Subscribe to Our Youtube Channel

Summary of Contents for Woodward TecJet 52 Gen II

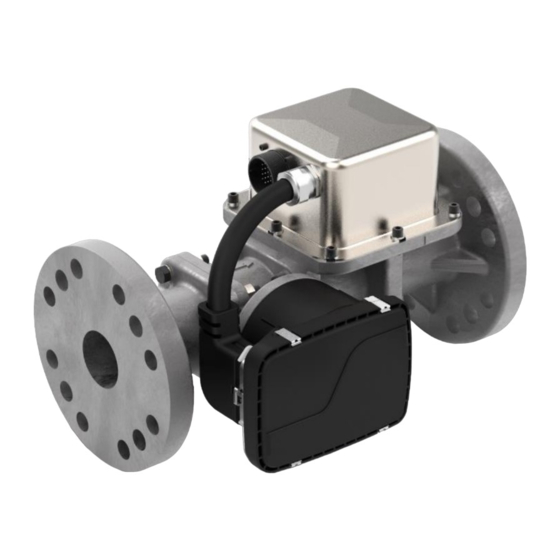

- Page 1 Product Manual 26833 (Revision C, 11/2022) Original Instructions TecJet™ 52 Gen II Installation and Operation Manual EC-US-L1...

- Page 2 Revisions— A bold, black line alongside the text identifies changes in this publication since the last revision. Woodward reserves the right to update any portion of this publication at any time. Information provided by Woodward is believed to be correct and reliable. However, no responsibility is assumed by Woodward unless otherwise expressly undertaken.

-

Page 3: Table Of Contents

Product Support Options ..........................79 Product Service Options ..........................79 Returning Equipment for Repair ......................... 80 Replacement Parts ............................80 Engineering Services ..........................81 Contacting Woodward’s Support Organization ................... 81 Technical Assistance ..........................82 ........................83 EVISION ISTORY ..........................84... - Page 4 Manual 26833 TecJet 52 Gen II Illustrations and Tables ILLUSTRATIONS Figure 2-1a. TecJet 52 Overview ........................ 14 Figure 2-1b. Allowable Actuator Orientations ..................... 15 Figure 2-1c. Allowable Bore Orientations ....................15 Figure 2-2a. TecJet 52 Outline Drawing ..................... 16 Figure 2-2b. TecJet 52 Outline Drawing ..................... 17 Figure 2-3.

-

Page 5: Warnings And Notices

Manual 26833 TecJet 52 Gen II Warnings and Notices Important Definitions This is the safety alert symbol used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. - Page 6 Manual 26833 TecJet 52 Gen II On- and Off-Highway Mobile Applications: Unless Woodward's control functions as the supervisory control, customer should install a system totally independent of the prime mover control system that monitors for supervisory control of engine (and takes appropriate...

-

Page 7: Electrostatic Discharge Awareness

Do not touch the components or conductors on a printed circuit board with your hands or with conductive devices. To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715 , Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules. -

Page 8: Regulatory Compliance

Manual 26833 TecJet 52 Gen II Regulatory Compliance European Compliance for CE Marking: These listings apply to stationary industrial markets only and are limited only to those units bearing the CE Marking. EMC Directive: Declared to Directive 2014/30/EU of the European Parliament and of the Council of 26 February 2014 on the harmonization of the laws of the Member States relating to electromagnetic compatibility (EMC). - Page 9 Manual 26833 TecJet 52 Gen II equipment that is excluded or does not fall within the scope of this Regulation, which can fulfil its function only if it is part of that equipment, and which can be replaced only by the same specifically designed equipment and therefore fulfills the requirements stated in Part 2 of Schedule1 clause 16 and as such is excluded from the scope of the Regulation.

- Page 10 Manual 26833 TecJet 52 Gen II Due to the hazardous location listing associated with this product, proper wire type and wiring practices are critical to operation. Do not connect any cable grounds to “instrument ground”, “control ground”, or any non-earth ground system. Make all required electrical connections based on the wiring diagram per Figure 2-5.

