Summary of Contents for Pottinger NOVACAT X8 ED

- Page 1 Operator‘s manual + INSTRUCTIONS FOR PRODUCT DELIVERY . . . Page 3 99 3843.GB.80L.1 "Translation of the original Operating Manual" NOVACAT X8 ED/RC/COLL (Type PSM 3843 : + . . 01001 • Disc mower...

- Page 2 Dear Farmer You have just made an excellent choice. Naturally we are very happy and wish to congratulate you for having chosen Pöttinger. As your agricultural partner, we offer you quality and efficiency combined with reliable servicing. In order to assess the spare-parts demand for our agricultural machines and to take these demands into consideration when developing new machines, we would ask you to provide us with some details.

- Page 3 INSTRUCTIONS FOR Dokument PRODUCT DELIVERY PÖTTINGER Landtechnik GmbH Industriegelände 1 A-4710 Grieskirchen Tel. 07248 / 600 -0 Telefax 07248 / 600-2511 According to the product liability please check the above mentioned items. Please check. Machine checked according to delivery note. All attached parts removed. All safety equipment, drive shaft and operating devices at hand.

-

Page 4: Table Of Contents

TABLE OF CONTENTS Table of contents WARNING SIGNS Collision safety device ..........35 Recommendations Working on slopes ........... 36 CE sign ..............6 for work safety Meaning of warning signs.......... 6 SWATH FORMER All points refering DESCRIPTION OF SERVICES Operating Principle ..........37 to safety in this Adjustment Possibilities .......... - Page 5 TABLE OF CONTENTS TECHNICAL DATA Technical data ............67 The defined use of the mower unit ......68 Position of Vehicle Identification Plate ....68 SUPPLEMENT Recommendations for work safety ......71 Driveshaft ..............72 Lubrication chart ............. 74 Lubricants ..............76 SERVICE Hydraulic plan (Select Control) ........

-

Page 6: Warning Signs

WARNING SIGNS CE sign The CE sign, which is affixed by the manufacturer, indicates outwardly that this machine conforms to the engineering guideline regulations and the other relevant EU guidelines. Recommendations EU Declaration of Conformity (see supplement) for work safety By signing the EU Declaration of Conformity, the manufacturer declares that the machine being All points referring brought into service complies with all relevant safety and health requirements. -

Page 7: Description Of Services

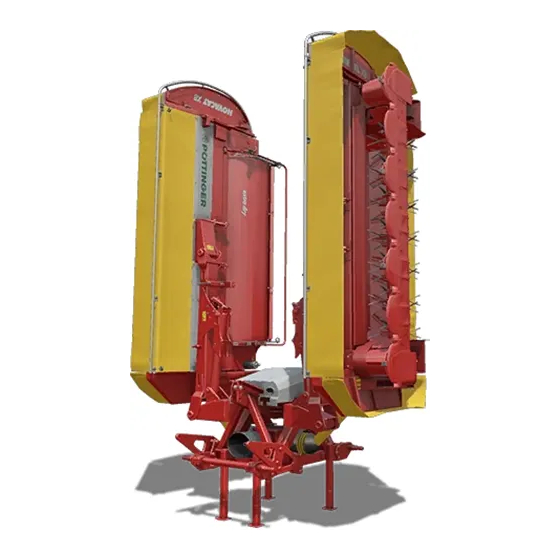

DESCRIPTION OF SERVICES Overview Designations: (1) Select Control (5) Swath former (2) Power Control (ISOBUS-compatible) (6) Tine conditioner (3) Coupling jack with removable lighting beam (7) Roller conditioner (4) Mower unit (8) Cross conveyor belt Versions Designation Description Select Control Operation by means of Select Control (preselection circuit), spring relief, (not suitable for roller conditioners) and manual side protection folding. -

Page 8: Tractor Requirements

TRACTOR REQUIREMENTS Tractor To operate this machine the following tractor requirements are necessary: - Tractor power: Combination “Front/rear mower" above 90 kW/120 PS, Combination “Reverse drive" from 130 kW/200 - Linkage: lower link cat. III - Connections: see table “Necessary hydraulic and power connections”... -

