Table of Contents

Advertisement

Quick Links

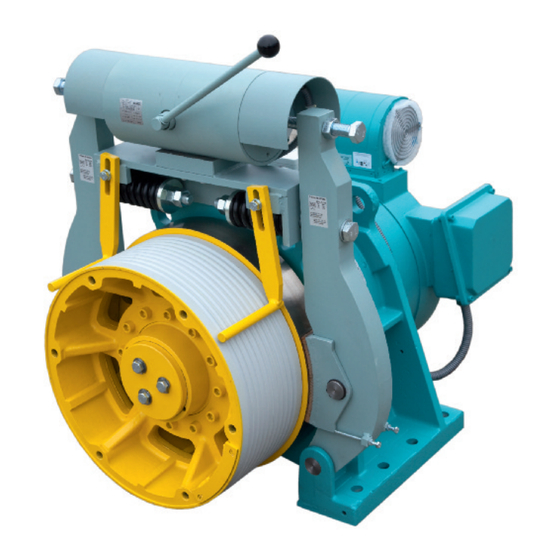

Gearless Lift Machine

WSG-19

Operating Instructions

Reprinting, translation or reproduction in any form -

whether in part or in full - requires the prior written

permission of WITTUR Holding GmbH.

Änderungen vorbehalten!

Gearless Lift Machines

beamer 2

WSG-19.1

WSG-19.2

WSG-19.4

WITTUR Holding GmbH

Rohrbachstraße 26-30 • D-85259 Wiedenzhausen, Germany

Tel. +49 (0) 81 34/18-0 • Fax +49 (0) 81 34/18-49

http://www.wittur.com, E-mail: info@wittur.com

Seite/page

Datum/date

Stand/version

Wittur Holding GmbH reserves the right to make

changes in the information and pictures contained in

these operating instructions without prior notice.

Subject to changes without notice!

1

28.01.2013

0.17

Advertisement

Table of Contents

Summary of Contents for WITTUR beamer 2

- Page 1 Tel. +49 (0) 81 34/18-0 • Fax +49 (0) 81 34/18-49 http://www.wittur.com, E-mail: info@wittur.com Reprinting, translation or reproduction in any form - Wittur Holding GmbH reserves the right to make whether in part or in full - requires the prior written changes in the information and pictures contained in permission of WITTUR Holding GmbH.

- Page 2 WSG - 19..with twin shoe brake WITTUR Electric Drives GmbH reserves the right to correct or change the contents of this manual and these product details without prior notice. expressly reserve the right to make technical changes which improve the lift machines or their safety stan- dards without prior notice.

-

Page 3: Table Of Contents

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions Contents 1. General safety instructions........................4 2. Product description...........................5 3. Nameplate..............................6 4. Scope of supply ............................6 5. Transport and storage ..........................7 6. Installation..............................8 7. Electrical connection ..........................9 7.1. General ................9 7.2. -

Page 4: General Safety Instructions

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 1. General safety instructions Explanation of symbols used in these instructions Safety precautions means that death or serious injury to persons or Only qualified personnel are authorised to perform any plan- serious damage to property will occur unless ning, installation or maintenance work, and this must be done the appropriate precautions are taken. -

Page 5: Product Description

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 2. Product description The compact flat-type gearless WSG-19 lift machines are roller bearing (15) which is preloaded by means of a cup designed for gearless traction sheave lifts with machine spring. -

Page 6: Nameplate

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 3. Nameplate The nameplate of the lift machine is on the motor frame. EC type-examination Type code of certificate lift machine Serial no. Rated current Rated speed Rated torque Weight Rated frequency 4. -

Page 7: Transport And Storage

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 5. Transport and storage The lift machines leave the factory in perfect condition This can be done, for instance, with heated air, in a dry- after being tested. ing oven, or by applying a d.c. voltage to the motor con- nections. -

Page 8: Installation

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 6. Installation Be sure to check the base frame or founda- tudes. In case of a deviating altitude and/or ambient tion loads by calculation before installing temperature, the reduction factors k shown in the dia- the lift machine. -

Page 9: Electrical Connection

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 7. Electrical connection 7.1. General 7.2. Motor connection / Winding protection The electrical connection may only be made The electrical connection of the motor and the winding by a qualified electrician. monitoring devices is made in the terminal box on top of the machine. - Page 10 Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions Motor connection diagram terminal strip for brake connection WAGO 261; Cable cross-section: PE connection (M 10) ...2.5 mm Stripping length required: 8 ... 9 mm terminal strip for fan and running capacitor winding protection con- for fan...

-

Page 11: Speed/Position Measuring System

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions PTC-thermistor 7.3. Speed/Position measuring system The basic version of the lift machines is equipped with a The operating voltage of the PTC thermis- ECN 1313 sine-cosine encoder from Heidenhain GmbH. tors is not allowed to exceed 25 V DC. -

Page 12: Measuring System Ecn 1313

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 7.3.1. Measuring system ECN 1313 7.3.2. Measuring system ERN 1387 Number of sine-cosine Number of sine-cosine periods per rotation: 2048 periods per rotation: 2048 Operating voltage: Operating voltage: Data interface: SSI or ENDAT Commutation signals: 1 sine and cosine signal... -

Page 13: Brake

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 7.4. Brake A.c. side switching The brake magnets are supplied with d.c. voltage by the • Low-noise switching of the brake overexcitation rectifier, which is supplied separately. The • No protective measures required for switching contact rectifier should be installed in the control cabinet of the lift system. - Page 14 Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions Circuitry suggestion for brake control WSG-19 Subject to changes without notice! Änderungen vorbehalten!