-

Page 11: Chapter 1. General Information

Throughout the remainder of the manual, the TecJet 52 Gen II valve and actuator system will be referred to simply as the TecJet 52. Connections to the TecJet 52... -

Page 12: Programmable Features

TecJet 52 Gen II Programmable Features Control setup is accomplished using a PC (personal computer), Woodward Service Tool software, and TTL to RS-232 adaptor. The TecJet 52 is provided pre-configured with default settings and may not require additional setup. The features identified below are described in Chapter 5. Briefly, the programmable features include: •... -

Page 13: Chapter 2. Installation

The TecJet 52 valve is pressure tested at Woodward. Allowable external leakage is less than 2 SCCM or 0.00015 kg/h. Leak-check all gaseous fuel connections. Leaking gaseous fuel can cause explosion hazards, property damage, or loss of life. -

Page 14: Mounting

Be careful when unpacking the TecJet 52. Check the assembly for signs of damage, such as bent or dented covers, scratches, and loose or broken parts. Be especially careful not to rest the TecJet 52 on the valve position pointer or on the actuator electrical connectors. Notify the shipper and Woodward if damage is found. -

Page 15: Figure 2-1B. Allowable Actuator Orientations

Manual 26833 TecJet 52 Gen II Figure 2-1b. Allowable Actuator Orientations Figure 2-1c. Allowable Bore Orientations For on-engine applications, a suitable bracket must be constructed to support the weight of the valve on the engine. See the outline drawing (Figure 2-2) for the valve mounting feet hole and hole-location details. -

Page 16: Outline Drawings

Manual 26833 TecJet 52 Gen II Outline Drawings Reference Woodward drawing 9999-1563 rev C. NOTES: 1. Interpret drawing per ASME 14.5-2009. 2. Dimensions are shown as inches [millimeters]. 3. Total weight approximately 33.1 lbs [15.0 kg] or 34.6 lbs [15.7 kg] with optional mounting support. -

Page 17: Figure 2-2B. Tecjet 52 Outline Drawing

Manual 26833 TecJet 52 Gen II Figure 2-2b. TecJet 52 Outline Drawing Woodward EC-US-L1... -

Page 18: Figure 2-3. Tecjet 52 Outline Drawing - Installation

Manual 26833 TecJet 52 Gen II OPTIONAL MOUNTING: 4 MOUNTING FEET WITH .3125-18 UNC-2A THREADED STUDS. (MOUNTING SUPPORT WITH HARDWARE MAY BE PURCHASED AS AN OPTIONAL KIT (B) Figure 2-3. TecJet 52 Outline Drawing - Installation Woodward EC-US-L1... -

Page 19: Electrical Connections

Manual 26833 TecJet 52 Gen II Figure 2-4. TecJet 52 Outline Drawing - Preferred Mounting with Actuator Positioned Horizontally Electrical Connections The TecJet 52 is electrically connected to the control system by the main connector shown in Figure 2-4. The mating connector should be torqued per the value indicated in Figure 2-4. The following mating connectors are compatible with the TecJet 52 control. - Page 20 Manual 26833 TecJet 52 Gen II EXPLOSION HAZARD—Do not remove covers or connect/disconnect electrical connectors unless power has been switched off or the area is known to be non-hazardous. Substitution of components may impair suitability for Class I, Division 2.

-

Page 21: Shielded Wiring

• Installations with severe electromagnetic interference (EMI) may require additional shielding precautions. Contact Woodward for more information. Failure to provide shielding can produce future conditions which are difficult to diagnose. Proper shielding, when provided, at the time of installation is recommended to assure satisfactory operation of the product. -

Page 22: Figure 2-5. Tecjet 52 Wiring Diagram

Manual 26833 TecJet 52 Gen II TecJet From Previous CAN Device CAN Gnd CAN Hi In CAN Lo In CAN Shield CAN Hi Out CAN Lo Out Jumper for CAN Termination Resistor To Next CAN 4-20mA Analog In + Device... -

Page 23: Supply Voltage

Manual 26833 TecJet 52 Gen II Supply Voltage W = Power-In (+) Z = Power-In (–) The supply voltage during normal operation must be 18 to 32 V, measured at the TecJet 52 connector. Steady state input current can reach 1.0 A, and transient input current may reach up to 4 A. The recommended power supply cable size is at least 1.3 mm²... -

Page 24: Can Id Inputs

Manual 26833 TecJet 52 Gen II Push-Pull PWM Source (three variations) Customer PWM Source TecJet PWM Input Circuit 4 - 32 Vdc + 5V TecJet Pin “K” 5 k Ω Internal 4 - 32 Vdc Command Processor Internal Command 4 - 32 Vdc... -