Page 9: Necessary Hydraulic Connections

TRACTOR REQUIREMENTS Necessary hydraulic connections Single action Double action Identification (on Design Used for hydraulic hydraulic the implement) connection connection Select Control Rear mower Front mower hydraulic upper link (version) Hydraulic connection “Advance” SN 16 red Power Control / ISOBUS Terminal Hydraulic connection “Return”... -

Page 10: Attaching To Tractor

ATTACHING TO TRACTOR Attaching implement to tractor Centre-mount (M) mower unit to tractor Setting upper link height using spindle Safety hints: - Adjust lower link accordingly. - By turning upper link spindle (16) the cutting height is see supplement- adjusted. - Secure the lower hydraulic link so that the appliance A1 points 7.), 8a. -

Page 11: To Make The Connection To The Tractor

ATTACHING TO TRACTOR To make the connection to the tractor Fitting drive shaft Important! Operation: - Before operating for the first time, drive shaft is to be checked and adapted if necessary. See also chapter Before putting - Connect the 3-channel plug to the DIN 9680 socket "Drive Shaft"... -

Page 12: Hydraulic Connection ("Power Control" Version)

ATTACHING TO TRACTOR Hydraulic connection ("Power Control” Version) Settings Screw (7) on the hydraulic block must also be adjusted. Caution Break electrical connection In tractors with “load sensing” - Completely screw in screw (7) on hydraulic block In tractors with closed hydraulic system - Completely screw in screw (7) on hydraulic block In tractors with open hydraulic system - Completely unscrew screw (7) on hydraulic block... -

Page 13: Unhitch Device From Tractor

ATTACHING TO TRACTOR Unhitch device from tractor Safety Caution! note: Only park the mower combination in the Only park the disc working position (both mower units are mower on firm, folded down). Maximum danger of tipping level ground and over if the mower combination is parked ensure a secure in the transport position. -

Page 14: Pressure Relief And Collision Lock

PRESSURE RELIEF AND COLLISION LOCK Mechanical pressure relief of the mower units (SELECT Control) The contact weight of the mower units is reduced in the Caution! “Select Control” version by way of an adjustable spring Only open the pressure relief. linch pin when the spring is not Adjustment:... -

Page 15: Transport

TRANSPORT Conversion from working to transport position Safety • Before swivelling the cutter bar up, turn Precaution! off the drive and wait for the mower discs to come to a complete standstill. Changing from working positi- • Make sure that swivel area is free and that on to transport nobody is standing in the danger area. -

Page 16: Driving On Public Roads

TRANSPORT Driving on public roads • Observe the official regulations of your country. Attention! • Driving on public roads must be carried out in the transport position only Be alert to the ma- • Protection devices must be in proper condition. ximum permissib- •... -

Page 17: Select Control

SELECT CONTROL Features of the Terminal Electrical Connection The terminal’s electricity is supplied via a plug in accordance with DIN 9680 from the tractor’s 12 V on-board electrical system. These 3-pin plugs are also used in a 2-pin version as only the two main connections (+12 V, earth) are required. Caution! Plugs and sockets of a different design are not permissible as functional safety is not guaranteed. -

Page 18: User Interface

SELECT CONTROL User Interface Meaning of Buttons LED (for keys a-i) Pre-select left mower unit Pre-select right mower unit Transport lock Pre-select automatic operation no function no function Road transport Operating Notes Press the desired key to pre-select a function. The activated function will be indicated by a lit LED. - Page 19 SELECT CONTROL Manual Mowing Operation: If necessary, it is also possible to operate without automatic pre-selection; the pre-selected function is carried out using the control device. Using the tractor’s control unit, both mowing units are swung between the “Field transport” and “Working position”...

