Table of Contents

Advertisement

Quick Links

Copyright

All of the information herein is the exclusive proprietary property of Maxcess International, and is

disclosed with the understanding that it will be retained in confidence and will neither be

duplicated nor copied in whole or in part nor be used for any purpose other than for which

disclosed. Copyright 2004, all rights reserved. Periodically there will be updates to this manual.

The latest version is available on our website or by calling the number on the back of this

publication.

Handling

Handle and install with care. This is a precision-assembled unit with close internal clearances.

Magnetic materials used are brittle by nature. Avoid subjecting to shock loads. DO NOT DROP.

Installation

Perma-Tork hollow shaft units are easily adaptable for use as either a clutch or brake. As a

clutch, either the hollow shaft or the housing can be the input. The unit mounts on a shaft, and a

convenient bolt circle and a pilot diameter provide ease of attachment to a gear, pulley, etc. A

stub shaft adapter can be used where a solid shaft interface is required.

Brake Units

HB6-1

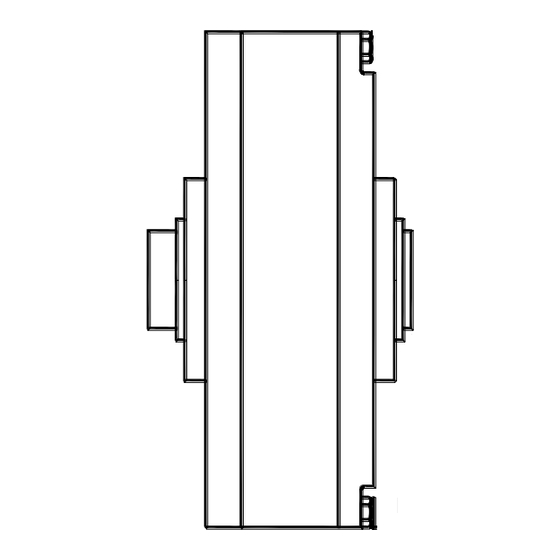

1. Brake units must be securely mounted to a

mounting bracket or plate, using three

¼-20 screws and lockwashers (see "A" in

Figure 1and Figure 4).

Locking bolts and spanner wrench holes

must be readily accessible for adjustment.

(See Figure 4.)

2. Mount sheave, pulley, or sprocket to output

shaft as shown in Figure 1.

www.maxcessintl.com

HB6-1,HC6-58,HC6-34

MAGPOWR Perma-Tork®

HB6-1, HC-58, HC6-34

Instruction Manual

Figure 1

Figure 1

MI 850A116 1 D

Page 1 of 4

Advertisement

Table of Contents

Summary of Contents for Maxcess MAGPOWR Perma-Tork HB6-1

- Page 1 MAGPOWR Perma-Tork® Copyright All of the information herein is the exclusive proprietary property of Maxcess International, and is disclosed with the understanding that it will be retained in confidence and will neither be duplicated nor copied in whole or in part nor be used for any purpose other than for which disclosed.

- Page 2 Clutch Units HC6-58 and HC6-34 Clutch units are designed to fit NEMA 56C motors with keyed 5/8" or 3/4" output shafts. 1. Drill two 0.18 inch diameter clearance holes in sheave or pulley 90º apart for access to set screws in clutch shaft. 2.

- Page 3 Adjusting Torque Generally, this should be done while the unit is firmly and properly mounted in place. The exception to this is when the adjustment must be done prior to mounting due to space limitations. This can be accomplished by restraining the housing and adjusting the end cap with a spanner wrench while rotating either the output shaft (brake) or input member (clutch).

- Page 4 AND AFRICA AND SE ASIA Tel +1.405.755.1600 Tel +86.756.881.9398 Tel +91.22.27602633 Tel +81.43.421.1622 Tel +49.6195.7002.0 asia@maxcessintl.com Fax +1.405.755.8425 Fax +86.756.881.9393 Fax +91.22.27602634 Fax +81.43.421.2895 Fax +49.6195.7002.933 www.maxcess.asia sales@maxcessintl.com info@maxcessintl.com.cn india@maxcessintl.com japan@maxcessintl.com sales@maxcess.eu www.maxcessintl.com www.maxcessintl.com.cn www.maxcess.in www.maxcess.jp www.maxcess.eu © 2018 Maxcess...

Need help?

Do you have a question about the MAGPOWR Perma-Tork HB6-1 and is the answer not in the manual?

Questions and answers