Summary of Contents for SCHUNK PZH-plus

- Page 1 Original operating manual Assembly and Operating Manual PZH-plus 3-finger centric gripper...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 389504 Version: 06.00 | 10/08/2022 | en...

-

Page 3: Table Of Contents

Assembly ........................ 18 Connections...................... 18 5.1.1 Mechanical connection................ 18 5.1.2 Air connection .................. 20 Mounting the sensor .................. 22 5.2.1 Overview of sensors ................ 22 5.2.2 IN 80 inductive proximity switch ............ 23 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 4 7.4.2 Assembly tool Y .................. 38 Servicing and assembling the module .............. 39 7.5.1 Screw tightening torques................ 39 Assembly drawing.................... 39 Translation of original declaration of incorporation .......... 41 Annex to Declaration of Incorporation .............. 42 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

-

Page 5: General

Dangers for persons! Non-observance can lead to irreversible injury and even death. CAUTION Dangers for persons! Non-observance can cause minor injuries. CAUTION Material damage! Information about avoiding material damage. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 6: Applicable Documents

ID.-No. of the accessory pack Accessory pack for ID number PZH-plus 20 5522173 PZH-plus 30 5522174 PZH-plus 50 5522175 PZH-plus 75 5522176 } 7.6 [ / Content of the accessories pack: 39]. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 7: Accessories

1.4.3 Pressure piece assembly kit ID no. of the assembly kit Assembly kit for ID number PZH-plus 20 0305363 PZH-plus 30 0305373 PZH-plus 50 0305383 PZH-plus 75 0305393 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 8: Basic Safety Notes

Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 9: Gripper Fingers

• Before working with the product, the personnel must have read and understood the complete assembly and operating manual. • Observe the national safety regulations and rules and general safety instructions. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 10: Personal Protective Equipment

• Wear protective gloves and safety goggles when handling hazardous substances. • Wear close-fitting protective clothing and also wear long hair in a hairnet when dealing with moving components. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 11: Notes On Safe Operation

• Do not recommission the product until the malfunction has been rectified. • Test the product after a malfunction to establish whether it still functions properly and no increased risks have arisen. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 12: Disposal

Falling loads may cause serious injuries and even death. • Stand clear of suspended loads and do not step into their swiveling range. • Never move loads without supervision. • Do not leave suspended loads unattended. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 13: Protection During Commissioning And Operation

• The effectiveness of the potential equalisation must be verified by executing regular safety measurements. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 14: Notes On Particular Risks

Do not reach into the open mechanism or the movement area • of the product. WARNING Risk of injury from sharp edges and corners! Sharp edges and corners can cause cuts. Use suitable protective equipment. • 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 15 Secure the end positions of the product with SCHUNK SDV-P • pressure maintenance valves. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

-

Page 16: Technical Data

Pressure range for air purge 0,5 – 1 [bar] Noise emission [dB(A)] ≤ 70 More technical data is included in the catalog data sheet. Whichever is the latest version. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

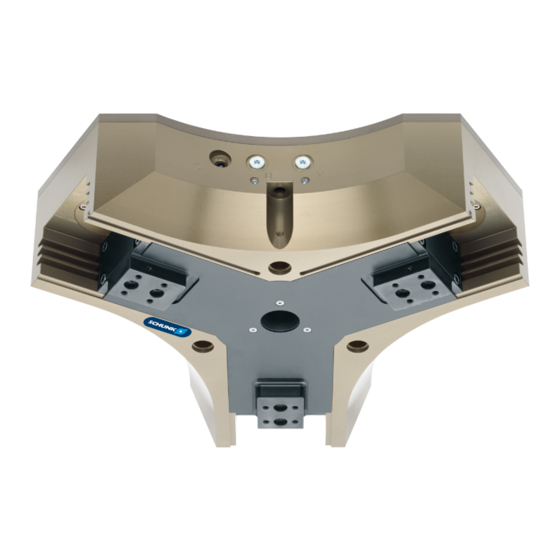

Page 17: Design And Description

3-finger centric gripper Housing Air purge connection Main air connections Base jaws 4.2 Description Universal centric gripper with high gripping force and maximum moments due to multi-tooth guidance 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 18: Assembly

Secure the unit during transport and assembly by sufficiently • large aids. The gripper is to be hoisted by the three transport threads. • Eye bolts in the transport threads 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 19 Mounting the pressure piece is described in the insert "Installation instructions - pressure piece", which is included in the pressure piece's scope of delivery. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

-

Page 20: Air Connection

Product variants are also offered with mechanical gripping force via springs, which also ensure a minimum clamping force in the event of a pressure drop. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 21 • If the maximum permitted finger weight is exceeded, a reduction is imperative so that the jaw movement occurs without any hitting or bouncing. Further information on the hose-free direct connection contains the catalog data sheet. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

-

Page 22: Mounting The Sensor

5.2.1 Overview of sensors Designation PZH-plus Inductive proximity switch IN 80 Magnetic switch MMS 22 Programmable magnetic switch MMS 22-PI1 Programmable magnetic switch MMS 22-PI2 Programmable magnetic switch MMS-P 22 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 23: In 80 Inductive Proximity Switch