Page 25: Can Termination

Manual 26833 TecJet 52 Gen II CAN Termination P = Termination resistor Q = Termination resistor The internal termination resistor (124 Ω) is used to terminate the CANbus. According to the CAN specification, every CANbus must be terminated at both ends of the bus. If a TecJet 52 valve is connected to the far end of the bus, this termination resistor can be used. -

Page 26: Figure 2-7. Tecjet 52 Can Wiring For Isolated/Non-Isolated Systems

Manual 26833 TecJet 52 Gen II TecJet CAN Interface User Control CAN High Controller CAN Low CAN Common Connect P and Q with a short jumper if termination is desired. Isolated User Source ONLY TecJet CAN Interface User Control CAN High... -

Page 27: Can Out

Manual 26833 TecJet 52 Gen II CAN Out T = CAN high out U = CAN low out The CAN output pins are connected to the CAN input pins internally. They are provided for linking more than one TecJet 52 to the CANbus without the need for junction boxes or doubled terminations to connector pins. -

Page 28: Status Output

(Woodward PN 1249-1039) is necessary to make communications possible with the Woodward TecJet Service Tool. The converter must be located a maximum of 1 meter from the TecJet 52. A connectivity kit can be purchased from Woodward to accomplish this. Further instructions for using this connectivity kit are provided in Chapter 5. -

Page 29: Chapter 3. Description Of Operation

Manual 26833 TecJet 52 Gen II Chapter 3. Description of Operation External fire protection is not provided in the scope of this product. It is the responsibility of the user to satisfy any applicable requirements for their system. Due to typical noise levels in engine environments, hearing protection should be worn when working on or around the TecJet 52 valve/actuator. - Page 30 Manual 26833 TecJet 52 Gen II Diagnostics The TecJet 52 may not return to minimum fuel for all faults. The engine, turbine, or other type of prime mover should be equipped with an overspeed, misfire, detonation detection shutdown device(s), that operate totally independently of the prime mover control...

-

Page 31: Figure 3-1. Current Limiting Based On Temperature

Manual 26833 TecJet 52 Gen II created, even with a substantially drooping fuel source, before allowing the TecJet 52 to begin metering fuel. An example of an abnormally low delta-p limiter: During start-up, if the valve is operating under very low differential pressure, and the valve indicates a "flow not reached"... - Page 32 Manual 26833 TecJet 52 Gen II SAE J1939 Communications with Woodward EGS-02 The TecJet 52 devices support CAN communications in the SAE J1939 Higher Layer Protocol format. Further detailed information regarding the J1939 Standards Collection can be purchased at www.sae.org. Information about CAN can be found at www.semiconductors.bosch.de. Specific information regarding TecJet 52 behavior is detailed below.

- Page 33 Manual 26833 TecJet 52 Gen II Gas Properties 100 ms (TecJet Engine Control) Transmission repetition rate: Data length: 8 bytes Data Page: PDU format: PDU specific: Default priority: PGN: 65533 (0xFFFD) Bytes 1, 2: Absolute Inlet Gas Pressure Data length:...

- Page 34 Manual 26833 TecJet 52 Gen II Byte 2 Bit 0: ELEC_TEMP_FAIL_HIGH Bit 1: FGT_FAIL_HIGH Bit 2: DELTA_P_FAIL_HIGH Bit 3: FGP_FAIL_HIGH Bit 4: COIL_CURRENT_FAIL_HIGH Bit 5: RESERVED Bit 6: RESERVED Bit 7: POSITION_FAIL_HIGH Byte 3 Bit 0: ELEC_TEMP_FAIL_LOW Bit 1: FGT_FAIL_LOW...

- Page 35 Manual 26833 TecJet 52 Gen II Bit 5: RESERVED Bit 6: RESERVED Bit 7: RESERVED Address Claimed Address Claimed / Cannot Claim Message Address Claimed Transmission rate: on start-up, on request, response to Address Claimed Data length: 8 bytes Data Page:...

- Page 36 Manual 26833 TecJet 52 Gen II Byte 8, Bits 4-1: Vehicle System Instance The Cannot Claim Address message will be sent out if the TecJet 52 receives an Address Claimed message with the same Source Address as the receiving node and with a higher priority (lower value) NAME.

