Summary of Contents for Verderflex Dura MK IV 05

- Page 1 Peristaltic Industrial Hose Pump Operating Manual Dura 5, 7, 10, 15, 25, 35 Version 2.6v-12/2022 Original instructions (en)

- Page 2 Dura 5 - 35 series - Operating manual Dura Version 2.6v-12/2022 5, 7, 10, 15, 25, 35 The information in this document is essential for the safe operation of Verderflex Dura pumps. ® This document must be read and understood thoroughly prior to installation of unit, electrical connection and commissioning.

-

Page 3: Table Of Contents

Dura 5 - 35 series - Operating manual Table of Contents Declaration of Conformity ..........................5 About this Document ............................7 Target Groups ................................7 Warnings and symbols used in this manual ....................... 7 Safety ..................................8 Intended Use ................................8 General Safety Instructions ............................8 3.2.1 Product Safety ............................ - Page 4 Dura 5 - 35 series - Operating manual 6.6.4 Standard Port Flange Assembly (Dura 15, 25 and 35) ................18 6.6.5 Split Flange Assembly (Dura 15, 25 and 35) ...................18 6.6.6 Dura MK III 15, 25 and 35- Hose and Flange Assembly ................18 Filling the Pump with Lubricant ..........................19 6.7.1 Fitting the Inspection Window ........................19...

-

Page 5: Declaration Of Conformity

EC declaration of conformity according to machinery directive, appendix II A VERDER Ltd., Unit 3 California Drive, Castleford hereby declare that the following machine adheres to the relevant EC directives detailed below: Designation Dura MK IV 05 Dura MK IV 07 Dura MK IV 10 Dura MK III 15... - Page 6 In accordance with the UK Supply of Machinery (Safety) Regulations 2008, No 1597 ANNEX II, Part I, Section B VERDER Ltd., Unit 3 California Drive, Castleford hereby declare that the following machine adheres to the relevant UK legislation detailed below: Designation Dura MK IV 05 Dura MK IV 07 Dura MK IV 10 Dura MK III 15...

-

Page 7: About This Document

About this Document The Verderflex Dura 05-35 is a range of peristaltic pumps which have been developed according to the latest technology and subject to continuous quality control. These operating instructions are intended to facilitate familiarisation with the pump and its designed use. -

Page 8: Safety

Dura 5 - 35 series - Operating manual requirements of installation given in this manual and any local, Safety national or regional health and safety regulations. 3.2.2 Obligation of the Operating Company The manufacturer does not accept any liability for damage resulting from disregard of this documentation. -

Page 9: Obligation Of Personnel

Dura 5 - 35 series - Operating manual 3.2.3 Obligation of Personnel It is imperative that the instructions contained in this manual are complied with by the operating personnel at all times. Pump and associated components: – Do not lean or step on them or use as climbing aid –... -

Page 10: Transport, Storage And Disposal

Dura 5 - 35 series - Operating manual Transport, Storage and 4.2 Storage Conditions Disposal Make sure the storage location meets the following conditions: 4.1 Transport – Dry, humidity not to exceed 85%, non-condensing – Out of direct sunlight – Frost-free;... -

Page 11: Disposal

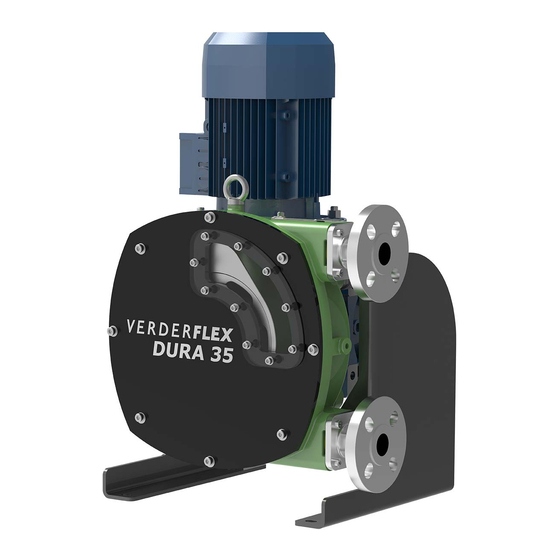

5.1 Design Details Verderflex Dura 05-35 is a twin lobe, single rotor, peristaltic pump with quick-fit tapered port flange design which clamps and seals in one easy movement to speed up hose replacement. -

