Graco SaniForce 2150 Repair Parts List Manual

Hide thumbs

Also See for SaniForce 2150:

- Operation (54 pages) ,

- Operation manual (52 pages) ,

- Repair parts (46 pages)

Advertisement

Quick Links

Repair/Parts List

SaniForce® Air

SaniForce®

SaniForce®

Sanitation Diaphragm

Sanitation

Sanitation

Diaphragm Pumps,

Diaphragm

2150, 3150,

3150, 4150

2150,

2150,

3150,

For use

For

For

use

use in in in sanitary

sanitary applications.

sanitary

applications.

applications.

For

For professional

For

professional

professional use

use only.

use

Important

Important Safety

Important

Safety Instructions

Safety

Read all warnings and instructions in this manual and related

manuals before using the equipment. Save

Maximum working pressure: 120 psi

(0.8 MPa, 8 bar)

See page 6 for approvals.

Tel: 866-777-6060

Fax: 866-777-6383

Air - - - Operated

Air

Operated High

Operated

Pumps, Models

Pumps,

4150

4150

only.

only.

Instructions

Instructions

Save all all all instructions.

Save

PROVEN QUALITY. LEADING TECHNOLOGY.

Springer Pumps, LLC

High

High

Models

Models

instructions.

instructions.

3A6782E

Website: www.springerpumps.com

Int'l: +001 267 404 2910

EN

Advertisement

Summary of Contents for Graco SaniForce 2150

- Page 1 Repair/Parts List SaniForce® SaniForce® Air SaniForce® Air - - - Operated Operated Operated High High High Sanitation Sanitation Diaphragm Sanitation Diaphragm Diaphragm Pumps, Pumps, Models Pumps, Models Models 3A6782E 2150, 3150, 3150, 4150 4150 2150, 2150, 3150, 4150 For use use in in in sanitary sanitary applications.

-

Page 2: Table Of Contents

Ordering Information ........... 6 Leak Detectors ..........20 Troubleshooting..........7 Parts..............21 Repair..............9 Technical Data ........... 30 Pressure Relief Procedure......9 Air Valve Repair........... 9 Graco Standard Warranty........32 Related Related Related Manuals Manuals Manuals Manual Number Title 3A5999... -

Page 3: Warnings

Warnings Warnings Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. - Page 4 Warnings WARNING EQUIPMENT MISUSE MISUSE HAZARD HAZARD EQUIPMENT EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

-

Page 5: Configuration Number Matrix

Configuration Number Matrix Configuration Number Number Matrix Matrix Configuration Configuration Number Matrix Check the identification plate (ID) for the Configuration Number of your pump. Use the following matrix to define the components of your pump. When you receive your pump, record the 9 character part number found on the shipping box (e.g., SP3F.0018): _____________ Also record the configuration number on the pump ID... - Page 6 Please Please call your distributor. Online Diaphragm Diaphragm Pump Pump Selector Selector at at at www.graco.com. . . Search for Selector Selector Use the Online Online Diaphragm Pump Selector www.graco.com www.graco.com Selector To Order Order Replacement...

- Page 7 Troubleshooting Troubleshooting Troubleshooting Troubleshooting • Follow the Pressure Relief Procedure, page 9 • Check all possible problems and causes before before checking or servicing the equipment. disassembly. Problem Problem Problem Cause Cause Cause Solution Solution Solution Pump cycles at stall or Worn checks or seats.

- Page 8 Troubleshooting Problem Problem Problem Cause Cause Cause Solution Solution Solution Fluid in exhaust air. Diaphragm ruptured. Replace. See standard or overmolded repair procedure. Loose diaphragm plate. Tighten or replace. See standard or overmolded repair procedure. Pump exhausts excessive Worn air valve block, plate, pilot Repair or replace.

- Page 9 Repair Repair Repair Repair Pressure Pressure Pressure Relief Relief Relief Procedure Procedure Procedure 1. Follow the Pressure Relief Procedure, page 9 2. With a Torx (T20) screwdriver or 7 mm (9/32 in.) Follow the Pressure Relief Procedure socket wrench, remove the six screws (107), air whenever you see this symbol.

