Summary of Contents for Pottinger NOVACAT X8 ED

- Page 1 Operator‘s manual 99+3843.EN.80V.0 Translation of the original Operating Manual Disc mower NOVACAT X8 ED/RCB/COLL (Type PSM 3843 : + . . 01483)

- Page 2 Pöttinger - Trust creates Affinity - since 1871 "Quality pays for itself." Therefore we apply the highest quality standards to our products which are constantly monitored by our in-house quality management and our management board. Because the safety, perfect function, highest quality and absolute reliability of our machines in operation are the core competencies for which we stand.

- Page 3 INSTRUCTIONS FOR PRODUCT HANDOVER PÖTTINGER Landtechnik GmbH Industriegelände 1 4710 Grieskirchen, Austria Tel. 07248 / 600 -0 Telefax 07248 / 600-2511 According to the product liability please check the above mentioned items. Please place a cross where appropriate. Machine checked according to delivery note. All attached parts removed. All safety equipment, drive shaft and operating devices at hand.

-

Page 4: Table Of Contents

Table of conTenTs Table of contents Important notes prior to starting work ..... 53 SymbolS uSed Recommendations oPeRATion CE mark ..............6 for work safety Mowing ..............55 Safety hints: ............... 6 All points refering Reversing ..............55 Introduction ............... 7 to safety in this Collision Avoidance .......... - Page 5 Table of conTenTs Lubricating the hydraulic relief ........ 86 Winter storage with optional extra: Parking supports..............87 Wear control cutting blades bracket ....... 88 Holder for the rapid change of mowing blades ..89 Mowing blades suspension checks ....... 89 Changing the mowing blades ........

-

Page 6: Symbols Used

SymbolS uSed CE mark The CE mark, which is affixed by the manufacturer, indicates outwardly that this machine conforms to the engineering guideline regulations and the other relevant EU guidelines. EU Declaration of Conformity (see Attachment) By signing the EU Declaration of Conformity, the manufacturer declares that the machine that is brought into service complies with all relevant fundamental safety and health requirements. -

Page 7: Introduction

inTroducTion Introduction These Operating Instructions are integral part of the imple- ment delivery scope. You should therefore hand them over to the new owner if ownership of the implement is transferred. Train and instruct the new owner in the regulations stated. Dear Customer These Operating Instructions are intended to allow you to familiarise yourself with the implement and provide... -

Page 8: Warning Signs

Warning SignS Meaning of warning signs bsb 447 410 Do not stand in the implement's swivel range. Danger - flying objects; keep safe distance from the machine as long as the engine is running. 495.167 Do not touch rotating machine components. Close both side protective coverings before engaging p.t.o.. -

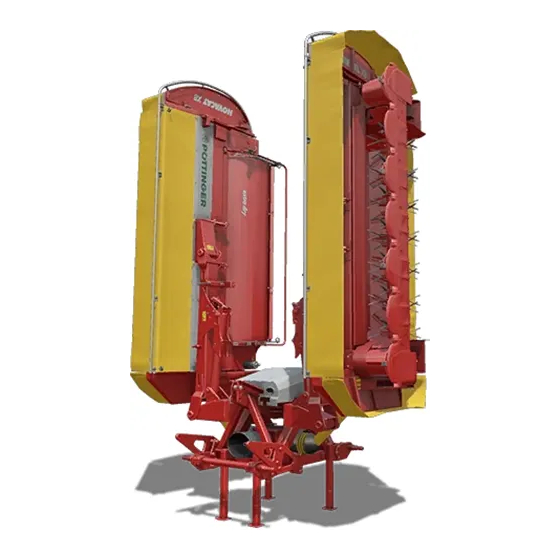

Page 9: Description Of Services

DescripTion of services overview designations: (1) Select Control (2) Power Control (ISOBUS-compatible) (3) Coupling jack with removable lighting beam (4) Mower unit (5) Swath former (6) (6) Tine conditioner (7) Roller conditioner (8) Cross conveyor belt versions control variants description Select Control Operation by means of Select Control (preselection circuit), spring relief, (not suitable for roller conditioners) and manual side protection folding. -

Page 10: Tractor Requirements

TracTor requiremenTS Tractor Hydraulic control on the lifting gear To operate this machine the following tractor requirements are necessary: - Tractor power: "Front- / Rear mower" combination from 90 kW / 120 hp "Push-drive" combination from 130 kW / 200 hp - Attaching: Lower link Cat. -

Page 11: Necessary Hydraulic Connections

TracTor requiremenTS Necessary hydraulic connections Design Consumer S i n g l e - a c t i n g D u a l - a c t i n g Identification (on the h y d r a u l i c h y d r a u l i c machine) connection... -

Page 12: Attaching To Tractor

aTTaching To TracTor Pin machine to three-point attaching frame Safety advice - Adjust the lower link bolts (1) on the bearing frame using the locating screw, according to the three-point DANGER category and the track width. The mower must not brush the tractor's rear tyres. -

