Summary of Contents for Siargo CS3001 Series

- Page 1 CS3001 series Fluidic Concentration Meters User Manual VA.0 @ 2021 Siargo Ltd. www.Siargo.com...

- Page 2 Fluidic Concentration Meters with thermal time‐of‐flight technology CS3001 Series User Manual Document No. 05‐2021‐CS1 EN Issue date: 2021.05 Revision: VA.0 Siargo Ltd. 3100 De La Cruz Boulevard, Suite 210 Santa Clara, CA 95054 USA Tel: +1(408)969.0368 Email: info@siargo.com © Copyright 2021 and Liability Disclaimer Siargo Ltd. and its subsidiaries reserve the right to change the specifications and/or descriptions without prior notice. Siargo and its subsidiaries shall not assume any inaccuracy or errors in this manual. For further information and updates, please visit www.Siargo.com. ...

- Page 3 Only the trained or qualified personnel shall be allowed to perform product services. Use with caution ! Be cautious for electrical safety, and even it operates at a low voltage, any electrical shock might lead to some unexpected damages. The liquid to be measured should be clean and free of particles, as even light particles may be accumulated inside the flow channel that may result in inaccuracy in metrology, clogging, or other irrecoverable damage. Do not apply for any unknown or non‐specified liquids that may damage the product. Be cautious for the bubbles or cavitation inside the fluid, visible or invisible, that may lead to inaccuracy or erroneous outputs. www.Siargo.com CS3001 User Manual 2 | ...

-

Page 4: Table Of Contents

Power and data cable description ...................... 7 3.2 3.3 Mechanical dimensions .......................... 8 4. Installation ............................... 8 5. Basic operation .............................. 9 5.1. Check the product specifications ...................... 9 5.2. Check the microfluidic system ...................... 10 5.3. Check the leakage .......................... 10 5.4. Connect the power supply ........................ 10 5.5. Analog interface/measurement ...................... 11 5.6. Digital interface/measurement ...................... 11 5.6.1. Hardware connection ......................... 12 5.6.2. Communication parameters ...................... 12 5.6.3. Frame .............................. 13 5.6.4. Function codes ............................ 13 5.6.5. Registers .............................. 13 6. Product selection and order information .................... 17 6.1. Product selection ........................... 17 6.2. Order contact and customer support .................... 17 7. Technical specifications .......................... 18 8. Technical notes for the product performance .................... 19 8.1. Measurement principle .......................... 19 8.2. Precautions for the best performance of the product ............... 19 8.2.1. Particle contamination ........................ 19 8.2.2. Bubbles or cavitation ........................ 19 8.2.3. Pressurized flow delivery ....................... 20 www.Siargo.com CS3001 User Manual 3 | ... - Page 5 8.2.4. Continuous operation ........................ 20 8.2.5. Measurement of non‐conventional fluid .................. 20 8.2.6. Product calibration ......................... 20 8.2.7. Use the meter for density measurement .................. 21 8.2.8. Temperature sensitivity of the concentration measurement ............ 21 9. Troubleshooting ............................ 22 10. Warranty and Liability .......................... 23 11. Service contact and information ........................ 25 Appendix I: Product evaluation kit ......................... 26 Appendix II: Document history ........................ 27 www.Siargo.com CS3001 User Manual 4 | ...

