Table of Contents

Advertisement

Quick Links

Gearless Synchronous Lift Machines

WSG09.X

Operating and maintenance manual J40003

Wittur Holding GmbH reserves the right to make

changes in the information and pictures contained in

these operating instructions without prior notice.

Gearless Synchronous Lift Machines

WSG .X

WITTUR Holding GmbH

Rohrbachstrase 26-30 . D-85259 Wiedenzhausen, Germany

Tel. +49 (0) 81 34/18-0 Fax +49 (0) 81 34/18-49

http://www.wittur.com, E-mail: info@wittur.com

09

Page

1

Date

21.05.2015

Version

E

Subject to changes without notice!

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for WITTUR WSG09

- Page 1 Rohrbachstrase 26-30 . D-85259 Wiedenzhausen, Germany Tel. +49 (0) 81 34/18-0 Fax +49 (0) 81 34/18-49 http://www.wittur.com, E-mail: info@wittur.com Wittur Holding GmbH reserves the right to make changes in the information and pictures contained in these operating instructions without prior notice.

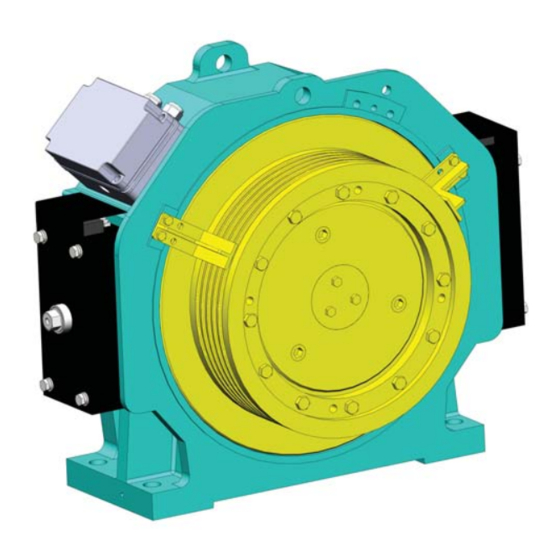

- Page 2 WSG09.X with block brake Wittur Holding GmbH reserves the right to correct or change the contents of this manual and these product details without prior notice. We expressly reserve the right to make technical changes which improve the lift machines or their safety standards without prior notice.

-

Page 3: Table Of Contents

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 Index 1. General safety instructions ............4 12. Operation and maintenance ..........21 2. Product description ..............6 12.1. General ................21 3. Nameplate...................7 12.2. Maintenance intervals ..........21 4. -

Page 4: General Safety Instructions

Note result. The WSG09.X lift machines are intended for use in an enclosed, lockable machine room or shaft to which only Intended use qualified personnel and personnel authorised by the customer have access. - Page 5 Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 High surface temperatures may occur on the external parts of the machine. Therefore, no temperature-sensitive parts may be in contact with Warning these parts or attached to them. Protection against accidental contact should be provided, if required.

-

Page 6: Product Description

Version Operating and maintenance manual J40003 2. Product description The gearless WSG09.X lift machines are designed by outer designed for mechanical evacuation. The wheels is intent rotor for gearless traction lifts with or without a machine to adapt to the system for the evacuation in emergency room. -

Page 7: Nameplate

CE Certificate No. TUV SUD Manufacture date C ontract N o. Serial N o. V/min -1 Wittur Elevator Components (Suzhou) Co.,Ltd Manufactured in China The nameplate of the brake is on the brake. Manufacture Date: Pull In Voltage: 110V DC Model Name:... -

Page 8: Type Code

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 4. Type code Example 09 . 09 . X3X4 X8X9 X5X6X7 Synchronous motor Frame type Overall length Identifyed by: 2, 3, 4 Customer specific identifer Motor voltage 0: Suitable for converter supply using a link voltage of 500 ... -

Page 9: Technical Data

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 5. Technical data Site conditions Duty type S3 - 40% Sheave Ø400mm / Ø450mm Max. Attitude Up to 1,000 m (At high altitude decrease this value) Traction sheave hardness Min. - Page 10 Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 Synchronous 22-pole Motor Type WSG09.3 Suspension Rated Torque [Nm] S3-40%,240s/h Groove profile ΦDt Sheave [mm] [kg] up to 1000 up to 800 loads v[m/s] [rpm] [kW]...

