Summary of Contents for SPX Waukesha Cherry-Burrell Universal Lobe Series

- Page 1 Indianapolis Chicago San Juan www.hollandapt.com 800-800-8464 Instruction Manual Universal Lobe Series Rotary Positive Displacement Pump viga@viga.design Read and understand this manual prior to operating or servicing this product.

- Page 2 Kalrez is a registered trademark of DuPont Dow Elastomers. ment on the part of SPX Corporation. No part of this man- Chemraz is a registered trademark of Green, Tweed & Co.

-

Page 3: Table Of Contents

Waukesha Cherry-Burrell Table of Contents Waukesha Cherry-Burrell Warranty ...............5 Shipping Damage or Loss ....................... 5 Warranty Claim ........................5 Safety ........................6 Replacement Labels ....................7 Application Instructions ......................7 Care of Stainless Steel ....................8 Stainless Steel Corrosion ......................8 Alloy 88 ............................ 8 Elastomer Seal Replacement Following Passivation ............... - Page 4 Table of Contents Waukesha Cherry-Burrell 320-UL PD Pumps ......................... 69 Universal UL PD Pump Seals ....................70 Vented Cover Parts - Model 018, 030, 034, 050, 054, 060, 130, 134 UL ......71 Vented Cover Parts - Model 220 UL ..................72 UL Pump Dimensions ...................

-

Page 5: Waukesha Cherry-Burrell Warranty

Waukesha Cherry-Burrell Warranty Waukesha Cherry-Burrell Warranty Seller warrants its products to be free from defect in materials and workmanship for a period of one (1) year from the date of shipment. This warranty shall not apply to products which require repair or replacement due to normal wear and tear or to products which are subjected to accident, misuse or improper maintenance. -

Page 6: Safety

Safety Waukesha Cherry-Burrell Safety READ AND UNDERSTAND THIS MANUAL PRIOR TO INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT Waukesha Cherry-Burrell recommends users of our equipment and designs follow the latest Industrial Safety Standards. At a minimum, these should include the industrial safety requirements established by: 1. -

Page 7: Replacement Labels

Waukesha Cherry-Burrell Replacement Labels Replacement Labels WARNING: The following labels are installed on your equipment. If these labels are removed or become unreadable contact Waukesha Cherry-Burrell customer service at 1-800-252-5200 or 262-728-1900, or refer to “Parts Lists” on page 46 for replacement part numbers. Application Instructions Apply to clean, dry surface. -

Page 8: Care Of Stainless Steel

Care of Stainless Steel Waukesha Cherry-Burrell Care of Stainless Steel Stainless Steel Corrosion Corrosion resistance is greatest when a layer of oxide film is formed on the surface of stainless steel. If film is disturbed or destroyed, stainless steel becomes much less resistant to corrosion and may rust, pit or crack. Corrosion pitting, rusting and stress cracks may occur due to chemical attack. -

Page 9: Introduction

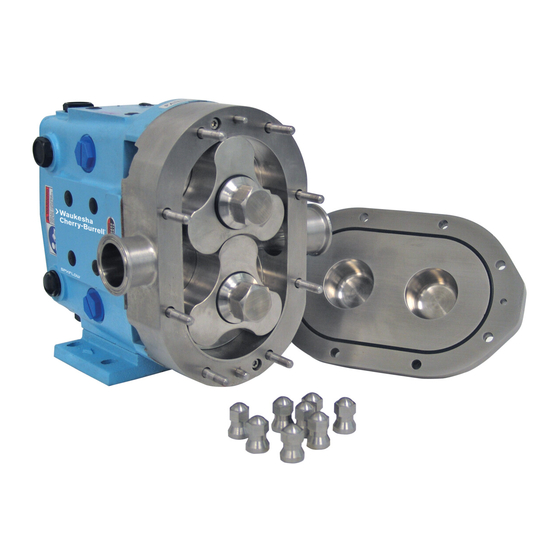

Waukesha Cherry-Burrell Introduction Introduction Pump Receiving DANGER: The pump contains All ports are covered at the factory to keep out foreign objects internal moving parts. DO NOT during transit. If covers are missing or damaged, remove the put hands or fingers into the pump pump cover and thoroughly inspect the fluid head. -