Page 12: Layout

Dura 5 - 35 series - Operating manual 5.3 Layout 5.3.1 Dura MK IV 5, 7 and 10 Exploded View Figure 3. - Dura MK IV 5, 7, 10 Exploded View (Generic View) Hose Inspection Window Shaft Assembly Pump Housing Inspection Window Gasket Clamp Ring Gearbox with Adaptor Flange... -

Page 13: Dura Mk Iii 15, 25 And 35 Exploded View

Dura 5 - 35 series - Operating manual 5.3.2 Dura MK III 15, 25 and 35 Exploded View Figure 4. - Dura MK III 15, 25 and 35 Exploded View (Generic View) Hose Inspection Window Shaft Assembly Pump Housing Inspection Window Gasket Clamp Ring Gearbox with Adaptor Flange Front Cover... -

Page 14: Installation And Connection

Dura 5 - 35 series - Operating manual Installation and Connection CAUTION Material damage due to unauthorised modification on pump! Unauthorised modification will invalidate the warranty. 6.1 Preparing for Installation 6.1.1 Checking the Ambient Conditions Make sure that the operating conditions are complied with (g11. Technical Specifications). Make sure the required ambient conditions are fulfilled (g11. -

Page 15: Planning The Pipes

Dura 5 - 35 series - Operating manual 6.3 Planning the Pipes Don’ts Short pipe run to suction side Long pipe run to suction side 6.3.1 Specifying Supports Flange Connections When planning pipe runs take every possible operating condition into account: –... -

Page 16: Electrical Connection

Dura 5 - 35 series - Operating manual 6.4 Electrical Connection 6.4.2 Connecting to Power Supply Connect motor to the rated power supply. Ensure the DANGER correct gland is used and that the earth connection is made and secured. Wiring instructions are available within the motor junction box. -

Page 17: Flange Assembly

Dura 5 - 35 series - Operating manual 6.6 Flange Assembly 6.6.3 Dura MK IV 5, 7, 10 - Hose and Flange Assembly 6.6.1 Solid Flange Assembly (Dura 5, 7, 10) 6.6.3.1 Solid flange assembly 6.6.3.2 Split flange assembly Attach the O-ring as shown below. Attach the O-rings as shown below Note The solid flange has no insert. -

Page 18: Standard Port Flange Assembly (Dura 15, 25 And 35)

Dura 5 - 35 series - Operating manual 6.6.4 Standard Port Flange Assembly 6.6.6 Dura MK III 15, 25 and 35- Hose and Flange Assembly (Dura 15, 25 and 35) 6.6.6.1 Standard Port Flange Assembly 6.6.6.2 Split Flange Assembly For Dura 15 and 25, install the hose in For Dura 15 and 25, the hose is in position position and protruding 15 mm from and protruding 15 mm from the pump... -

Page 19: Filling The Pump With Lubricant

Dura 5 - 35 series - Operating manual 6.7 Filling the Pump with Lubricant 6.8 Connecting the Pipes Safety data sheets for both Verderlube and Verdersil are Note available from the manufacturer for compatibility check. Provide a suitable container to collect spilt lubricant. Contamination of pumped media due to impurities in the Ensure compatibility of lubricant with the pumped liquid. -

Page 20: Operation

Dura 5 - 35 series - Operating manual Operation 7.1.3 Switching OFF the Pump 7.1 Pre-commissioning the Pump WARNING 7.1.1 Checking the Direction of Rotation Risk of injury due to hot pump parts! with Dry Pump Use personal protective equipment when carrying out any work on the pump. -

Page 21: Commissioning The Pump

Dura 5 - 35 series - Operating manual 7.2 Commissioning the Pump 7.3 Shutting Down the Pump 7.2.1 Switching ON the Pump Take the following measures whenever the pump is shut down: Pump is... Measure DANGER shut down Take measures according to the pumped liquid (g Table 9). -