-

Page 11: Dimension Drawing

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 6. Dimension drawing Dimensions (mm) Subject to changes without notice! -

Page 12: Scope Of Supply

Encoder cables Manual release lever (for machine room solution) 8. Transport and storage The WSG09.X lift machines leave the factory in perfect Measure the insulation resistance before initial operation condition after being tested. of the machine. If the value has dropped below < 1 k... -

Page 13: Installation

The machine or base frame should be mounted on rubber pads for vibration damping. Degree of protection The machine is fastened using 4x M24 bolts WSG09.X Lift machines are designed with degree of Note (strength class8.8;). protection IP 40. Make sure that the cable entries to... -

Page 14: Electrical Connection

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 10. Electrical connection 10.1. General The electrical connection may only be made by a quali ed electrician. Before starting any work on the machines, Danger ensure that the lift machine or system is properly isolated. - Page 15 WSG09.X Version Operating and maintenance manual J40003 The WAGO terminal strips are suitable for the following Technical data: types of copper conductors: WSG09.2/09.3 1.0m/s: 2.5mm WSG09.2/09.3 1.5m/s: 4mm single-core conductor WSG09.2/09.3 1.75m/s: 4mm WSG09.2/09.3 2m/s: 4mm WSG09.2/09.3 2.5m/s: 6mm stranded conductor WSG09.4 1.0m/s: 2.5mm...

- Page 16 For safety reasons, it is very important that the motor be The currents speci ed under the machine data properly and carefully earthed. for the series WSG09.X refer to duty type S3- 40%. This must be taken into account when It is essential to use the earthing terminal...

-

Page 17: Speed/Position Measuring System

Version Operating and maintenance manual J40003 10.3. Speed/Position measuring system 10.3.1 Measuring system ECN 1313 EnD at Lift machine of WSG09.X are equipped with ECN1313 EnDat or ERN1387 encoder from Heidenhain GmbH. or encoder of 2048 Resolution : TS5213N2503 from TAMAGAWA... -

Page 18: Measuring System Ern 1387

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 10.3.2 Measuring system ERN 1387 10.3.3 Measuring system TS5213N2503 (TAMAGAWA) 2048 2048 Resolution: Resolution : Operating voltage: Operating voltage: Commutation signals: sine and cosine Commutation signals:... -

Page 19: Brake

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 10.4. Brake Monitoring the brakes The brakes are supplied and held with 110V DC . 75-80V DC for holding voltage is preferred for best performances in tem... -

Page 20: Commissioning

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 11. Commissioning The following points should be checked or completed: Is the measuring system properly connected? Remove all securing, auxiliary and installation tools from Check that the offset value indicated on the measuring the danger area. -

Page 21: Operation And Maintenance

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 12. Operation and maintenance 12.1. General 12.2. Maintenance intervals The regulations concerning operation, maintenance and inspection in accordance with the applicable safety regu- Relubricate the bearings see section 12.3. -

Page 22: Lubricating Instructions

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 12.3. Lubricating instructions The main bearing (self-aligning roller bearing) has been lled at the factory with a quantity of grease sufficient for the nominal service life of the machine. -

Page 23: Replacing The Traction Sheave

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 12.6. Replacing the traction sheave 12.7. Brake Electromagnetic brakes is a kind of special The traction sheave has to be replaced when a product for lift using. It is always pre-adjusted limited situation. - Page 24 Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 5. When the gap is about 0.55mm, use a feeler gauge Procedure of assembling and adjustment measuring the gap (operation gap) between the static 1. Screw the adjustment sets into the bottom place of the plate and moving plate.

- Page 25 Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 7. After setting, power on the brake. The moving plate would Operation and safety instruction be pulled in. Use the feeler gauge again to measure the gap Ensure working situation of brake is inside the min.

-

Page 26: Replacing The Measuring System

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 12.8. Replacing the measuring system Disassembly Remove the cable cover from the measuring system; pull out the cable p.c.b. connector. The measuring system is only accessible from Loosen the clamping ring on the measuring system (2mm the rear side of the motor. - Page 27 Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 12.8. Replacing the measuring system Disassembly The measuring system is only accessible from Loosen the clamping ring on the measuring system (2mm the rear side of the motor.

-

Page 28: Trouble Shooting

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 12.9. Trouble shooting Fault Possible cause Remedy Motor does not start, operates Motor not connected in proper phase sequence Connect motor correctly out of control or develops no... -

Page 29: Accessories

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 13. Accessories 13.1. Connecting cable for measuring systems Converter Connection Encoder Order number Emerson Unidrive Z320WSGS30010V0X ECN1313 EnDat Yaskawa-L1000 Schneider Altivar Z320WSGS30006V0X ERN1387 Monarch Z320WSGS30008V0X Meiden VT... -

Page 30: Mechanical Evacuation

Page 30 0 Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 13. Accessories 13.2. Mechanical evacuation 13.4. Brake manual release In urgent situation, like power off or emergency rescure, in In order to open the brake in the shaft, a manual brake release case the system weight at car side equals to cwt side, the car is needed. -

Page 31: Spare Parts

Page Gearless Synchronous Lift Machines Date 21.05.2015 WSG09.X Version Operating and maintenance manual J40003 14. Spare parts Subject to changes without notice!

Need help?

Do you have a question about the WSG09 and is the answer not in the manual?

Questions and answers