-

Page 37: Figure 3-2. Address Claimed State Chart

Manual 26833 TecJet 52 Gen II Start executing Power On Self Test POST Complete- Send Address Claim Random Delay before sending Address Delay Complete- Claimed Send Address Claim “Bus-off Error occurred or collision detected Check for Message Received a contending... -

Page 38: Table 3-1. Transmit Pdos

Manual 26833 TecJet 52 Gen II CANopen Communications The TecJet 52 supports CAN communications in the CIA CANopen Protocol format complying with DS301 version 4.02. Further detailed information regarding CANopen can be obtained at www.can- cia.org. Information about CAN is available at www.semiconductors.bosch.de. Specific information regarding TecJet behavior is detailed below. - Page 39 Manual 26833 TecJet 52 Gen II Transmit PDO 1 - Fuel Valve Parameters Transmission rate: 99 ms Message type = “ASYNC” (does not require SYNC message) COB Id: 402 (0x192) default for Node Id = 18. All others 384+Node Id.

- Page 40 Manual 26833 TecJet 52 Gen II Byte 1 (Overall Status) Bit 0: OVERALL_STATUS_OK Bit 1: HOLD_POSITION_WARN Bit 2: ZERO_PRESSURE_DETECTED Bit 3: ZERO_FLOW_DETECTED Bit 4: FLOW_NOT_REACHED Bit 5: VALVE_POSITION_ERROR Bit 6: HIGH_ELEC_TEMP Bit 7: RESERVED Byte 2 Bit 0: ELEC_TEMP_FAIL_HIGH Bit 1: FGT_FAIL_HIGH...

- Page 41 Manual 26833 TecJet 52 Gen II Byte 8 Bit 0: RESERVED Bit 1: RESERVED Bit 2: RESERVED Bit 3: RESERVED Bit 4: RESERVED Bit 5: RESERVED Bit 6: RESERVED Bit 7: RESERVED Receive PDO 1 - Gaseous Fuel Command Maximum Reception rate: 3 ms (Engine Control to TecJet 52) Message type = “ASYNC”...

-

Page 42: Table 3-3. Pdo Summary

Manual 26833 TecJet 52 Gen II CANopen Data Summary PDO Summary Node/PDO represents the Node ID + PDO combination from the standard connection set. Table 3-3. PDO Summary CANopen Name Node/PDO Location Type Fuel Specific Gravity 18/1(R) Bytes 1-2 UINT16... -

Page 43: Tecjet 52 Specifications

EN61000-6-4 (2001): Emissions for Industrial Environments The unit is un-powered during storage temperature. ǂ) It is recommended that engine vibration data for each new application be evaluated to ensure that TecJet test levels are adequate. Contact Woodward engineering for further details. Woodward EC-US-L1... - Page 44 Manual 26833 TecJet 52 Gen II Fuel Specifications The TecJet 52 fuel metering valve is designed to operate on gases ranging from pipeline quality natural gas to specialty gas (such as landfill, digester, or other biogases), and propane. Proper application of the valve for fuel flow, pressure, energy content, etc.

- Page 45 Manual 26833 TecJet 52 Gen II Flow Characteristics Accuracy The TecJet 52 meters fuel accurately such that the engine starts consistently and accelerates smoothly to idle speed. The required fuel delivery up to 7% of valve maximum rated effective area is within ±20% of the mass flow demand.

-

Page 46: Chapter 4. Valve Sizing

Manual 26833 TecJet 52 Gen II Chapter 4. Valve Sizing Figures 4-1 through 4-4 show the maximum and minimum amounts of gas that the TecJet 52 will flow as a function of pressure differential in kPa(d). Figures 4-1 and 4-2 indicate flow values for specialty gas, while Figures 4-3 and 4-4 indicate flow values for natural gas. -

Page 47: Figure 4-1. Maximum Specialty Gas Flow Capacity Of Tecjet 180, 110, 85, 52 And 37

Manual 26833 TecJet 52 Gen II Figure 4-1. Maximum Specialty Gas Flow Capacity of TecJet 180, 110, 85, 52 and 37 (Specialty Gas, SG=1, Sea Level) Woodward EC-US-L1... -

Page 48: Figure 4-2. Minimum Specialty Gas Flow Capacity Of Tecjet 180, 110, 85, 52 And 37