Page 13: Connect To Tractor

aTTaching To TracTor Adjust upper linkage spindle For tractors with Isobus control - Cutting height is set by turning upper link spindle (16). - Connect the 9-pin ISO plug to the ISObus socket on the tractor. Attach connecting lines from the front A hydraulic upper link is recommended (double-acting implement). -

Page 14: Attach The Cardan Shaft

aTTaching To TracTor Attach the cardan shaft Hydraulic connection ("Power Control" version) - Before initial operation, check the cardan shaft length and adapt if necessary. See also chapter "Drive Shaft" Minimum hydraulic system: in Supplement B. 1 single-acting hydraulic circuit (EW) with depressurized return flow (T) Optimum hydraulic system: 1 single-acting hydraulic circuit (EW) with depressurized... - Page 15 aTTaching To TracTor Settings The screw (7) on the hydraulic block must also be adjusted. Separate the electrical connections! Depressurize the hydraulics! Power Control: Press key until signal tone is heard (approx. 3 Sec) Isobus: Press key until signal tone (approx. 3 Sec) For tractors with "Load sensing"...

-

Page 16: Be Aware Of Cutting Disc's Direction Of Rotation

aTTaching To TracTor Be aware of cutting disc's direction of rotation - Select appropriate rotation direction for the drive - If the necessary p.t.o. direction of rotation cannot be selected from the tractor, then turn the gearing (G1) 180° . In this case, replace the ventilation screw with the drain screw. -

Page 17: Remove Machine From Tractor

aTTaching To TracTor Remove machine from tractor WARNING Risk of serious injury or injury resulting in death due to the machine tipping over. • Park the machine only on firm, level ground. Make sure the ground is stable! • Park the cross conveyor only on firm, level ground. -

Page 18: Pressure Relief And Collision Prevention

PreSSure relief and colliSion PrevenTion Mechanical pressure relief of the mower Hydraulic relief of mower units (Power units (Select Control) Control) The support weight of the mower units in the "Select In the "Power Control" version, the support weight of the Control"... -

Page 19: Collision Prevention

pressure relief anD collision prevenTion Collision Prevention Collision Prevention: Work pressure (x): 110 An adjustable counter-pressure is generated hydraulically - Close stopcock (Ab) (position A). for the collision prevention system. The mower unit swings - Disconnect plug coupling (St). back slightly if this is exceeded. The return-swivel to the working position takes place automatically. -

Page 20: Transport

TranSPorT Changing from working position to Raise to road transport position transport position Swivelling into the road transport position can only be ac- tivated if all mowing units are in the field transport position (headland FT). DANGER - Switch drive off and wait for complete stop. Life-threatening danger through the mower tipping - Swivel all hoop guards on mower in over... -

Page 21: Travelling On Public Roads

TranSPorT Travelling on public roads Transport position 3000 DANGER Life-threatening danger during transportation • Travelling on public roads may only take place in the transport position. • Check that the lights are working before travelling. • Observe the max. permissible transport height (4m)! •... -

Page 22: Select Control

SelecT conTrol Terminal performance features Starting work Electrical connection 1. Positioning The terminal’s electricity is supplied via a plug in accordance Position the Select Control terminal so that it is easily with DIN 9680 from the tractor’s 12 V on-board electrical visible in the tractor cab. -

Page 23: Operating Interface

SelecT conTrol Operating interface Meaning of keys Hour counter (partial and total hour counter) Transport guard Road Transport Preselect left mower unit Preselect automatic operation Preselect right mower unit Arrow down Arrow up I/O or menu Operating notes To preselect a function, press the required key. The preselected function will be displayed on the screen. - Page 24 SelecT conTrol Example: Control device: Float po- Control device: Raise Control device: Float position Control device: Raise sition If automatic operation is pre- The left mower is located in If the second mower has selected, the second mower the float position again with- returned to the headland unit is automatically switched out any further preselecting.

- Page 25 SelecT conTrol DANGER Life-threatening danger exists through machine tipping over. There is a danger of tipping when swivelling the machine on slopes. • When swivelling in the road transport position: Always swivel the downhill-side mower first and then the uphill-side mower. 4.

- Page 26 SelecT conTrol 7. System menu Keys Display Note Press the key "IO" for a short time to access the brightness menu. Adjust the display brightness using the arrow keys. Note: When selecting a brightness of <30%, the keyboard lighting will be activated. Press the key "IO"...

-

Page 27: Power Control

PoWer conTrol Terminal performance features Electrical connection The power supply for the entire electronic system (job cal- culator and terminal) is conducted through a plug (compliant with DIN 9680) from the tractor's 12V onboard electrical system. These 3-pin plugs may also be 2-pin versions as only two main wires (+12 V, ground) are required. -

Page 28: Initial Start

PoWer conTrol Initial start ISOBUS-capable job calculator Power-Control Terminal Plug 1 ISO Bus Plug 10 Amp fuse Tractor cable with ISO-Bus Plug 3 Plug 4 with Tractor socket (DIN 11786) Operating with the Power Control Terminal 1. Position the Power Control Terminal in tractor cabin where it can be clearly seen. (To secure the terminal there is a holder on the back. -