-

Page 20: Power Control - Operation

POWER CONTROL - OPERATION Control panel Display indicator: Note!! • Main indicator Always store • Special menu control panel in a - SET weather-resistant (Settings for machines, setting the time differences, location. setting the speed control) - TEST (sensor test) - DATA (software versions, operating hours) •... -

Page 21: Button Functions

POWER CONTROL - OPERATION Button functions Take note! Buttons to start a swivelling function By pushing the “Transport positi- “Transport position” selection button Function of “Raise mower units” buttons • By pressing one of the buttons, the corresponding on” button Button function: for 3 seconds, the - This button has a preselection function... -

Page 22: Set Menu

POWER CONTROL - OPERATION Cross conveyor belt speed rate Button function: - By pressing the button the cross conveyor belt speed rate is changed between fast and slow - On the display the tortoise (slow) and hare (fast) symbols represent the speed of the relevant cross conveyor belt - The relevant settings are carried out in the SET menu. - Page 23 POWER CONTROL - OPERATION Speed control of cross conveyor belts Set operating method Tick = varying speed between left and right cross conveyor belt (for mowing in lineal contours) Cross = Even speed for both cross conveyor belts with the possibility of switching between two speed rates Set speed rate Two speed rates can be set for cross conveyor...

-

Page 24: Test Menu

POWER CONTROL - OPERATION TEST menu Note! The following menu pages are displayed by pressing the Meanings of Indicators: Navigating to “Menu” button on the console. input fields takes place with the In the left field the sensor function during p.t.o still arrow buttons The TEST menu comes after the SET menu stand is checked. -

Page 25: Diagnostic Function

POWER CONTROL - OPERATION Diagnostic Function Note! Monitoring of the job computer for Any desired function may be - operating voltage established ma- nually using the - sensor supply voltage emergency actua- tor in the event of - short-circuit to ground or 12 V a malfunction (see - cable break Section “Electro-... -

Page 26: Configuration Menu

POWER CONTROL - OPERATION Configuration Menu The following menu is displayed on the control panel Meaning of display: Pivoting aid after pressing the “menu” key for 10 seconds. This configuration must be deactivated in the case of Novacat X8 and X8 Collector ! Hydraulic pressure relief Individual cross conveyor belt pivoting Speed control of the cross conveyor belts... -

Page 27: Isobus - Terminal

ISOBUS - TERMINAL Job calculator with additional Version ISO board Operation with an ISO control terminal Joystick ISO Control panel I S O b u s adaptor 10-amp fuse Tractor cable with ISO Version Operation via ISO Bus tractor terminal Display Tractor terminal 473A2000.0... -

Page 28: Operation Iso-Terminal

ISOBUS - TERMINAL Operation ISO-terminal Note! A malfunction caused through incorrect sensor values can put the control into an undefined state. Pressing the STOP button for 10 seconds will reset the control to the normal state. This is confirmed by an audible signal. -

Page 29: Button Indication

ISOBUS - TERMINAL Button indication Start menu Transport menu T1 STOP T2 Switch to page 2 (change to screen (F4)) T2 Work menu T3 Swing cross conveyor belts out T3 Transport menu T4 Swing cross conveyor belts in T4 Data menu T7 Change from working position to road transport position T5 Set menu Press button T7 for 3 seconds ->... - Page 30 ISOBUS - TERMINAL Set menu Increase relieving pressure Decrease relieving pressure Individual cross conveyor belt pivoting Set machine type Activate/deactivate front mower Set push movement (only possible without cross conveyor belt) Set relieving pressure T7 Navigating the “Time-traverse dependant lowering/raising” menu - change to screen (F7) T8 Navigating the “Test”...

- Page 31 ISOBUS - TERMINAL Meanings of Indicators: Tick = different speed between left and right cross conveyor belt (for mowing on contour line on slopes) Cross = same speed of both cross conveyor belts with possibility of switching between two speed levels. Set speed levels Two speed levels of the cross conveyor belts may be set.

