Summary of Contents for Genmitsu 3018-PROVer

- Page 1 Genmitsu 日 本 語 組 み 立 て 説 明 書 3018-PROVer V2 CNC Machine English 01 - 33 CNC 3018-PROVer Fräs-/Graviermaschine Deutsch 35 - 67 3018-PROVer V2 CNC マシン 日 本 語 69 - 101 V1.0 Sep. 2022...

-

Page 2: Table Of Contents

Contents Welcome Disclaimer Specifications Part 1- Unboxing & Checking Package Contents Part 2- Mechanical Installation Part 3- Wiring Part 4- Software Setup Part 5- Test Project Part 6- Z Probe Setup Part 7- Offline Controller... -

Page 3: Welcome

Welcome Thank you for purchasing the Genmitsu 3018-PROVer V2 CNC Machine from SainSmart. Included in your package will be a USB Stick, you will find: https://docs.sainsmart.com/3018-prover-v2 support@sainsmart.com Scan QR code to join the group... -

Page 4: Disclaimer

Disclaimer dangerous areas. with the machine. Router into an extension cord, or power strip as it may damage the machine. operating.Serious injury may oCcur. during operation. -

Page 5: Specifications

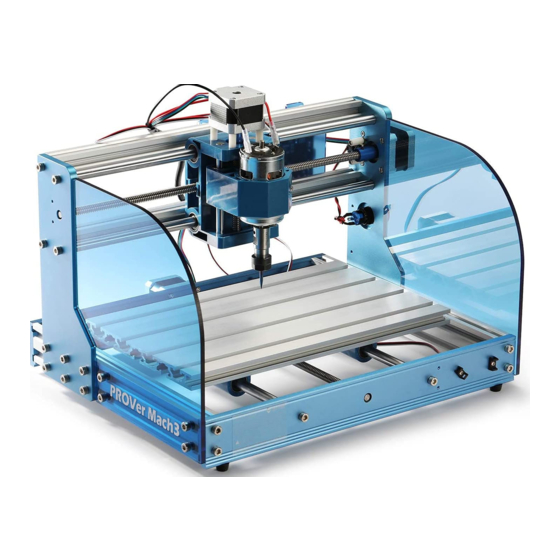

Specifications Model Name 3018-PROVer V2 Control Board Compatibility GRBL 1.1h TB67S109 32 bit Max Speed , UGS Plastic Leadscrew Control Software Motion System Spindle Motor 775 motor, 12V~24V, 000 RPM Stepper Motor Power Supply... -

Page 6: Part 1- Unboxing & Checking Package Contents

Part 1- Unboxing & Checking Package Contents Spindle Offline Controller Power Supply... - Page 7 Offline Controller Cable Z-Probe Kit 20-degree V Bit Cable Tie User Manual 3mm, 5mm...

- Page 8 Optional Accessories (Not Included) Consider following optional upgrades or accessories to make your CNC experience better! Compressed Spot CNC Cutter Milling Laser Module...

-

Page 9: Part 2- Mechanical Installation

Part 2- Mechanical Installation 2.1 Preparing your base assembly What you will need 3mm, 5mm Step 1: Step 2: seat as shown below. Step 3: Screws Holes of the Spoilboard Centered Screw Holes Nut Seat of the Nut Seat... - Page 10 2.2 Installing Rubber Feet to Y-Axis Base Assembly What you will need 3mm, 5mm Step 1:...

- Page 11 2.3 Install Y-Axis Base to X / Z Axis Gantry What you will need 3mm, 5mm Step 1: Step 2: Screw Holes of...

- Page 12 Step 3:...

- Page 13 2.4 Installing the Spindle What you will need Spindle 3mm, 5mm Step 1: Unscrew the black collar from the spindle and insert the collet. Make sure the collet is locked in place by pushing Step 2: Loosen the Spindle Mount Hex Screw. Step 3:...

- Page 14 Step 4: Spindle Hex Screw...

- Page 15 2.5 Install the Acrylic Baffles What you will need 3mm, 5mm Step 1: Step 2: Place T-Slot nuts into the side of the machine so that the baffle is aligned with the edge of the frame. 2-3mm 20M5 T-Slot Nut...

- Page 16 Step 3: Now tighten the M5 bolts to secure the baffle. Repeat the steps to install the other side.

