Table of Contents

Advertisement

Quick Links

Gearless Lift Machine

WSG/WGG-29

Operating Instructions

Reprinting, translation or reproduction in any form -

whether in part or in full - requires the prior written

permission of WITTUR Holding GmbH.

Subject to changes without notice !

Gearless Lift Machines

beamer 2

WSG / WGG-29.1

WSG / WGG-29.2

WSG / WGG-29.3

Translation of the Original Operating Instructions

WITTUR Holding GmbH

Rohrbachstraße 26-30 • D-85259 Wiedenzhausen, Germany

Tel. +49 (0) 81 34/18-0 • Fax +49 (0) 81 34/18-49

http://www.wittur.com, E-mail: info@wittur.com

Code

Date

Version

Page

Wittur Holding GmbH reserves the right to make

changes in the information and pictures contained in

these operating instructions without prior notice.

Subject to changes without notice !

EN

EN

GM.8.002662.EN

04.02.2019

0.19

1

Advertisement

Table of Contents

Summary of Contents for WITTUR WGG-29.1

- Page 1 Tel. +49 (0) 81 34/18-0 • Fax +49 (0) 81 34/18-49 http://www.wittur.com, E-mail: info@wittur.com Reprinting, translation or reproduction in any form - Wittur Holding GmbH reserves the right to make whether in part or in full - requires the prior written changes in the information and pictures contained in permission of WITTUR Holding GmbH.

- Page 2 WSG / WGG-29.1 WSG / WGG-29.2 WSG / WGG-29.3 WITTUR Electric Drives GmbH reserves the right to correct or change the contents of this manual and these product details without prior notice. We expressly reserve the right to make technical changes which improve the lift machines or their safety standards without prior notice.

-

Page 3: Table Of Contents

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page Contents 1. General information...........................4 1.1. About this operating manual ............4 1.2. -

Page 4: General Information

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 1. General information 1.1. About this operating manual The purpose of this operating manual is to ensure that any work on WxG-29 lift machines is carried out safely. Please regard it as part of the product and keep it within easy reach. -

Page 5: Format Of The Safety Instructions

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page Qualified personnel Only qualified personnel are authorised to perform any planning, installation or maintenance work, and this must be done in accordance with the relevant instructions. The personnel must be trained for the job and must be familiar with the installation, assembly, commissioning and operation of the product. -

Page 6: Product Overview

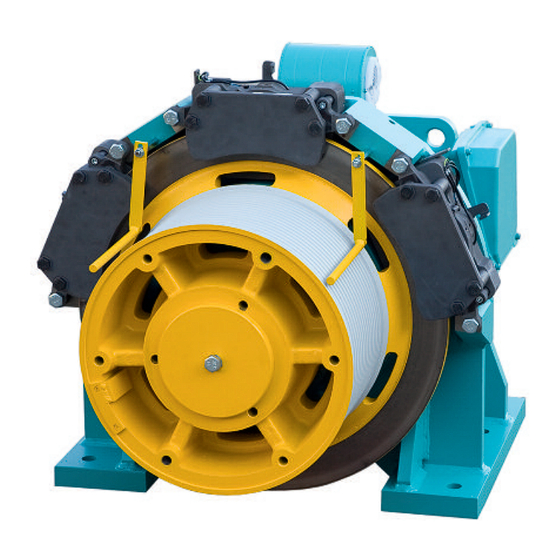

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 3. Product overview 3.1. Product description The compact gearless WxG-29 synchronous lift machines are designed for traction sheave lifts. They are distin- guished by their high efficiency, extremely low noise and excellent operating characteristics. The machines can be supplied for several rated speeds. -

Page 7: Transport And Storage

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 3.2. Transport and storage • The lift machines leave the factory in perfect condition after being tested. • Make a visual check for any external damage immediately upon their arrival on site. If any damage is found to have occurred in transit, make a notice of claim in the presence of the carrier. -

Page 8: Installation

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 4. Installation 4.1. Setting up Be sure to use calculations to check the base frame or foundation loads before installing the Danger lift machine. • The machines can be used in lift systems with or without a machine room •... -

Page 9: Electrical Connection

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page Ambient conditions • The following ambient conditions must be ensured on site Altitud: max. 1,000 m a.s.l. Ambient temperature: -5°C ... 40 °C Max. rel. humidity: 85% at 20°C (no moisture condensation) •... -

Page 10: Motor Connection / Winding Protection / Separately Driven Fan

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 4.2.2. Motor connection / Winding protection / Separately driven fan • The electrical connection of the motor, the separetely driven fan and the winding sensors to the mains is made in the motor terminal box. - Page 11 Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page Cable cross-section required: Cable cross-section Permissible max. The table on the right gives the standard values for required motor current I (S1) the current-carrying capacity of PVC cables at a maximum ambient temperature of 40°C.