-

Page 32: Diagnostic Function

ISOBUS - TERMINAL Diagnostic Function Time out monitoring When, after 6 seconds and after pressing the “Raise front mower or Monitoring of the job computer for all mowers” button, the front mower sensor is not reached. operating voltage sensor supply voltage Diag short-circuit to ground or 12 V cable break... -

Page 33: Joystick - Mower Configuration

ISOBUS - TERMINAL Joystick - Mower Configuration The joystick has 8 equivalent function keys (1-8), a green activation button (A0) and a levels switch (E1/E2/E3). The keys can be used to assign 8 different functions per level (E1/E2/E3) = max. 24 different functions can be carried out using the joystick. Check assignment of joystick function keys Starting from the START menu, press T8. -

Page 34: Operation

OPERATION Important points before starting work Safety hints: 1. Checking the knives 6. Stay clear while engine is running. see supplement-A1 - Check the condition of knives and the knife holder. points 1. - 7.) - Check cutting drums for damage (see also chapter "Maintenance"). -

Page 35: Mow

OPERATION Caution! 1. Adjust cutting height by turning upper link Risk of injury due spindle (inclination of the cutting discs max. to flying parts. 5°). Keep a sufficient- ly safe distance from people while 2. To mow, gradually supply power to the p.t.o. mowing. -

Page 36: Working On Slopes

OPERATION Working on slopes Take care when turning on slopes! Safety advice • Reduce speed in curves accordingly. The tractor's travelling characteristics are influenced by the weight (G) of the mower unit. This can lead to • It is better to travel in reverse on a slope than to carry out a risky dangerous situations, especially on slopes. -

Page 37: Swath Former

SWATH FORMER Operating Principle A narrow swath is formed when using the swath plates while mowing. This avoids driving over the crop with wide tractor tyres. Safety note: Read and comply with the Opera- ting Instructions and particularly the safety notes prior to commis- sioning. -

Page 38: Maintenance

SWATH FORMER Conveying cone The conveying cones are recommended: - To improve the output for the swath deposit, particularly with heavy, dense fodder crops. - See Spare Parts List for spare parts maintenance The swath former is maintenance-free with the exception of cleaning activities. Removal and installation of the swath former Caution! Switch off the engi-... -

Page 39: Tine Conditioner

TINE CONDITIONER Operating Principle The aim of processing is to roughen the wax layer (protective layer) on the blade of grass. The feed thus releases water more easily and dries faster. Processing is carried out with V-shaped tines that are arranged in a spiral shape on the processor shaft. - Page 40 TINE CONDITIONER Baffle plate: The angle of the baffle plate is adjustable for the desired casting distance of the crop: - Loosen clamping screw (P) - Adjust baffle plate - Fix clamping screw (P) Adjust swath width: The mown and conditioned crop is formed into the desired swath width using the swath plates.

-

Page 41: Use

TINE CONDITIONER Travelling speed: Adapt the driving speed to the amount of feed. Too high a speed reduces the quality and evenness of processing. Caution! Working without processor: Risk of injury due The tine conditioner can also be dismantled if necessary to flying parts. -

Page 42: Maintenance

TINE CONDITIONER Maintenance Correct belt tension: Check dimension X2 NOVACAT X8: X2 = 185 mm (lateral mower units) Caution! Switch off the engi- ne before carrying out maintenance and repair work and remove the ignition key. Position of rotor tines Item Z1: Position of rotor tines for normal conditions of use. -

Page 43: Roller Conditioner

ROLLER CONDITIONER Operation The roller conditioner is suitable for lucerne and clover types. Two driven intermeshing rollers crush the fodder. This damages the plant’s natural wax coating and the drying time is accelerated. Safety tip: Before initial operation read and observe the operator’s manu- al, especially the safety tips. -

Page 44: Operation

ROLLER CONDITIONER Upper roller spring tension: The upper roller is moveable and is tensioned left and right with a spring. The spring tension intensity can be adjusted at any time with nut (WS). Standard setting (SE): 210 mm Set swath width: The swath boards shape the cut and conditioned fodder to the desired swath width. -

Page 45: Maintenance

ROLLER CONDITIONER Maintenance Cleaning: (every 20 operating hours) • Unscrew the covers and maintenance openings (WA) during belt and chain drive • Remove deposited dirt Take care! • Clean rubber rollers Turn motor off and remove key be- Dirt can impair lubrication that will fore any mainte- subsequently cause equipment damage! nance and repair... - Page 46 ROLLER CONDITIONER Altering the roller position: (when required) After the drive chains have been tensioned several times the roller position changes. Alter roller position: Loosen the screws (WS) and rotate the roller. Set the position of the lower roller so that the profile of both rollers is optimally interlock and not touch each other.