-

Page 17: Part 3- Wiring

Part 3- Wiring Black Positi e Pole Negati e Pole... - Page 18 shown below. Motor Socket Cable Socket...

- Page 19 Cable Management What you will need Cable Tie 1. Use the cable ties to fix the cable management on the cable holder as shown below. the cables. Cable Tie...

- Page 20 Tips for Installing the Clamps Please refer to the below images to install the clamps. Make sure that the screw screwing depth can not exceed the bottom of the aluminum platform, otherwise the screw will hit the frame of the machine. Screw The Bottom of the Screw...

- Page 21 Diagram X-axis Motor Z-axis Motor Spindle Motor Handwheel Laser Module USB Connecting Cable Power Switch Power Supply Z-Height Offline Controller Mapping Probe Stopping Switch...

- Page 22 Label Description Marker Instruction Power 24V Power Interface USB Interface Offline controller Offline Control Interface Probe X-LIM Z-LIM Laser Laser Module Interface Spindle Spindle Motor Interface...

-

Page 23: Part 4- Software Setup

Part 4- Software Setup 1. Driver Installation... - Page 24 2. To Determine your Machine's COM port: Windows XP: Windows 7: Click "Start" Right click"Computer" Select "Manage" If there are multiple USB serial ports, right click each one and check the manufacturer, the machine will be "CH340".

- Page 25 3. Grblcontrol (Candle) Connecting to the Controller Step 1: Software should automatically select the port number. Step 2: Step 3:...

-

Page 26: Part 5- Test Project

Part 5- Test Project 1. Grblcontrol (Candle) - Page 27 2. Run G code for processing 1. Click [open], Select the G code to run. workpiece just touch. 4. Click [Send] running G code. 3. About firmware parameters...

-

Page 28: Part 6- Z Probe Setup

Part 6- Z Probe Setup Probe Function Introduction 1. Grblcontrol (Candle) Probe operating instructions Step 1: Probe commands editing... - Page 29 Step 2: Probe commands filled in Grblcontrol (Candle)

- Page 30 Step 3: Connect the probe tool to the controller probe interface. Step 4: Click the “Z-probe” button, Z-axis automatic tool to zero.

-

Page 31: Part 7- Offline Controller

Part 7- Offline Controller The offline interface is designed according to our offline controller and does not match with other companies' offline controllers.Do not connect other devices or controllers, or risk damaging the control board or other devices. 1. Button Functions Introduction Marker Instruction Manual moving distance option (xC, x0.01, x0.1, x1) in xC mode,... - Page 32 2. Parameter Settings igure 1 igure 2 Function Instruction Spindle RPM Spindle speed Probe Tool Height Modify the height of Z Probe Z Rise Height Select...

- Page 33 3. Introduction of Control Functions Select the "Prepare" screen icon, as shown below: Function Instruction Spindle Probe Z-axis automatic tool setting Home Start Project Reset Reset the router Jog Step: xC mm...

- Page 34 4. Run the G-code program Processing Figure 2 Figure 1 time Coordinates Figure 4 Repeat Figure 3 processing Machine status Processing progress...

- Page 35 5. Machine Alarm and Solutions stop button. Figure 1 Figure 2...

- Page 36 Inhalt Willkommen Warnhinweise Specifications 1 – Lieferumfang 2 – Mechanischer Zusammenbau 3 – Elektrischer Anschluss 4 – Software Einrichtung 5 – Test Projekt 6 – Z Probe Einstellungen 7 – Offline Controller...

-

Page 37: Willkommen

Willkommen https://docs.sainsmart.com/3018-prover-v2 support@sainsmart.com https://www.facebook.com/groups/SainSmart.GenmitsuCNC Scannen Sie den QR-Code, um der Gruppe beizutreten... -

Page 38: Warnhinweise

Warnhinweise... -

Page 39: Specifications

Specifications Modell Name 3018-PROVer V2 GRBL 1.1h Schrittmotortreiber TB67S109 32-bit Maximale Verfahrgeschwindigkeit , UGS Material der Konstruktion Kunststoff Leitspindel Maße und Typ Bewegungssystem Spindelantrieb Spindel 775 Motor, 12V~24V, 9000 RPM Schrittmotoren... -

Page 40: Lieferumfang

1 – Lieferumfang Spindelmotor mit Offline Controller Kabel... - Page 41 20° V Bit Set Offline Controller SechskantSechs- Kabelbinder M6 x 10 mm M5 x 22 mm Nutenstein M5 x 20 mm M5 x 10 mm...