Page 10: Installation

Installation Waukesha Cherry-Burrell Installation Install the pump and piping system in accordance with local codes and restrictions. Practices described in this manual are recommended for optimum performance. All system equipment, such as motors, sheaves, drive couplings, speed reducers, etc., must be properly sized to ensure satisfactory operation of your Waukesha Cherry-Burrell pump within its limits. -

Page 11: Install Connections And Piping

Waukesha Cherry-Burrell Installation Install Connections and Fittings Piping Waukesha Cherry-Burrell produces a wide variety of fittings made to meet your needs. Contact Waukesha Cherry-Burrell Customer Service at 1-800-252-5200 or 262-728-1900 for information on fittings. Piping Support Support all piping to the pump independently with hangers or pedestals to minimize the forces exerted on the pump. -

Page 12: Install Check Valves

Installation Waukesha Cherry-Burrell Install Check Valves Inlet Side on Lift Applications Use check valves to keep the inlet line full, particularly with low- viscosity fluids (Figure 11). A. Inlet Check Valve B. Foot Check Valve Figure 11 - Inlet/Foot Check Valve Discharge Side For systems with liquid under a vacuum, install a check valve on the discharge side of the pump. -

Page 13: Inlet Side Strainers And Traps

Waukesha Cherry-Burrell Installation Inlet Side Strainers and Traps Inlet side strainers and traps (Figure 15, items A and B) can be used to prevent foreign matter from damaging the pump. Make the selection carefully to prevent cavitation caused by the restriction of the inlet. -

Page 14: Cip (Clean-In-Place) Features

Installation Waukesha Cherry-Burrell 5. Also install a solenoid valve in the flush supply and wire it in series with the motor starter to provide an automatic start/ stop of the flush media flow before the motor turns on and after the motor turns off. NOTE: If the pumped product contains abrasive solids or hardens on the seal faces, an alternate high pressure barrier flush arrangement may be used. -

Page 15: Check Coupling Alignment

Waukesha Cherry-Burrell Installation Check Coupling Alignment Pumps and drives ordered from the factory and mounted on a common base plate are aligned before shipment. Alignment must be re-checked after the complete unit has been installed and piping completed. Periodic re-checking is advisable during the pump service life. -

Page 16: Check Belt And Chain Drive Alignment

Installation Waukesha Cherry-Burrell Check Belt and Chain Drive Alignment Use a straight edge to visually check the belt or chain alignment. Keep the shaft distance to a minimum (Figure 22, item A). After the piping is complete and before the belts are installed, manually turn the pump shaft to ensure that it turns freely. -

Page 17: Operation

Waukesha Cherry-Burrell Operation Operation DANGER: The pump contains internal moving parts. DO NOT put hands or fingers into the pump body ports or drive area at any time during operation. To avoid serious injury, DO NOT install, clean, service, or repair the pump unless all power is off and locked out. -

Page 18: Maintenance

Maintenance Waukesha Cherry-Burrell Maintenance Important Safety DANGER: The pump contains internal moving parts. DO Information NOT put hands or fingers into the pump body ports or drive area at any time during operation. To avoid serious injury, DO NOT install, clean, service or repair the pump unless all power is off and locked out. -

Page 19: Maintenance Inspections

Waukesha Cherry-Burrell Maintenance Maintenance Inspections DANGER: The pump contains internal moving parts. DO NOT put hands or fingers into the pump body ports or drive area at any time during operation. To avoid serious injury, DO NOT install, clean, service or repair the pump unless all power is off and locked out. - Page 20 Maintenance Waukesha Cherry-Burrell Inspection of Shaft Shoulder Visually inspect the shaft shoulder (Figure 27, item A) for excessive wear; replace it as necessary. If the shaft shoulder has a sharp edge, remove the edge with a file to prevent cutting the shaft o-ring on installation.