-

Page 47: Roller Conditioner For Collector

ROLLER CONDITIONER Roller conditioner for collector A dedicated roller conditioner is necessary if the mower combination is fitted with a collector. The differences are: - greater ejection - additional roller 278-09-45 Adjust ejection angle: The additional roller affects the ejection angle of the mowed material. -

Page 48: Replace Conditioner

REPLACE CONDITIONER Operating Principle The mower unit is compatible for optional hitching of a tine conditioner, roller conditioner or swath former. The conditioners or swath formers are additionally designed as a safety device and are imperative for use. Dismantle conditioner 1. -

Page 49: Install Conditioner

REPLACE CONDITIONER 5. Open retaining bolt The conditioners are each attached to the mower unit with 2 retaining bolts. Standard (A): Screw + sleeve Non-standard equipment (B): Spring-assisted quick closure. 6. Disconnect lubricating line: (The lubricating line is only attached when using the roller conditioner!) Close shut-off valve of central oil lubrication on coupling jack (pos. -

Page 50: Cross Conveyor Belt

CROSS CONVEYOR BELT Function A variable swath deposit is possible using a cross conveyor belt (single swath, broad deposit or triple swath). Using the operating terminal, the cross conveyor belt is swung out or in and the belt speed per unit infinitely adjusted. Safety note: Before initial operation read... -

Page 51: Operation

CROSS CONVEYOR BELT Accelerating roller (Option): Accelerating rollers are used to convey forage closer to the centre. Setting: The height of accelerating rollers can be adjusted to alter the throw distance. - Remove screw (1) (front and rear) - Move roller to the desired position - Insert screw (1) into the appropriate hole and tighten Note! - Page 52 CROSS CONVEYOR BELT Swing cross conveyor belt out: Warning! Cross conveyor belts must be swung in when swinging from working to transport posi- tion (danger of collision). If a swath is not to be deposited, the cross conveyor belts can be swung out. - Swinging the cross conveyor belts in and out is carried out using the operating panel.

-

Page 53: Laying Down Swaths

CROSS CONVEYOR BELT Laying down swaths A variable swath deposit is possible using a cross conveyor belt (single swath, broad deposit or triple swath). Using the operating terminal, the cross conveyor belt is swung out or in and the belt speed per unit infinitely adjusted. Mowing without a cross conveyor belt - Forage is deposited with the same swath width as the conditioner (= single swath). -

Page 54: Dismounting The Cross Conveyor Belt

CROSS CONVEYOR BELT Dismounting the Cross conveyor belt 1. Move the mower unit to the starting Be aware! position: Park cross con- - Raise and place in turn-over position veyor belt only on - Briefly swing cross conveyor belt out and then swing firm, even ground. -

Page 55: Mounting The Cross Conveyor Belt

CROSS CONVEYOR BELT 7. Unplug connection lines: - Unplug electrical connection lines - Unplug hydraulic connection lines Be aware: Do not unplug hydraulic lines if the line pressure is too high. To assist, screw in the emergency actuation of the last 4 valve blocks on the hydraulic block (under the white hitching frame protection cover). -

Page 56: Cross Conveyor Belt Maintenance

CROSS CONVEYOR BELT Cross conveyor belt maintenance • Set belt tension by turning the perforated disk (L) • Set the roller position by moving the tensioning block Take care! - Set the roller so that the belt runs centrically Turn motor off and remove key Possible causes for high belt wearing: before any main-... -