- Page 42 Optionales Zubehör (nicht im Lieferumfang enthalten) Sie finden sie auf www.sainsmart.com komprimiertem Punkt Staub-Schuh...

-

Page 43: Mechanischer Zusammenbau

2 – Mechanischer Zusammenbau 2.1 Vorbereitung der Basisbaugruppe Was wird benötigt: Schritt 1: Schritt 2: Schritt 3: der Spindelhalterung... - Page 44 2.2 Montage von Gummifüßen an der Y-Achsen-Basisbaugruppe Was wird benötigt: Schritt 1:...

- Page 45 2.3 Montage der Brückenbaugruppe auf der Basisbaugruppe Was wird benötigt: Schritt 1: Basisbaugruppe Schritt 2: M5 x 22 mm...

- Page 46 Schritt 3:...

- Page 47 2.4 Montage des Spindelmotors Was wird benötigt: Spindelmotor mit Schritt 1: sicher, dass das Spannfutter durch Schieben arretiert wird. Schrauben Sie dann den Spannring wieder auf die Spindel. Schritt 2: Schritt 3:...

- Page 48 Schritt 4: Sechskantschraube der Spindelbefestigung...

- Page 49 2.5 Montage der Acryl-Seitenwände Was wird benötigt: M5x10mm M5x20mm Schritt 1: Schritt 2: 2-3mm Schraube M5 x 10 mm Nutenstein M5 x 20 mm...

- Page 50 Schritt 3:...

-

Page 51: Elektrischer Anschluss

3 – Elektrischer Anschluss Spindelmotors. Rotes Kabel Pluspol Minuspol... - Page 53 Kabel Management Was wird benötigt: Kabelbinder dass die Bewegungen nicht durch die Kabel behindert werden. Kabelbinder...

- Page 54 Tipps zur Montage der Klemmen die Schraube sonst den Rahmen der Maschine trifft. Schraube Schraube...

- Page 55 Anschlussbelegung Spindelmotor Luftpumpe Bedienungshandrad Laser-Modul USB-Schnittstelle Offline Controller Notaus-Schalter...

- Page 56 Bezeichnungen auf der Steuerbaugruppe Marker Beschreibung Power Offline controller Probe X-LIM Z-LIM Laser Spindle...

-

Page 57: Software Einrichtung

4 – Software Einrichtung 1. Treiber Installation... - Page 58 2. COM-Anschluss Ihres Rechners ermitteln: Windows XP: Windows 7:...

- Page 59 3. Steuerung mittels Grblcontrol (Candle) Schritt 1: Schritt 2: Schritt 3:...

-

Page 60: Test Projekt

5 – Test Projekt 1. Grblcontrol(Candle) linke Maustaste, um den einen Computer mit Grafikkarten wechseln. Manuelles Bedienfeld G-Code an Befehl senden Befehlseingabefeld Befehl senden Steuerbaugruppe senden... - Page 61 2. G-Code zur Bearbeitung ausführen 2. Klicken Sie auf das manuelle Bedienfeld. 3. Über Firmware Einstellungen...

-

Page 62: Z Probe Einstellungen

6 – Z Probe Einstellungen Übersicht der Funktionalität 1. Grblcontrol (Candle) Probe Anleitung Schritt 1: Probe Befehle bearbeiten werden. G-Code für Messwerkzeug Nach der Bearbeitung Dicke des Messwerkzeugs... - Page 63 Schritt 2: Befehle für Messwerkzeug in Grblcontol(Candle) eingeben Befehle ein...

- Page 64 Schritt 3: Schließen Sie das Messwerkzeug an die entsprechende Schnittstelle der Steuerbaugruppe an. Schritt 4: Klicken sie auf "Z-probe" um die Z-Achse automatisch auf 0 zu setzen.

