Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Verderflex Dura 45

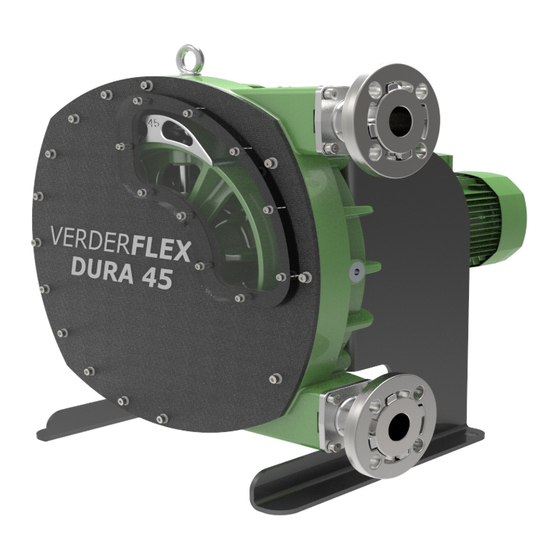

- Page 1 Peristaltic Hose Pump Operating Manual Dura 45 Version 3.1v-07/2016 Print-No.

- Page 2 Dura 45 Version 3.1v-07/2016 Print-No. 01 The information in this document is essential for the safe operation and servicing of Verderflex ® pumps. This document must be read and understood thoroughly prior to installation of unit, electrical connection and commissioning.

-

Page 3: Table Of Contents

5.6.2 Fitting the port flange 11.2 List of tables 5.6.3 Filling the pump with lubricant 5.6.4 Fitting the inspection window Declaration of conformity according to EC Machine Directive Connecting the pipes 5.7.1 Installing the piping Dura 45 3.1v-07/2016 3 | Page... -

Page 4: About This Document

Take note of all information highlighted by the safety warning sign and follow the instructions to avoid injury or death. Instruction 1., 2., Multiple-step instructions Precondition Cross-reference Information, recommendation Table 3 Symbols and their meaning Dura 45 3.1v-07/2016 4 | Page... -

Page 5: Safety

Operate the pump only if the pumping unit and all should be provided by the operating company. associated systems good functional – For potential build up of electrostatic charge: condition. ensure appropriate grounding when Only use the pumping system as intended, fully required. Dura 45 3.1v-07/2016 5 | Page... -

Page 6: Obligation Of Personnel

Peristaltic hose pump, Verderflex Dura, is simple by conform to the illustration or descriptions. design in its construction and operation. The medium Obtain the manufacturer’s approval prior to carrying... -

Page 7: Layout

¼ turn flange Slip bush Bearing housing Mounting frame 3.4 Bearings and Lubrication Pump: To be filled at installation with appropriate lubricant supplied filled. (g10.1.6 Lubricants) Bearings are sealed units and need no additional lubricant. Dura 45 3.1v-07/2016 7 | Page... -

Page 8: Transport, Storage And Disposal

Use lifting gear appropriate for the total weight to be transported. Fasten the lifting gear to the lifting eye as shown in the following illustration. Do not stand under suspended loads. Figure 3 Fastening lifting gear to pump unit Dura 45 3.1v-07/2016 8 | Page... -

Page 9: Treatment For Storage

Put the pump unit down at the instillation site. – Neutralize residues pumped liquid Bolt the pump down; use all 4 holes. the pump. Dispose of the pump unit and associated parts in accordance with statutory regulations. Dura 45 3.1v-07/2016 9 | Page... -

Page 10: Planning The Pipes

For maintenance and repair work. Provide shut-off valves in the suction and discharge Bellows lines Table 4 Do’s and Don’ts Allowing safe removal of product Include drainage taps in suction and discharge lines at the lowest point. Dura 45 3.1v-07/2016 10 | Page... -

Page 11: Shimming

5.5.1 Installing motor and gearbox (where not supplied) DANGER Death or crushing of limbs caused by falling loads! Use lifting gear appropriate for the total weight to be transported. Figure 6 Inserting Hose Do not stand under suspended loads Dura 45 3.1v-07/2016 11 | Page... -