-

Page 15: Commissioning

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions Monitoring the brakes Dimension drawing brake control unit The switching state and wear of the brakes are monitored by means of dust-proof microswitches with gold con- tacts. The contacts are designed as n.c. contacts, i.e. the contact is opened if the armature is attracted (brake released). -

Page 16: Operation And Maintenance

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 9. Operation and maintenance 9.1. General 9.2. Maintenance intervals The regulations concerning operation, maintenance and Check the thickness every six inspection in accordance with the applicable safety regu- see section 9.7. of the brake linings months lations in lift construction such as DIN EN 81 "Safety rules... -

Page 17: Lubricating Instructions

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 9.3. Lubricating instructions 9.5. Replacing the traction sheave Relubricate the main bearing after about 7,000 hours of operation, using a KP 2 N-30 to DIN 51 502 grease such The traction sheave can work loose if it is as Wälalit LZ 2 or Klüberlub BE 41-542 (approx. -

Page 18: Emergency Evacuation

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 9.6. Emergency evacuation The lift design engineer must always pro- While releasing the brake magnets, either electrically or vide for an electric return motion control using the brake lever plates, the slide block can be dis- placed by turning the corresponding nuts. -

Page 19: Testing The Brake System To En 81-1

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 9.7. Testing the brake system to EN 81-1 The brake system should be tested with the Monitoring the brakes car about halfway down the shaft. If any Check the brake monitoring switches individually. No car motor short-circuit connections have been travel must be permitted if a micro switch signal is miss- made, these should be deactivated so that... -

Page 20: Brake

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 9.8. Brake Example: Replacing the brake shoe Lift machine WSG-19.4 Replace the brake linings when they are Rated motor torque M = 2500 Nm worn down to a thickness of less than 3- 4 mm or no longer usable. - Page 21 Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions Brake lever Brake spring Switching plunger Lever bolt Pull rod Magnet bracket Brake shoe Braking data label Fastening bolt Bolt Setting screw Locknut Circlip Manual release lever Brake magnet Setting screw Microswitch Spring plate...

- Page 22 Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions Monitoring / Readjusting the remaining play The play x between the thrust member and the brake magnet (18) is reduced with increasing lining wear. It must therefore be checked and readjusted at regular intervals. Note If the linings are worn down to such an extent that the remaining play x has been...

-

Page 23: Replacing The Measuring System

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 9.9. Replacing the measuring system • Reinstall the cable cover (5). The measuring system is only accessible • Reinstall the cover plate (4). from the rear side of the motor. Note Disassemble the measuring system only if this is necessary because of a defect. -

Page 24: Trouble Shooting

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 9.10. Trouble shooting Fault Possible cause Remedy Motor does not start, operates out of • Motor not connected in proper • Connect motor correctly phase sequence control or develops no torque •... -

Page 25: Type Code

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 10. Type code Example: G- 19 . 5 3 A G- 19 . Z3 - X3 X4 X5 X6 X7 X8 X9 Customer specific identifier S = Synchronous motor G = Gearless U = Gearless, UL-CSA approved Frame size... -

Page 26: Technical Data

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 11. Technical data Duty type: S3 - 40 % ED Shoe brake Traction sheave: dia. 420 mm, dia. 530 or dia. 650 mm WSG-19.1/2 WSG-19.4 Traction sheave hardness: min. 220 HB 30 Type: TB 550-BW-I TB 550-BW-II... - Page 27 Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions Brake monitoring contacts Loadability of contacts: ...250VAC/1mA...3A (resristive load) Mechanical life of contacts: 5 x 10 switching operations Degree of protection: IP 67 Separate fan Type: D2E 133 AM47-A5 Operating voltage: 230 V / 50/60 Hz Current consumption:...

-

Page 28: Dimension Drawing

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 12. Dimension drawing Dimensions (mm) Treibscheibe WSG- 19.1 19.2 19.4 Motor / motor traction sheave WSG- Æ D [kg] Masse / weight 19.1 19.2 19.4 [kN]] Trägheitsmoment [kgm 684,5 817,5 904,5 87,5 inertia 97,5... -

Page 29: Accessories

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 13. Accessories 13.1. Connecting cable for measuring systems recom. recommended Inverter type encoder system measurement system cable ARKEL ADrive ECN 1313 502 452 021 xx (EnDat or SSI) CT unidrive SP ECN 1313 emotron / Dietz 501 112 022 xx... -

Page 30: Rope Clamp

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 13.2. Rope clamp A rope clamp is used, for example, to pull Magnetkonsole the car from the safety devices if the solenoid bracket ropes are slipping. Fasten the clamp to the traction sheave by inserting two M 20 bolts in the appro- priate threaded holes in the traction sheave. -

Page 31: Option Anti-Condensation Heater

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 13.5. Option anti-condensation heater For motors which are used at high temper- ature differences or at places with extreme climatic situations with high humidity, we recommend to use a motor with an anti- condensation heater to prevent the unit of condensation water inside the housing . -

Page 32: Spare Parts

Gearless Lift Machine Seite/page Datum/date 28.01.2013 WSG-19 Stand/version 0.17 Operating Instructions 14. Spare parts Item Part Description Motor Traction sheave incl. M16 x 70 jack bolts Acc. to machine nameplate type code X5 X6 X7 D2E 133 AM47-A5 Fan filter mats ET 36 13 113 0545 Rope slip-off guard, compl.

Need help?

Do you have a question about the beamer 2 and is the answer not in the manual?

Questions and answers