Page 29: Key Assignment

PoWer conTrol Key assignment Function keys Function key 1* Function key 2* Function key 3* Function key 4* Raising and lowering the mower unit Raise left mower unit Raise front mower unit Raise right mower unit Raise all mower units Lower left mower unit Lower front mower unit Lower right mower unit... -

Page 30: Menu Tree

PoWer conTrol Menu tree Press and hold for 10 seconds! - 30 - 2000_GB_Power Control_3843... -

Page 31: Menus

PoWer conTrol Menus Every menu can be exited by pressing the ESC key. Pressing the "Stop" key will stop all functions. Start menu Display: After turning on the Power Control Terminal 1 … Cross conveyor belt speed: the Start menu appears. Fast (hare)/Slow (tortoise) (only with X8 Collector) 2 ... - Page 32 PoWer conTrol 13 ... Road transport symbol Lifting and lowering from or to the road transport position is only possible when the symbol is displayed. If symbol begins to flash then press [Road transport] key once again. To set the relief pressure, the mower units must be in the floating position.

- Page 33 PoWer conTrol Raise right mower unit Raises right mower unit from working position to field transport position. Raise all mower units Raises all mower units from working position to field transport position Road transport prese- lection In order to activate the [Preselect road transport] key •...

- Page 34 PoWer conTrol Hard keys: Side shift (only Novacat V10) Slope travel preselection 1. Press the preselection key to move both rear mower units in the same direction, consecutively. 2. Press the appropriate key [side shift] to start side shifting in the relevant direction.

- Page 35 PoWer conTrol Set menu 8 ... Speed selection for cross conveyor belt: Tick = Differing speeds between the left and right cross conveyor belt (for mowing in contour lines) Cross = Same speed for both cross conveyor belts with the possibility of switching between In the Start menu, press function key to access the two speeds.

- Page 36 PoWer conTrol Changing a value 1. Press function key to change a value. 2. Press function key until cursor has reached the value to be changed. Cursor 3. Change the value with the keys [ until the desired value is reached. 4.

- Page 37 PoWer conTrol Sensor test menu (together) Values: In the Start menu, press the function key to access the Sensor Test menu. Press function key to return to the Start menu. Display: A shaded square shows an active sensor. A white square shows an inactive sensor. When a rotating component rotates past the sensor ...

- Page 38 PoWer conTrol Sensor test menu Novacat X8 Collector ...S9 Initiator position for right cross conveyor ...S10 Initiator position for left cross conveyor Sensor test menu Novacat V10 ...S11 Left angle sensor voltage ...S12 Right angle sensor voltage - 38 - 2000_GB_Power Control_3843...

- Page 39 PoWer conTrol Data menu Resetting partial counters: Press function key in the Start menu to access the Data menu. Press function key , to return to the Start menu. The hectare counters only function when the "kph" has been selected in the configuration menu and the cable is connected to the tractor's signal socket.

- Page 40 PoWer conTrol Configuration menu Changing a value In the Start menu, press the function key for 10 sec- onds to access the Configuration Menu. Press function key to return to the Start Menu. 1. Press function key [ ] to change a value. 2.

- Page 41 PoWer conTrol System Menu Press the key briefly to access the System Menu. Press the key once again to return to the previous menu. A display brightness of less than 60% automatically switches on the Power Control Terminal keyboard lighting. Function keys: ...

-

Page 42: Diagnosis Function

PoWer conTrol Diagnosis function Sensor power fault (Example: Sensor power supply < 12V) When faults occur, the relevant alarm message is displayed and an acoustic warning signal is audible. Function keys: ...the respective alarm is suppressed until the next system start.. - Page 43 PoWer conTrol Angle sensor malfunction: Warning: Mower units not in neutral position There is no automatic guarantee that the machine does There are two possible causes for this warning: not exceed the max. transport height of 4m. 1. The mower units are not in the neutral position and Remedy: therefore filling the hydraulic relief is impossible.

-

Page 44: Isobus - Terminal

iSobuS - Terminal variant Operation with ISO Control Terminal ISOBUS-capable job calculator Joystick ISO Control panel ISOBUS adaptor 10 amp fuse Tractor cable with ISO-Bus variant Operation via ISOBUS tractor terminal Display Tractor terminal 473A2000.0 - 44 - 1401_GB-ISObus Terminal_3846... -

Page 45: Operation Structure - Mower With Isobus Solution

iSobuS - Termi iSobuS - Termi iSobuS - Term nal inal Operation structure - mower with ISObus solution F = Display menu T = Key numbering - 45 - 1401_GB-ISObus Terminal_3846... -

Page 46: Meaning Of Keys

iSobuS - Termi iSobuS - Termi iSobuS - Term nal inal Meaning of keys Start menu Start menu Meaning of display: T1 STOP T2 Work menu T3 Transport menu T4 Data menu T5 Set menu T6 Test menu STOP-key function ... - Page 47 iSobuS - Terminal To go to the road transport position • the cardan shaft must be stationary. • The [preselect] road transport key - T8] cannot be used as long as the cardan shaft is still turning. • The [preselect] road transport key - T8] can- T1 Increase working width not be used as long as both cross conveyor T2 Decrease working width...

