Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MR MESSKO MFLOC 2.0

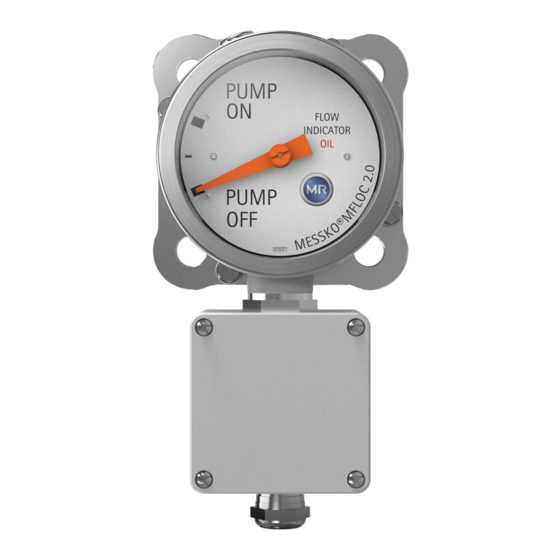

- Page 1 Flow Indicator ® MESSKO MFLOC 2.0 Operating Instructions BA6500372-01 EN...

- Page 2 © All rights reserved by Messko GmbH Dissemination and reproduction of this document and use and disclosure of its content are strictly prohibited unless expressly permitted. Infringements will result in liability for compensation. All rights reserved in the event of the granting of patents, utility models or designs. The product may have been altered since this document was published.

-

Page 3: Table Of Contents

Table of contents Introduction................ 5 Manufacturer.................. 5 Safekeeping.................. 5 Notation conventions ............... 5 1.3.1 Hazard communication system .............. 5 1.3.2 Information system.................. 7 1.3.3 Instruction system .................. 7 1.3.4 Typographic conventions ................ 8 Safety.................. 9 Intended use .................. 9 Fundamental Safety Instructions ........... 10 Personnel qualification.............. - Page 4 Table of contents Electrically connecting the micro-switches ........ 24 5.3.1 Cable recommendation ................ 24 5.3.2 Connection via terminal box............... 25 5.3.3 Connection via ANSI plug / MIL plug ............ 27 Tests .................... 28 Removal................ 29 Maintenance and care ............ 32 Disposal................ 33 Technical data.............. 34 Drawings ................ 38 10.1 10120555..................

-

Page 5: Introduction

1 Introduction This technical document contains detailed descriptions on the safe and proper installation, connection, commissioning and monitoring of the prod- uct. This technical document is intended solely for specially trained and autho- rized personnel. 1.1 Manufacturer The product is manufactured by: Messko GmbH Gewerbegebiet An den Drei Hasen Messko-Platz 1... - Page 6 1 Introduction 1.3.1.1 Warning relating to section Warnings relating to sections refer to entire chapters or sections, sub-sec- tions or several paragraphs within this technical document. Warnings relat- ing to sections have the following format: WARNING Type of danger! Source of the danger and its consequences. ►...

-

Page 7: Information System

1 Introduction Pictograms warn of dangers: Pictogram Definition Warning of a danger point Warning of dangerous electrical voltage Warning of combustible substances Warning of a tipping hazard Warning of a hot surface Table 2: Pictograms used in warning notices 1.3.2 Information system Information is designed to simplify and improve understanding of particular procedures. -

Page 8: Typographic Conventions

1 Introduction Single-step instructions Instructions which consist of only a single process step are structured as fol- lows: Aim of action ü Requirements (optional). ► Step 1 of 1. ð Result of step (optional). ð Result of action (optional). Multi-step instructions Instructions which consist of several process steps are structured as follows: Aim of action ü... -

Page 9: Safety

2 Safety This technical document contains detailed descriptions on the safe and proper installation, connection, commissioning and monitoring of the prod- uct. ▪ Read this technical file through carefully to familiarize yourself with the product. ▪ This technical file is a part of the product. ▪... -

Page 10: Fundamental Safety Instructions

2 Safety 2.2 Fundamental Safety Instructions To prevent accidents, disruptions and damage as well as unacceptable ad- verse effects on the environment, those responsible for transport, installa- tion, operation, maintenance and disposal of the product or parts of the prod- uct must ensure the following: Personal protective equipment Loosely worn or unsuitable clothing increases the danger of becoming... - Page 11 2 Safety Safety markings Warning signs and safety information plates are safety markings on the product. They are an important aspect of the safety concept. Safety mark- ings are depicted and described in the chapter "Product description". ▪ Observe all safety markings on the product. ▪...

- Page 12 2 Safety Electrically skilled person The electrically skilled person has a technical qualification and therefore has the required knowledge and experience, and is also conversant with the ap- plicable standards and regulations. The electrically skilled person is also pro- ficient in the following: ▪...