-

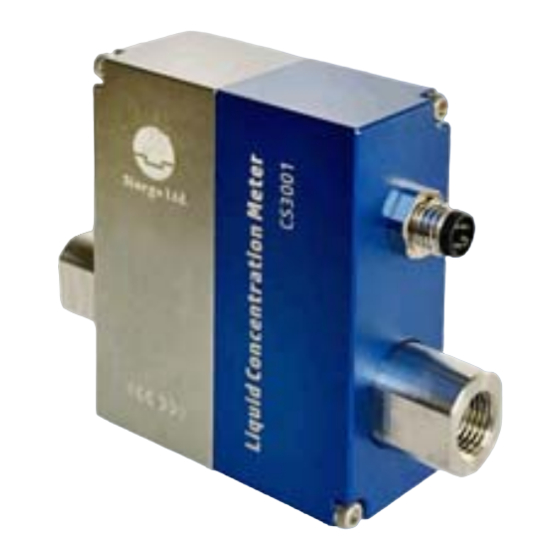

Page 6: Overview

Some medical or cross‐contamination sensitive applications would have a disposable approach as the only practical path. For any other forms of packages that are not described in this manual, please contact the manufacturer. The default data interfaces include I C, RS485 Modbus, analog with optional wireless data. Other options include IO‐Link, 4~20 mA, etc. This variety of communication options cover most of the current and near‐future application requirements, and each or multiple can be requested upon order from the manufacturer. www.Siargo.com CS3001 User Manual 5 | ... -

Page 7: Receipt / Unpack Of The Products

2. Receipt / unpack of the products Upon receipt of the products, please check the packing box before the dismantlement of the packing materials. Ensure no damages during shipping. If any abnormality is observed, please contact and notify the carrier who shipped the product and inform the distributors or sales representatives if the order is not placed directly with the manufacturer; otherwise, the manufacturer should be notified For any further actions, please refer to the return and repair section in this manual. If the packing box is intact, proceed to open the packing box, and you shall find the product, together with the power and data cable as shown below. The product Power and data cable, 1.0m (3.28’) Please check immediately the integrity of the product and the power/data cable; if any abnormality is identified, please notify the distributor/sales representative or manufacturer as soon as you can. If any defects are confirmed, an exchange shall be arranged immediately via the original sales channel. This user manual shall also be included in the packing box or via an online request for an electronic version. In most cases, this manual shall be made available to the customer before the actual order. Important : The basic specifications of the product are written in the 2D code at the back of the product. Use a smartphone to read the information and verify your order before further process. If there are any questions or doubts, please contact the manufacturer or your sales agent. www.Siargo.com CS3001 User Manual 6 | ... -

Page 8: Knowing The Products

Power and data interface, M5 3.2 Power and data cable description Table 3.2: CS3001 pin assignment. Pin Color Definition 1 Yellow GND 2 Green RS485 A 3 Red VCC, power supply (8~15 Vdc) 4 White RS485 B 5 Black Vout (0.5~4.5Vdc) Figure 3.2. Cable and alignment sketch. www.Siargo.com CS3001 User Manual 7 | ... -

Page 9: Mechanical Dimensions

Do not open or alter any part of the product, which would lead to malfunction and irrecoverable damage. To ensure the best performance of the products, the products should be installed at a base that eliminates environmental vibration as much as possible. There are two pre‐threaded M3 ports at the bottom of the product, as described in Section 3.1. A flat metal plate is suggested to be used as the holder before being fixed onto a solid base. The product is preferable to be installed horizontally. However, if the vertical installation is necessary, the fluid in the tubing must be fully filled, in particular at the measurement position. www.Siargo.com CS3001 User Manual 8 | ... -

Page 10: Basic Operation

For the other connections, please contact the manufacturer before the order for customization. The measurement is not directional dependent, and any side of the meter can be used as an inlet. It is important to make sure there are no bubbles inside the fluid for the product's best performance. Therefore, it is highly recommended a de‐bubbler should be installed in the testing loop. The proposed installation schematics are shown in Figure 4. 5. Basic operation 5.1. Check the product specifications Before starting to use this product, check the product specifications found in this manual, Section 7, or the basic information located on the back panel of the product. The product information from this manual is based on the model defined in Section 6. Use any optical scanner such as those with a smart mobile device to read the 2D code on the label for the basic product specifications. In particular, the pressure rating must not be higher than the system pressure of the fluid to be measured. In some cases, the product may be calibrated for specific ranged liquid concentrations for a particular application. The fluid to be measured must also be consistent with that specified by the product. Be particularly cautious about the supplied voltage indicated in the specification. A higher voltage may lead to irrecoverable damage, and a lower voltage will not power the product for any desired functions. www.Siargo.com CS3001 User Manual 9 | ... -