- Page 48 iSobuS - Terminal SET menu T2 Save value T4 Navigating in the "Cross conveyor belt swivelling" T3 Calibrate max. working width position menu (F12) T4 Calibrate min. working width position T7 Navigating in the "Time-distance dependent lowering/raising" menu - Switch to mask (F8) novacat v10 T9 Navigating in the "Side shift calibration"...

- Page 49 iSobuS - Terminal Set speed level S5 Left mower unit field transport and working Two speed levels can be set for the cross conveyor positions belts. Left mower unit Setting: in 5% steps, setting range: 5 – 100% transport position Right mower unit transport position S3 Right mower unit field...

-

Page 50: Diagnosing Function

iSobuS - Termi iSobuS - Termi iSobuS - Term nal inal Diagnosing function Time out - monitoring If the front mower sensor is not reached within 6 seconds Monitoring the job calculator for after pressing the "Raise front mower or all mowers" key. Operating voltage diag Voltage supply sensor... -

Page 51: Configuration Menu

iSobuS - Termi iSobuS - Termi iSobuS - Term nal inal Angle sensor malfunction: Configuration menu There is no automatic guarantee that the machine does not exceed the max. transport height of 4m. In the START Menu ( ) press and hold the “Set” key diag for 10 seconds to access the Configuration Menu. -

Page 52: Joystick - Mower Assignment

iSobuS - Terminal Joystick - Mower assignment On the joystick there are 8 equivalent function keys (1 – 8), a green release key (A0) and a level switch (E1/E2/E3). The keys enable 8 different functions to be allocated per level (E1/E2/E3) = max. 24 different functions can be performed with the joystick. -

Page 53: Safety Advice

oPeraTion Safety advice 2. Safety devices - Fold down side guard for the "Select Control" variant or check activated side guard for the "Power Control" DANGER variant Life-threatening danger exists through blades being - Check safety devices (covers, protective aprons, ejected. - Page 54 oPeraTion If a collision should occur, 7. Wear hearing protection • Stop immediately and switch off the drive. • If a noise level of 90 dB (A) is reached or exceeded, then hearing protection must be worn (UVV 1.1 § 16). • Check the machine carefully for any damage In particular, check the mowing discs and their drive shafts (4a). • If necessary have it checked over in a specialist work shop as well. After contact with a foreign object • Check condition of blades and blade holder (see chapter "Maintenance and Service").

-

Page 55: Mowing

oPeraTion Mowing Collision Avoidance 1. Set mowing height by turning the upper link When mowing around trees, fences, boundary stones etc., collisions between the cutter bar and obstacles spindle (16) (max. 5° mowing disc incline). can occur despite careful and slow driving. In order to avoid damage, a collision safety device is provided on the mower. -

Page 56: Working On Slopes

oPeraTion Working on slopes DANGER DANGER Life hazard - due to tandem tipping. There is a danger Life hazard - due to tandem tipping. The tractor's travelling characteristics are influenced by the weight of tipping when swivelling the implement on headland. (G) of the mower unit. -

Page 57: Swath Former

SWaTh former Mode of operation A narrow swath is formed when using the swath plates while mowing. This avoids driving over the crop with wide tractor tyres. 278-09-06 Designations: (1) Swath disc (2) Swath disc holder Working area: Possible settings The horizontal working range of the swath former is ad- justable via the slots (L). -

Page 58: Optional Equipment

SWaTh former Optional equipment: Removal and installation of the swath former Additional swath disc The mower unit is compatible for the optional attachment of a tine, roller conditioner or swath former. Special work steps are necessary for the conversion depending on the unit to be attached. -

Page 59: Ed Tine Conditioner

ed Tine condiTioner Operation mode The aim of conditioning is to ream the wax layer (protection layer) from the blade of grass. Consequently, the fodder looses moisture more easily and dries more quickly. Conditioning is carried out using V-shaped tines, placed in a spiral on the conditioner shaft. - Page 60 Tine condiTioner Setting the position of swath and guide plates Among other things, the right setting depends on the quantity of cut material, driving speed and tractor capacity. Therefore, a binding recommendation cannot be provided NOTE regarding the correct lever setting. Property damage through the swath and guiding plates being too narrowly set.

-

Page 61: Operation

Tine condiTioner Operation Maintenance DANGER DANGER Life-threatening danger exists through parts being Life-threatening danger exists through another thrown out. person starting the tractor and driving off, or switching on the cardan shaft while maintenance work is being • Make sure that third parties also keep a carried out. -

Page 62: Rotor Tines

Tine condiTioner Rotor tines: 1. Replacing tine fixings If signs of wear are found on the tine fixings, then the affected component(s) must be replaced. (tines, bolt, slotted spring pin ...) 2. Rotor tines position Pos. Z1: Rotor tines position for normal operating conditions. Pos. -

Page 63: Position Of The Rotor Tines On The Conditioner

Tine condiTioner Position of the rotor tines on the conditioner NOTE Risk of material damage during operation with unbalance. • Always remove both opposite tine holders and install them if you want to remove damaged tines. • In case of noticeable vibrations, stop immediately and check the tine conditioner for lost tines. •... -