Manual 26833 TecJet 52 Gen II Figure 4-2. Minimum Specialty Gas Flow Capacity of TecJet 180, 110, 85, 52 and 37 (Specialty Gas, SG=1, Sea Level) Woodward EC-US-L1... -

Page 49: Figure 4-3. Maximum Natural Gas Flow Capacity Of Tecjet 180, 110, 85, 52 And 37

Manual 26833 TecJet 52 Gen II Figure 4-3. Maximum Natural Gas Flow Capacity of TecJet 180, 110, 85, 52 and 37 (Natural Gas, SG=0.6, Sea Level) Woodward EC-US-L1... -

Page 50: Figure 4-4. Minimum Natural Gas Flow Capacity Of Tecjet 180, 110, 85, 52 And 37

Manual 26833 TecJet 52 Gen II Figure 4-4. Minimum Natural Gas Flow Capacity of TecJet 180, 110, 85, 52 and 37 (Natural Gas, SG=0.6, Sea Level) Woodward EC-US-L1... -

Page 51: Chapter 5. Service Tool

52 control via RS-232 connection. An external TTL to RS-232 transceiver (Woodward P/N 1249-1039) is needed to make possible communications with the Woodward TecJet Service Tool. This works best if it is wired into the harness within 18 inches (1 meter max) of the TecJet 52 control. -

Page 52: Figure 5-1. Communication- Harness Connections

Manual 26833 TecJet 52 Gen II System Requirements The following hardware is required to work with the TecJet 52 control: • PC-compatible laptop or desktop computer Microsoft Windows XP, 7, or 10 300 MHz Pentium CPU 64 MB of RAM Minimum 800 by 600 pixel screen with 256 colors •... -

Page 53: Troubleshooting The Driver

Manual 26833 TecJet 52 Gen II Service Tool Help Online Service Tool help is available and included with the installation of the Service Tool product. Help can be accessed from the Service Tool ‘Help’ menu located on the main screen Service Tool Security There are no password security levels provided by the TecJet Service Tool. - Page 54 Manual 26833 TecJet 52 Gen II Flow Demand CAN or PWM Displayed value of the flow demand input, in kilograms/hour. Gas Density Displayed value of the gas density, in grams/cubic meter, at FGT and FGP. Fuel Gas Temperature (FGT) Displayed value of the inlet fuel gas temperature, in degrees Celsius.

-

Page 55: Figure 5-3. Troubleshooting Screen

Manual 26833 TecJet 52 Gen II Troubleshooting Screen Select the Troubleshooting tab to view general TecJet control parameters. This screen dynamically populates based on the TecJet configuration. If a function is not programmed, then it will not appear. Figure 5-3. Troubleshooting Screen Electronics Temperature Displayed value of the electronics temperature sensor, in degrees Celsius. -

Page 56: Figure 5-4. Warnings Screen

Manual 26833 TecJet 52 Gen II CAN Tx Error Count Displayed value of the CAN transmit error counter. Warnings Screen It is recommended that all faults be used and configured as shutdowns to ensure maximum fault protection. Select the Warnings tab to view TecJet active or previously active warning conditions. Warnings indicate a problem has occurred that needs attention, but the valve attempts continued operation. -

Page 57: Figure 5-5A. Errors Screen Before Power Cycle

Manual 26833 TecJet 52 Gen II Errors Screen Select the Errors tab to view active TecJet error conditions. Errors indicate a serious problem has occurred and the valve is not able to operate. This screen dynamically populates based on the TecJet configuration. -

Page 58: Figure 5-5B. Errors Screen After Power Cycle

Manual 26833 TecJet 52 Gen II Figure 5-5b. Errors Screen after Power Cycle Shutdown Indicates the valve is closed or attempting to close due to a detected error. Internal Fault Indicates an internal fault has occurred that prevents normal operation of the valve. -

Page 59: Figure 5-6. Configuration Screen

Manual 26833 TecJet 52 Gen II Configuration Screen Select the Configuration tab to view the TecJet configuration. This screen dynamically populates based on the existing TecJet configuration. If a function is not programmed, then it will not appear. The configuration settings are grouped into 4 or 5 sub-screens. Select a sub-tab to view the configuration settings for that group. -

Page 60: Configuring The Driver

Manual 26833 TecJet 52 Gen II Identification Screen Select the Identification tab to view TecJet identification information. Figure 5-7. Identification Screen Software Part Number Displayed software part number and revision letter. Serial Number Displayed TecJet valve serial number. Hardware Part Number Displayed TecJet valve part number and revision letter. -