Page 11: Check The Microfluidic System

Take special care, connect ONLY the power to the RED power cord/wire, and ensure the power supply is within the specified 8~15Vdc before switching on the power. In addition, the power supply should be properly grounded, connecting the YELLOW wire terminal to the ground on the power supply or other safe system ground. The product's power terminal has the incoming voltage internally filtered and regulated to power the product circuitry. The product operates at a maximum current of less than 25mA, commonly available for most power supply. The terminal Vout (BLACK cable) is for analog data output from 0.5 to 4.50 Vdc, corresponding to the specified flow range from zero to full‐scale concentration per calibration. www.Siargo.com CS3001 User Manual 10 | ... -

Page 12: Analog Interface/Measurement

Another analog interface such as 4~20mA is also optional and can be requested by directly contacting the manufacturer. 5.6. Digital interface/measurement The default digital interface for the current product is RS485 Modbus. The other standard digital interfaces such as I C or IO‐Link are also available by request. For each of the specified digital interfaces, the corresponding protocol and a special cable for each shall be required. Please contact the manufacture for detailed information. For each digital interface, the manufacturer also provides a Microsoft Windows‐based evaluation kit for simple operation and measurement tasks. Please contact the manufacturer for detailed information. For the default RS485, the digital interface is the half plex Modbus. One can connect the RS485A (Green wire) and RS485B(white wire) terminals of the provided cable to the corresponding port of an RS485 bus interface on the user's electronics. www.Siargo.com CS3001 User Manual 11 | ... -

Page 13: Hardware Connection

Alternatively, one can order the special cable by the manufacturer in which an RS485 to USB port converter is integrated. Therefore, it can be plugged into the computer for performing the desired tasks. The digital communication protocol is based on standard Modbus RTU Half‐plex mode. A master (PC or PLC) can communicate with multiple slaves (the current product) for data exchange and communication parameter configuration. 5.6.1. Hardware connection The hardware layer is TIA/EIA‐485‐A, as illustrated below. In this configuration, the product (CS3001) is a slave. 5.6.2. Communication parameters The PC UART communication parameters are listed in the following table. Protocol Parameters RTU Baud rate (Bits per second) 38400 bps Start bits 1 Data bits 8 Stop bits 1 Even/Odd parity None Bits period 104.2 µsec Bytes period 1.1458 msec Maximum data length 20 Maximum nodes 247 www.Siargo.com CS3001 User Manual 12 | ... -

Page 14: Frame

The Modbus function codes applied for the product are the sub‐class of the standard Modbus function‐codes. These codes are used to set or read the registers of the product: Code Name Functions 0x03 Read register Read register(s) 0x06 Set single register Write one single 16‐bit register 0x10 Set multiple registers Write multiple registers 5.6.5. Registers The product (CS3001 ) has multiple registers available for the assignment of the various functions. With these functions, the user can obtain the data from the products, such as product address and flow rates from the registers, or set the product functions by writing the corresponding parameters. The currently available registers are listed in the following table, and the registers may be customized upon contact the manufacturer. Where R: read; W: write‐only; W/R: read and write. Note: At the time of shipping, the write protection function is enabled except for address and baud rate. Once the user completes the register value change, the write protection will be automatically enabled once again to prevent incidental data loss. www.Siargo.com CS3001 User Manual 13 | ... - Page 15 Series Number of the product, SN Value type UINT8 (12 bits) SN= value(0x0030), value(0x0031),….,value (0x0035); Notes Receiving 12 bits as: 2A 47 37 41 45 49 30 32 30 35 38 2A, the corresponding Serial Number is *G7AEI02058*. Write N Fluid 0x0047 Read Y concentration Description Fluid concentration Value type UINT 16 Concentration = Value (0x0047)/100 Notes e.g.: for a concentration of 20.34 %.w.t., the user will read “2034” from register 0x0047. Write Y Baud rate 0x0082 Read Y Description Communication baud rate with a PC Value type UINT 16 0=4800; 1=9600; 2=19200; 3=38400; 4=57600; 5=115200. The default value is 2. Notes For example, when the user reads “2” from register 0x0082, the baud rate is 19200. www.Siargo.com CS3001 User Manual 14 | ...

