..................4-5 STARTUP AND OPERATION OF HAZARDOUS AREA OXYMITTER 4000 WITH MEMBRANE KEYPAD ..................5-1 Power Up ......................... 5-1 Operation ......................... 5-2 Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 6 Calibration – Hazardous Area Oxymitter 4000 with LOI..........9-5 Hazardous Area Oxymitter 4000 Repair ................. 9-7 10-0 RETURN OF MATERIAL ....................10-1 11-0 REPLACEMENT PARTS ....................11-1 12-0 OPTIONAL ACCESSORIES..................12-1 INDEX ............................13-1 Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 7 Fault 4, A/D Comm Error ..................8-8 Figure 8-7. Fault 5, Open Heater ..................... 8-9 Figure 8-8. Fault 6, High High Heater Temp ................8-10 Figure 8-9. Fault 7, High Case Temp..................8-11 Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 8 Diagnostic/Unit Alarm Fault Definitions – Membrane Keypad Only ...... 8-4 Table 8-2. Diagnostic/Unit Alarm Fault Definitions – LOI ............8-4 Table 11-1. Replacement Parts for Probe ................11-1 Table 11-2. Replacement Parts for Electronics ..............11-4 Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 9: Preface

The number in the lower right corner of each illustration in this publication is a manual illus- tration number. It is not a part number, and is not related to the illustration in any technical manner. Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 10: Safety Instructions

9. Where equipment or covers are marked with the symbol to the right, refer to the Operator Manual for instructions. 10. All graphical symbols used in this product are from one or more of the fol- lowing standards: EN61010-1, IEC417, and ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 11 Waar toestellen of deksels aangegeven staan met het symbool gelieve het handboek te raadplegen. 10. Alle grafische symbolen gebruikt in dit produkt, zijn afkomstig uit een of meer van devolgende standaards: EN61010-1, IEC417 en ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 12 Hvor udstyr eller dæksler er mærket med dette symbol, se da i betjeningsmanual for instruktion. 10. Alle benyttede grafiske symboler i dette udstyr findes i én eller flere af følgende standarder:- EN61010-1, IEC417 & ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 13 10. Alle grafische symbolen gebruikt bij dit produkt zijn volgens een of meer van de volgende standaarden: EN 61010-1, IEC 417 & ISO 3864. Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 14 Tällainen pinta voi säilyä kosketuskuumana jopa 45 mi-nuuttia. Mikäli laite tai kosketussuoja on merkitty tällä merkillä katso lisäohjeita käyt- töohjekirjasta 10. Kaikki tässä tuotteessa käytetyt graafiset symbolit ovat yhdestä tai useammasta seuraavis-ta standardeista: EN61010-1, IEC417 & ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 15 Lorsque les équipements ou les capots affichent le symbole suivant, se reporter au manuel d’instructions. 10. Tous les symboles graphiques utilisés dans ce produit sont conformes à un ou plusieurs des standards suivants: EN61010-1, IEC417 & ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 16 Mit dem Symbol sind Geräte oder Abdeckungen gekennzeichnet, bei denen vor dem Eingriff die entsprechenden Kapitel im Handbuch sorgfältig durchgelesen werden müssen. 10. Alle in diesem Gerät verwendeten graphischen Symbole entspringen einem oder mehreren der nachfolgend aufgeführten Standards: EN61010-1, IEC417 & ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 17 Se lo strumento o il coperchio di protezione riportano il simbolo, fare riferimento alle istruzioni del manuale Operatore. 10. Tutti i simboli grafici utilizzati in questo prodotto sono previsti da uno o più dei seguenti standard: EN61010- 1, IEC417 e ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 18 Der hvor utstyret eller deksler er merket med symbol, vennligst referer til instruksjonsmanualen for instrukser. 10. Alle grafiske symboler brukt i dette produktet er fra en eller flere av følgende standarder: EN61010-1, IEC417 & ISO3864. P-10 Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 19 Sempre que o equipamento ou as tampas contiverem o símbolo, o Manual de Funcionamento deve ser consultado para obtenção das necessárias instruções. 10. Todos os símbolos gráficos utilizados neste produto baseiam-se em uma ou mais das seguintes normas: EN61010-1, IEC417 e ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management P-11...

- Page 20 Cuando el equipo o la tapa lleve impreso el simbolo, se consultara el manual de instrucciones. 10. Todos los simbolos graficos usados en esta hoja, estan de acuerdo a las siguientes normas EN61010-1, IEC417 & ISO 3864. P-12 Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 21 När utrustning eller hölje markerats med vidstående symbol bör instruktionsmanualen studeras för information. Samtliga grafiska symboler som förekommer i denna produkt finns angivna i en eller flera av följande föreskrifter:- EN61010-1, IEC417 & ISO3864. Rosemount Analytical Inc. A Division of Emerson Process Management P-13...

- Page 22 Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 P-14 Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 23 May be irritating to skin, eyes and respiratory tract. • May be harmful if inhaled. • Cristobalite (crystalline silica) formed at high temperatures (above 1800ºF) can cause severe respiratory disease. Rosemount Analytical Inc. A Division of Emerson Process Management P-15...