- Page 10 Repair 5. Inspect the valve plate (110) in place. If 3. Install the u-cups (106) onto the actuator pistons damaged, use a Torx (T20) screwdriver or 7 mm (E) and insert the travel restrictors (2) from the (9/32) in.) socket wrench to remove the three diaphragm install tool kit into the actuator pistons screws (107).

- Page 11 Repair Reassemble Air Air Valve Valve Reassemble Reassemble Valve 6. Lubricate the u-cups (106) and actuator pistons (114). Insert the actuator pistons in the bearings wide wide wide (115), end first. Leave the narrow end of 1. If the center section was disassembled to replace the pistons exposed.

- Page 12 Repair Check Valve Valve Repair Repair Check Check Valve Repair 3. Remove the clamps (23) on the outlet manifold (17) and remove the manifold. NOTE: NOTE: NOTE: Kits are available for new check valve NOTE: NOTE: Use care while removing manifold to NOTE: flappers, or check valve balls in a range of materials.

- Page 13 Repair Reassemble the the Check Check Valves Valves Reassemble Reassemble Check Valves Vertical Vertical Vertical flapper flapper flapper pump pump pump shown shown shown NOTE: NOTE: NOTE: Lubricate clamps and clamping surfaces with waterproof, sanitary lubricant. 1. Reassemble ball or flapper check assembly in reverse order.

-

Page 14: Standard Diaphragm Repair

Repair Standard Diaphragm Diaphragm Repair Repair Standard Standard Diaphragm Repair NOTE: Overmolded diaphragms are covered in NOTE: NOTE: 5. Disassemble the free diaphragm assembly. Overmolded Diaphragm Repair, page 6. Remove plate (12) with bolt (14) installed, diaphragm (10), backer (11) if present, and plate Tools Tools Tools Required... - Page 15 Repair Reassemble the the Standard Standard Diaphragms Diaphragms Reassemble Reassemble Standard Diaphragms 7. Align the fluid covers (4, 15) and the center NOTICE NOTICE NOTICE housing. Secure the covers with the clamps (21) and hand tighten. The opposing diaphragm After reassembly, allow the thread locker to cure may protrude away from the center housing for 12 hours, or per manufacturer’s instructions, after the first fluid cover is secured, leaving...

- Page 16 Repair Overmolded Diaphragm Diaphragm Repair Repair Overmolded Overmolded Diaphragm Repair Tools Tools Tools Required Required Required 6. Pull the opposite diaphragm assembly and shaft (24) out of the center housing (101). Hold the • Torque wrench shaft flats with a 19 mm open end wrench and remove the diaphragm and air side plate from •...

- Page 17 Repair Reassemble the the Overmolded Overmolded Diaphragms Diaphragms Reassemble Reassemble Overmolded Diaphragms 4. Grease the length of the diaphragm shaft (24), NOTICE NOTICE NOTICE and slide it through the housing (101). After reassembly, allow the thread locker to cure 5. Assemble the other diaphragm assembly to the for 12 hours, or per manufacturer’s instructions, shaft as explained in step 2.

-

Page 18: Air Valve Repair

Repair Center Section Section Repair Repair Center Center Section Repair Tools Tools Tools Required Required Required 6. Use a 10 mm socket wrench to remove the screws (104) holding the air covers (103) to the • Torque wrench center housing (101). •... - Page 19 Repair Reassemble the the Center Center Section Section Reassemble Reassemble Center Section 1. Install the shaft u-cups (106) so the lips face 5. Align the air cover (103) so the pilot pin (112) fits of the housing. in the middle hole (M) of the three small holes near the center of the cover.

- Page 20 Repair Leak Leak Leak Detectors Detectors Detectors Leak detectors are sensors that are mounted in the 5. If the leak detector successfully detected the air covers of the pump to monitor for fluid leakage product, clean the bushing and leak detector and caused by a diaphragm rupture.

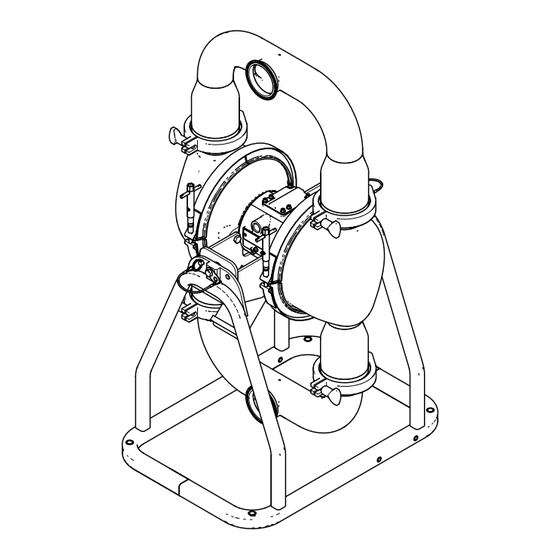

- Page 21 Parts Parts Parts Parts SP2B.xxxx model shown 3A6782D Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910...