-

Page 12: Speed/Position Measuring System

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 4.2.3. Speed/Position measuring system • The basic version of the lift machines is equipped with an ECN 1313 SineCosine encoder from Heidenhain GmbH. The encoder is connected via a 17-pole signal plug connector fitted to the measuring system housing. •... -

Page 13: Brake

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 4.2.4. Brake • Please refer also to the operating instructions for the brake. • The brakes are supplied with DC voltage by the overexcitation rectifiers, which are fitted in the brake terminal box. - Page 14 Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page Monitoring the brakes • The switching states and the wear of the brakes are monitored by means of dust-proof microswitches (see connecting diagram). • Please assure that the contact-current is at least 10 mA to keep the contacts clean. The microswitches must be evaluated separately for each partial brake to ensure compliance Warning with the requirements of the type examination.

- Page 15 Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page Circuitry suggestion for brake control WxG-29 Subject to changes without notice ! Subject to changes without notice !

-

Page 16: Commissioning

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 5. Commissioning The following points should be checked or completed: • Check that all performance and application data specified on the name plate of the machine are consistent with your application. -

Page 17: Operation And Maintenance

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 6. Operation and maintenance 6.1. General • The regulations concerning operation, maintenance and inspection pursuant to the applicable safety regula- tions for lift construction such as DIN EN 81-20, DIN EN 81-50, LD 2014/33/EU and other relevant regulations are to be strictly observed. -

Page 18: Relubrication Of The Bearings

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 6.3. Relubrication of the bearings Relubricate the main bearing after about 7,000 hours of operation or every 3 years, using a KP 2 N-30 to DIN 51 502 grease such as Wälalit LZ 2 or Klüberlub BE 41-542 (approx. -

Page 19: Filter Mats

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page Extraction of the grease With the re-lubrication the old or surplus grease is pressed in a collector duct. The collector duct is big enough to catch grease of 12…15 proper re-lubrications and is therefore sufficient for the lifetime of the machine. If necessary, the collector duct can be opened with a grub screw on D-end and ND-end. -

Page 20: Emergency Evacuation

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 6.5. Emergency evacuation Only qualified service personnel are permitted to take any evacuation measures in the event Danger of an emergency. Emergency evacuation by mechanical means • The brakes (3) can be released remotely by hand using a lever block (1) and Bowden ca- Remote brake control by Bowden cable bles (2). - Page 21 Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page Mechanical return motion device • For cases such as lift failure or the car being retained by the safety device, a mechanical return motion device can be used to move the lift manually. Use of the return motion device is shown in the drawing. •...

-

Page 22: Testing The Brake System To En 81

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 6.6. Testing the brake system to EN 81 The brake system should be tested with the car about halfway down the shaft. If any motor short-circuit connections have been made, these should be deactivated so that the brake effect can be tested independently. -

Page 23: Replacing The Measuring System

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 6.7. Replacing the measuring system The measuring system is only accessible from the rear side of the motor. See the mounting instructions for the Heidenhain encoder. Disassemble the measuring system only if this is necessary because of a defect. Remember to readjust the offset value after reassembly (see the inverter operating instructions). -

Page 24: Trouble Shooting

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 6.8. Trouble shooting Fault Possible cause Remedy Motor does not start, operates out of • Motor not connected in proper • Connect motor correctly phase sequence control or develops no torque •... -

Page 25: Type Code

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 7. Type code Example: G- 29 . 6 5 A G- 29 . Z3 - X3 X4 X5 X6 X7 X8 X9 Customer specific identifier S = Synchronous motor G = Synchronous motor, split housing design G = gearless... -