- Page 24 SECTION IV. FIRE AND EXPLOSION DATA FLASH POINT: None FLAMMABILITY LIMITS: N.A. EXTINGUISHING MEDIA Use extinguishing agent suitable for type of surrounding fire. UNUSUAL FIRE AND EXPLOSION HAZARDS / SPECIAL FIRE FIGHTING PROCEDURES N.A. P-16 Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 25 There are several occupational and non-occupational causes for pleural plaque. It should be noted that plaques are not “pre-cancer” nor are they associated with any measurable effect on lung function. Rosemount Analytical Inc. A Division of Emerson Process Management P-17...

- Page 26 SECTION VI. REACTIVITY DATA STABILITY/CONDITIONS TO AVOID Stable under normal conditions of use. HAZARDOUS POLYMERIZATION/CONDITIONS TO AVOID N.A. INCOMPATIBILITY/MATERIALS TO AVOID Incompatible with hydrofluoric acid and concentrated alkali. HAZARDOUS DECOMPOSITION PRODUCTS N.A. P-18 Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 27 Wear safety glasses or chemical worker’s goggles to prevent eye contact. Do not wear contact lenses when working with this substance. Have eye baths readily available where eye contact can occur. Rosemount Analytical Inc. A Division of Emerson Process Management P-19...

- Page 28 If airborne fiber or cristobalite concentrations are not known, as minimum protection, use NIOSH/MSHA approved half face, air-purifying respirator with HEPA filter cartridges. P-20 Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 29 Dust-suppressing components can be used to clean up light dust. Product packaging may contain product residue. Do not reuse except to reship or return Ceramic Fiber products to the factory. Rosemount Analytical Inc. A Division of Emerson Process Management P-21...

- Page 30 Do not place cylinders where they may become part of an electric circuit. When electric arc welding, precautions must be taken to prevent striking an arc against the cylinder. P-22 Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 31: Description And Specifications

This For best results, use clean, dry, instru- same information, plus additional details, ment air (20.95% oxygen) as the refer- can be accessed with the ence air. Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications... -

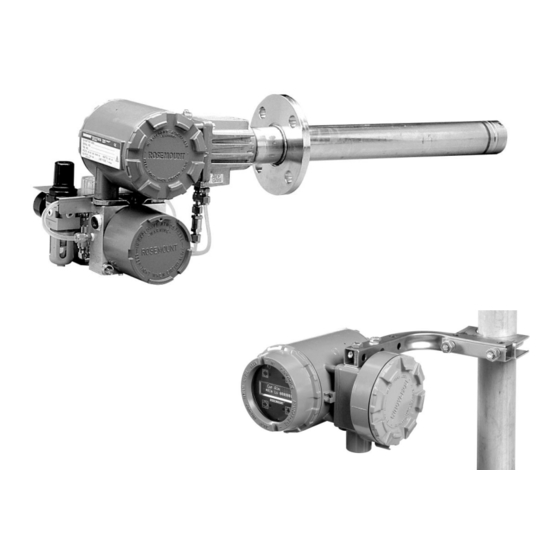

Page 32: Figure 1-1. Typical System Package

Hazardous Area Oxymitter 4000 with Remote Electronics (Optional) Reference Air Set (used if SPS 4000 without reference air option or IMPS 4000 not supplied) Figure 1-1. Typical System Package Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 33: Figure 1-2. Hazardous Area Oxymitter 4000 Autocalibration System Options

HART or the IMPS 4000, nected devices. The output is an isolated or whenever a calibration request is 4-20 mA linearized current. initiated. Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications... -

Page 34: Figure 1-3. Membrane Keypad

(AMS) software for the PC. 4. An optional Local Operator Interface 37260004 Figure 1-4 allows continual O display and full interface capability. Figure 1-4. Local Operator Interface (LOI) Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 35 (I/O) hardware with the electronics. Refer to Sec- and AMS software which tion 4 for more information. permit HART communica- tions. Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications...

-

Page 36: Figure 1-5. Hazardous Area Oxymitter 4000 Hart Connections And Ams Application

TERMINATION IN BY CUSTOMER CONTROL ROOM [300 FT (90 M) MAX] ASSET MANAGEMENT SOLUTIONS LINE VOLTAGE 37270009 Figure 1-5. Hazardous Area Oxymitter 4000 HART Connections and AMS Application Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 37: Figure 1-6. Typical System Installation - Oxymitter 4000 With Integral Electronics

INSTRUMENT AIR SUPPLY LOGIC I/O CALIBRATION GAS 2 RELAY OUTPUTS AND REMOTE CONTACT INPUT LINE VOLTAGE 37270014 Figure 1-6. Typical System Installation – Oxymitter 4000 with Integral Electronics Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications... -

Page 38: Figure 1-7. Typical System Installation - Oxymitter 4000 With Remote Electronics

EXPLOSIVE-FREE ENVIRONMENT. CALIBRATION GAS 2 4-20 mA SIGNAL, RELAY LINE OUTPUTS, AND REMOTE VOLTAGE CONTACT INPUT 37270006 Figure 1-7. Typical System Installation – Oxymitter 4000 with Remote Electronics Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 39: Imps 4000 (Optional)