- Page 13 2 Safety E-mail: service@reinhausen.com Internet: www.reinhausen.com 2.4 Personal protective equipment Personal protective equipment must be worn during work to minimize risks to health. ▪ Always wear the personal protective equipment required for the job at hand. ▪ Never wear damaged personal protective equipment. ▪...

- Page 14 2 Safety Hard hat To protect from falling and flying parts and mate- rials. Hearing protection To protect from hearing damage. Protective gloves To protect from mechanical, thermal, and electri- cal hazards. BA6500372-01 EN...

-

Page 15: Product Description

3 Product description This chapter contains an overview of the design and function of the product. 3.1 Scope of delivery The product is packaged with protection against moisture and is delivered as follows: ▪ Flow indicator ▪ Fastening materials ▪ Gasket ▪... - Page 16 3 Product description The micro-switches installed in the flow indicator are designed as changeover contacts, which you can electrically connect using either a termi- nal box or an ANSI plug / MIL plug. Figure 1: MESSKO® MFLOC 2.0 1 Nameplate 2 Pressure equalization element 3 Marking for mounting position 4 Paddle 5 Grounding screw...

-

Page 17: Packaging, Transport And Storage

4 Packaging, transport and storage 4.1 Purpose The packaging is designed to protect the packaged product during transport, loading, unloading and during periods of storage in such a way that no detri- mental changes occur. The packaging must protect the goods against per- mitted transport stresses such as vibration, knocks and moisture (rain, snow, condensation). - Page 18 4 Packaging, transport and storage Every delivered shipment must be checked for the following by the recipient before acceptance (acknowledgment of receipt): ▪ Completeness based on the delivery slip ▪ External damage of any kind. The checks must take place after unloading, when the box or transport con- tainer can be accessed from all sides.

-

Page 19: Further Transport

4 Packaging, transport and storage 4.5 Further transport Use the original product packaging for further transport. If you transport the product to the final installation site in a mounted state, observe the following information in order to protect the product against me- chanical damage due to external influences. -

Page 20: Mounting

5 Mounting DANGER Electric shock! Danger of death due to electrical voltage when assembling the device. ► Switch off transformer on high and low-voltage side. ► Lock transformer to prevent unintentional restart. ► Make sure that everything is de-energized. ► Visibly connect all transformer terminals to ground (grounding leads, grounding disconnectors) and short circuit them. - Page 21 5 Mounting Therefore, make sure of the following: ▪ Flanges – Flush and even – Evenness deviation ≤ 0.2 mm ▪ Sealing surface of the flanges – Clean and undamaged – Without any damage along the radial surface such as scratches or points of impact –...

-

Page 22: Fastening The Flow Indicator To A Pipe

5 Mounting 5.2 Fastening the flow indicator to a pipe There are various versions of the flow indicator, depending on various factors (e.g. coolant used, electrical connection, flange design). The display part and transmitter part are adjusted to one another at the factory and have identical serial numbers. Only attach transmitter parts and display parts together that have identical serial numbers. - Page 23 5 Mounting Proceed as follows to fasten the flow indicator to the pipe: 1. Loosen the screws on the display part and remove the display part from the transmitter part. Figure 4: Removing the display part 2. Fasten the transmitter part with gasket on the flange such that the im- printed arrow points in the flow direction of the cooling medium.

-

Page 24: Electrically Connecting The Micro-Switches

5 Mounting the pointer is not pointing to PUMP OFF, remove the display part from the transmitter part and turn the magnet on the bottom of the display part until the pointer points to PUMP OFF. Screw the display part back onto the transmitter part. -

Page 25: Connection Via Terminal Box

5 Mounting The cables used must be flame-resistant in accordance with IEC 60332-1-2 or UL 2556 VW-1. Cable Termi- Conductor cross-section / cable diameter nals External protective con- ≥ all other wires ductor Wires for connection via 12/11/1 Standard device version: 6 x 0.25 mm …... - Page 26 5 Mounting 5. Tighten the cable gland (wrench size 24, 10 Nm). 6. Put the cover on the terminal box and tighten the cross recessed head screws (bit size PH 2) crosswise with a torque of 3 Nm. 7. Ground the flow indicator using a grounding cable with a ring-type cable socket.