Page 26: Technical Data

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 8. Technical data Duty type: S1 (S3 - 40 % ED) Dual-circuit fail-safe brake Traction sheave: dia. 650 mm Brake type: RSD 10 Traction sheave hardness: mind. 220 HB 30 Brake torque: 2/3 x 4600 Nm DE bearing:... -

Page 27: Dimension Drawing

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 9. Dimension drawing Subject to changes without notice ! Subject to changes without notice ! -

Page 28: Accessories

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 10. Accessories 10.1. Connecting cable for measuring systems recommended recommended measurement Measurement cable type Inverter type encoder system system cable E-Pack ECN 1313 503 325 021 xx (EnDat or SSI) Arkel ARCODE D-Pack... -

Page 29: Rope Clamp

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 10.2. Rope clamp Seilniederhalter Rope slip-off guard Stützschraube Back-up bolt DIN 933- M24x55 DIN 125- A25 DIN 933- M16x55 A rope clamp is used, for example, to pull the car from the safety devices if the ropes are slipping. -

Page 30: Remote Brake Control By Bowden Cable

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 10.4. Remote brake control by Bowden cable The Bowden cable remote control is used to release the brakes mechanically in the event of an emergency. See section 6.5 "Emergency evacuation"... - Page 31 Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 4. Tension the Bowden cables on the lever block (1) using the nuts (10 and 11) on the threaded rod (12). The manual release levers (4) of the brakes (3) must not move.

-

Page 32: Return Motion Device

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 10.5. Return motion device Only qualified service personnel are permitted to take any evacuation measures in the event Danger of an emergency. The return motion device is used to M 36 x 1,5 SW 55 move the lift manually in an emer- †... - Page 33 Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 5. Insert the threaded rod (1) into the bearing block (8) and fasten it using the nut (7). Ensure that the nut (7) is completely screwed onto the threaded rod (1) with 2-4 mm of thread left protruding beyond the nut.

-

Page 34: Special Features Of Wgu-29 Lift Machines

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 11. Special features of WGU-29 lift machines The maximum permissible shaft load of the WGU-29 lift machines is 280 kN (lift machines Danger with split housing design and with UL/CSA approval). The shaft load must be further reduced, dependent on the load direction (see diagram below.) load force angle a 180°... -

Page 35: Spare Parts

Gearless Lift Machine Code GM.8.002662.EN Date 04.02.2019 WSG/WGG-29 Version 0.19 Operating Instructions Page 12. Spare parts Item Part Description Motor traction sheave acc. machine nameplate type code X5 X6 X7 Measuring system (depending on spec.) ECN 1313 / SSI / 2048 incr. / clamping ring ECN 1313 / ENDAT / 2048 Inkr. -

Page 38: Annex

Annex to the EC Type-Examination Certificate No. EU-BD 1030 of 2017-01-18 Scope of application Use as braking device – part of the the protection device against overspeed for the car moving in upwards direction – permissible brake force and tripping speed 1.1.1 Permissible brake force when the braking device acts on the brake disk while the car is moving upward... -

Page 39: Annex

Annex to the EC Type-Examination Certificate No. EU-BD 1030 of 2017-01-18 Conditions Above mentioned safety component represents only a part at the protection device against over- speed for the car moving in upwards direction and unintended car movement. Only in combination with a detecting and triggering component in accordance with the standard (two separate compo- nents also possible), which must be subjected to an own type-examination, can the system created fulfil the requirements for a protection device. -

Page 40: Annex

Annex to the EC Type-Examination Certificate No. EU-BD 1030 of 2017-01-18 This EU type-examination certificate was issued according to the following standards: EN 81-1:1998 + A3:2009 (D), Annex F.7 and F.8 EN 81-20:2014 (D), part 5.6.6.11, 5.6.7.13 EN 81-50:2014 (D), part 5.7 and 5.8 A revision of this EU type-examination certificate is inevitable in case of changes or additions of the above mentioned standards or of changes of state of the art. - Page 41 Enclosure to the EU Type-Examination Certificate No. EU-BD 1030 of 2017-01-18 Authorised Manufacturer of Serial Production – Production Sites (valid from: 2017-01-18): Company Chr. Mayr GmbH & Co. KG Address Eichenstr. 1 87665 Mauerstetten - Germany Company Mayr Polska Sp. z. o. o. Address Rojów, ul.