Mounting kit To use the inductive sensor, the gripper has to be retrofitted with a special mounting kit. This mounting kit is available from SCHUNK for the models below. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 24 (5). 7. Fasten the proximity switch (1) by tightening the screws (3). 8. Open and close the gripper to test its functioning. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

-

Page 25: Mms 22 Magnetic Switch

For example: Adapter plate made of ordinary steel. At ferromagnetic adapter plates: • First mount the product on the adapter plate. • Then set the position of the magnetic switch. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 26 3. Tighten the set-screw (3) to clamp the magnetic switch 2 (2) in this position in the groove. 4. Open and close the gripper to test its function. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

- Page 27 4. Tighten the set-screw (3) to clamp the magnetic switch 1 (1) in this position in the groove. 5. Close and close the gripper to test its function. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

-

Page 28: Mms-P Programmable Magnetic Switch

The V2-M8-4-2XM8-3 distributor is used to convert the 4-pin connector plug of the MMS-P 22-S-M8-PNP sensor to two standard M8 plugs with 3 pins each. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 29 2. Turn in the sensor (1 - 4). Push the sensor axially into the slot until it contacts the stop (5). 3. Fix the sensor with an Allen wrench (6). 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

- Page 30 (outer edge of gripper up to the double arrow on the sensor) and then mount with a Allen key. Dimensions I1 / I2 Size [mm] [mm] PZH-plus 20 49.1 58.0 PZH-plus 30 62.8 71.7 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

- Page 31 “the adjustment of the switching points”, you may correct the value as follows. The sensor avoids a too small hysteresis during hysteresis adjustment. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

- Page 32 5. Move the gripper to the "switch-off point for switching point 2" position. 6. Briefly press the "Teach" button (4). LED 2 (5) flashes twice. ✓ The assembly of the MMS-P sensor is completed. ✔ 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

-

Page 33: Troubleshooting

One-way flow control valve is missing or Install and adjust one-way flow control adjustet incorrectly. valve. Loading too large. Check permissible weight and length of the gripper fingers. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 34: Gripping Force Is Dropping

SCHUNK recommends the use of quick-air-vent- valves directly at the product. Loading too large. Check permissible weight and length of the gripper fingers. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 35: Maintenance

During maintenance, treat all greased areas with lubricant. Thinly apply lubricant with a lint-free cloth. Lubricant point Lubricant Metallic sliding surfaces Toothgood 1 All seals Sealgood 1 Bore hole at the piston Sealgood 1 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 36: Disassembly Of The Module

8. Remove the bearings (20 / 21), fitting disks (39) and the eccentric (9). 9. Base jaw clamping piece (10) and centering sleeves (62). 10. Remove the base jaw (4). 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 37: Assembly Tool X

113.95 112.0 10.5 10.0 16.0 1.95 111.5 109.0 17.0 10.0 22.0 12.0 11.0 107.75 104.0 25.5 13.0 32.0 17.0 16.0 3.75 123.5 117.5 34.0 15.0 45.0 21.0 22.5 15.0 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 38: Assembly Tool Y

8.0 13.0 17.0 1.0 15.0 25.0 2.6 15.0 M5 200 15.0 26.0 13.0 8.0 21.0 27.0 1.0 20.0 36.0 5.1 20.0 M8 Assembly tool Y, part 2 (Dimensions in mm) PZH-plus 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 39: Servicing And Assembling The Module

7.6 Assembly drawing The following figure is an example image. It serves for illustration and assignment of the spare parts. Variations are possible depending on size and variant. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 40 Wearing part, replace during maintenance. Included in the seal kit. Seal kit can only be ordered completely. Positions are adapted to each other and can not be replaced by the customer. 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

-

Page 41: Translation Of Original Declaration Of Incorporation

Person authorized to compile the technical documentation: Robert Leuthner, Address: see manufacturer's address Lauffen/Neckar, August 2022 p.p. Ralf Winkler; Head of Technology & Engineering, Mechanics Gripping Systems 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... -

Page 42: Annex To Declaration Of Incorporation

Risks due to falling or ejected objects 1.3.4 Risks due to surfaces, edges or angles 1.3.5 Risks related to combined machinery 1.3.6 Risks related to variations in operating conditions 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504... - Page 43 Risk of slipping, tripping or falling 1.5.16 Lightning Maintenance 1.6.1 Machinery maintenance 1.6.2 Access to operating positions and servicing points 1.6.3 Isolation of energy sources 1.6.4 Operator intervention 1.6.5 Cleaning of internal parts 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

- Page 44 Supplementary essential health and safety requirements for machinery intended for underground work Supplementary essential health and safety requirements for machinery presenting particular hazards due to the lifting of persons 06.00 | PZH-plus | Assembly and Operating Manual | en | 389504...

- Page 48 Original operating manual SCHUNK GmbH & Co. KG Clamping and gripping technology Bahnhofstr. 106 - 134 D-74348 Lauffen/Neckar Tel. +49-7133-103-0 Fax +49-7133-103-2399 info@de.schunk.com schunk.com Folgen Sie uns I Follow us...

Need help?

Do you have a question about the PZH-plus and is the answer not in the manual?

Questions and answers