-

Page 21: Maintenance Inspection Chart

Waukesha Cherry-Burrell Maintenance Maintenance Inspection Chart Problem POSSIBLE causes possible Solutions Rotor to rotor contact Hard object jammed into rotors Replace shafts. or uneven rotor to and twisted shafts. Install strainers if necessary. rotor clearance. Check and replace gears if necessary. Re-time rotors. -

Page 22: Annual Maintenance

Maintenance Waukesha Cherry-Burrell Annual Maintenance DANGER: The pump contains internal moving parts. DO NOT put hands or fingers into the pump body ports or drive area at any time during operation. To avoid serious injury, DO NOT install, clean, service or repair the pump unless all power is off and locked out. -

Page 23: Fluid Head Disassembly

Waukesha Cherry-Burrell Maintenance Fluid Head Disassembly DANGER: The pump contains internal moving parts. DO NOT put hands or fingers into the pump body ports or drive area at any time during operation. To avoid serious injury, DO NOT install, clean, service, or repair the pump unless all power is off and locked out. - Page 24 Maintenance Waukesha Cherry-Burrell Remove Rotors 1. Using only your hands, remove the rotors and place them on a clean, protected surface to prevent damage to close toler- ance parts. If the rotors cannot be removed by hand: • Use plastic or hardwood dowels to pry out the rotors. •...

-

Page 25: Gear Case Disassembly

Waukesha Cherry-Burrell Maintenance Gear Case Disassembly DANGER: To avoid serious injury, DO NOT install, clean, service, or repair the pump unless all power is off and locked out. DANGER: To avoid serious injury, shut off and drain the product from the pump prior to disconnecting the piping. Remove Gear Case Cover 1. - Page 26 Maintenance Waukesha Cherry-Burrell 2. Loosen the locking screw or screws on the locking assembly and tap them lightly with a mallet (or use thread jacking holes) to loosen the gear. Remove the gear and locking assembly (Figure 38). NOTE: Wrap the liquid end shafts with tape to prevent damage to the threads.

- Page 27 Waukesha Cherry-Burrell Maintenance 7. Scrape the silicone sealant (Figure 42, item B); then press out and discard the grease seal (item A) from the front bear- ing retainers (item C). 8. Remove the shims. If the shafts and bearings will be reused, identify the shims and bearings that belong with each shaft.

-

Page 28: Shaft Assembly

Maintenance Waukesha Cherry-Burrell Shaft Assembly Front Bearing Assembly NOTE: The following instructions cover assembly of a six-piece front bearing assembly. For a four-piece assembly, only one spacer and cup is used. 1. Lubricate the front bearing area of the shaft (Figure 45, item 7, 8) with oil or grease. - Page 29 Waukesha Cherry-Burrell Maintenance 7. Place the upper cup (Figure 49, item E) on top of the outer spacer. 8. Lubricate the remaining upper cone and roller assembly (Fig- ure 49, item F) with oil or grease and slip it over the shaft with the roller radius facing up.

-

Page 30: Gear Case Assembly

Maintenance Waukesha Cherry-Burrell Gear Case Assembly Shimming 1. When installing the shafts in the gear case, shim behind the Suggested Shims front bearing to achieve the proper backface clearance between the back of the rotors and the body. The backface Standard Replacement Model... - Page 31 Waukesha Cherry-Burrell Maintenance Install Shaft 1. With the shims in place, install the shaft assembly in the front bearing bore with the fluid end facing up. Ensure that the shaft is installed in its original location. NOTE: The shafts may need to be removed for a final shim adjustment.

- Page 32 Maintenance Waukesha Cherry-Burrell 15. After obtaining the proper clearance, remove the rotor nuts, rotors, body, and bearing retainers. 16. Grease the front and rear bearings through the grease fittings until the grease is visible around the bearing assemblies. The amount of grease required is listed in “Grease Quantity (per Bearing)”...

- Page 33 Waukesha Cherry-Burrell Maintenance 5. Place the pump upright. Insert the rotor on the short shaft. Install the rotor nut assembly to hold the rotor in place. Hand tighten only. NOTE: Place a plastic rod or wood dowel across the rotor to keep the short shaft from turning.

- Page 34 Maintenance Waukesha Cherry-Burrell Timing Gear Assembly 1. Install the timing gear on the drive shaft. Figure 60 - Install timing gear on drive shaft 2. Place the timing gear on the short shaft with the solid side facing in. Figure 61 - Install timing gear on short shaft 3.

- Page 35 Waukesha Cherry-Burrell Maintenance 4. Hand-tighten the locking assembly bolts in an alternating pat- tern. 5. If replacing the body studs, apply anti-seize and carefully thread all the studs into the body. Tighten the studs using a wrench on a double nut or a nut driver. Figure 63 - Body studs 6.