-

Page 65: Offline Controller

7 – Offline Controller Die Offline-Schnittstelle ist für unseren Offline-Controller konzipiert und passt nicht zu den Offline-Steuergeräten anderer Hersteller; schließen Sie keine anderen Geräte oder Steuergeräte an, sonst riskieren Sie eine Beschädigung der Steuerbaugruppe oder anderer Komponenten. 1. Funktionserläuterung der Schaltflächen Label Funktion Manuelle Verfahrweg Option (xC, x0.01, x0.1, x1) in xC-Modus, drücken... - Page 66 2. Parametereinstellungen Label Funktion Spindle RPM Probe Tool Height Z Rise Height Bewegen Sie den Cursors Select...

- Page 67 3. Einführung in die Kontrollfunktionen Label Funktion Spindle Probe Home Start Project Reset Jog Step: xC mm...

- Page 68 4. G-Code ausführen Abbildung 2 Abbildung 1 Koordinaten Abbildung 4 Abbildung 3 der Bearbeitung Beenden Status der Maschine Status der Bearbeitung...

- Page 69 5. Beenden des Alarms Abbildung 1 Abbildung 2...

- Page 70 目次 ようこそ! 免責事項 仕様 パート1−開梱およびパッケージ内容の確認 パート2−フレーム組立 パート3−配線 パート4−ソフトウェア設定 パート5−プロジェクトテスト パート6−Zプローブの設定方法 パート7−オフラインコントローラー...

- Page 71 ようこそ! SainSmart Genmitsu 3018-PROVer V2 CNCマシンをお買い上げいただき、ありがとうございます。 パッケージに同梱されているMicroSDカードには、以下の内容が含まれています。 PDF版マニュアル Windows USB ドライバー Windows用GRBLコントロールソフトウェア「Candle」 サンプルファイル SainSmartオンラインリソースセンターにアクセスし、CNCドライバーとソフトウェアをインストールしてく ださい。https://docs.sainsmart.com/3018-prover-v2 ドライバーとソフトウェアは、付属のMicroSDカードに含まれています。 技術サポートについては、support@sainsmart.com までメールでお問い合わせください。 ヘルプとサポートは、Facebookからも利用できます。(SainSmart Genmitsu CNC Usersグループ) QRコードをスキャンしてグループに参加しましょう。 QRコードをスキャ ンしてグループに 参加しましょう!...

- Page 72 免責事項 本機は、可動部分と危険な領域を持つ電気工作機械です。ご使用の際はご注意ください。 SainSmart Genmitsu CNCマシンは屋内専用です。 工作機械に精通した監督者がいない限り、本機の操作は18歳以上の成人に制限します。 CNCマシンは常に安定した面に設置してください。 CNCマシンには、AC230VとAC115Vで使用可能な電源アダプターが付属しています。他のアダプターは使用 しないでください。機械の誤動作や、損傷の原因となります。 3018-PROVer V2は、高出力ACアダプターを使用しています。機械に損傷を与える可能性があるため、CNC ルーターを延長コードや電源タップに接続しないことをお勧めします。 非常停止ボタンは、常時、手早く操作できるようにしてください。 ACアダプターや電装品は絶対に分解しないでください。保証が無効になります。 CNCマシンの作動中は、スピンドルに触れたり、作業エリアに人体や手指を近づけたりしないでください。 重大な傷害が発生する可能性があります。 CNCマシン停止中は、近くにいるお子様から目を離さないでください。けがのおそれがあります。 運転中はCNCマシンから目を離さないでください。 CNCマシンが換気の良い場所に設置されていることを確認してください。一部の材料は、操作中に煙やガス を放出する場合があります。...

- Page 73 仕様 モデル名 3018-PROVer V2 作業領域 284 x 180 x 40 mm GRBLバージョン GRBL 1.1h モータードライバー TB67S109 制御ボードMCU 32ビット 最大移動速度 2000 mm/分 対応CAMソフトウェア Candle, Carveco Maker, Easel, UGS フレーム材質 アルミニウム X-Z軸ASSY材質 プラスチック 送りねじ ACME T8(8mm), Pitch: 2 mm, Lead: 4mm 制御ソフトウェア Grblcontrol (Candle) モーションシステム ねじ駆動 スピンドルモーター 775 motor, DC12-24V , 9000 RPM ステッピングモーター 1.3 A, DC12V, トルク0.25 Nm 電源アダプター DC24V/4A...