Oxymitter 4000, the IMPS 4000 sequencer must LCD Display be installed in a non-hazardous, explosive-free environment. For further IMPS 4000 information, refer to the IMPS 4000 Intelligent Multiprobe Test Gas Sequencer Instruction Bulletin. Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications... -

Page 40: Probe Options

Assembly longer probes. The abrasive shield assembly uses a modified diffusor and vee deflector assembly, fitted with dual dust seal packing. 1-10 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 41: Figure 1-11. Abrasive Shield Assembly

Figure 1-11. Abrasive Shield Assembly NOTE In highly abrasive applications, rotate the shield 90 degrees at normal service intervals to present a new wear surface to the abrasive flow stream. Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-11... -

Page 42: Specifications

IMPS 4000 or SPS 4000. Self-powered (+5 V), in series with 340 ohms Conduit port — 3/4 in.-14 NPT (for analog output and logic I/O signal lines) 1-12 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 43: Hazardous Area Certifications

Class I, Zone 1, AEx de IIB+H (Remote Electronics) Class I, Zone 1, AEx d IIB+H (Remote Probe) Class I, Zone 1, AEx de IIB+H (Remote Electronics) Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-13... -

Page 44: Table 1-1. Product Matrix

Integral Electronics, Transient Protected Termination, CSA/FM Certification ® HART Remote Electronics (requires cable), Standard Filtered Termination, CSA/FM Certification ® HART Remote Electronics (requires cable), Transient Protected Termination, CSA/FM Certification OXT4C Example 1-14 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 45 Startup, calibration, and operation can be implemented using the standard membrane keypad. Remote access and additional functionality available via HART Communications [Model 275/375 Handheld Communicator with Hazardous Area Oxymitter 4000 device descriptor (DD)] required. Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-15...

-

Page 46: Table 1-2. Calibration Components

IMPS w/115 V Heater 3D39695G08 IMPS w/115 V Heater 3D39695G09 IMPS w/220 V Heater 3D39695G10 IMPS w/220 V Heater 3D39695G11 IMPS w/220 V Heater 3D39695G12 IMPS w/220 V Heater 1-16 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 47: Installation

70°C boilers). (150°F). For higher ambient tempera- 3. Weld or bolt mounting plate (Figure tures, we recommend the remote 2-5) onto the duct. mounted electronics option. Rosemount Analytical Inc. A Division of Emerson Process Management Installation... -

Page 48: Figure 2-1. Hazardous Area Oxymitter 4000 Probe Installation

Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 35910002 Figure 2-1. Hazardous Area Oxymitter 4000 Probe Installation Installation Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 49: Figure 2-2. Hazardous Area Oxymitter 4000 Remote Electronics Installation

INCHES IN PARENTHESES. 56.0 2.21 164.6 189.8 6.48 7.47 84.6 246.9 9.72 3.33 140.2 5.52 66.5 93.5 ( 3.68 2.62 37270013 Figure 2-2. Hazardous Area Oxymitter 4000 Remote Electronics Installation Rosemount Analytical Inc. A Division of Emerson Process Management Installation... -

Page 50: Figure 2-3. Hazardous Area Oxymitter 4000 Probe With Abrasive Shield

Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 35910003 Figure 2-3. Hazardous Area Oxymitter 4000 Probe with Abrasive Shield Installation Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 51: Figure 2-4. Hazardous Area Oxymitter 4000 Mounting Plate Dimensions

Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 27540003 Figure 2-4. Hazardous Area Oxymitter 4000 Mounting Plate Dimensions Rosemount Analytical Inc. A Division of Emerson Process Management Installation... -

Page 52: Figure 2-5. Hazardous Area Oxymitter 4000 Mounting Plate Installation

PLATE TO METAL WALL OF STACK OR DUCT. NOTE: DIMENSIONS IN MILLIMETERS WITH JOINT MUST BE AIRTIGHT. INCHES IN PARENTHESES. 27540004 Figure 2-5. Hazardous Area Oxymitter 4000 Mounting Plate Installation Installation Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 53: Figure 2-6. Orienting The Optional Vee Deflector

To maintain CE compliance, ensure a good connection exists between the mounting plate studs or earthing screws on electronics housing and 27540009 earth. Figure 2-6. Orienting the Optional Vee Deflector Rosemount Analytical Inc. A Division of Emerson Process Management Installation... -

Page 54: Electrical Installation (For Hazardous Area Oxymitter 4000 With Integral Electronics)

Install all protective equipment covers and safety ground leads after installa- tion. Failure to install covers and ground leads could result in serious injury or death. 37260016 Figure 2-8. Remote Electronics Mounting Installation Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 55 Install cover (17, Figure 9-3) and secure VAC line voltage and 50/60 Hz. To avoid a with captive washer (20), cover lock (19), shock hazard, the power terminal cover and screw (18). must be installed. Rosemount Analytical Inc. A Division of Emerson Process Management Installation...