- Page 36 Maintenance Waukesha Cherry-Burrell 8. Place the body on the studs and push it against the gear case. Figure 66 - Place body on studs 9. Lubricate the two socket head retaining bolt threads with anti- seize, install, and tighten the bolts to the body. Figure 67 - Tighten bolts 10.

- Page 37 Waukesha Cherry-Burrell Maintenance 11. Insert a plastic or wood rod between the rotors. Place the rotor nut assembly on the top rotor shaft and tighten it to the proper torque specs. (See “Torque Values” on page 44.) 12. Place the rotor nut assembly on the bottom rotor shaft and place the rod between the rotors.

- Page 38 Maintenance Waukesha Cherry-Burrell 15. Tighten the locking assembly bolts evenly by hand so that the 30° locking assembly begins to grip the shaft. 16. Align the rotors to attain the specified clearance between the wings. See Table 8, “Standard Rotor Clearance,” on page 39. PD100-511a Figure 72 - Align rotors 17.

- Page 39 Waukesha Cherry-Burrell Maintenance Checking for Proper Clearance Waukesha Cherry-Burrell pumps are designed with close running clearances. Backface clearances are set with shims during assembly. 30° Shafts are positioned with shims behind the front bearing and locked into the gear case with bearing retainers. Rotors lock against shaft shoulder.

- Page 40 Maintenance Waukesha Cherry-Burrell Install Gear Case Cover 1. Lubricate the inside diameter of the new oil seal. 2. Press the new oil seal (Figure 75, item 12) into the gear case cover (item 4) flush with outside face, with the spring facing Figure 75 - Orientation of Oil Seal 3.

-

Page 41: Fluid Head Assembly

Waukesha Cherry-Burrell Maintenance Fluid Head Assembly Install Mechanical Seal 1. Lubricate the shaft o-ring (Figure 77, item 92) with a lubrica- tion compound compatible with the o-ring material and pro- cess fluid(s). Place the o-ring on the shaft. 2. Install the rotating seal seat (item 93) on the shaft. Align the drive flats on the seat with the drive flats on the shaft. - Page 42 Maintenance Waukesha Cherry-Burrell 2. Install the body (Figure 80, item 1) to the gear case assem- bly, aligning the body with the body studs. Avoid damaging the seals as the body is drawn over the shafts. 3. Secure the body to the gear case using two cap screws (Fig- ure 80, item 45).

- Page 43 Waukesha Cherry-Burrell Maintenance Install Rotor Nut Assemblies 1. Install the belleville-style washer (Figure 80, item 26B) into rotor nut with raised side of washer toward rotor nut. 2. Place the retainer o-ring (item 26C) into rotor nut to retain the belleville-style washer.

-

Page 44: Reference Tables

Maintenance Waukesha Cherry-Burrell Reference Tables Universal Series Wrench Sizes Body Retaining Model Rotor Nut Cover Nut Cap Screw 018UL 15/16" 3/16" 5/8" 030UL, 050UL 1-1/4" 3/16" 5/8" 060UL, 130UL 1-5/8" 1/4" 7/8" 220UL 2-1/4" 5/16" 7/8" 320UL 2-3/8" 5/16" 1" Torque Values Locknuts Locknut... -

Page 45: Standard Wcb O-Ring Selections, Descriptions And Color Codes

Waukesha Cherry-Burrell Maintenance Standard WCB O-Ring Selections, Descriptions and Color Codes Nitrile (Buna-N) (NBR) Silicone (Si) Compound Color: Black Compound Color: Orange Color Code: Yellow Color Code: Black FDA Compliant to FDA Compliant to 21CFR177.2600 21CFR177.2600 3A Sanitary 3A Sanitary Ethylene Propylene Diene Perfluoroelastomer (FFKM) Rubber (EPDM) -