- Page 74 パート1−開梱およびパッケージ内容の確認 Y 軸基台ASSY スピンドル ER11コレット(1/8“) X/Z軸ガントリー オフライン USB A-to-B ゴム脚 (4p) アクリル バッフル (2p) コントローラー ケーブル リミット 電源アダプター 電源ケーブル (US/JP) 電源ケーブル(EU) スイッチ(2p)

- Page 75 オフラインコント ワーククランプセット Zプローブ 20度Vビット ローラーケーブル 六角棒レンチ 結束バンド 板スパナ ユーザーマニュアル 3mm,5mm MicroSDカード MicroSD カードリーダー M6x10mmねじ(2p) M5x22mm ねじ(9p) M5x10mm ねじ(9p) 20-M5T溝ナット(9p)

- Page 76 追加できるアクセサリ (含まれていません) 下記のアクセサリをチェックし、CNCマシンをアップグレードしましょう! jp.sainsmart.com で下記の製品を探せます。コードを入力すると10%割引になります! ディスカウントコード:PROVER10JP 圧縮スポット固定 MC40A、1/8インチシャン KABAデスクトップ 焦点FACレーザー ダストシュー ク、CNCカッターフライス CNCエンクロージャー モジュール 彫刻ビットセット、40PCS...

- Page 77 パート2−フレーム組立 2.1 Y軸基台ASSYの準備 必要なもの Y 軸基台ASSY 5mm六角棒レンチ M6x10mmねじ(2p) ステップ1 : Y軸基台ASSYを裏に返し、結束バンドをベアリングマウントから取り外します。 ステップ2 : 下図に示すように、スポイルボードを移動させ、ボード中央部2つのねじ穴をナットシートのねじ穴に合わ せます。 ステップ3 : ねじ2本でねじ止めします。 スポイルボードねじ穴 M6x10mmねじ (2p) ナットシートを 中央に移動 ナットシートねじ穴...

- Page 78 2.2 Y軸基台ASSYへのゴム足の取り付け 必要なもの ゴム脚(4p) 3mm六角棒レンチ ステップ1 : 基台裏の四隅に開けられた4つの穴に、六角棒レンチを使用してゴム脚を取り付けます。...

- Page 79 2.3 Y軸基台ASSYへのX/Z軸ガントリーの取り付け 必要なもの 軸ガントリー M5x22mmねじ 3mm六角棒レンチ ステップ1 : Y軸基台ASSYを表に返し、平らな面に置きます。 ステップ2 : ガントリー固定穴を、Y軸基台ASSY両側面の対応ねじ穴に合わせます。 M5x22mmねじ (4p) ガントリー固定穴 Y軸基台ASSYねじ穴 M5x22mmねじ...

- Page 80 ステップ3 : ねじをガントリー固定穴とY軸基台ASSYねじ穴に通し、六角棒レンチで締め付けます。...

- Page 81 2.4 スピンドルの取り付け 必要なもの スピンドル コレット 板スパナ 3mm六角棒レンチ ステップ1 : スピンドルから黒いカラーを外し、コレットを挿入します。「カチッ」と音がするまで押し込み、コレッ トが所定の位置に固定されていることを確認します。次に、カラーとコレットをスピンドルにねじ込みます。 ステップ2 : スピンドルマウントの六角ねじを緩めます。 ステップ3 : スピンドルの外筒が完全に挿入されるまで、スピンドルをマウントにスライドさせます。...

- Page 82 ステップ4 : 六角ねじを締めてスピンドルを固定します。マウントを損傷する可能性があるため、ねじを締めすぎないで ください。 スピンドル六角ねじ...

- Page 83 2.5 アクリルバッフルの取り付け 必要なもの アクリルバッフル 3mm六角棒レンチ M5x10mmねじ 最初に、アクリルバッフルの左側と右側を決める必要があります。下図のようにバッフルをアルミフレームに沿って配 置すると、各ピースがフレームの形状に適合します。左右を決めた後、バッフルから保護紙をはがします。 ステップ1 : バッフルの外側からねじを挿入し、T溝ナットを仮止めします。(例:左側バッフルの場合は、ねじは左側か ら) T溝ナットを水平に向けます。(T溝ナットとバッフルの隙間が2~3 mmになるようにねじ込んでください。) ステップ2: バッフルがフレームの端に揃うように、T溝ナットをフレームの側面溝に入れ込みます。 2-3mm M5x10mmねじ 20-M5T溝ナット...