- Page 16 UINT 16 Alarm values = Value (0x00B8) Notes When the concentration is above a set value, an alarm will be triggered. Write Y Alarm: 0x00B9 The lower limit of a Read Y concentration Description Set alarm value for a lower concentration limit Value type UINT 16 Alarm values = Value (0x00B9) Notes When the concentration is below a set value, an alarm will be triggered. Write Y Offset calibration 0x00F0 Read N Description Reset or calibrate the offset Value type UINT 16, Fixed value 0xAA55 To reset or calibrate the offset, write 0xAA55 to register 0x0027. Notes When you execute this function, make sure there is NO flow in the flow channel. www.Siargo.com CS3001 User Manual 15 | ...

- Page 17 Write Y Write protection 0x00FF Read N Description Write protection disabler for a set value to a specific register. Value type UINT 16, Fixed value 0xAA55 This function is enabled at the time of product shipment. To enable the write function of a specific parameter, such as K‐factor, filter, the user needs to send 0xAA55 to the register 0x00FF, and then the write function will be enabled Notes (write protection is disabled). After the write execution is completed, the firmware will automatically re‐enable the write protection. Only Address and Baud rate will not be write‐protected. www.Siargo.com CS3001 User Manual 16 | ...

-

Page 18: Product Selection And Order Information

6. Product selection and order information 6.1. Product selection The product part number comprises the product model number and suffixes, indicating the full‐ scale flow rate and the other parameters. Refer to the following for details. CS3001 ‐ ‐ ‐ ‐ Medium: E – Ethanol; M – Methanol; X – customized (please contact the manufacturer). Output: V – analog; A – 4~20mA; B – RS485 Connection: D – default: 1/8” NPT; X‐ customized. Full scale range: 0~10 …100 (% w.t.). 6.2. Order contact and customer support The sales offices and the sales distributors/representatives are listed at the end of this document. For small quantities, the order can be placed either through the Siargo website: www.siargo.com or the sales office. For large quantities, please contact the sales office, distributors, or sales representatives. Siargo is making every effort to ensure the quality of the products. However, in case of questions and/or product supports, please contact the customer service listed at the end of the document. www.Siargo.com CS3001 User Manual 17 | ... -

Page 19: Technical Specifications

1.0 MPa Power supply 8~15 Vdc Electrical interface 0.5~4.5 Vdc / RS485 / 4~20mA Cable M5 Mechanical connection 1/8” NPT‐F or customized Wetted materials SiNx, Stainless steel 304 Ambient conditions 25°C, 101.325 kPa, DI water‐based solutions Storage temperature ‐10 ~ 70 °C Weight 300 Gram Protection IP67 Fluid compatibility Non‐corrosive CE EN61326‐1; ‐2; ‐3 *Note: IO‐Link is optional for the electrical interface. www.Siargo.com CS3001 User Manual 18 | ... -

Page 20: Technical Notes For The Product Performance

8.2. Precautions for the best performance of the product 8.2.1. Particle contamination It is critical to have the measured fluid free of particle contamination. Since the fluidic measurement channel is relatively small, any particle's presence may create a deformed channel that may create undesired phenomena such as cavitation, leading to large measurement errors. In addition, the particle deposition may also clog the channel, creating instability, resulting in unpredictable measurement circumstances. 8.2.2. Bubbles or cavitation As the measurement principle is via thermal transportation, the presence of the bubbles or cavitation shall significantly alter the thermal property of the fluid. In most cases, the bubble inclusion inside the fluid would lead to a negative deviation of the measurement. Therefore, it is recommended to www.Siargo.com CS3001 User Manual 19 | ... -

Page 21: Pressurized Flow Delivery

The measurement channel's wetted materials ensure it is inert to most conventional fluids, but precaution should be applied for any possible damages. 8.2.6. Product calibration The product is calibrated with a high‐precision reference gravimetric system that is traceable to NIST standard. Additional verification with a high precision Coriolis for calibration is also periodically performed. In normal operation, the product should maintain its status as that at the shipment. However, it is recommended that the product be re‐calibrated at least once a year for heavy usage. www.Siargo.com CS3001 User Manual 20 | ... -

