Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Knauer BlueShadow Pump 10P

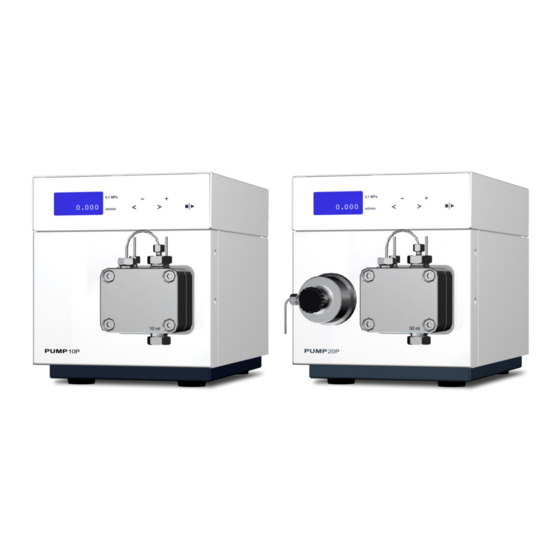

- Page 1 BlueShadow Pump 10P/20P Service V7635A HPLC...

-

Page 2: Table Of Contents

Table of contents Table of contents Note: For your own safety, read the manual and always observe the warnings and safety information on the device and in the manual! Safety for service technicians ........Protective measures . - Page 3 Table of contents Tightening torque for screws ........Screws in materials made of metal .

-

Page 4: Safety For Service Technicians

Safety for service technicians Safety for service technicians Checking intended use Only use the device for applications that fall within the range of the intended use. Otherwise, the protective and safety equip- ment of the device could fail. The installation manual is an addition to the existing device manual;... -

Page 5: Protective Measures

Safety for service technicians Protective measures The following applies for all repairs on the device: Hazard symbol Title DANGER! Danger of electric shock! Switch off power supply! Pull the power plug! DANGER! Danger due to toxic, caustic, or radioactive substances due to conta- mination of the device. -

Page 6: Power Supply And Mains Connection

Safety for service technicians Power supply and mains connection The device is intended for use with AC power networks of 100- 240 V. The supplied power cable is to be used in connection with the external power supply to connect the device to the mains sup- ply. -

Page 7: What Is Maintained Or Repaired

What is maintained or repaired? What is maintained or repaired? Check operating hours Check the number of operating hours on the display. Hours in operation Measures 1000 Check the torque of the screw fittings Clean the pistons Check ball valves ... -

Page 8: Pump Head Repair

Pump head repair Pump head repair WARNING! Aggressive or toxic solvent residue can irritate the skin! Wear protective gloves! In case of a malfunction or as part of routine maintenance, the pump head can be disassembled into individual parts and clea- ned. -

Page 9: Removing The Pump Head

Pump head repair Removing the pump head Procedure 1. Remove tubing from the connections of the piston backflus- hing (A). 2. Remove all connections from the solvent bottles. 3. Unscrew the eluent line (D). 4. Unscrew the outlet fitting 2 (E) and the inlet fitting pressure sensor (F) so as to remove the capillary. -

Page 10: Disassembling The Pump Head

Pump head repair Disassembling the pump head CAUTION! Avoid breaking the piston rods! Before disassembly, first remove the two piston rods. Deposit the two piston rods in the correct orientation to ensure correct orientation when putting them back in. A Capillary screw fitting B Seal ring C Capillary connection kit D Inlet screw fitting... -

Page 11: Fig. 3: Back Of The Device, The Subassemblies Are Visible

Pump head repair Complete disassembly Process Figure of the pump head 1. Flush the pump head with water or isopro- panol if the pump head is to be stored. 2. Remove the pump head (see manual). 3. Remove and inspect the piston rods (A) of the removed pump head, e.g. -

Page 12: Fig. 5 Parts Of The Piston Guide

Pump head repair Removing the piston Process Figure guide A Remove the parts and securely deposit them in the proper sequence and in the correct orientation. A Low-pressure seal B Washer C Compression spring Fig. 5 Parts of the piston guide D Bushing E Piston guide F Piston rod... -

Page 13: Fig. 8: O-Ring Of The Piston Backflushing

Pump head repair Replacing the seals of Process Figure piston backflushing 1. Replace O-rings (A) of the piston backflushing. Fig. 8 O-ring of the piston backflushing 2. Screw the spe- cial tool into the low-pres- sure seal (B) and pull from the flushing block. -