Page 64: Rc = Roller Conditioner

rc = roller condiTioner Safety advice DANGER Life-threatening danger exists through being drawn in by rotating parts. • Never open or remove the safety devices as long as the engine is running or parts are moving. • Never enter the danger area within the protective installations as long as components are moving. •... -

Page 65: Possible Settings

roller condiTioner Possible settings Upper roller spring pre-tension: DANGER Life-threatening danger exists through being drawn in by rotating parts. • Never open or remove the safety devices as long as the engine is running or parts are moving. • Never enter the danger area within the pro- tective installations as long as components are moving. -

Page 66: Maintenance

roller condiTioner Cleaning: (after every 20 operating hours) • Remove the covers and maintenance openings (WA) DANGER for the V-belt and chain drive Life-threatening danger exists when detaching the • Remove dirt deposits conditioner. If the conditioner is detached, the cutting • Clean rubber rollers blades are freely accessible. NOTE •... - Page 67 roller condiTioner • Check oil level (The oil container is attached to the bearing frame) NOTE Risk of material damage to the drive chains due to inadequate lubrication. • Check the central lubrication unit oil level before each start-up. (1) Oil reservoir (2) Adjusting screw (3) Lock nut (4) Stopcock (Lubrication on/off)

- Page 68 roller condiTioner Chain tension: (after every 60 hours in operation) Alter roller position: Loosen screws (WS) and rotate roller. Set lower roller po- sition so that the profile of both rollers optimally interlock Short drive chain but do not make contact with each other. Optimum roller position prevents premature wear of the rubber rollers.

-

Page 69: Roller Conditioner For Collector

roller condiTioner Check tensioner pulley run (Every 100 operating hours) Check the tensioner pulley running after the initial operation and after every change to the drive. The tensioner pulley must run parallel to the drive belt (see illustration). • SP 2 (Unscrew the top cover to lubricate!) Gear oil: (After every 100 operating hours) The gearbox is located on the outside of the cutter bar. -

Page 70: Maintenance Of The Rotor Tines

roller condiTioner Maintenance of the rotor tines: Adjust ejection angle: 1. Replacing tine fastening The additional roller affects the ejection angle of the mowed material. The roller height can be altered to adjust the ejection angle. If signs of severe wear on the tine fastening are discovered, - Unscrew the 4 bolts (AW) left and right it must be replaced completely (tines, screw, clamping - Adjust the roller height and fix in position... -

Page 71: Change Conditioner

change condiTioner Mode of operation Then remove blade wrench. The belts must be removed completely if a swath former The mower unit is designed to allow attachment of either a is attached. Uncouple cardan drive shaft (3) and remove tine conditioner, a roller conditioner or a swath former. The belt. -

Page 72: Attach Conditioner

change conDiTioner 6. Disconnect lubrication line: Check the relief pressure: The mower unit can be raised manually externally (approx. 80 kg relief pressure). 9. Adapt the lighting support (The lubrication line is only connected if the roller conditioner is used!) Close shut-off valve of central oil lubrication on coupling jack (pos. -

Page 73: General Safety Information

croSS conveyor belT General safety information Mode of operation A variable swath deposit is possible using a cross conveyor DANGER belt (single swath, broad deposit or triple swath). Using the operating terminal, the cross conveyor belt is swung out or Life-threatening danger exists through being drawn in and the belt speed per unit infinitely adjusted. -

Page 74: Operation

croSS conveyor belT Operation Accelerating roller (Optional): Check and clean the belt run regularly to prevent premature wear (see chapter "Maintenance"). Swinging in the cross conveyor: Accelerator rollers (W) are used to transfer the cut forage further into the middle. Setting: The height of the accelerator rollers can be adjusted to Cross conveyor belts will always be in this position when... -

Page 75: Swath Deposit

croSS conveyor belT Swath deposit Mowing with only one cross conveyor - If operating with only one cross conveyor, there is a A variable swath deposit is possible using a cross conveyor chance of depositing a swath row over the remaining belt (single swath, broad deposit or triple swath). -

Page 76: General Safety Information

croSS conveyor belT General safety information The support stands are not transported together with DANGER the mower unit. Life-threatening danger through machine tipping over. - Secure support stand (3) on the rear main frame of • Park the cross conveyor belt only on even, the cross conveyor belt at the very outside position. -

Page 77: Attaching The Cross Conveyor Belt

croSS conveyor belT 6. Uncouple upper link: 8. Lower mower unit and move off freely - Relax the top link (7) and hang it on the side of the mower unit. - Lower mower unit until cross conveyor belt lower links (9) are free. -

Page 78: Cross Conveyor Belt Maintenance

croSS conveyor belT Connections: 1. Check the belt run every 5, 10, 20 hours. Then every 20 hours thereafter. • The belt must not run to the sides. • The belt must be centred on both rollers. Possible causes for high belt wear: - Belt tension to loose - Belt not running centred Setting belt tension 278-09-43 A 1 = raise left Collector 2 = raise right Collector... - Page 79 croSS conveyor belT Adjust the feed plate Oil change Interval: Annually Quantity: 0.3 litres Type: SAE 90 278-09-07 Always adjust the distance between the feed plate and the conveyor belt with the screws (1) so that the gap on the discharge side (A) of the conveyor belt is larger than the gap on the intake side (E).