-

Page 56: Figure 2-9. Electrical Installation - Hazardous Area Oxymitter 4000 With Integral Electronics

4 - 20mA + 4 - 20mA GROUND CALIBRATION HANDSHAKE REFER TO IMPS 4000 INSTRUCTION MANUAL 37270012 Figure 2-9. Electrical Installation – Hazardous Area Oxymitter 4000 with Integral Electronics 2-10 Installation Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 57: Electrical Installation (For Hazardous Area Oxymitter 4000 With Remote Electronics)

Superimposed on the 4-20 mA signal is such as IEC 947. HART information that is accessible through a Model 275/375 Handheld Communicator or AMS software. Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-11... -

Page 58: Figure 2-10. Electrical Installation - Hazardous Area Oxymitter 4000 With Remote Electronics

GROUND LINE 1 90-250 VAC, 50-60 HZ NEUTRAL LINE VOLTAGE INPUT GROUND 37270023 Figure 2-10. Electrical Installation – Hazardous Area Oxymitter 4000 with Remote Electronics (Sheet 1 of 2) 2-12 Installation Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 59 LINE 1 90-250 VAC, 50-60 HZ SPS 4000 NEUTRAL LINE VOLTAGE INPUT GROUND 37270024 Figure 2-10. Electrical Installation – Hazardous Area Oxymitter 4000 with Remote Electronics (Sheet 2 of 2) Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-13...

-

Page 60: Pneumatic Installation

Hazardous Area Oxymitter total hydrocarbons. Regulator outlet pres- 4000, consult the factory for the proper sure should be set at 35 kPa (5 psi). wire type and gauge. 2-14 Installation Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 61: Imps 4000 Connections

SPS b. Calibration Gas 4000 Single Probe Autocalibration Sequencer Two calibration gas concentrations are used Instruction Bulletin. Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-15... - Page 62 If the ducts will be washed down during outage, MAKE SURE to power down the Hazardous Area Oxymitter 4000 units and remove them from the wash area. 2-16 Installation Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 63: Configuration Of Hazardous Area Oxymitter 4000 With Membrane Keypad

HEATER T/C - 4-20 mA HIGH SIGNAL TERMINAL TEST GAS + PROCESS - % 02 BLOCK LOGIC I/O GROUND LUGS 37270002 Figure 3-1. Electronics Housing Terminals and Membrane Keypad Rosemount Analytical Inc. A Division of Emerson Process Management Configuration with Keypad... - Page 64 Once the cell is up to operating tempera- 1. Position 1 is HART/LOCAL. This switch ture, the O percentage can be read: setting controls the configuration of the Configuration with Keypad Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 65: Figure 3-2. Defaults - Hazardous Area Oxymitter 4000 With Membrane Keypad

(AUTO TUNE = NO). HEATER T/C + POINTS HEATER T/C - HIGH TEST GAS + PROCESS - % O2 37270001 Figure 3-2. Defaults – Hazardous Area Oxymitter 4000 with Membrane Keypad Rosemount Analytical Inc. A Division of Emerson Process Management Configuration with Keypad... -

Page 66: Logic I/O

* The default condition for a Hazardous Area Oxymitter 4000 without an IMPS 4000 or SPS 4000. ** The default condition for a Hazardous Area Oxymitter 4000 with an IMPS 4000 or SPS 4000. Configuration with Keypad Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 67: Recommended Configuration

Rosemount Analytical Inc. A Division of Emerson Process Management Configuration with Keypad... - Page 68 Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 Configuration with Keypad Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 69: Configuration Of Hazardous Area Oxymitter 4000 With Loi

85-264 VAC 48-62 Hz 500 VA OUTPUT: 4-20 mA LINE FUSE: 5 Amps 4-20 mA SIGNAL TERMINAL BLOCK LOGIC I/O GROUND LUGS 37270010 Figure 4-1. Electronics Housing Terminals with LOI Rosemount Analytical Inc. A Division of Emerson Process Management Configuration with LOI... - Page 70 SW2 the internal electronics auto detect the input line voltage and sets the heater The factory sets this switch as follows: voltage accordingly (Auto Tune = Yes). Configuration with LOI Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 71: Figure 4-2. Defaults - Hazardous Area Oxymitter 4000 With Loi

POSITION 4 IS ACTIVE ONLY WHEN THE HEATER VOLTAGE OPTION IS SET TO MANUAL IN THE SOFTWARE. 37270011 Figure 4-2. Defaults – Hazardous Area Oxymitter 4000 with LOI Rosemount Analytical Inc. A Division of Emerson Process Management Configuration with LOI... -

Page 72: Logic I/O

* The default condition for a Hazardous Area Oxymitter 4000 without an IMPS 4000 or SPS 4000. ** The default condition for a Hazardous Area Oxymitter 4000 with an IMPS 4000 or SPS 4000. Configuration with LOI Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 73: Recommended Configuration

Rosemount Analytical Inc. A Division of Emerson Process Management Configuration with LOI... - Page 74 Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 Configuration with LOI Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 75: Startup And Operation Of Hazardous Area Oxymitter 4000 With Membrane Keypad

HEATER HIGH O CELL TEST GAS + PROCESS - % O2 CALIBRATION LIGHTING SEQUENCE DURING NORMAL OPERATION (OPERATING DISPLAY) 22220056 Figure 5-1. Startup and Normal Operation Rosemount Analytical Inc. A Division of Emerson Process Management Startup and Operation with Keypad... -