Page 14: Assembling The Pump Head

Pump head repair Assembling the pump head Order of operation The pump head is assembled in this sequence: for assembly • The pump head is assembled. • Peripherals are attached to the pump head. • Pump head is installed into the pump. Assembly begins with inserting the new seals on the feed and flushing blocks. -

Page 15: Fig. 12 Sapphire Ring In The Adaptor Ring

Pump head repair Inserting the spacer Process Figure 1. Insert sapphire ring into adaptor ring (A) and place on sealing tool. 2. Using the special tool, insert the adap- Fig. 12 Sapphire ring in the adaptor tor ring, together ring with the sapphire ring, into the feed block. -

Page 16: Fig. 14: Special Tool And Low-Pressure Seal

Pump head repair Press in the low-pres- Process Figure sure seal into the pis- ton backflushing 1. Place the low- pressure seal (A) onto the special tool (B). 2. Press in the seal with the special tool. Fig. 14 Special tool and low-pressure seal Fig. -

Page 17: Fig. 16: Piston Backflushing With Washers

Pump head repair Positioning the Process Figure washers flat, compres- sion springs, bushings The springs for the pis- ton guide can be positi- oned on the feed block and piston backflus- hing, which have been put together. 1. Positioning the washers (A) flat 2. -

Page 18: Fig. 18: Mounting The Piston Guide

Pump head repair Screwing the pump Process Figure head together 1. Position piston guide (A). 2. Insert screws with Allen wrench (B). 3. Manually press the piston guide (C) down against the compression springs. 4. Alternately screw in the screws with a size 4 Allen wrench to 3 Nm, making sure that no tilting or jam-... -

Page 19: Replacing The Ball Valves

Pump head repair Replacing the ball valves Dirty ball valves may not open and close correctly. The entire ball valve is replaced. For replacement of the ball valves, the manu- facturer recommends removing the pump head. Prerequisite • Pump has been flushed with water and isopropanol. •... -

Page 20: Exchanging The Ball Valves

Pump head repair Torques Torque Wrench C, K 7.5 Nm Size 10 5 Nm 1/4" E, J 15 Nm Size 13 Exchanging the ball valves Note: The ball and position of the valves have been harmo- nized to each other. Insert the valves in the direction of flow! Legend A Ball valve... -

Page 21: Fig. 22 Exchange The Ball Valves

Pump head repair Legend A Inlet screw fitting 2 B Capillary screw fitting C Outlet screw fitting 1 D Ball valve E Inlet screw fitting 1 Fig. 22 Exchange the ball valves Clean ball valves 1. Put the valve in a beaker with rinsing solvent, for example iso- propanol or methanol. -

Page 22: Disassembling The Housing

Disassembling the housing Disassembling the housing Disassembly of the housing hood and the sides of the device is necessary when carrying out certain repairs inside the device. Removing the housing hood The housing hood is attached to the rear side of the device by 2 hexagonal socket screws. -

Page 23: Spare Parts

Disassembling the housing Spare parts Component Comment Order number Housing angle complete P6610XA Device hood P6603 Power supply external M1642 Removing the side panels of the device The two side panels are inserted into the front side of the housing. Prerequisite The housing hood is open. -

Page 24: Overview Of The Open Device

Disassembling the housing Overview of the open device Legend A Pressure sensor B Motherboard C Fan D Motor E Pump drive F Pump head Fig. 26 Overview of the open device Legend A Pump drive B Drive shaft C Hall sensor D Timing belt Fig. -

Page 25: Removing And Maintaining The Pump Drive

Removing and maintaining the pump drive Removing and maintaining the pump drive Prerequisite The housing has been opened. The pump head has been removed. Procedure Procedure for removing the pump drive Disconnect all electrical connections of the pump drive. ... -

Page 26: Fig. 29 Underside Of The Device

Removing and maintaining the pump drive 5. Remove the 3 cross- head screws (A) on the bottom of the device. 6. Remove pump drive from the device. Fig. 29 Underside of the device Intermediate result The pump drive has been removed. Next steps Open pump drive and lubricate all movable parts. -

Page 27: Fig. 32 Drive Shaft With Gearwheel

Removing and maintaining the pump drive Removing the drive shaft Process Figure 1. Remove drive shaft. 2. Check drive shaft for signs of wear. 3. Replace drive shaft if necessary. 4. Grease the cam pla- tes on the drive shaft with Molykote gre- ase paste. -