Page 57: Reverse Drive

REVERSE DRIVE Requirements for reverse drive - Tractor suitable for reverse drive - Conditioner suitable for reverse drive - ”Non-standard equipment” conversion set Establish suitability for reverse drive The following additional components must be mounted on the coupling jack (3) for reverse drive suitability. - Upper link (1) Remove depending on central mower unit or A-frame mounting and adjust desired inclination - Attach hitching lugs for central mower unit (2) or A-frame mounting... -

Page 58: Maintenance

MAINTENANCE Safety point Parking in the ope Safety points! • Turn engine off when adjustment, service and repair When parking in the open for work is to be done. long periods of time, clean • Turn engine off piston rods and then coat when adjustment, with grease. -

Page 59: Oil Change On Cutter Bar

MAINTENANCE Oil change on cutter bar Note: Changing oil • Change oil when - Change oil after first 100 operating hours the at least at operating tem- once a year perature. - Raise cutter bar on the outer side The oil is too vis- - Take out oil drain plug (62), let run out and duly dispose cous when cold. -

Page 60: Gearing Maintenance

MAINTENANCE Gearing maintenance Note: Under normal ope- Input Gearbox rating conditions, (If the mower combination is supplied without oil is to be reple- collector preparation, the gearbox is only designed nished annually with 3 stubs) (OIL LEVEL). - Oil change after the first 50 hours of operation. - Oil change after no more than 100 h. -

Page 61: Setting The Field Transport Position (End-Of Run Turns)

MAINTENANCE Setting the field transport position (end-of run turns) The following guide is valid for both cutter bars. 1. Set sensors´ gap (3-5 mm). 2. Raise both cutter bars until hydraulic cylinders have travelled in to a measurement of ”1100 mm”. 3. -

Page 62: Winter Storage Using Optional Parking Supports

MAINTENANCE Winter storage using optional parking supports 1. Remove mower’s support stands: remove the spring Tip! pin then the clamping sleeve from each stand, then During winter park remove the stands. the mower on level, firm ground. 2. Bring the rear guides left and right into position and secure with linch pin. -

Page 63: Checking Wear On Mowing Blade Holders

MAINTENANCE Checking wear on mowing blade holders Wearing parts are: Attention! - mounting of mowing blades (30) Danger of accident - bolts of mowing blades (31) if wearing parts are worn If such wearing parts are worn out they must not be used any longer. -

Page 64: Holder For A Quick Change Of Cutter Blades

MAINTENANCE Holder for a quick change of cutter blades Changing the Cutter Blades Attention! 1. Insert lever from left or right side on the cutter disc Take note! ”Pos A” until it stops. For Your Safety Damaged, buckled 2. Swing lever from ”pos. A” to ”pos. B” and push the and worn out •... -

Page 65: Electro-Hydraulics

ELECTRO-HYDRAULICS Disruptions and remedies to power failure The hydraulic block is located under the front protective When there is a disruption in the electrical unit, the required cover. hydraulic function can be carried out by means of an emergency application. To carry out the desired hydraulic function - Screw in the correct valve knob - Turn on servo-valve on the towing vehicle... -

Page 66: Disruptions And Remedies To Power Failure

ELECTRO-HYDRAULICS Disruptions and remedies to power failure The hydraulic block is located under the front protective When there is a disruption in the electrical unit, the required cover. hydraulic function can be carried out by means of an emergency application. To carry out the desired hydraulic function - Screw in the correct valve knob - Turn on servo-valve on the towing vehicle... -

Page 67: Technical Data

PTO drive shaft overload protection [Nm] 1100 NovaCat X8 2020 NovaCat X8 ED 2550 Weight [kg] NovaCat X8 RC 2760 NovaCat X8 ED Coll 3810 NovaCat X8 RC Coll 4120 Continuous sound pressure level [db(A)] 93.6 Dimensions: Transport [mm] 3000 3960... -

Page 68: Technical Data

TECHNICAL DATA Position of Vehicle Identification Plate The chassis number is engraved on the name plate illustrated on the left. Warranty claims, enquiries and spare parts orders cannot be made without quoting the chassis number. Please enter the number on the title page of the Operating Instructions immediately on taking delivery of the vehicle/ equipment. -

Page 69: Supplement

SUPPLEMENT GB-Anhang Titelblatt _BA-Allgemein... - Page 70 The original cannot be copied ... Things will run better with genuine Pöttinger parts • Quality and precise fitting The decision must be made, ”original” or ”imitation”? The decision is often governed by price and a ”cheap buy” can sometimes be very expensive. - Operating safety.