Page 46: Parts Lists

Parts Lists Waukesha Cherry-Burrell Parts Lists 018-UL PD Pumps QTY. ITEM PART DESCRIPTION NOTES PUMP Pump Body See Note 1 Pump Body with Flush See Note 1 Drive Shaft (Obsoletes 103219) 122406+ Short Shaft (Obsoletes 103220) 122407+ Rotor, 3 Lobe, Alloy 88 (Obsoletes 103202) 117494+ 2, 22 Rotor, 3 Lobe, 316SS (Obsoletes 105689) - Page 47 Waukesha Cherry-Burrell Parts Lists 018-UL PD Pumps QTY. ITEM DESCRIPTION PART NO. NOTES PUMP Pump Cover 103213+ Jacketed Cover 107665+ Pump Cover Vented - Complete Assembly Manual (over 150 PSI) CVR00113 Manual (under 150 PSI) CVR00083 Pneumatic CVR00084 Piston CVR00085 Gear Case, CI 102276+ Gear Case, SS;...

- Page 48 Parts Lists Waukesha Cherry-Burrell 018-UL PD Pumps Page 48 95-03092 November 2009...

- Page 49 Waukesha Cherry-Burrell Parts Lists 018-UL PD Pumps QTY. ITEM DESCRIPTION PART NO. NOTES PUMP Shim Kit 117889+ Spacer, Gear to Rear Bearing 015055000+ Bearing Spacer 101814+ Bearing Retainer, Front 120332+ 1/4-20 x .75" HHCS, STD 30-287 33A, 33B 1/4-20 x .75" HHCS, SS 30-58 1/4"...

-

Page 50: 030-Ul, 034-Ul, 050-Ul, 054-Ul Pd Pumps

Parts Lists Waukesha Cherry-Burrell 030-UL, 034-UL, 050-UL, 054-UL PD Pumps Page 50 95-03092 November 2009... - Page 51 Waukesha Cherry-Burrell Parts Lists 030-UL, 034-UL, 050-UL, 054-UL PD Pumps QTY. ITEM PART DESCRIPTION NOTES PUMP 030-UL Pump Body See Note 1 030-UL Pump Body with Flush See Note 1 034-UL Rectangular Flange Inlet Body See Note 1 034-UL Rectangular Flange Inlet Body with Flush See Note 1 050-UL Pump Body See Note 1...

- Page 52 Parts Lists Waukesha Cherry-Burrell 030-UL, 050-UL PD Pumps Page 52 95-03092 November 2009...

- Page 53 Waukesha Cherry-Burrell Parts Lists 030-UL, 034-UL, 050-UL, 054-UL PD Pumps QTY. ITEM PART DESCRIPTION NOTES PUMP Pump Cover 103214+ Jacketed Cover 107667+ Pump Cover Vented - Complete Assembly Manual (over 150 PSI) CVR00018 Manual (under 150 PSI) CVR00044 Pneumatic CVR00086 Piston CVR00087 Gear Case, CI...

- Page 54 Parts Lists Waukesha Cherry-Burrell 030-UL, 034-UL, 050-UL, 054-UL PD Pumps Page 54 95-03092 November 2009...

- Page 55 Waukesha Cherry-Burrell Parts Lists 030-UL, 034-UL, 050-UL, 054-UL PD Pumps QTY. ITEM DESCRIPTION PART NO. NOTES PUMP Shim Kit 117890+ Spacer, Gear to Rear Bearing 030055000+ Bearing Spacer 101815+ Bearing Retainer, Front 101811+ 5/16-18 x 3/4" HHCS, STD 30-283 5/16-18 x 3/4" SHCS, SS 30-29 5/16-18 x 3/4"...

-

Page 56: 060-Ul, 130-Ul, 134-Ul Pd Pumps

Parts Lists Waukesha Cherry-Burrell 060-UL, 130-UL, 134-UL PD Pumps Page 56 95-03092 November 2009... - Page 57 Waukesha Cherry-Burrell Parts Lists 060-UL, 130-UL, 134-UL PD Pumps QTY. ITEM DESCRIPTION PART NO. NOTES PUMP 060-UL Pump Body See Note 1 060-UL Pump Body with Flush See Note 1 130-UL Pump Body See Note 1 130-UL Pump Body with Flush See Note 1 134-UL Rectangular Flange Inlet Body See Note 1...

- Page 58 Parts Lists Waukesha Cherry-Burrell 060-UL, 130-UL, 134-UL PD Pumps Page 58 95-03092 November 2009...