Page 76: Operation

MEMBRANE determines that a calibration is recom- MEMBRANE mended. Further information is avail- KEYS able in Section 9, MAINTENANCE 22220023 AND SERVICE. Figure 5-2. Calibration Keys Startup and Operation with Keypad Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 77: Ib-106-340C Rev. 4.1

HEATER T/C + POINTS HEATER T/C - LIGHTING SEQUENCE DURING NORMAL OPERATION HIGH CAL LED TEST GAS + PROCESS - % O2 22220055 Figure 5-3. Normal Operation Rosemount Analytical Inc. A Division of Emerson Process Management Startup and Operation with Keypad... - Page 78 Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 Startup and Operation with Keypad Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 79: Startup And Operation Of Hazardous Area Oxymitter 4000 With Loi

Ensure the reference air, if used, is set to 56.6 l/hr (2 scfh). START UP OXYMITTER 4000 CALIBRATION Refer to Section 9, MAINTENANCE AND SERVICE, for calibration instructions. 37260036 Figure 6-2. Normal Display Rosemount Analytical Inc. A Division of Emerson Process Management Startup and Operation with LOI... -

Page 80: Navigating The Local Operator Interface

They are functionality anywhere the 4-20 mA signal also used for incrementing values up and down terminates via a HART model 275/375 for data input. handheld communicator. Startup and Operation with LOI Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 81: Loi Menu Tree

Italics Purge user configurable. All other (CONTINUED ON parameters are display only. SHEET 2) 37260017 Figure 6-4. Local Operator Interface Menu Tree (Sheet 1 of 2) Rosemount Analytical Inc. A Division of Emerson Process Management Startup and Operation with LOI... - Page 82 6. O2-Next Cal – If automatic calibration Refer to Section 9, MAINTENANCE AND is selected, this selects the time until SERVICE, for calibration instructions. the first initial calibration takes place. Startup and Operation with LOI Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 83 One hour is process alarm, set the value the default, and it is user configurable. here. 7. Luminance – Gas florescence bright- ness is user adjustable. Rosemount Analytical Inc. A Division of Emerson Process Management Startup and Operation with LOI...

-

Page 84: Loi Installation

(Some LOI MODULE REAR VIEW process temperatures can exceed the 736°C setpoint temperature, 37260055 and this will indicate this condition.) Figure 6-5. LOI Module Connectors Startup and Operation with LOI Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 85: Oxymitter 4000 Test Points

Refer to Remote Powered Loop LCD manual percentage of oxygen present. for calibration and operation. 37260037 Figure 6-6. Test Points Rosemount Analytical Inc. A Division of Emerson Process Management Startup and Operation with LOI... - Page 86 Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 Startup and Operation with LOI Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 87: Hart/Ams

1. For applications in which the and a minimum load resistance of 250 ohms signal line load resistance is less than 250 between the communicator and the power ohms, refer to method 2. supply. Rosemount Analytical Inc. A Division of Emerson Process Management HART/AMS... -

Page 88: Figure 7-1. Signal Line Connections, ≥ 250 Ohms Load Resistance

00275 0013 ONLY CHARGER MUST SERIAL PORT NOT BE USED IN HAZARDOUS AREAS HART COMMUNICATOR LEAD SET HART COMMUNICATOR REAR PANEL 23230001 Figure 7-1. Signal Line Connections, ≥ 250 Ohms Load Resistance HART/AMS Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 89: Hart Communicator Pc Connections

HART the On-line Menu. Refer to the HART Communicator manual for detailed menu Communicator with a PC (refer to applica- information. ble HART documentation regarding HART/PC applications. Rosemount Analytical Inc. A Division of Emerson Process Management HART/AMS... -

Page 90: Logic I/O Configurations

*The default condition for a Hazardous Area Oxymitter 4000 without an IMPS 4000 or SPS 4000. **The default condition for a Hazardous Area Oxymitter 4000 with an IMPS 4000 or SPS 4000. HART/AMS Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 91: Figure 7-3. Hart/Ams Menu Tree (Sheet 1 Of 3)

LAST Cal const CALCONSTANTS Cell Imp (CONTINUED ON SHEET 2) Reset RESET CalConstants CALCONSTANTS method... D/A TRIM D/A trim method 37270003 Figure 7-3. HART/AMS Menu Tree (Sheet 1 of 3) Rosemount Analytical Inc. A Division of Emerson Process Management HART/AMS... - Page 92 CALIBRATION SHEET 3) OP tracks TGtime PurgeTime Manual Cal Mode Auto Cal Intrvl h Next CalTime h O2 ALARMS LoAlarmSP 35910004 Figure 7-3. HART/AMS Menu Tree (Sheet 2 of 3) HART/AMS Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 93 PV AO Slope DEVICE CONFIG PV LRV Constant PV URV LoAlarmSP OUTPUTS I/O Pin Mode CONFIG Poll addr Num req preams 26170030 Figure 7-3. HART/AMS Menu Tree (Sheet 3 of 3) Rosemount Analytical Inc. A Division of Emerson Process Management HART/AMS...

