Subscribe to Our Youtube Channel

Summary of Contents for Sprint Electric JL130

- Page 1 Slip Ring Drive product manual JL / JLX 130 - 1680 Use in conjunction with PL/X manual HG103521 V5.15h Oct 2010...

-

Page 3: Table Of Contents

JL/X130 - 1680 This manual should be read in conjunction with the PL / PLX Digital DC Drive Manual. (Parts 1, 2 and 3) Important. See section 2 in main PL / PLX Digital DC Drive Manual for WARNINGS 1 Table of contents 1 Table of contents ....................1 2 Introduction ......................2 Operation of Slip Ring Motor .................... -

Page 4: Introduction

JL/X130 - 1680 2 Introduction A slip ring motor is a type of induction motor having a wound rotor connected to slip rings. The stator (U, V, W) is phase angle controlled by the JL/X in a closed loop with speed feedback derived from a tacho generator or encoder mounted on the motor shaft. -

Page 5: Operation Of Slip Ring Motor

JL/X130 - 1680 2.1 Operation of Slip Ring Motor 2.1.1 Stator Voltage Control The Speed / Torque curve for a Slip Ring Motor is shown in the diagram below for the case where the Rotor resistors are static. The curved lines represent the Speed / Torque relationship at 100% and 80% Stator voltage. -

Page 6: Rotor Control To Optimise Torque Across Speed Range

JL/X130 - 1680 2.1.3 Rotor Control to optimise torque across speed range The diagram shows all 4 quadrants of Speed against Torque, with curves for a shorted rotor and for 4 other values of rotor resistance. This diagram is of course a simplistic representation to facilitate the explanation of the control strategy. -

Page 7: Hyper-Synchronous Regeneration

JL/X130 - 1680 2.1.4 Hyper-synchronous regeneration The shaded areas in the braking quadrants are where regeneration can occur. Outside the shaded areas any braking that occurs is achieved through a process known as plugging in which the absorbed energy is dissipated in the rotor and the rotor resistors. -

Page 8: Control Terminal Default Functions

JL/X130 - 1680 2.2 Control terminal default functions When the JL/X is shipped the control terminals are allocated with the following functions. All the programmable terminals are available to be re-allocated to an alternative function by the user if desired. IMPORTANT WARNING: The JL/X default configuration is locked in recipe page 3. -

Page 9: Run, Jog, Start, Cstop

JL/X130 - 1680 Rotor Resistor Control R4 Digital Output DIO2 Output high to control second highest rotor resistor shorting contactor. Nominal 24VDC output with internal flywheel. Short circuit protected and drive ALARM - DOP SCCT TRIP protected. Rotor Resistor Control R3 Digital Output DIO3 Output high to control third highest rotor resistor shorting contactor. - Page 10 JL/X130 - 1680 Digital input When the Jog Input is held high the drive jogs (rotates slowly while requested to), provided input Start T33 is low. When the Jog Input is removed the drive will ramp down to zero obeying the Jog/Slack Ramp time. T19 JOG MODE SELECT is not available on the JL/X, if selectable JOG reference is required a spare input must be configured for the purpose Start...

-

Page 11: Summary Of Default Terminal Functions

JL/X130 - 1680 2.2.2 Summary of default terminal functions OV terminal No function by default Analogue input UIP2 No function by default Analogue input UIP3 Ramped speed reference Analogue input UIP4 Progressive joystick input Digital input UIP5 Progressive joystick input Digital input UIP6 Progressive joystick input... -

Page 12: Rating Table For Jl/X Standard Versions

JL/X130 - 1680 Rating Table for JL/X standard versions JL/X standard versions Rating Table These models have a 150% overload capability for 25 seconds Nominal maximum continuous shaft ratings Model 100% Line Cooling air Dimensions mm 690V Output reactor flow and JL 2 quadrant Current type... - Page 13 JL/X130 - 1680 Standard Models Main 3 phase supply 50 - 60hz Any supply from 12 to 480V AC +/- 10% Auxiliary 3 phase supply 50 - 60hz Any supply from 100 to 480V AC +/- 10% Control 1 phase (50VA) 50 - 60Hz Any supply from 110 to 240V AC+/- 10% High Voltage (HV) Models Main 3 phase supply...

-

Page 14: Basic Speed Control Wiring Diagram

JL/X130 - 1680 4 Basic speed control wiring diagram Dwg no. HC103527 Isolator circuit main breaker semi-conductor fuses 3 phase See Rotor Wiring motor Diagram for further blower main contactor connection information type AC1 rated Important. EL1 to L1 phase main EL2 to L2 phase contactor... -

Page 15: Rotor Wiring Diagram

JL/X130 - 1680 4.1 Rotor Wiring Diagram TERMINALS 13 -24 FUNCTION Take account of cable resistance when calculating resistor values Snubber 13 14 15 16 17 18 19 20 21 22 23 24 Contactor Coils 24V DC SLAVE RELAY 24V DC SLAVE RELAY 24V DC... -