- Page 84 ステップ3 : ねじを締めてバッフルを固定します。同じ手順で反対側を取り付けます。 おめでとうございます!これでフレームが完全に組み立てられました。配線に移りましょう。...

- Page 85 パート3−配線 1. 下図に従って、スピンドルモーターケーブルを接続します。赤線はモーターの(M+)極、黒線はモーターの(M-)極に 接続してください。 黒線 赤線 M(+)極 M(-)極...

- Page 86 2. 下図に示すように、 軸ステッピングモーターケーブルと 軸リミットスイッチケーブルを、制御ボード ソケット に接続します。 Y軸 ステッピングモーター ケーブルソケット Y軸 ステッピングモーター ケーブル (4線) Y軸 リミットスイッチ ケーブルソケット Y軸 リミットスイッチ ケーブル (3線)

- Page 87 配線処理 必要なもの 結束バンド 1. 下図に示すように、結束バンドを使用してケーブル類をケーブル固定具に固定します。 2. 各軸ステッピングモーター軸の手動ジョグホイールを回してX/Y/Z軸を可動全域に動かし、ケーブルによって制限さ れずに自由に動かせることを確認します。 結束バンド...

- Page 88 クランプの取り付けに関するヒント クランプの取り付けは、下記の画像を参照してください。 ねじをねじ込む際に、ねじ先端がアルミプラットフォームの裏面を突き抜けないようにしてください。突き抜けると、 ネジが装置のフレームにぶつかります。 ねじ アルミプラット フォーム裏面 ねじ先端が突き抜けている...

- Page 89 制御ボードI/F配置図 X軸ステッピングモーター Y軸ステッピングモーター Z軸ステッピングモーター スピンドルモーター 手動ホイール エアポンプ コントローラー レーザーモ ジュール USB接続 電源スイッチ 電源アダプター DC24V 5A オフラインコントローラー 緊急停止スイッチ リミットスイッチ Zプローブ...

- Page 90 I/Fラベル説明 ラベル I/F説明 Power DC24Vアダプター 手動ホイールコントローラー Offline controller オフラインコントローラー E-STOP 緊急停止スイッチ Probe Zプローブ X-LIM X軸リミットスイッチ Y-LIM Y軸リミットスイッチ Z-LIM Z軸リミットスイッチ Laser レーザーモジュール エアポンプ Spindle スピンドルモーター X Axis X軸ステッピングモーター Y Axis Y軸ステッピングモーター Z Axis Z軸ステッピングモーター...

- Page 91 パート4−ソフトウェア設定 1. ドライバーのインストール ドライバーをインストールします sofware → Driver → H340SER.exe...

- Page 92 2. マシンのCOMポートを確認します: Windows XP: 「マイコンピュータ」を右クリックし、「マネージャー」を選択し、「デバイスマネージャー」を選択 します。 Windows 7 or later: 「スタート」をクリックし、「コンピュータの管理」を右クリックし、「マネージャー」を選択 し、左ペインで「デバイスマネージャー」を選択します。 ツリーで、「ポート(COM & LPT)」 を展開します。 マシンはUSBシリアルポート(COMX)になります。"X "はCOM番号を表し、例えばCOM12です。 USBシリアルポートが複数ある場合は、それぞれを右クリックしてメーカーを確認すると、マシンは "CH340 "になり ます。...

- Page 93 3. Grblcontrol (Candle) をコントローラに接続します 初めて使用する場合は、適切なCOM PORTとボーレートを設定する必要があります。 ステップ1 : ソフトウェアが自動的にポート番号を選択します。 ステップ2 : 自動選択されない場合は、"Baud "のドロップダウンメニューから115200を選択します。 ステップ3 :「OK」をクリックして保存します。...