-

Page 94: Hart Communicator Ocal Method

CAL screen, view the calibration status updates. menu item 3, CALSTATE, to monitor the calibration status as it updates. Or, access n. When CALSTATE displays COMPLETE, the calibration is finished. HART/AMS Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 95 (in hours) at which an automatic calibration to select the menu item number. To will occur; then press ENTER. return to a preceding menu, press the left arrow key. Rosemount Analytical Inc. A Division of Emerson Process Management HART/AMS...

- Page 96 Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 7-10 HART/AMS Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 97: Troubleshooting

27.2 31.2 36.0 0.01 EMF(mV) 42.3 51.1 66.1 71.0 77.5 81.5 86.3 101.4 116.6 166.8 Figure 8-1. O Sensor mV Reading vs. % O at 736°C (Reference Air, 20.9% O Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting... -

Page 98: General

The Hazardous Area Oxymitter 4000 uses a microprocessor and supporting integrated circuits (IC). If the electronics are handled 37260044 roughly during installation or located where Figure 8-2. Diagnostic LEDs subjected to severe vibration, the ICs could Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 99: Alarm Contacts

LOI display window when the alarm status bottles empty”). display is accessed via the LOI menu. A listing of the alarm/fault messages and the related fault status descriptions and fault numbers are shown in Table 8-2. Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting... -

Page 100: Table 8-1. Diagnostic/Unit Alarm Fault Definitions - Membrane Keypad Only

O2 CELL OPEN O2 CELL BAD O2 CELL FAILED 11, 13, 14 EEPROM CORRUPT EEPROM FAILED CALIB FAILED LAST CALIBRATION FAILED LINE FREQ ERROR INCORRECT INPUT LINE FREQUENCY DETECTED ON POWER UP Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 101: Figure 8-3. Fault 1, Open Thermocouple

O2 T/C Open assembly. 2. Reconnect power to the Oxymitter 4000. 3. Perform the diagnostic steps 1 through 4 shown for the membrane keypad. 37260019 Figure 8-3. Fault 1, Open Thermocouple Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting... -

Page 102: Figure 8-4. Fault 2, Shorted Thermocouple

O2 T/C Shorted 2. Reconnect power to the Oxymitter 4000. 3. Perform the diagnostic steps 1 through 4 shown for the membrane keypad. 37260020 Figure 8-4. Fault 2, Shorted Thermocouple Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 103: Figure 8-5. Fault 3, Reversed Thermocouple

O2 T/C Reversed 2. Reconnect power to the Oxymitter 4000. 3. Perform the diagnostic steps 1 through 3 shown for the membrane keypad. 37260021 Figure 8-5. Fault 3, Reversed Thermocouple Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting... -

Page 104: Figure 8-6. Fault 4, A/D Comm Error

KEYPAD LOI. When Fault 4 is detected, the LOI displays the “ADC Error” message. 1. Call the factory for assistance. Alarms Error 37260022 Figure 8-6. Fault 4, A/D Comm Error Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 105: Figure 8-7. Fault 5, Open Heater

LOI module from the electronic as- sembly. Alarms 2. Perform the diagnostic steps 2 through O2 Heater Open 4 shown for the membrane keypad. 37260023 Figure 8-7. Fault 5, Open Heater Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting... -

Page 106: Figure 8-8. Fault 6, High High Heater Temp

4000 to cool for five minutes. Restore power. 4. If the condition repeats, replace the electronic assembly per paragraph 9-4c, Electronic Assembly Replace- ment. 37260024 Figure 8-8. Fault 6, High High Heater Temp 8-10 Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 107: Figure 8-9. Fault 7, High Case Temp

LOI. When Fault 7 is detected, the LOI displays the “Board Temp Hi” message. Alarms Refer to the comments in paragraphs 1 through 4 above. Board Temp Hi 37260025 Figure 8-9. Fault 7, High Case Temp Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting 8-11... -

Page 108: Figure 8-10. Fault 8, Low Heater Temp

O2 Temp Low displays the “O2 Temp Low” message. Refer to the comments and procedures in paragraphs 1 through 4 above. 37260026 Figure 8-10. Fault 8, Low Heater Temp 8-12 Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 109: Figure 8-11. Fault 9, High Heater Temp

“O2 Temp Hi” message. Refer to the comments and procedures in para- graphs 1 through 4 above. Alarms O2 Temp Hi 37260027 Figure 8-11. Fault 9, High Heater Temp Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting 8-13... -

Page 110: Figure 8-12. Fault 10, High Cell Mv

2. Reconnect power to the Oxymitter 37260028 4000. Figure 8-12. Fault 10, High Cell mV 3. Perform the diagnostic steps 1 through 4 shown for the membrane keypad. 8-14 Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 111: Figure 8-13. Fault 11, Bad Cell

“O2 Cell Bad” message. Refer to the comments and procedures in para- graphs 1 and 2 above. Alarms O2 Cell Bad 37260029 Figure 8-13. Fault 11, Bad Cell Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting 8-15... -

Page 112: Figure 8-14. Fault 12, Eeprom Corrupt

LOI. When Fault 12 is detected, the LOI displays the “EEprom Corrupt” message. Refer to the comments and procedures in paragraphs 1 through 4 above. Alarms O2 Cell Bad 37260029 Figure 8-14. Fault 12, EEprom Corrupt 8-16 Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 113: Figure 8-15. Fault 13, Invalid Slope