Page 12: Fitting The Port Flange

Tighten the bolts in a 1–3–4–2 sequence until the through lowest bolt hole inspection flange is evenly fitted, but not completely tightened, window (→ 10.1.6 Lubricants). leaving about 10mm slack. Figure 10 Filling pump with lubricant Figure 8 Fitting the port flange Dura 45 3.1v-07/2016 12 | Page... -

Page 13: Fitting The Inspection Window

Run the pipes in a continuous upward or downward Perform a second flush by running the pump, 10–20 slope to avoid air pockets revolutions with pumped liquid, to remove residue Connect the piping and water inside the pump. Dura 45 3.1v-07/2016 13 | Page... -

Page 14: Switching Off

NOTE Damage to hose due to sediments! If the pumped liquid crystallizes, polymerizes or solidifies – Flush the hose – Make sure that the flushing liquid is compatible with the pumped liquid. Dura 45 3.1v-07/2016 14 | Page... -

Page 15: Shutting Down The Pump

Treat the pump with preservative. Liquid, non-corrosive Liquid, Empty the Empty the corrosive pump pump. Treat the pump with preservative. Table 6 Measures depending on the behaviour of the pumped liquid Dura 45 3.1v-07/2016 15 | Page... -

Page 16: Start-Up Following A Shutdown Period

- safely relieve the pressure inside the casing before disassembling the pump . WARNING Risk of injury and poisoning due to hazardous pumped liquids! Use protective equipment when carrying out any work on the pump. Dura 45 3.1v-07/2016 16 | Page... -

Page 17: Maintenance Schedule

– After 30,000 running hours Check bearing play and function. – When damage is suspected Replace bearing housing seal – When damage is suspected Replace worn components. – When leak is detected Table 7 Maintenance schedule Dura 45 3.1v-07/2016 17 | Page... -

Page 18: Repairs

WARNING Risk of injury while dismounting the pump! Use protective equipment when carrying out any work on the pump. Observe manufacturer’s instructions (e.g. for Motor, coupling, gearbox). Dura 45 3.1v-07/2016 18 | Page... -

Page 19: Rebuild / Repair

Clean the pump housing. Inspect the flanges for damage and signs of wear. 7.4.2 Re-installing the hose, port flanges, lubricant refill and fitting the inspection window Follow step step, instructions listed section g 5.6 (Installing the hose) Dura 45 3.1v-07/2016 19 | Page... -

Page 20: Ordering Spare Parts

EHEDG Approval The following information is mandatory when ordering spare parts (g Name plate): VERDERFLEX NBRF food grade hoses can be used with suitably – Pump model specified VERDERFLEX pumps to form an EHEDG accredited – Year of manufacture hygienic pumping system. -

Page 21: Storage Conditions

VERDERFLEX’s recommendations. Should there be any doubt about any consult the manufacturer. - Page 22 Large particles in the product Mount sieve or filter in suction line to avoid very large particles from entering the hose. Do not allow filters to limit suction below accepted levels. Table 9 Pump troubleshooting list Dura 45 3.1v-07/2016 22 | Page...

-

Page 23: Appendix

40 rpm at 16 bar Pump type Amount of Lubricant Dimensions Setup drawing Dura 45 7.5*Litres (2.2 US Gallons) Table 10 Pump Specifications Table 13 Amount of Lubricant *The pump is filled to the lowest screw hole on the window. -

Page 24: List Of Figures And Tables

Table 12 Cleaning agents 10.1.5 Table 13 Amount of Lubricant cover 10.1.6 Table 14 Number of shims required 10.1.7 Table 15 Rotor settings distance 10.1.8 Table 16 Declaration of conformity according to EC Machine Directive Dura 45 3.1v-07/2016 24 | Page... -

Page 25: Declaration Of Conformity According To Ec Machine Directive

EC declaration of conformity according to machine directive, appendix II A VERDER Ltd., Unit 3 California Drive, Castleford hereby declare that the following machine adheres to the relevant EC directives detailed below Designation Dura 45 EC directives: • Machine Directive (2006/42/EC) • Low-voltage directive (2014/35/EU) • EMC directive (2014/30/EU) Applicable harmonized norms: •...

Need help?

Do you have a question about the Dura 45 and is the answer not in the manual?

Questions and answers