-

Page 27: Connection Via Ansi Plug / Mil Plug

5 Mounting 5.3.3 Connection via ANSI plug / MIL plug 1. Attach the socket with the cable to the plug. Hold the cable tightly and turn the socket clockwise as far as it will go. Figure 9: ANSI plug Figure 10: MIL plug BA6500372-01 EN... -

Page 28: Tests

5 Mounting 2. Ground the flow indicator using a grounding cable with a ring-type cable socket. The copper-aluminum washer must be on the display part here. Figure 11: Ground connection 5.4 Tests After installing the flow indicator, check to make sure the flange joint is sealed and the micro-switches function correctly. -

Page 29: Removal

6 Removal DANGER Electric shock! Danger of death due to electrical voltage when assembling/ disassembling the device. ► Switch off transformer on high-voltage side and low-voltage side. ► Lock transformer to prevent unintentional restart. ► Make sure that everything is de-energized. ►... - Page 30 6 Removal 5. Loosen the screws on the display part and remove the display part from the transmitter part. Figure 12: Removing the display part 6. To install a new display part on the existing transmitter part, continue to Fastening the flow indicator to a pipe [►Section 5.2, Page 22]. If you also have to remove the transmitter part, proceed as follows.

- Page 31 6 Removal 3. Install new transmitter part, see Assembly [►Section 5, Page 20]. 4. Alternatively, close off the open flange with a suitable dummy flange. BA6500372-01 EN...

-

Page 32: Maintenance And Care

3. Check the device function (signaling and switches), see Tests [►Section 5.4, Page 28]. In the event of questions or irregularities, contact the Technical Service de- partment: Maschinenfabrik Reinhausen GmbH MR Service & Complaint Falkensteinstrasse 8 93059 Regensburg, Germany E-mail: service@reinhausen.com or complaint@reinhausen.com BA6500372-01 EN... -

Page 33: Disposal

8 Disposal Observe the national disposal regulations in the country of use. BA6500372-01 EN... -

Page 34: Technical Data

9 Technical data Basic materials Housing / terminal box Aluminum alloy, RAL 7033 or 7038, powder- coated in accordance with DIN EN ISO 12944 part 9, class C4H or CX Mounting flange Aluminum alloy Paddle Glass fiber-reinforced plastic / polyamide copoly- mer, 50% glass fiber Indicator dial Aluminum, matted, anodized Color: black text on white indicator dial or white... - Page 35 9 Technical data Flange gasket Material NBR for mineral insulating oil FPM (Viton) for alternative insulating fluids EPDM for water Material hardness 75 shore Micro-switches Number and type 2 changeover contacts, electrically isolated, fixed setting Max. contact rating with resis- Utilization category AC-12;...

- Page 36 9 Technical data ANSI plug / MIL plug Cable type 6 x AWG16, SOOW, 600 V Electrical connection MIL plug Terminal box ANSI plug Minimum flow speed for the flow indicator to respond Nomi- Piping interior diam- Minimum flow speed Oil flow rate for the flow nal di- eter in accordance for the flow indicator...

- Page 37 9 Technical data Offshore model Paint of terminal box as per DIN EN ISO 12944 Part 9, Protection class CX Unpainted parts made from stainless steel BA6500372-01 EN...

-

Page 38: Drawings

10 Drawings BA6500372-01 EN... - Page 39 110 4.33" 3.11" 123 4.84" 85 3.35" O 14,5 .57" SERIAL NUMBER TRANSFORMER ACCESSORIES DIMENSION IN mm FLOW INDICATOR MFLOC SHEET MATERIAL NUMBER EXCEPT AS VERSION WITH MIL CONNECTOR 101205891E NOTED...

- Page 40 82 3.25" 123 4.84" 85 3.35" max. [4.57"] 79 3.09" 60 2.36" M20 x 1,5 80 3.15" 3.11" 3/4" NPT SERIAL NUMBER TRANSFORMER ACCESSORIES DIMENSION IN mm FLOW INDICATOR MFLOC SHEET MATERIAL NUMBER EXCEPT AS VERSION WITH TERMINAL BOX 101205871E NOTED...

- Page 41 110 4.33" 3.11" 123 4.84" 85 3.35" O 14,5 .57" SERIAL NUMBER TRANSFORMER ACCESSORIES DIMENSION IN mm FLOW INDICATOR MFLOC SHEET MATERIAL NUMBER EXCEPT AS VERSION WITH ANSI CONNECTOR 101205881E NOTED...

- Page 44 Messko GmbH Gewerbegebiet An den Drei Hasen Messko-Platz 1 61440 Oberursel, Germany +49 (0)6171 6398 0 +49 (0)6171 6398 98 messko-info@reinhausen.com www.reinhausen.com/messko ® BA6500372-01 EN - MESSKO MFLOC 2.0 - F0372801 - 06/19 - Messko GmbH 2019 THE POWER BEHIND POWER.

Need help?

Do you have a question about the MESSKO MFLOC 2.0 and is the answer not in the manual?

Questions and answers