Page 61: Figure 5-8. Edit Tecjet Configuration - General

Manual 26833 TecJet 52 Gen II This opens an Edit TecJet Configuration screen, (e.g., Figure 5-8), to permit driver configuration setting changes. The configuration settings are provided in a common area of the Edit TecJet Configuration screen and on several tabbed screens. -

Page 62: Figure 5-9A. Edit Tecjet Configuration - Flow (Can Demand)

Manual 26833 TecJet 52 Gen II ΔP Warning Thresholds - Low ΔP Sets the differential pressure, in millibar, which triggers a ΔP Low warning indication. Adjustable range: 0 to 1600 mbar ΔP Warning Thresholds - High ΔP Sets the pressure, in millibar, which triggers a ΔP High warning indication. -

Page 63: Figure 5-9B. Edit Tecjet Configuration - Flow (Analog Demand)

Manual 26833 TecJet 52 Gen II Figure 5-9b. Edit TecJet Configuration - Flow (Analog Demand) Analog Input Minimum Sets the current, in milliamps, which triggers an Analog Flow Demand Low warning. Adjustable range: 0–22 mA Analog Input Maximum Sets the current, in milliamps, which triggers an Analog Flow Demand High warning. -

Page 64: Figure 5-9C. Edit Tecjet Configuration - Flow (Pwm Demand)

Manual 26833 TecJet 52 Gen II Figure 5-9c. Edit TecJet Configuration - Flow (PWM Demand) PWM Duty Cycle Minimum Sets the PWM duty cycle, in percent, which triggers a PWM Flow Demand Low warning. Adjustable range: 2 to 50 % PWM Duty Cycle Maximum Sets the PWM duty cycle, in percent, which triggers a PWM Flow Demand High warning. -

Page 65: Figure 5-10. Edit Tecjet Configuration - Failed Sensor Defaults

Manual 26833 TecJet 52 Gen II Edit TecJet Configuration - Failed Sensor Defaults This screen provides for editing the Failed Sensor Default configuration settings used by the control in the event a sensor input fails. To change a value, highlight the value and type the desired value. The status bar displays the valid adjustable range for the highlighted value. -

Page 66: Figure 5-11. Edit Tecjet Configuration - Filters

Manual 26833 TecJet 52 Gen II Edit TecJet Configuration - Filters This screen provides for editing various input signal filter configuration settings. To change a value, highlight the value and type the desired value. The status bar displays the valid adjustable range for the highlighted value. -

Page 67: Figure 5-12A. Edit Tecjet Configuration - Can (Default)

Manual 26833 TecJet 52 Gen II Edit TecJet Configuration - CAN This screen provides for editing CAN communication configuration settings. To select a ‘Default’ or ‘User Configured’ baud rate, click the radio button adjacent to the choice. Figure 5-12a. Edit TecJet Configuration - CAN (Default) Baud Rate, Default Sets the default baud rate of the CAN communication in kbps. -

Page 68: Figure 5-12C. Edit Tecjet Configuration - Can (User Configured)

Manual 26833 TecJet 52 Gen II • TSEG01 Sets the Tseg1 value in the CAN controller. Tseg1 combines the PROP_SEG and PHASE_SEG1 segments of the CAN protocol. Adjustable range: 3 to 16 • TSEG02 Sets the Tseg2 value in the CAN controller. Tseg2 defines the PHASE_SEG2 segment of the CAN protocol. -

Page 69: Figure 5-13. Load Configuration Settings

Manual 26833 TecJet 52 Gen II Load Configuration Settings Figure 5-13. Load Configuration Settings Review ALL settings shown on ALL tabbed Edit TecJet Configuration screens to verify that all configuration settings are correct before loading settings to the control. Configuration changes do not take effect until they are loaded to the control. -

Page 70: Chapter 6. Troubleshooting

Manual 26833 TecJet 52 Gen II Chapter 6. Troubleshooting The tables in this chapter refer to status indications, warnings, and errors that can be viewed on the Service Tool. See Chapter 5 for information on installing the Service Tool. The actions described may not be appropriate for all situations. The... - Page 71 Manual 26833 TecJet 52 Gen II Table 6-1. Status Indications Troubleshooting (cont’d.) Status Description Possible Cause Possible Actions Zero Flow If the CAN Flow ECM is requesting zero Status indication, no action Detected Demand Failed warning flow. required. (Flow demand...