- Page 94 パート5−プロジェクトテスト 1. Grblcontrol (Candle) 3Dプレビューインターフェ ースです。マウスの左ボタン 座標表示 を押したまま、角度を回転さ せることができ、マウスホイ 一般的な操作ボタン、上記 ールを回して、拡大、縮小す のマウスアイコンは、特定 ることができます。 の機能を示しています 何も表示されない場合は、 OpenGL2.0のグラフィックカ クリックして展開します ードに対応するパソコンに変 更する必要があります。 手動操作インターフェース Gコーを開きます Gコーをド コマンド入 コマンドを 発送します 力ボックス 発送します...

- Page 95 2. Gコードを実行して彫刻し始めます 「open」をクリックして、Gコード を選択して実行します。 手動操作パネルをクリックして、 ビット先端と彫刻材料がちょうど 接触するように、スピンドルを彫 刻の開始点に移動させます。 「ZeroXY」「Zero Z」をクリック し、XYZ軸の座標を初期化します。 「Send」をクリックしてGコードを 実行します。 3. ファームウェアのパラメータにつ いて コントロールボードのパラメータ は 3018-PROVer V2に従って設定 されます。...

- Page 96 パート6−Zプローブの設定方法 プローブ機能紹介 1. Grblcontrol (Candle) プローブ操作紹介 ステップ 1: プローブコマンドを編集します Z14はG-codeでブロックの高さを示し、同梱してあるプローブの寸法を実測する必要があります。Z25はG-codeで切削 工具昇降の高さを示し、必要に応じて設定してください。 プローブ G code プローブ G code プローブ G code G90G21G38.2Z- G90G21G38.2Z- G92 Z G92 Z14 G0 Z25 G0 Z...

- Page 97 ステップ 2 : Grblcontrol (Candle)にプローブコマンドを入力します ここにコマンドを入力 してください...

- Page 98 ステップ 3 : コントローラプローブインタフェースにプローブツールを接続します。 ステップ 4 :「Z-probe」ボタンをクリックして、Z軸は自動的にゼロに戻します。 「Z-probe」ボタンをクリック します...

- Page 99 パート7−オフラインコントローラー オフラインI/Fは当社のオフラインコントローラー専用設計です。他社のオフラインコントローラーとは一致しません。 他のデバイスやコントローラーを接続しないでください。制御ボードや他のデバイスを損傷する危険があります。 1. ボタン機能紹介 記号 命令 手動移動距離オプション(xC, x0.01, x0.1, x1) xCモード: 方向キーを押して移動します STEP x0.01: 方向キーを1回押すと、命令方向に0.01mm移動します。 x0.1: 方向キーを1回押すと、命令方向に0.1mm移動します。 x1: 方向キーを1回押すと、命令方向に1mm移動します。 Select カーソル移動 保存/確認/一時停止/開始/メイン画面に戻る(長押し)、リミットス Enter イッチのトリガーアラーム解除(長押し) X軸右移動ジョグ、パラメータ修正(Setting画面) X軸左移動ジョグ、パラメータ修正(Setting画面) Y軸奥行移動ジョグ、パラメータ修正(Setting画面) Y軸手前移動ジョグ、パラメータ修正(Setting画面) Z軸上移動ジョグ Z軸下移動ジョグ...

- Page 100 2. パラメータ設定 図1に示すように、「Settings」アイコンを選択し、「Enter」ボタンをクリックすると、図2のパラメータ設定画面に入 ります。 図1 図2 項目 命令 J0G Feed X/Y/Z軸移動速度 Spindle RPM スピンドル回転数 Probe Feed Zプローブ使用時の移動速度 Probe Tool Height Zプローブツール高さ変更 Z Rise Height Z持ち上げ高さ(カウンターブロック値よりも大きくする必要があります) X/Y/Z軸移動速度変更 (1クリック +10),スピンドル回転数変更 (1クリック +100),ツールビット設 定時Z軸移動速度変更 (1クリック +1),Zプローブ高さ変更 (1クリック +1),ツールビット持ち上げ高 さ変更 (1クリック +1) X/Y/Z軸移動速度変更 (1クリック -10),スピンドル回転数変更 (1クリック -100),ツールビット設定 時Z軸移動速度変更 (1クリック -1),Zプローブ高さ変更 (1クリック -1),ツールビット持ち上げ高さ 変更 (1クリック -1) Zプローブツール高さ変更 (1クリック +1) Zプローブツール高さ変更 (1クリック ‒1) Select カーソル移動 Enter 保存して戻る...

