Advertisement

Quick Links

Product overview

2

1

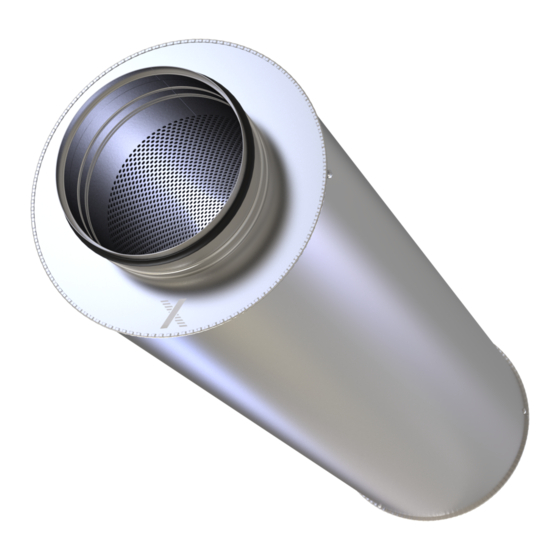

Fig. 1: Schematic representation, CA

1

Casing of the silencer

2

Spigot

3

Lip seal

Important notes

Safety

Correct use

Circular silencers are used to reduce noise in the

circular ducts of ventilation and air conditioning sys-

tems within closed rooms.

For the reduction of air-regenerated noise of air

terminal units and mechanical self-powered control-

lers, etc.

Installation manual

Circular silencer

CA

3

Circular silencer CA

GB/en

Do not use circular silencers in extract air systems

in commercial kitchens unless the extract air has

been cleaned as much as possible with high-effi-

ciency aerosol separators; see VDI 2052.

Use in potentially explosive atmos-

pheres (ATEX)

Circular silencers do not fall under the scope

in accordance with Chapter 1, Article 1, Point

1a, 1b and 1c of EU Directive 2014/34/EU. The

circular silencers must be used in areas with

a potentially explosive atmosphere, zones 1, 2

and zones 21, 22 (outside), in accordance with

Guideline 1999/92/EC.

Please note:

–

Max. operating temperature 90 °C

–

Max. airflow velocity 20 m/s

–

When using lip seals for tube attachment,

a grounding cable must be provided for the

sound attenuator/tube.

–

Earth circular silencers!

–

Clean sound attenuators regularly to prevent

accumulated dust!

–

Clean circular silencers in such a way that

no electrostatic charge builds up!

Manufacturer's statement

www.troxtechnik.com.

TROX GmbH

Heinrich-Trox-Platz

47504 Neukirchen-Vluyn, Ger-

many

Germany

+49 (0) 2845 202-0

+49 (0) 2845 202-265

E-mail: trox@trox.de

www.troxtechnik.com

Þ

1

Advertisement

Summary of Contents for Trox Technik CA

- Page 1 Max. operating temperature 90 °C – Max. airflow velocity 20 m/s – When using lip seals for tube attachment, Fig. 1: Schematic representation, CA a grounding cable must be provided for the sound attenuator/tube. Casing of the silencer – Earth circular silencers!

-

Page 2: Transport, Storage And Packaging

Check delivered items immediately after arrival for description of each type of work. transport damage and completeness. In case of any damage or an incomplete shipment, contact the shipping company and your supplier immediately. Circular silencer CA... - Page 3 Length (L) refers to the airflow direction. Installation material is not part of the supply package unless stated otherwise. Airflow direction freely selectable. Torsion-free installation. Circular silencer CA...

- Page 4 Circular silencer units and mechanical self-powered controllers. The Drilling screw for affixing to the ducting installation takes place immediately downstream of Clamp the control component. Suspension, e.g., with threaded rod Circular silencer CA...

- Page 5 Double lip seal: Fit the short lip (1) on the connection side Fit the ring seal as shown; avoid excessive stretching. Check for proper seating in the groove Apply talcum around the ring seal Circular silencer CA...

-

Page 6: Technical Data

≤ 80%, no condensation Casing leakage according to Class D (up to and including EN 15727 nominal size 400) Class C (from nominal size 450) * No corrosion resistance according to ISO 12944-2 has been speci- fied for circular silencers. Circular silencer CA... - Page 7 No registration: Spigot with groove according to EN 1506 / ØD D2 Spigot with lip seal on both sides acc. to EN 1506 / ØD AS Spigot with lip seal - ØD and socket-type spigot on one end - ØD2 ØD3 outer diameter Circular silencer CA...

- Page 8 The standard describes the essential commis- eign matter. sioning steps of the completeness check, func- tion check, function measurement as well as report generation and handover. Circular silencer CA...

-

Page 9: Maintenance

Check all screws for firm seating and retighten them, if necessary. Document the maintenance work. Repair Repair work is only allowed to be carried out by specialist personnel or by the manufacturer. Only genuine replacement parts must be used. Circular silencer CA... - Page 10 EAK Casing, inner 170405 duct, spigot and splitter frame Lip seal, Plastic EAK According to cover fleece 170203 Absorption Mineral wool According to material EAK 170604 EWC European Waste Catalogue Circular silencer CA...

Need help?

Do you have a question about the CA and is the answer not in the manual?

Questions and answers