- Page 22 Parts SP3F.xxxx model shown Replacement Replacement Replacement Unloader Unloader Pumps Unloader Pumps Pumps To order a replacement pump for use in a drum or tote unloader, obtain the six digit number from the pump being replaced and refer to the table below to determine the part number to order.

- Page 23 Parts Parts/Kits Quick Quick Reference Reference Parts/Kits Parts/Kits Quick Reference Use this table as a quick reference for parts/kits. Go to the pages indicated in the table for a full description of kit contents. Description Qty. Description Qty. Part/Kit Description Description Qty.

- Page 24 Parts Center Section Section Center Center Section Sample Configuration Number Pump Wetted Drive Center Section Manifolds Seats Checks Seals Certifica- Model Section and Air Valve aphragms tion Material Material 2150 SP1A SP1A SP1A 3A6782D Springer Pumps, LLC Tel: 866-777-6060 Website: www.springerpumps.com Fax: 866-777-6383 Int'l: +001 267 404 2910...

- Page 25 Parts Part Description Part Description Part Part Description Description Part Part Description Description 116344 HOUSING, center, SCREW includes plugs assembly; 108† 157628 O-RING — — — Aluminum Axxx) (Axxx Axxx COVER 15K009 Stainless Steel (S01A, 25P128 S01A, S02A S02A) 15K010 Stainless Steel (S03A) 25P129 S03A...

- Page 26 Parts Fluid Covers Covers and and Manifolds Manifolds Fluid Fluid Covers Manifolds Sample Configuration Number Pump Wetted Drive Center Section Manifolds Seats Checks Diaphragms Seals Certifica- Model Section and Air Valve tion Material Material 2150 S01A Manifold* Fluid Cover Pump PN Wetted Inlet Manifold...

- Page 27 Parts SP4F SSA, SSB 25P024 25P025 SSE, SSF 25N998 25N999 HS WYE 25P029 25P029 * Requires DIN adapter fitting, DIN adapter gasket, and clamp on each manifold for manifold type SSB, SSD, SSF. Dual Inlet Inlet and and Dual Dual Outlet Outlet Dual Dual...

- Page 28 Parts Diaphragms Diaphragms Diaphragms Sample Configuration Number Pump Wetted Drive Center Section Manifolds Seats Checks Diaphragms Seals Certifica- Model Section and Air Valve tion Material Material 2150 SP1A Bolt Bolt Bolt- - - Through Through Through Diaphragm Diaphragm Kits Diaphragm Kits Kits Overmolded...

- Page 29 Parts Frames Frames Frames 24L978 shown (includes items 2 and 3) Qty. Ref. Part/Kit Description Description Description Qty. Qty. Ref. Ref. Part/Kit Part/Kit 203† — — — SCREW, 3/8-16 UNC 204† 111743 WASHER, flat 205† — — — BUSHING 206† — — — NUT, acorn 207* —...

- Page 30 Technical Data Technical Technical Technical Data Data Data SaniForce SaniForce 2150, SaniForce 2150, 2150, 3150, 3150, 4150 3150, 4150 4150 Air Air- - - Operated Operated Double Operated Double Double Diaphragm Diaphragm Diaphragm Pump Pump Pump Metric Metric Metric Maximum fluid working pressure 120 psi 0.8 MPa, 8 bar...

- Page 31 Technical Data Fluid Fluid Fluid Temperature Temperature Temperature Range Range Range NOTICE NOTICE NOTICE Temperature limits are based on mechanical stress only. Certain chemicals will further limit the fluid temperature range. Stay within the temperature range of the most-restricted wetted component. Operating at a fluid temperature that is too high or too low for the components of your pump may cause equipment damage.

- Page 32 With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the SaniForce 2150 and is the answer not in the manual?

Questions and answers