-

Page 80: Reverse Drive

reverse Drive Requirements for reverse drive - Tractor suitable for reverse drive - Conditioner suitable for reverse drive - ”Non-standard equipment” conversion set establish suitability for reverse drive The following additional components must be mounted on the coupling jack (3) for reverse drive suitability. - Upper link (1) Remove depending on central mower unit or A-frame mounting and adjust desired inclination - Attach hitching lugs for central mower unit (2) or A-frame mounting... -

Page 81: General Maintenance

general mainTenance Safety advice Spare parts a. Genuine parts and accessories are specially designed for the machines. DANGER b. We expressly draw your attention to the fact that genuine Life-threatening danger exists through moving or parts and accessories not supplied by us, have not been rotating parts tested and approved by us. -

Page 82: Articulated Shafts

general mainTenance Articulated shafts - See information in the supplement Please observe the following for maintenance! The directions in these Operating Instructions apply. If no particular instructions are available here, then the information in the instructions supplied by the respective cardan shaft manufacturer apply. -

Page 83: Oil Change On Cutter Bar

mainTenance Oil change on cutter bar 1. Lift one side of the mower bar X3 and support X3 = X2 + X1 X1 = Distance from ground to upper skid edge. • Carry out oil change at operating tempera- X2 = Vertical measurement from the upper left skid edge ture to the upper right skid edge •... - Page 84 mainTenance 4. Oil level check NOTE Property damage through too much or too little oil. • The full length of the cutter bar is propped up. The width of the cutter bar must be exactly horizontal (see illustration). The oil level is correct if x= 16 mm. X is the oil depth at the lower edge of the level opening (63) OIL LEVEL 169-16-06...

-

Page 85: Maintaining The Gearbox

mainTenance Installing cutter blades Maintaining the gearbox • The arrow on the cutter blade shows the • The oil is to be replenished annually (OIL cutter disc's direction of turn. LEVEL) when operating under normal conditions. • The mounting surfaces must be free of paint before fitting. -

Page 86: Setting The Field Transport Position (Headlands Ft)

mainTenance Setting the field transport position Lubricating the hydraulic relief (headlands FT) The following guide is valid for both cutter bars. 278-09-20 1. Reduce relief pressure 2. Lubricate cylinder suspension (A) 3-5 mm NOTE Risk of material damage due to excessive wear. 278-09-24 1. -

Page 87: Winter Storage With Optional Extra: Parking Supports

mainTenance Winter storage with optional extra: 4. Use wedges with front guides on the parking stands to secure against tipping. Parking supports WARNING Risk of serious injury or injury resulting in death due to the machine tipping over. • Place the mower on firm, level ground dur- ing the cold season. -

Page 88: Wear Control Cutting Blades Bracket

mainTenance Wear control cutting blades bracket The following parts are subject to wear: • Cutting blade brackets (30) • Cutting blades pins (31) Procedure - Visual control 1. Remove the cutting blades. 2. Remove grass residues and dirt - around the pin (31). DANGER Life hazard - due to projected parts when - the blade pin in the middle is worn off up to 15 mm - the wear area (30a) has reached the edge of... -

Page 89: Holder For The Rapid Change Of Mowing Blades

mainTenance Holder for the rapid change of mowing Changing the mowing blades blades 1. Insert lever (H) from left or right side on the cutter disc ”Pos A” until it stops. 2. Swivel the lever from "Pos. A" to "Pos. B" and push the movable holder (30) downwards. -

Page 90: Electro - Hydraulics

elecTro - hydraulicS Disruptions and remedies for electrical failures When there is an electrical system interruption, then the The hydraulic block is located under the front protective desired hydraulic function can be carried out using an cover. emergency action. To carry out the desired hydraulic function DANGER - Screw the allocated valve button in - Actuate servo-valve on tractor... -

Page 91: Disruptions And Remedies For Electrical Failures

elecTro - hydraulicS Disruptions and remedies for electrical failures When there is an electrical system interruption, then the The hydraulic block is located under the front protective desired hydraulic function can be carried out using an cover. emergency action. To carry out the desired hydraulic function DANGER - Screw the allocated valve button in - Actuate servo-valve on tractor... -

Page 92: Disruptions And Remedies For Electrical Failures

elecTro - hydraulicS Disruptions and remedies for electrical failures When there is an electrical system interruption, then the The hydraulic blocks are located between the folding arms desired hydraulic function can be carried out using an for the cross conveyors. emergency action. -

Page 93: Technical Data

PTO drive shaft overload protection [Nm] 1100 NovaCat X8 2020 NovaCat X8 ED 2550 Weight [kg] NovaCat X8 RC 2760 NovaCat X8 ED Coll 3810 NovaCat X8 RC Coll 4120 Continuous sound pressure level [db(A)] 78,9 dimensions: Transport [mm] 3000 3960... -