Page 16: Mechanical Dimensions

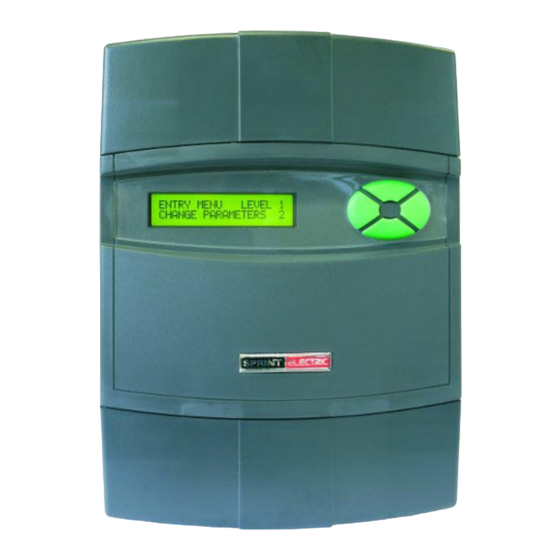

JL/X130 - 1680 5 Mechanical Dimensions 5.1 Frame 2 JL/X 130 - 270 Auxiliary 3 power terminals terminals PRESS RIGHT KEY FOR ENTRY MENU LEVEL 1 International ground symbol (black on green background) identifies main equipment ground connection on heatsink Control terminals Output... -

Page 17: Frame 4 Jl/X 370-780

JL/X130 - 1680 5.2 Frame 4 JL/X 370-780 Air out. IMPORTANT. Ensure 200mm area Ensure exit top and bottom of drive for air is not unrestricted air entry/exit. deflected towards air intake. Venting kit L1, L2, L3 Available. Top entry AC supply. Air Intake Busbar connection 698 Drive mtg point. -

Page 18: Frame 5 Jl/X 860-1680

JL/X130 - 1680 5.3 Frame 5 JL/X 860-1680 Air out. IMPORTANT. Ensure 200mm area Ensure exit top and bottom of drive for air is not unrestricted air entry/exit. deflected towards air intake. Venting kit Available. Air Intake L1, L2, L3 Busbar connection 698 AC supply input Drive mtg point 690... -

Page 19: Venting

JL/X130 - 1680 6 Venting 6.1 General venting information for frame 4 and 5 In order to keep these units within the required operating temperatures under all operating limits they are equipped with a very efficient cooling system. It consists of a powerful centrifugal fan system integral to the unit mounted at the bottom, which blows air over a high dissipation heatsink. -

Page 20: Frame 4 And 5 Jl/X 370 - 1680 Venting Kit Diagram

JL/X130 - 1680 Cowl mounted on enclosure 6.2.1 Frame 4 and 5 JL/X 370 - 1680 venting kit diagram roof using 70mm pillars provided The cowl must be fitted with this lip facing forward to direct exhaust air away from the air intakes. -

Page 21: Air Supply To Enclosure

JL/X130 - 1680 The cowl is fixed on top of the enclosure to prevent pollutants from dropping into the exhaust outlet of the drive. The cowl is supplied with 6 off 50mm mounting pillars, and 6 M6 holes must be drilled in the roof of the enclosure, to allow the mounting pillars to be fixed such that the cowl is positioned centrally over the duct. -

Page 22: Diagram Of Airflow For Frame 4 And 5

JL/X130 - 1680 6.6.1 Diagram of airflow for frame 4 and 5 This diagram shows a side view of a unit in an enclosure. This is the recommended method for arranging the flow of cooling air. The fan in the JL/X will draw air into the top and bottom air intakes of the unit. -

Page 23: Product Rating Table

JL/X130 - 1680 7 Product rating table Nominal maximum continuous shaft ratings Model 100% Line Cooling air Dimensions mm 690V Output reactor flow and JL 2 quadrant JLX 4 quadrant Current type dissipation Volt Volt Volt Suffix HV for 690 VAC model watts W x H x D... -

Page 24: Semiconductor Fuses

JL/X130 - 1680 7.2 Semiconductor fuses WARNING. All units must be protected by correctly rated semi-conductor fuses. Failure to do so will invalidate warranty. For semi-conductor fuses please refer to supplier. Model Main fuses Main fuses Main fuses Main fuses Max I Max I Max I... -

Page 25: Terminal Information

JL/X130 - 1680 7.3 Terminal information 7.3.1 Control Terminals See main product manual for control terminal information section 3.3.3, 3.4 and 3.5. 7.3.2 Powerboard Terminals Remove busbar cover plate to reveal powerboard terminals. For terminals T41 to T53 refer to main manual section 3.3.3, for power terminals refer to section 3.3.2. 7.3.2.1 Fan supply input Remove busbar cover plate to reveal powerboard terminals. -

Page 26: Avoid Dropping Small Objects Into Unit

JL/X130 - 1680 When tightening the connecting bolts of the terminals L1/2/3 A+ A- please ensure that the busbar is not subjected to a turning moment as the nut is torqued down. To do this always use two spanners, one on the bolt head to provide a counter torque and one on the nut to provide tightening torque. - Page 27 JL/X130 - 1680 Oct 2010 HG103521issh...

- Page 29 Sprint Electric Limited Arundel, UK Tel. +44 (0)1903 730000 Fax. +44 (0)1903 730893 Email. info@sprint-electric.com www.sprint-electric.com...

Need help?

Do you have a question about the JL130 and is the answer not in the manual?

Questions and answers