LOI. When Fault 13 is detected, the LOI displays the “O2 Cell Bad” message. Refer to the comments and procedures in para- graphs 1 through 4 above. 37260031 Figure 8-15. Fault 13, Invalid Slope Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting 8-17... -

Page 114: Figure 8-16. Fault 14, Invalid Constant

“O2 Cell Bad” message. Refer to the comments and procedures in para- graphs 1 through 4 above. Alarms O2 Cell Bad 37260032 Figure 8-16. Fault 14, Invalid Constant 8-18 Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 115: Figure 8-17. Fault 15, Last Calibration Failed

LOI. When Fault 15 is detected, the LOI displays the “Calib Failed” message. Refer to the comments in paragraphs 1 and 2 above. Alarms Calib Failed 37260033 Figure 8-17. Fault 15, Last Calibration Failed Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting 8-19... -

Page 116: Hazardous Area Oxymitter 4000 Passes Calibration, But Still Reads Incorrectly

(See Section 9, MAINTENANCE Never readjust this flow upwards. AND SERVICE). Adjust this flow only when a new diffuser is installed. 8-20 Troubleshooting Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 117 3. Adjust the flow rate back up until this process is on line. mixing is just eliminated. Calibrate at this flow rate. Replace the diffuser at the first opportunity. Rosemount Analytical Inc. A Division of Emerson Process Management Troubleshooting 8-21...

- Page 118 Response When the second calibration gas is turned off, note the number of seconds required for final the O value to settle out at the process value. Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 119: Maintenance And Service

(See paragraph 5-2a.5 or 6-5.) used when calibrating the unit and by setting the calibration gas flowmeter. Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service... -

Page 120: Figure 9-1. Membrane Keypad

(in hours). To configure the CAL INTRVL parameter, refer to paragraph 7-8 for the HART/AMS, or paragraph 6-5 for the LOI. Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 121 4000. Refer to the documentation TP5 and TP6, the reading will available for the control system in display the percentage of use for more information. oxygen seen by the cell. Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service...

-

Page 122: Figure 9-2. Inside Right Cover

3 pattern flash (2 pattern flash (default time of five minutes). equals a valid calibration, 3 When the timer times out, the pattern flash equals an invalid Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 123: Calibration - Hazardous Area Oxymitter 4000 With Loi

Apply Gas 2 was initiated, and the parameters Hit E when ready will not be updated. (e) Place control loop in automatic. Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service... - Page 124 3. Next O2 Cal – Time until the next O mode. calibration, if different than the next scheduled calibration. Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 125: Hazardous Area Oxymitter 4000 Repair

(e) Turn on the calibration gases at the Rosemount label, remove screw cylinders and turn on instrument (18, Figure 9-3 or Figure 9-4), air. cover lock (19), and captive Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service... -

Page 126: Figure 9-3. Hazardous Area Oxymitter 4000 With Integral Electronics - Exploded View

33. Tube Clamp 34. Silicon Tube 35. Strut Pressure Clamp Note: Not all parts shown. 37270004 Figure 9-3. Hazardous Area Oxymitter 4000 with Integral Electronics – Exploded View Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 127: Figure 9-4. Hazardous Area Oxymitter 4000 With Remote Electronics - Exploded View

13. Lock Washer 22. Screw 33. Probe 37270005 14. Cable Clamp 23. Mounting Kit 34. Housing Figure 9-4. Hazardous Area Oxymitter 4000 with Remote Electronics – Exploded View Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service... -

Page 128: Figure 9-5. Electronic Assembly

CAL and REF gas ports. Install 37270018 four washers (21) and screws (22). Tighten screws. Figure 9-5. Electronic Assembly 9-10 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 129: Figure 9-6. J8 Connector

9. Gently try to rotate the electronic assembly to check for full seating. If the electronic assembly rotates, remove the assembly and repeat step 8. Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service 9-11... -

Page 130: Figure 9-7. Fuse Location

Ensure the connector is secure. new one. 14. Tighten the three captive screws (10, Figure 9-3 or Figure 9-4) in the top of the microprocessor board (5). 9-12 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 131 [up to 300°C (572°F)] in the on the heater strut assembly (32). region of the probe heater. Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service 9-13...

-

Page 132: Figure 9-8. Heater Strut Assembly

2-1b to install the Hazardous Area rectly, the strut will slide in the rest of Oxymitter 4000 into the stack or duct. the way. 9-14 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 133: Figure 9-9. Cell Replacement Kit

FLANGE flame arrestor/snubber diffuser assem- ASSEMBLY bly. 26310016 NOTE To determine if the diffuser needs to Figure 9-9. Cell Replacement Kit be replaced, refer to paragraph 9-2. Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service 9-15... -

Page 134: Figure 9-10. Ceramic Diffuser Element Replacement

If the contact pad shield, install the dust seal gaskets, stays fused to the cell, a new con- with joints 180° apart. tact/thermocouple assembly must be 9-16 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management... - Page 135 (i) Thoroughly mix cement and insert tip of squeeze bottle into cement (b) Loosen setscrews, Figure 9-10, port. Tilt bottle and squeeze while using hex wrench from Probe simultaneously turning ceramic Rosemount Analytical Inc. A Division of Emerson Process Management Maintenance and Service 9-17...