- Page 101 3. 制御機能の紹介 下図に示すように、「Prepare」画面アイコンを選択します。 項目 命令 Spindle スピンドルをON/OFFします。 Probe Z軸自動ツールを設定します。 Home スピンドルをホームポジションに移動します。 X/Y作業原点を現在のXYビット位置に設定します。 Zero-XY Zプローブを使用してZ軸をゼロ点調整にする場合に設定します。 Zero-XYZ X/Y/Z作業原点を現在のXYビット位置に設定します。Z-Probe を使用しない場合に設定します。 Start Project Gコードを選択して加工ジョブを開始します。 Reset 装置をリセットします。 1ステップでの移動距離を設定します。STEP ボタンを押して距離パラメータ0.01/0.1/1/xCを切り Jog Step: xC mm 替えます。xCモードでは連続で移動します。例えば、Y+ボタンを長押しすると、マシンはY+方向 に移動し続け、ボタンを離すと停止します。 装置の状態を表示します。リミットスイッチまたは緊急停止ボタンの作動 Status IDLE を検知すると、ALARMが表示されます。障害を解消し、装置をリセットする必要があります。...

- Page 102 4. Gコードプログラムの実行 ステップ1 :「Start project」を選択、「Enter」をクリックして、図1に示すプログラム選択画面に入ります。 ステップ2 :「選択] ボタンをクリック、実行したいプログラムを選択、「Enter」をクリックして、図2に示す準備プロ グラム画面に入ります。 ステップ3 :「Enter」をもう一度クリックし、プログラム実行を開始します。 図3に示すように、「Enter」をクリックすると処理が一時停止し、もう一度「Enter」をクリックして処理を再開します。 「Enter」を長押しするとメイン画面に戻ります。 ステップ4 : 図4に示すように、「Exit」をクリックしてプログラムを終了します。または、加工完了後に「Repeat」を クリックしてプログラムを再度実行します。 図2 図1 処理時間 座標 ファイルサイズ 図4 図3 繰り返し処理 終了 装置ステータス 処理の進行状況...

- Page 103 5. 装置警報と解決方法 1. 図1は、制御ボードに電源が入っていない、または緊急停止ボタンが押されたときの警報を示しています。まず、電 源スイッチを押して警報が解除したことを確認します。それでも同じく警報が表示される場合は、緊急停止ボタンをリ セットしたことを確認してください。 2. 図2は、リミットスイッチが作動したときの警報を示しています。 Status: ALARM → IDLE になるまでENTERボタンを長押ししてください。 図1 図2...

- Page 104 Genmitsu Desktop CNC & Laser www.sainsmart.com support@sainsmart.com Vastmind LLC, 5892 Losee Rd Ste. 132, N. Las Vegas, NV 89081...

Need help?

Do you have a question about the 3018-PROVer and is the answer not in the manual?

Questions and answers

オフラインコントローラーの使い方を教えてください. フュージョン360CAM機能で加工パスの原点と機械原点が異なってしまいます。オフラインコントローラーで原点を認識させる方法はありますでしょうか?

The offline controller for the Genmitsu 3018-PROVer V2 is designed specifically for this machine and should not be used with other devices. It includes various movement options and functions:

1. Movement Controls

- Use the direction keys to move the machine's axes.

- Movement increments include 0.01mm, 0.1mm, and 1mm.

- Pressing "X+" moves the X-axis right, "X-" moves it left, "Y+" moves the Y-axis forward, and "Y-" moves it backward.

- "Z+" and "Z-" move the Z-axis up and down.

2. Setting the Origin Point (Zeroing)

- Move the tool to the desired starting position using the direction keys.

- Click "ZeroXY" to set the X and Y axes to zero.

- Click "Zero Z" to set the Z-axis to zero.

- This ensures proper alignment for cutting.

For Fusion 360 CAM, follow these steps to set the origin correctly:

1. In Fusion 360, set the work coordinate system (WCS) in CAM settings to match the machine's zero point.

2. Export the G-code and load it into the offline controller.

3. Ensure the machine's zero point matches the WCS in Fusion 360 before starting the job.

4. Use the "Send" button to begin executing the G-code.

This ensures accurate cutting based on the Fusion 360 toolpath.

This answer is automatically generated