Page 28: Spare Parts

Removing and maintaining the pump drive Spare parts Component Comment Order number Pump drive complete G1244 Slider complete G2719-1 Drive shaft complete G2720-1 Molykote bearing grease MOS2 U0200 Molykote grease paste U0190... -

Page 29: Replacing The Motor

Replacing the motor Replacing the motor Prerequisite The housing has been opened. Procedure Procedure for removing the 24-V motor of the pump: Disconnect all electrical motor connections. Loosen timing belt to be able to remove the motor. Remove the motor. -

Page 30: Spare Parts

Replacing the motor 2. Turn the gearwheel of the drive shaft together with the timing belt to a posi- tion where the retai- ning screws of the motor become visi- ble through one of the openings of the drive shaft. 3. -

Page 31: Tightening The Timing Belt

Replacing the motor Tightening the timing belt Prerequisite The housing has been opened. The right side panel of the device has been removed. Procedure Procedure for tightening the timing belt: Tightening the timing belt. Inspect the tension of the timing belt. Tools Cross-head screwdriver (321/PH 2×100 size) Duration... -

Page 32: Replacing The Fan

Replacing the fan Replacing the fan Legend A PIN connector B Fan with power cable Fig. 39 Removing the fan Prerequisite The housing hood has been removed. The right side panel of the device has been removed. Procedure Remove the PIN connector ... -

Page 33: Installing The Fan

Replacing the fan Process Figure 1. Remove the fan power supply cable from the PIN con- nector (A) on the main board. 2. Use the wrench to hold the nuts (B) inside the device in place. 3. While gripping the fan securely (C), loo- sen the four Phillips- head screws on the... -

Page 34: Fig. 41: Installing The Fan

Replacing the fan Process Figure 1. Set the fan (B) onto the rear panel of the device, so that the arrow on the fan indicating the direc- tion of rotation cor- responds with the arrow in the dra- wing. A B C 2. -

Page 35: Replacing The Hall Sensor

Replacing the Hall sensor Replacing the Hall sensor CAUTION! Electrostatic discharge can destroy the electronics! Wear protective bracelet against electrostatic discharge and ground. Legend A Cable plug on the motherboard B Hall sensor C Cable plug, Hall sen- sor motor Fig. -

Page 36: Spare Parts

Replacing the LCD display Spare parts Component Comment Order number Hall sensor G1595 Replacing the LCD display Prerequisite The housing is open Procedure Open the screw connections Unscrew LCD display Tools Small cross-head screwdriver Duration About 5 minutes Level of difficulty Level 2 (from 1 to 7, very easy to very difficult) CAUTION! -

Page 37: Replacing The Keyboard

Replacing the keyboard Replacing the keyboard Prerequisite The housing is open. Procedure Open the plug connections. Tools Knife or small flat blade screwdriver Duration About 15 minutes Level of difficulty Level 5 (from 1 to 7, very easy to very difficult) Removing the keyboard Process Figure... -

Page 38: Gluing On The Keyboard

Replacing the keyboard Gluing on the keyboard The control panel is self-adhesive. The adhesive surface is covered by a protective film. Practical tip Apply the control panel at the top at first, because corrections can be made here easier. Process Figure 1. -

Page 39: Replacing The Motherboard

Replacing the motherboard Replacing the motherboard Legend A Cable plug, LCD dis- play B Cable plug, key- board C Cable plug, pressure sensor D Cable plug, Hall sen- E Cable plug, power supply motor F Cable plug, fan Fig. 48 Cable plug on the motherboard What can be replaced? Motherboard... -

Page 40: Fig. 49 Cable Plug To Lcd Display

Replacing the motherboard Loosening the cable plug on the motherboard Process Figure 1. Hold the connector of the broad flat rib- bon cable to the LCD display (A) on both sides and pull it out. 2. Pull off the plug of the flexible flat cable to the keyboard (B). -

Page 41: Spare Parts

Replacing the motherboard Removing a mother- board Process Figure 1. Remove both Phil- lips-head screws (A) on the back side of the device. 2. Remove the mother- board. Fig. 53 Motherboard spacer bolt Result The motherboard has been removed. Next steps Replace pressure sensor. -

Page 42: Replacing The Pressure Sensor

The pressure sensor is adjusted to the mechanical and electrical properties of the pump with a calibration procedure. The calibra- tion requires a test station from KNAUER and the service software. For better results, the calibration is repeated once. ... -