- Page 44 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Please read these Operational Instructions carefully and follow them accordingly! Ignoring these Instructions can lead to lethal accidents, malfunctions, brake failure and damage to other parts. These Installation and Operational Instructions (I + O) are part of the brake delivery.

- Page 45 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Safety and Guideline Signs DANGER Immediate and impending danger, which can lead to severe physical injuries or to death. CAUTION Danger of injury to personnel and damage to machines.

- Page 46 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Safety Regulations These Safety Regulations are user hints only and may not be complete! General Guidelines Guidelines for Electromagnetic Compatibility (EMC) DANGER In accordance with the EMC directives 2014/30/EU, the Danger of death! individual components produce no emissions.

- Page 47 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Safety Regulations These Safety Regulations are user hints only and may not be complete! Dimensioning Earthing Connection Attention! The brake is designed for Protection Class I. This protection When dimensioning the brake, please take into consideration covers not only the basic insulation, but also the connection of all whether a load torque is present when selecting the protection.

- Page 48 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Safety Regulations These Safety Regulations are user hints only and may not be complete! User-implemented Protective Measures: Please cover moving parts to protect against injury through seizure.

- Page 49 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Hand release stroke Air gap “a” Fig. 1 Fig. 2 Fig. 3 incl. 3 mm stroke Fig. 4 of the hand release Earthing strand Coil cable Fig.

- Page 50 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Friction surface limitation for brake disk diameter: Fig. 6 Fig. 7 Fig. 8 (alignment mechanism) 23/03/2017 TK/TL/GC/SU Chr. Mayr GmbH + Co. KG Eichenstraße 1, D-87665 Mauerstetten, Germany Tel.: +49 8341 804-0, Fax: +49 8341 804-421 Page 7 of 16 www.mayr.com, E-Mail:...

- Page 51 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Parts List (Only use mayr original parts) Item Name Pcs. Coil carrier assembly with coil Armature disk Counterplate Friction pad assembly Cap screw M6 x 12 Hand release assembly Hand release lever Lock washer...

- Page 52 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Table 1: Technical Data Max. braking force: 11182 N Min. braking force: 4551 N Braking force tolerance: 0 / +60 % Max. friction work per braking action: 400000 J r max.

- Page 53 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Table 2: Switching Times [ms] Design min. nominal braking force max. nominal braking force Attraction t Drop-out t (DC) from holding voltage / overexcitation: 210 / 260 55 / 60 Drop-out t...

-

Page 54: Annex

® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Application Installation Conditions ® ® ROBA -diskstop for use as a holding brake with CAUTION Please observe precisely the following occasional EMERGENCY STOP braking actions installation conditions and the brake ... - Page 55 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Adjustment Installation of Bowden Cable Hand Release The hand release is pre-assembled manufacturer-side. The brakes are equipped manufacturer-side with the respective springs for the braking force In order to install the Bowden cable, the lock washer (6.2) must stated on the Type tag.

- Page 56 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Electrical Connection and Wiring Magnetic Field Removal AC-side switching The brakes must only be operated with The power circuit is overexcitation. interrupted in front of the rectifier.

- Page 57 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Release Monitoring (Item 12 / Fig. 5 / Optional) Wear Monitoring (Item 13 / Fig. 5 / Optional) ® ® The ROBA -diskstop brakes are supplied optionally with manufacturer-side installed and adjusted wear monitoring (13) Please carry out a functional inspection before device.

- Page 58 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Maintenance Disposal ® ® The ROBA -diskstop is mainly maintenance-free. Our electromagnetic brake components must be disposed of The friction lining pairing is robust and wear-resistant. This separately as they consist of different materials.

- Page 59 ® ® Installation and Operational Instructions for ROBA -diskstop Type 894.5_ _._ _ Size 10 (B.8.4.5.EN) Malfunctions / Breakdowns: Malfunction Possible Causes Solutions Incorrect voltage on rectifier Apply correct voltage Rectifier failure Replace rectifier Air gap too large (worn friction lining) Replace the friction pads Brake does not release...

Need help?

Do you have a question about the WGG-29.1 and is the answer not in the manual?

Questions and answers