-

Page 136: Figure 9-11. Contact And Thermocouple Assembly Replacement

3. Use a pencil to mark locations of the SUPPORTS SPRING spring clips on the ceramic rod of the CLIP contact and thermocouple assembly. 26310022 SPRING Figure 9-11. Contact and Thermocouple Assembly Replacement 9-18 Maintenance and Service Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 137: Return Of Material

4. Whether warranty or nonwarranty and returned as directed by the purchase service is requested. order and shipping instructions. Rosemount Analytical Inc. A Division of Emerson Process Management Return of Material 10-1... - Page 138 Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 10-2 Return of Material Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 139: Replacement Parts

ANSI 18" Cell Replacement Kit, High Sulfur/HCl Resistant* 11-1 4849B94G03 ANSI 3' Cell Replacement Kit, High Sulfur/HCl Resistant* 11-1 4849B94G04 ANSI 6' Cell Replacement Kit, High Sulfur/HCl Resistant* *Includes pad and wire. Rosemount Analytical Inc. A Division of Emerson Process Management Replacement Parts 11-1... -

Page 140: Figure 11-1. Cell Replacement Kit

CONNECTOR CALIBRATION GAS PASSAGE SET SCREWS M6-1 x 6 mm TEFLON SOCKET HEAD TUBING CORRUGATED CAP SCREWS SEAL CELL AND FLANGE 27540010 ASSEMBLY Figure 11-1. Cell Replacement Kit 11-2 Replacement Parts Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 141: Figure 11-2. Probe Disassembly Kit

5R10130H01 Strut Pressure Clamp 9-10 6292A74G02 Ceramic Diffusion Element Replacement Kit HEX KEYS SPANNER WRENCH ANTI-SEIZE COMPOUND PHILIPS SCREWDRIVER TUBE INSERTION TUBE 26310008 Figure 11-2. Probe Disassembly Kit Rosemount Analytical Inc. A Division of Emerson Process Management Replacement Parts 11-3... -

Page 142: Table 11-2. Replacement Parts For Electronics

Cable Assembly, 200 ft. (61 m) 9-4, 32 3D39866G01 Termination Block, Standard, Remote Probe Head 9-4, 32 3D39866G02 Termination Block, Transient Protected, Remote Probe Head 9-4, 34 4850B86G01 Housing 11-4 Replacement Parts Rosemount Analytical Inc. A Division of Emerson Process Management... -

Page 143: Optional Accessories

For more information, call Rosemount Analytical at 1-800-433-6076. 26170024 Rosemount Analytical Inc. A Division of Emerson Process Management Optional Accessories 12-1... - Page 144 (IN A SAFE AREA) Hazardous Area Oxymitter 4000 is out of calibration. For more information, call Rosemount Analytical at 1-800-433-6076. 26310009 12-2 Optional Accessories Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 145 Rosemount Analytical’s oxygen analyzers. These lightweight, disposable gas cylinders eliminate the need to rent gas bottles. For more information, call Rosemount Analytical at 1-800-433-6076. 26170021 Rosemount Analytical Inc. A Division of Emerson Process Management Optional Accessories 12-3...

- Page 146 Instruction Manual IB-106-340C Rev. 4.1 Hazardous Area Oxymitter 4000 July 2004 12-4 Optional Accessories Rosemount Analytical Inc. A Division of Emerson Process Management...

-

Page 147: Index

Membrane Keypad, 1-4, 4-3, 5-1, 6-1, 9-2 Electrical Noise, 8-2 Mounting Plate, 1-2, 2-1, 2-5, 2-6, 2-7 Electrostatic Discharge, 8-2 Equipment Return, 10-1 Error, 5-1 Nernst Equation, 1-1 Rosemount Analytical Inc. A Division of Emerson Process Management Optional Accessories 13-1... - Page 148 Reference Air Set, 1-2, 2-15 Remote Contact, 9-3 Wiring, 3-1, 4-1 Replacement Parts, 11-1 Zirconia Disc, 1-1 Semi-Automatic Calibration, 9-3 Signal, 4-20 mA, 12-1 Specifications, 1-12 SPS 4000, 1-2, 1-3, 1-9, 12-2 13-2 Index Rosemount Analytical Inc. A Division of Emerson Process Management...

- Page 149 WARRANTY Rosemount warrants that the equipment manufactured and sold by it will, upon shipment, be free of defects in workmanship or material. Should any failure to conform to this warranty become apparent during a period of one year after the date of shipment, Rosemount shall, upon prompt written notice from the purchaser, correct such nonconformity by repair or replacement, F.O.B.

- Page 150 Hazardous Area Oxymitter 4000 July 2004 Hazardous Area Oxymitter 4000 Part no. Serial no. Order no. Emerson Process Management Rosemount Analytical Inc. Fisher-Rosemount GmbH & Co. Process Analytic Division Industriestrasse 1 1201 N. Main St. 63594 Hasselroth Orrville, OH 44667-0901...

Need help?

Do you have a question about the Rosemount Analytical Oxymitter 4000 and is the answer not in the manual?

Questions and answers