-

Page 71: Recommendations For Work Safety

Recommendations for work safety SUPPLEMENT - A Recommendations for work safety 6.) Transport of persons prohibited All points refering to safety in this manual are indicated a. The transport of persons on the machine is not permitted. by this sign. b. -

Page 72: Driveshaft

DRIVESHAFT Supplement - B Matching driveshaft to tractor Rules for working To determine the actual length required, hold the two Never exceed the maximum p. t. o. speed when using halves of the driveshaft side by side. the implement. Important! - When the p.t.o. - Page 73 DRIVESHAFT Supplement - B How a cam type cut out safety clutch works This overload clutch switches the torque transmitted to zero if overloaded. To revert to normal operation, stop the p.t.o. drive briefly. The clutch reengages at a speed below 200 rpm. IMPORTANT! Re-engaging is also possible by decreasing the p.t.o.

-

Page 74: Lubrication Chart

FETT Schmierplan Plan de graissage Lubrication chart alle X Betriebsstunden Toutes les X heures de service after every X hours operation 40 F alle 40 Fuhren 40 F Tous les 40 voyages 40 F all 40 loads 80 F alle 80 Fuhren 80 F Tous les 80 voyages 80 F... - Page 75 FETT FETT FETT FETT FETT 5x (IV) 5x (IV) FETT FETT FETT FETT FETT FETT FETT FETT 1x (IV) 3x (IV) 3x (IV) 1x (IV) FETT FETT FETT FETT FETT FETT FETT FETT 1x (IV) 1x (IV) 1x (IV) 1x (IV) FETT FETT FETT...

-

Page 78: Service

SERVICE Hydraulic plan (Select Control) Explanation: Directional control valve - right mower unit Directional control valve - mower unit left Directional control valve - interlock floating position Directional control valve - interlock raise/lower 1100-GB SERVICE_3843 - 78 -... -

Page 79: Electrical Circuit Diagram (Select Control)

SERVICE Electrical circuit diagram (Select Control) Note! Ansicht auf Sensorstecker (S3, S6, S7) (von außen) All plug views are seen from the outside. Signal Ansicht auf Sensorstecker (S5) (von außen) Colour code: blue brown green gnge green/yellow grey black white br bl br bl br bl br bl 1 2 3 4 5 6 7 8... -

Page 80: Hydraulic Plan (Power Control/Isobus)

SERVICE Hydraulic plan (Power Control/ISOBUS) Pressure transducer Pump Tank Load-sensing connection (LS) Explanation: Seat valve - interlock Y11/12 Cross conveyor belt - swivelling (left) Directional control valve - raise Seat valve - hydraulic pressure relief right Directional control valve - lower Seat valve - hydraulic pressure relief left Seat valve - mower unit right Restrictor - CCB speed right... -

Page 81: Electrical Circuit Diagram (Power Control/Isobus)

SERVICE Electrical circuit diagram (Power Control/ISOBUS) Note! All plug views are seen from the outside. Signal Colour code: blue brown green gnge green/yellow grey black white Explanation: Cross conveyor belt (QFB) - swivelling (left) Directional control valve - raise Seat valve - side protection Directional control valve - lower Cross conveyor belt (QFB) - swivelling (right) Seat valve - mower unit right... -

Page 82: Electrical Circuit Diagram (Hydraulic Pressure Relief)

SERVICE Electrical circuit diagram (Hydraulic pressure relief) Note! All plug views are seen from the outside. Signal Colour code: blue brown green gnge green/yellow grey black white 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 A B C D E F G H J K L M N O Explanation: Seat valve - hydraulic pressure relief right... -