Page 22: Use The Meter For Density Measurement

The fluidic concentration of a specific fluid is sensitive to the fluidic temperature. In the same example of methanol, every 3°C change (as shown in the left figure for 50%wt methanol concentration in water) will lead to a variation in the fluidic density equivalent to the fluidic concentration change of about 1%. Therefore, please pay attention to the temperature value during the fluidic concentration measurement. The current product is calibrated at an ambient temperature of 25°C. If the measurement temperature deviates from the reference conditions, there could be an expected reading shift due to the fluidic temperature change. www.Siargo.com CS3001 User Manual 21 | ... -

Page 23: Troubleshooting

9. Troubleshooting Phenomena Possible causes Actions Connect the power, check the Power not connected cable. Cable connection incorrect Check cable No signal / display No fluids or clogging Check flow and cavitation. Power regulator failure Return to factory Sensor failure Return to factory Large errors or unexpected Bubbles, clogging, fluid type. Check system, dry, and flush. concentration Erroneous or large noise Vibration, unstable flow Check system Offset unstable Vibration, overheat Check system, power off. No digital interface Wrong address, software Check commands, connection. www.Siargo.com CS3001 User Manual 22 | ... -

Page 24: Warranty And Liability

Siargo makes no warranty, representation, or guarantee and shall not assume any liability regarding the suitability of the products described in this manual for any purposes that are not specified in this manual. The users shall be held for full responsibility for validating the performance and suitability of the products for their particular design and applications. For any of the misusage of the products out of the scope described herein, the user shall indemnify and hold Siargo and its officers, employees, subsidiaries, affiliates, and sales channels harmless against all claims, costs, damages, and expense or reasonable attorney fee from direct or indirect sources. Siargo makes no other warranty, express or implied, and assumes no liability for any special or incidental damage or charges, including but not limited to any damages or charges due to installation, ... - Page 25 (2) Products that have been subject to chemical attacks, including exposure to corrosive substances or contaminants. In the case of battery usage, long term discharge or leakage induced damages; (3) Products that have been opened or dismantled for whatever reasons; (4) Products that have been subject to working conditions beyond the technical specification as described by this manual or related datasheet published by the manufacturer; (5) Any damages incurred by the incorrect usage of the products; (6) Siargo does not provide any warranty on finished goods manufactured by others. Only the original manufacturer's warranty applies; (7) Products that are re‐sold by unauthorized dealers or any third parties. ...

-

Page 26: Service Contact And Information

11. Service contact and information Siargo Ltd. is making every effort to ensure the quality of the products. However, please contact customer service at the address listed below in case of questions and or product supports. We will respond to your request in a timely fashion and work with you toward your complete satisfaction. Customer service and all orders should be addressed to Sales Representative Europe: IDENTIC GmbH In der Siedlerruh 24 69123 Heidelberg / Germany Phone: +49-(0)6221-7509777 Email: info@identic.de info@ identic.de Please contact to obtain Return Materials Authorization (RMA) before shipping the product back to the factory for returns or factory services such as calibration. Please specify as clear and detailed as possible in your email message the product's status that you intend to ship back to the factory. Be sure to write the RMA on the returned package or include a letter with the RMA information. For further information and updates, please visit www.Identic.de ... -

Page 27: Appendix I: Product Evaluation Kit

Appendix I: Product evaluation kit Siargo offers a sensor evaluation kit, including a digital data converter, USB data cable, and a User Application software, that allows the user to evaluate the product performance on a Microsoft Windows‐based computer. The user can read and visualize the flow rate of the product, obtain the totalized values, and save the data for further analysis. For further information and purchase of the evaluation kit, please contact the manufacturer or the sales representative. Each converter has a fixed cable that can be directly connected to the product. The USB ... -

Page 28: Appendix Ii: Document History

Appendix II: Document history 04.2021 VA.0 ‐ First release Sales Europe: IDENTIC GmbH In der Siedlerruh 24 69123 Heidelberg /Germany Phone: +49 6221 7509 777 Email: info@identic.de www.Siargo.com CS3001 User Manual 27 | ...

Need help?

Do you have a question about the CS3001 Series and is the answer not in the manual?

Questions and answers