Page 94: The Defined Use Of The Mower Unit

Technical DaTa Position of vehicle identification Plate The chassis number is engraved on the name plate illustrated on the left. Warranty claims, enquiries and spare parts orders cannot be made without quoting the chassis number. Please enter the number on the title page of the Operating Instructions immediately on taking delivery of the vehicle/ equipment. -

Page 95: Supplement

supplemenT GB-Anhang Titelblatt _BA-Allgemein... - Page 96 The original cannot be copied ... Things will run better with genuine Pöttinger parts • Quality and precise fitting The decision must be made, ”original” or ”imitation”? The decision is often governed by price and a ”cheap buy” can sometimes be very expensive. - Operating safety.

-

Page 97: Safety Advice

annex -a SafeTy advice 6.) Appropriate use a. see technical data This operating manual contains this symbol at all points b. Intended use also includes compliance with the relating to the safety of persons. manufacturer's stipulated operating, maintenance and service conditions. 1.) Operating instructions a. - Page 98 annex -a SafeTy advice 10.) Asbestos 13.) General a. Certain sub-supplied components of the vehicle may a. Before attaching implements to the three-point linkage, contain asbestos due to technical reasons. Please move system lever into a position whereby unintentional observe the marking of spare parts. raising or lowering is ruled out! b.

- Page 99 carDan shafT Supplement - b Adapting cardan shaft to tractor Safety chain - Use chain to prevent tube guard from rotating. Ensure sufficient swivel space for the cardan shaft! NOTE - Trim the safety chain so that it cannot wind around the Material damage - due to inferior spare parts cardan shaft.

- Page 100 carDan shafT Supplement - b Important for driveshafts with friction - Lubricate with a brand-name grease before starting work and every 8 hours worked. clutch - Before any extended period of non-use, clean and lubricate driveshaft. Torque is limited with overloading and brief torque peaks and evenly transferred during slipping.

-

Page 101: Lubrication Chart

Lubrication chart after every X hours operation 40 F all 40 loads 80 F all 80 loads once a year every 100 hectares 100 ha if necessary FETT GREASE Number of grease nipples Number of grease nipples (III), (IV) see supplement „Lubrificants“ Litre Variation See manufacturer’s instructions... -

Page 102: X8 Ed / Rc Collector

X8 ed / Rc collector X1 = 300 mm 100h (III) (III) (III) 3,0 [l] SAE90 0,8 [l] SAE90 4,0 [l] SAE90 4,8 [l] SAE90 - 102 - 1900-SCHMIERPLAN_3843... -

Page 103: Lubricants

- 103 - 1400_EN-BETRIEBSSTOFFE... - Page 104 - 104 - 1400_EN-BETRIEBSSTOFFE...

- Page 105 - 105 - 1400_EN-BETRIEBSSTOFFE...

-

Page 106: Service

Service Hydraulics diagram (Select Control) Explanation: Y1 Directional control valve - Right mower unit Y8 Directional control valve - Left mower unit Y7 Directional control valve - Neutral lock Y2 Directional control valve - Raise / Lower lock 2000-GB SERVICE_3843 - 106 -... -

Page 107: Eelctrical Circuit Diagram (Select Control)

Service Eelctrical circuit diagram (Select Control) All plug views are external! Colour code: blue brown green gnge green / yellow grey black NW13 - 350 white NW4,5 - 100 NW4,5 - 100 NW4,5 - 100 NW4,5 - 100 NW4,5 - 500 NW4,5 - 100 Explanation: Directional control valve - Right mower unit... -

Page 108: Pin Configuration For Plug (Select Control)

SelecT conTrol Pin configuration for plug (Select Control) 20-pin plug Ansicht auf 20 pol. Stecker von außen Ansicht auf Stecker von außen sw 1 Si FK1 10A Power Blindstopfen Female connector: rt + br - sw 1 Piezophon Anschlussbelegung Buchsenkabel 18p sw 2 Steckerkabel 10A ColourLP... -

Page 109: Hydraulics Diagram (Power Control / Isobus)

Service Hydraulics diagram (Power Control / ISOBUS) 1,5mm 1,5mm Novacat X8 Collector 0,8mm 0,8mm 1,5mm Pressure transducer 0,8mm 1,5mm 120bar Pressure transducer 60bar 0,8mm Pump Tank Load sensing connection (LS) 3843.41.999.0 Explanation: Seat valve - Mower unit in neutral, centre Directional control valve - Raise Y9 Seat valve - Side protection Directional control valve - Lower... -

Page 110: Electrical Circuit Diagram (Power Control / Isobus)

Service Electrical circuit diagram (Power Control / ISOBUS) 32 - brrs 0,5 4 - grvio 0,5 26 - gert 0,5 All plug views are 25 - gews 0,5 external! 2 - swws 0,5 17 - brge 0,5 NW13-40 SPL 6 SPL 7 SPL 1 11 11a... -

Page 111: Terminal (Power Control)