Page 43: Fig. 55 Pressure Sensor, Front View

Replacing the pressure sensor Calibrating the The pressure sensor is calibrated at the following values: pressure sensor HPLC pumps at 0 bar (at calibration zero point) in the range of 350–400 bar (end point of the calibration) Tools Allen wrench for hexagon socket screws (Allen screws), 3.0 mm diameter... -

Page 44: Spare Parts

Tightening torque for screws Spare parts Component Comment Order number Pressure sensor G2703V1 Ventilation screw Without O-ring P2719XA O-ring M1368 Result The pressure sensor has been replaced. Tightening torque for screws Practical tip The use of a dynamometric screwdriver for the tightening torques is highly recommended. -

Page 45: Screws In Materials Made Of Plastic

Tightening torque for screws Screws in materials made of plastic The following materials are considered plastic: PEEK PETP PMMA PTFE Size Tightening torque (in Nm) -

Page 46: Possible Problems And Rectifications

Tightening torque for screws Possible problems and rectifications First measures 1. Check all cabling 2. Check all screw fittings 3. Check whether air has gotten into the supply lines 4. Check device for leaks 5. Observe system messages on the display In the following table, approximately 90% of the problems that occur in practical use are listed with possible solutions. - Page 47 Tightening torque for screws Pressure display Motherboard Calibrate mother- shows incorrect not calibrated board of pump values Pressure sensor Replace pressure defective sensor Loud running Timing belt Replace timing noise from worn belt and adjust pump belt tension...

-

Page 48: Spare Parts

Spare parts Spare parts Pump head 10 ml Stainless steel head Fig. 57 10 ml Stainless steel head Order number Name E3111 Pump head G0563 Ball valve P7316 Washer P3830 Bushing G0926 Pipe connection M1310 Seal N0202 Support ring P6122 Piston guide M1371 O-ring... -

Page 49: Pump Head 10 Ml Titanium

Spare parts Pump head 10 ml titanium Fig. 58 Pump head, 10 ml, titanium Order number Name E3121 Pump head G0563 Ball valve P7316 Washer P3830 Bushing G0926 Pipe connection M1310 Seal N0202 Support ring P6122 Piston guide M1371 O-ring M1458 Seal R0462... -

Page 50: 50 Ml Pump Head, Stainless Steel

Spare parts 50 ml Pump head, stainless steel Fig. 59 50 ml Pump head, stainless steel Order number Name E3112 Pump head G0563 Ball valve P7316 Washer M1300 Seal N0202A Support ring M2252 O-ring R0462 Compression spring P6117 Piston guide P2712-1 Piston rod P2738... -

Page 51: 50 Ml Pump Head, Titanium

Spare parts 50 ml Pump head, titanium Fig. 60 50 ml Pump head, titanium Order number Name E3131 Pump head G0563 Ball valve P7316 Washer M1300 Seal M1371 O-ring R0462 Compression spring P6117 Piston guide P2712-1 Piston rod P2738 Screw fitting M1057 Seal... -

Page 52: Device

Spare parts Device Fig. 61 Device Order number Name K0779 External power supply M2146XA Keyboard P6601 Side panel, right P6602 Side panel, left P6603 Device hood P6610XA Housing angle, complete Fig. 62 Order number Name G4117V1... -

Page 53: Pressure Sensor

Spare parts Pressure sensor Fig. 63 Pressure Sensor Order number Name G2703 Pressure sensor, complete G2704 Bushing G2727 Pressure sensor M1368 O-ring P2719XA Ventilation screw P7015 Sealing ring, PTFE P7022 Sealing ring, PEEK Drive Fig. 64 Drive Order number Name G1244 Drive, complete G2719-1... -

Page 54: Motor

Spare parts Motor Order number Name G2718-1 Motor M1840 Timing belt Boards Fig. 65 Motherboard Order number Name G4119XB Motherboard G1613 LCD display M2146XA Keyboard G1595 Hall sensor... -

Page 55: Table Of Figures

Table of Figures Table of Figures Fig. 1: Pump head ......... . . 10 Fig. - Page 56 Table of Figures Fig. 43: Loosening the Hall sensor ....... . 36 Fig.

- Page 57 © Wissenschaftliche Gerätebau Dr. Ing. Herbert Knauer GmbH All rights reserved. The information in this document is subject to change without prior notice. Translation of the original German edition of this manual. 2011-10-28 Printed in Germany. www.knauer.net HPLC · SMB · Osmometry Wissenschaftliche Gerätebau...

Need help?

Do you have a question about the BlueShadow Pump 10P and is the answer not in the manual?

Questions and answers