- Page 59 Waukesha Cherry-Burrell Parts Lists 060-UL, 130-UL, 134-UL PD Pumps QTY. ITEM PART DESCRIPTION NOTES PUMP Pump Cover 103215+ Jacketed Cover 107669+ Pump Cover Vented - Complete Assembly Manual (over 150 PSI) CVR00036 Manual (under 150 PSI) CVR00088 Pneumatic CVR 00089 Piston CVR00090 Gear Case, CI...

- Page 60 Parts Lists Waukesha Cherry-Burrell 060-UL, 130-UL, 134-UL PD Pumps Page 60 95-03092 November 2009...

- Page 61 Waukesha Cherry-Burrell Parts Lists 060-UL, 130-UL, 134-UL PD Pumps QTY. ITEM DESCRIPTION PART NO. NOTES PUMP Shim Kit 117891+ Spacer, Gear to Rear Bearing 107187+ Bearing Spacer 060055003+ Grease Retainer, Rear Bearing STD091002 Bearing Retainer, Front, STD 123531+ Bearing Retainer, Front, SS 121828+ 3/8-16 x 3/4"...

-

Page 62: 220-Ul Pd Pumps

Parts Lists Waukesha Cherry-Burrell 220-UL PD Pumps QTY. ITEM DESCRIPTION PART NO. NOTES PUMP Pump Body See Note 1 Pump Body with Flush See Note 1 Drive Shaft (Replaces 108425) 122504+ Short Shaft (Replaces 108426) 122505+ Rotor, 3 Lobe, Alloy 88 (Obsoletes 103206) 123841+ 2, 22 Rotor, 3 Lobe, 316SS (Obsoletes 104350) - Page 63 Waukesha Cherry-Burrell Parts Lists 220-UL PD Pumps QTY. ITEM PART DESCRIPTION NOTES PUMP Pump Cover 103216+ Jacketed Cover 107671+ Pump Cover Vented - Complete Assembly Manual (over 150 PSI) CVR00114 Manual (under 150 PSI) CVR00064 Piston CVR00091 Gear Case, CI 230005000+ Gear Case, SS;...

- Page 64 Parts Lists Waukesha Cherry-Burrell 220-UL PD Pumps Page 64 95-03092 November 2009...

- Page 65 Waukesha Cherry-Burrell Parts Lists 220-UL PD Pumps QTY. ITEM PART DESCRIPTION NOTES PUMP Shim Kit 117892+ Spacer, Gear to Rear Bearing 40878+ Bearing Spacer 40752+ Bearing Retainer, Front, STD 220080000+ Bearing Retainer, Front, SS 101813+ 3/8-16 x 3/4" HHCS, STD Gear Case Cover 30-314 3/8-16 x 3/4"...

-

Page 66: 320-Ul Pd Pumps

Parts Lists Waukesha Cherry-Burrell 320-UL PD Pumps QTY. ITEM DESCRIPTION PART NO. NOTES PUMP Pump Body See Note 1 Pump Body with Flush See Note 1 Drive Shaft (Obsoletes 108427) 123847+ Short Shaft (Obsoletes 108428) 123848+ Rotor, 3 Lobe, Alloy 88 (Obsoletes 105496) 117518+ 2, 22 Rotor, 3 Lobe, 316SS (Obsoletes 105498) - Page 67 Waukesha Cherry-Burrell Parts Lists 320-UL PD Pumps QTY. ITEM PART DESCRIPTION NOTES PUMP Pump Cover 105425+ Gear Case, CI 105478+ Gear Case Cover, Steel 40669+ Gear, Drive Shaft, Spur 102470+ Gear, Short Shaft, Spur 102471+ Hex Nut 108373+ Wing Nut, Optional 110858+ Oil Seal, Gear Case Cover STD030004...

- Page 68 Parts Lists Waukesha Cherry-Burrell 320-UL PD Pumps Page 68 95-03092 November 2009...