Page 22: Inspection, Maintenance And Repair

8.2.2 Cleaning Protocol for Hoses pump in operation. Do not block the breather tube which is designed for VERDERFLEX hoses should be cleaned with the following pressure relief. protocol – In the unlikely event of a hose burst which leads to... -

Page 23: Figure 25. - Verderflex Nbrf Food Grade Hose Identification

Final flush: flush with clean water to remove all traces of cleaning solutions Under no circumstances should VERDERFLEX NBRF Figure 25. - Verderflex NBRF food grade hose identification food grade hoses be cleaned with Sodium Hypochlorite (NaOCl) based cleaning solutions, neither should the above... -

Page 24: Maintenance Schedule

Dura 5 - 35 series - Operating manual 8.2.3 Maintenance Schedule Task Frequency Action Repair leaks and damage before – Before pump start up Check pump and gearbox for leaks and operating the pump – Daily visual inspection damage Replace components as necessary. –... -

Page 25: Repair

Dura 5 - 35 series - Operating manual 8.3 Repair Repairs Measure for Return ...at the customer’s – Return defective premises component DANGER manufacturer. – Decontaminate if necessary. Risk of death due to electric shock! ...at the manufacturer’s – Flush pump Have all electrical work carried out by qualified electrician premises... -

Page 26: Hose Change

Dura 5 - 35 series - Operating manual 8.4 Hose Change 8.4.2 Re-installing the Hose, Port Flanges, Lubricant Refill and Fitting the Inspection Window WARNING – Follow step by step, the instructions listed in section Risk of injury! (g 6. Installation and Connection) Always isolate the power supply before working on the pump. -

Page 27: Troubleshooting

Dura 5 - 35 series - Operating manual Troubleshooting 9.1 Pump malfunctions If malfunctions occur which are not specified in the following table or cannot be traced back to the specified causes, please consult the manufacturer. Possible malfunctions are identified and respective cause and remedy are listed in the table. - Page 28 Dura 5 - 35 series - Operating manual Possible cause Solution Consult the manufacturer to obtain correct Incorrect lubricant lubricant Low lubricant level Add required amount Consult the manufacturer regarding Product ambient temperature too high maximum temperature Check pipework and valves for blockages Check that the suction pipework is as short Blocked suction/ bad suction characteristics / no and as large in diameter as feasible.

-

Page 29: Table 12. - Pump Troubleshooting List

Dura 5 - 35 series - Operating manual Possible cause Solution Shorten long suction/discharge lines Long suction/discharge lines/ dampener wherever possible. malfunction Consult the manufacturer High product specific gravity / viscosity Consult the manufacturer Increase suction/discharge pipework Undersized suction/discharge diameter diameter. -

Page 30: List Of Tables & Figures

Figure 21. - 5mm protrusion (split flange) Figure 22. - Filling the pump with lubricant Figure 23. - Fitting the inspection window Figure 24. - Nozzle loading on flanges Figure 25. - Verderflex NBRF food grade hose identification Original instructions (en) Version 2.6v-12/2022 30 | Page... -

Page 31: Technical Specifications

11.3 Tightening Torques inspection window. Tightening torques should be applied at the following 11.7 Rotor Options torque values: Torque Values (Nm) Verderflex Dura 5-35 range has standard and high Position D5,7,10 pressure rotor options: Inspection Window Pump Type Rotor Option (bars) -

Page 32: Trademarks

Dura 5 - 35 series - Operating manual 12. Trademarks VERDERFLEX® is a registered trademark of Verder Liquids B.V. No permission is granted to use any Verder, trademarks or trade names included in this document without the prior written agreement of Verder Liquids B.V.

Need help?

Do you have a question about the Dura MK IV 05 and is the answer not in the manual?

Questions and answers

An end user with a Dura 15 is in need of a rotor (mechanism that pushes the lime slurry through the hose).Assuming this is the part of the shoe assembly? Please provide part id.