Page 83: Hydraulic Plan (Collector)

SERVICE Hydraulic plan (Collector) Rücklauffilter 445.320 Eigenversorgung Tank 445.286 Y16 od. Y17 Antrieb Zapfwelle 0,8 mm 445.248 445.170.011 Antrieb QFB 175 bar Y18 od. Y19 Antrieb Rolle 445.198 Explanation: Directional control valve - right mower unit Directional control valve - left mower unit Directional control valve - interlock floating position Directional control valve - interlock raise/lower... -

Page 84: Electrical Circuit Diagram (Cross Conveyor Belts)

SERVICE Electrical circuit diagram (Cross conveyor belts) Note! All plug views are seen from the outside. Signal Colour code: blue brown green gnge green/yellow grey black white Explanation: Sensor - cross conveyor belt right Restrictor - CCB speed right Sensor - Cross conveyor belt left Restrictor - CCB speed left Seat valve - cross conveyor belt on/off right Seat valve - cross conveyor belt on/off left... -

Page 85: Repairs On The Cutter Bar

REPARAIR INSTRUCTIONS Repairs on the cutter bar • Adjust markings in a line (K1, K2). • Only screw the nut (M) on when there is sufficient thread length in order to prevent any damage. • Secure nut (M) against loosening. - with „Loctite 242“... -

Page 86: Taper Bushes

TAPER BUSHES Taper bushes installation instructions To assemble 1. Clean and degrease the bore and taper surfaces of the bush and the tapered bore of the pulley. 2. Insert the bush in the pulley hub and line up the holes (half thread holes must line up with half straight holes). -

Page 87: Combination Of Tractor And Mounted Implement

IMPORTANT! ADDITIONAL INFORMATION Combination of tractor and mounted implement The mounting of implements on the front or rear three point linkage shall not result in exceeding the maximum permissible weight, the permissible axle loads and the tyre load carrying capacities ot the tractor. The front axle of the tractor must always to be loaded with at least 20 % of the unladen weight of the tractor. - Page 88 IMPORTANT! ADDITIONAL INFORMATION 3. CALCULATION OF THE REAL FRONT AXLE LOAD T V tat (If with the front mounted implement (G ) the required minimum front ballasting (G ) cannot be reached, the weight of the front mounted V min implement has to be increased to the weight of the minimum ballasting at the front!) Record the calculated real front axle load and the permissible front axle load of the tractor into the table.

- Page 89 EC Conformity Declaration Original Conformity Declaration Name and address of the manufacturer: PÖTTINGER Landtechnik GmbH Industriegelände 1 AT - 4710 Grieskirchen Machine (interchangeable equipment): NOVACAT X 8 ED / RC / COLL mower 3843 Type Serial no. The manufacturer declares that the machines adhere to all relevant provisions in the following EU directive: machinery 2006/42/EG In addition to this, the manufacturer also declares adherence to the other following EU...

- Page 90 Im Zuge der technischen Weiterentwicklung La société PÖTTINGER Landtechnik GmbH Following the policy of the PÖTTINGER arbeitet die PÖTTINGER Landtechnik améliore constamment ses produits grâce Landtechnik GmbH to improve their products GmbH ständig an der Verbesserung ihrer au progrès technique. as technical developments continue, Produkte.

- Page 91 PÖTTINGER Landtechnik GmbH A-4710 Grieskirchen Telefon: +43 7248 600-0 Telefax: +43 7248 600-2513 e-Mail: info@poettinger.at Internet: http://www.poettinger.at PÖTTINGER Deutschland GmbH Verkaufs- und Servicecenter Recke Steinbecker Strasse 15 D-49509 Recke Telefon: +49 5453 9114-0 Telefax: +49 5453 9114-14 e-Mail: recke@poettinger.at PÖTTINGER Deutschland GmbH Servicecenter Landsberg Spöttinger-Straße 24 Postfach 1561...

Need help?

Do you have a question about the NOVACAT X8 ED and is the answer not in the manual?

Questions and answers