Service Terminal (Power Control) 2,0 m Kontakt Farbe Funktion CAN_L gnge CAN_H TBC PWR ECU PWR ECU GND 2000-GB SERVICE_3843 - 111 -... -

Page 112: Electrical Circuit Diagram (Hydraulic Relief) Power Control / Isobus

Service Electrical circuit diagram (Hydraulic relief) Power Control / Isobus All plug views are external! 16 - blrt 10 - rt NW13 - 450 NW10 - 150 Colour code: ELEKTRONIK blue 473C4100 00xxMMJJ brown green gnge green / yellow Kontaktbelegung X1 grey A 40 gesw 1 black... -

Page 113: Hydraulics Diagram (Collector)

Service Hydraulics diagram (Collector) Rücklauffilter 445.320 Eigenversorgung Tank 445.286 Y16 od. Y17 Antrieb Zapfwelle 0,8 mm 445.248 445.170.011 Antrieb QFB 175 bar Y18 od. Y19 Antrieb Rolle 445.198 Explanation: Y16 Directional control valve - Cross conveyor belt speed regulator, right Y17 Directional control valve -Cross conveyor belt speed regulator, left Y18 Directional control valve -Cross conveyor belt on/off, right Y19 Directional control valve -Cross conveyor belt on/off, left... -

Page 114: Electrical Circuit Diagram (Cross Conveyor Belts)

Service Electrical circuit diagram (Cross conveyor belts) All plug views are external! Signal Colour code: blue brown green gnge green / yellow grey black white Explanation: Throttle - QFB speed, right Sensor - Cross conveyor belt, right Sensor - Cross conveyor belt, left Throttle - QFB speed, links Seat valve - Cross conveyor belt on/off, right Seat valve - Cross conveyor belt on/off, left... -

Page 115: Processor

Service Processor Ansicht auf 42 pol. Steckverbinder ST2 (von außen) TBC RTN CAN1H CAN1L ECU PWR wsgn TBC DIS TBC PWR 6² sw ECU GND Masse 6² rt +12V LP nicht vollständig bestückt dargestellt rt (6mm²) Power + rt (2,5mm²) sw (2,5mm²) Ansicht auf 42 pol. -

Page 116: Signal Socket Connection Cable

Service Signal socket connection cable Signal socket connection cable Toggle switch: G: Tractor transmission signal Anschlusskabel Signalsteckdose: R: Tractor radar sensor signal (if available) Kippschalter: G: Getriebesignal vom Schlepper R: Radarsensorsignal vom Schlepper (wenn verfügbar) Kippschalter – Litze Nr. 2– Schalterstellung R –... -

Page 117: Taper Bushes

Taper bushes Taper bushes installation instructions To assemble 1. Clean and degrease the bore and taper surfaces of the bush and the tapered bore of the pulley. 2. Insert the bush in the pulley hub and line up the holes (half thread holes must line up with half straight holes). -

Page 118: Combination Of Tractor And Mounted Implement

imporTanT aDDiTional informaTion for your safeTy combination of tractor and mounted implement DANGER Life hazard or material hazard - due to overload on tractor or wrong tractor ballast distribution. • Make sure that hitching the implement (in the front and rear three-point linkage) does not lead to exceeding the maximum total admissible weight of the tractor, the axle loads or the load capacity of the tyres. - Page 119 imporTanT aDDiTional informaTion for your safeTy cAlculATion of The ReAl fRonT AXle loAd T v tat (If the front hitched implement (G ) does not reach the minimum required ballasting Front (G ), the weight of the front hitched implement must V min be increased to the minimum ballasting Front!) Record the calculated real front axle load and the permissible front axle load of the tractor into the table.

- Page 120 The CE norm is not valid in the United States of America and Canada. EC Conformity Declaration Original Conformity Declaration Name and address of the manufacturer: PÖTTINGER Landtechnik GmbH Industriegelände 1 AT - 4710 Grieskirchen Machine (interchangeable equipment): NOVACAT X 8 ED / RC / COLL mower 3843 Type...

- Page 121 Im Zuge der technischen Weiterentwicklung La société PÖTTINGER Landtechnik GmbH Following the policy of the PÖTTINGER arbeitet die PÖTTINGER Landtechnik améliore constamment ses produits grâce Landtechnik GmbH to improve their products GmbH ständig an der Verbesserung ihrer au progrès technique. as technical developments continue, Produkte.

- Page 122 PÖTTINGER Landtechnik GmbH A-4710 Grieskirchen Telefon: 0043 (0) 72 48 600-0 Telefax: 0043 (0) 72 48 600-2511 e-Mail: info@poettinger.at Internet: http://www.poettinger.at GEBR. PÖTTINGER GMBH Stützpunkt Nord Steinbecker Strasse 15 D-49509 Recke Telefon: (0 54 53) 91 14 - 0 Telefax: (0 54 53) 91 14 - 14 PÖTTINGER France 129 b, la Chapelle F-68650 Le Bonhomme...

Need help?

Do you have a question about the NOVACAT X8 ED and is the answer not in the manual?

Questions and answers