-

Page 69: 320-Ul Pd Pumps

Waukesha Cherry-Burrell Parts Lists 320-UL PD Pumps QTY. ITEM DESCRIPTION PART NO. NOTES PUMP Bearing Retainer, Front 123533+ 3/8-16 x .75" HHCS 30-314 5/16-18 HHCS 30-353 3/8" Flat Washer 43-189 Dowel Bushings OH1116000 N70383 O-Ring, Pump Cover, Buna N O-Ring, Pump Cover, EPDM E70383 O-Ring, Pump Cover, FKM V70383... -

Page 70: Universal Ul Pd Pump Seals

Parts Lists Waukesha Cherry-Burrell Universal UL PD Pump Seals PD100-221 Note: Item 96, 97, 98 used with Double Mechanical Seal. Qty. Part No. by Model Item Description Notes 030, 034, 060, 130, 018 UL 220 UL 320 UL Pump 050, 054 134 UL MECHANICAL SEAL PARTS O-Ring, Inner Seal, Buna N... -

Page 71: Vented Cover Parts - Model 018, 030, 034, 050, 054, 060, 130, 134 Ul

Waukesha Cherry-Burrell Parts Lists Vented Cover Parts - Model 018, 030, 034, 050, 054, 060, 130, 134 UL 114 113 MANUAL 112 117 PISTON PD100-448 PNEUMATIC Qty. Part No. By Model Item Description Notes 030, 034, 050, 060, 130, 134 018 UL Pump 054 UL... -

Page 72: Vented Cover Parts - Model 220 Ul

Parts Lists Waukesha Cherry-Burrell Vented Cover Parts - Model 220 UL 114 113 PD100-300 PISTON PD100-298 MANUAL Qty. Item Description Part No. Notes Pump MANUAL VENTED COVER 101 Vented Cover 103676+ 102 Adjusting Screw GD0072100 103 Spring Plunger GD0073000 104 Locknut GD0074000 Spring, Medium (less than 150 PSI) 113400+... -

Page 73: Ul Pump Dimensions

Waukesha Cherry-Burrell UL Pump Dimensions UL Pump Dimensions Universal UL Pump Dimensions and Model Weights CP1 Jacketed Cover Inlet CP Standard Cover 3/4”-14NPT, Models 018UL-050;UL 1”-11 1/2 NPT, Models 060UL-220 UL Optional Mounting Pad Location Eye Bolts, Models 060UL- 320UL Optional Upper Shaft K- Key... -

Page 74: Rectangular Flange Universal Ul Pump Dimensions And Model Weights

UL Pump Dimensions Waukesha Cherry-Burrell Rectangular Flange Universal UL Pump Dimensions and Model Weights CP4 Manual Vented Cover CP3 Pneumatic Vented Cover - Diaphragm CP2 Pneumatic Vented Cover - Piston CP1 Jacketed Cover CP Standard Cover K-Key Models 034-054, 3/8-16 Models 134-224, 1/2-13 SMLH Drive -Nominal... -

Page 75: Troubleshooting

Waukesha Cherry-Burrell Troubleshooting Troubleshooting WARNING: To avoid serious injury, do not install or service pump unless all power is off and locked out. Shut off and drain product from pump prior to disconnecting piping. PROBLEM POSSIBLE CAUSE SUGGESTED ACTION No flow, pump not turning Drive motor not running Check resets, fuses, circuit breakers Keys sheared or missing. - Page 76 Troubleshooting Waukesha Cherry-Burrell PROBLEM POSSIBLE CAUSE SUGGESTED ACTION Fluid vaporization Strainers, foot valves, inlet fittings Clear lines. If problem continues, inlet (“starved” pump inlet) or lines clogged system may require changing Inlet line size too small; inlet line Increase inlet line size. Reduce too long;...

- Page 77 Waukesha Cherry-Burrell Troubleshooting PROBLEM POSSIBLE CAUSE SUGGESTED ACTION Noisy operation caused by Rotor to body contact due to Check clearances and adjust mechanical problems. improper assembly of pump shimming Rotor to body contact caused by Change piping installation to eliminate distortion of pump due to improper piping stress and distortion on body piping installation...

- Page 78 Troubleshooting Waukesha Cherry-Burrell Notes Page 78 95-03092 November 2009...

- Page 80 For more information about our worldwide locations, approvals, certifications, and local representatives, please visit www.spxpe.com. SPX Corporation reserves the right to incorporate our latest design and material changes without notice or obligation. Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information only and should not be relied upon unless confirmed in writing.

Need help?

Do you have a question about the Waukesha Cherry-Burrell Universal Lobe Series and is the answer not in the manual?

Questions and answers