-

Page 72: Table 6-2. Warnings Troubleshooting

Manual 26833 TecJet 52 Gen II Warnings Table 6-2. Warnings Troubleshooting Warning Description Possible Cause Possible Actions Analog Flow The analog flow demand Analog input wiring Check the analog input Demand High exceeds the analog flow problem. wiring for shorts, open... - Page 73 Manual 26833 TecJet 52 Gen II Table 6-2. Warnings Troubleshooting (cont’d.) Warning Description Possible Cause Possible Actions CAN Flow The CAN flow demand Incorrect TecJet 52 Check the CAN ID inputs to Demand is not being received. number. the valve.

- Page 74 Manual 26833 TecJet 52 Gen II Table 6-2. Warnings Troubleshooting (cont’d.) Warning Description Possible Cause Possible Actions Electronics The internal electronics Internal fault. Replace the valve. Temperature temperature sensor has High failed to a high value. The valve may not reach specified performance.

- Page 75 Manual 26833 TecJet 52 Gen II Table 6-2. Warnings Troubleshooting (cont’d.) Warning Description Possible Cause Possible Actions Fuel Gas The Fuel Gas Internal fault. Replace valve. Temperature Temperature sensor has Sensor High failed to a high value and the default fuel gas temperature is being used instead.

-

Page 76: Table 6-3. Errors Troubleshooting

Manual 26833 TecJet 52 Gen II Errors When an error occurs, the valve closes, if possible. It will not attempt to operate again until power to the valve is cycled. If the error persists, the valve must be replaced. Table 6-3. Errors Troubleshooting... - Page 77 Manual 26833 TecJet 52 Gen II Chapter 7. Maintenance General Build-up of deposits near the metering area of the TecJet 52 can develop depending on the quality of the gas being metered. This build-up can affect the performance of the TecJet 52 and may appear as degradation of actual flow vs command flow accuracy, or as flow control instability.

- Page 78 Manual 26833 TecJet 52 Gen II • Fill the TecJet again with fresh 60 °C tap water and move the water around in the valve bore with a long plastic rod or equivalent. • Dump the rinse water out of the TecJet.

-

Page 79: Chapter 8. Product Support And Service Options

• An Authorized Independent Service Facility (AISF) provides authorized service that includes repairs, repair parts, and warranty service on Woodward's behalf. Service (not new unit sales) is an AISF's primary mission. • A Recognized Engine Retrofitter (RER) is an independent company that does retrofits and... -

Page 80: Returning Equipment For Repair

To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715, Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules. -

Page 81: Engineering Services

Field Service engineering on-site support is available, depending on the product and location, from one of our Full-Service Distributors. The field engineers are experienced both on Woodward products as well as on much of the non-Woodward equipment with which our products interface. -

Page 82: Technical Assistance

TecJet 52 Gen II Technical Assistance If you need to contact technical assistance, you will need to provide the following information. Please write it down here before contacting the Engine OEM, the Packager, a Woodward Business Partner, or the Woodward factory: General... -

Page 83: Revision History

Manual 26833 TecJet 52 Gen II Revision History Changes in Revision C— • Added Lockout/Tagout and I/O Lock warnings to Warnings section • Updated Electrostatic Discharge Awareness section • Updated Regulatory Compliance section; added UKCA compliance • Added mounting diagrams Figures 2-1a, 2-1b, 2-1c to Chapter 2 •... -

Page 84: Declarations

Manual 26833 TecJet 52 Gen II Declarations Woodward EC-US-L1... - Page 85 Manual 26833 TecJet 52 Gen II Woodward EC-US-L1...

- Page 86 Manual 26833 TecJet 52 Gen II Woodward EC-US-L1...

- Page 87 Manual 26833 TecJet 52 Gen II Woodward EC-US-L1...

- Page 88 Email and Website—www.woodward.com Woodward has company-owned plants, subsidiaries, and branches, as well as authorized distributors and other authorized service and sales facilities throughout the world. Complete address / phone / fax / email information for all locations is available on our website.

Need help?

Do you have a question about the TecJet 52 Gen II and is the answer not in the manual?

Questions and answers

Please give us your best quotation for Tecjet pn 460-2083 of Caterfiller engine 131833