Allied Systems W8L Operating Manual

Towing winch for caterpillar dozers

Hide thumbs

Also See for W8L:

- Service manual (176 pages) ,

- Operating manual (74 pages) ,

- Quick start manual (2 pages)

Table of Contents

Advertisement

Quick Links

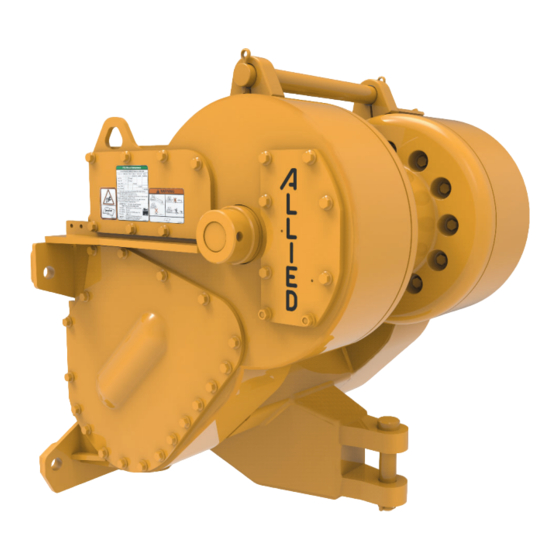

Operating Manual

W8L

Towing Winch

for Caterpillar Dozers

This manual must be with the vehicle

on which this winch is installed.

Please check the Allied Systems website

regularly for updates to this manual.

www.alliedsystems.com

A Product of

A Product of

Applicable to winches with serial number AW8L***3900*** and later.

Sherwood, OR USA

P/N 599018W-CAT

Printed in U.S.A.

5/28/2020

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Allied Systems W8L

- Page 1 Operating Manual Towing Winch for Caterpillar Dozers This manual must be with the vehicle on which this winch is installed. Please check the Allied Systems website regularly for updates to this manual. www.alliedsystems.com A Product of A Product of Applicable to winches with serial number AW8L***3900*** and later.

- Page 2 Serial Number Winch Model Date Installed Date Delivered Special Equipment or Attachments A Product of Allied Systems Company 05/28/2020 Sherwood, Oregon Printed in U.S.A. U.S.A.

-

Page 3: Foreword

Operating Manual, contact your local winch dealer, in good condition. or contact Allied Systems Company: • Read and understand the SAFETY SUMMARY and OPERATING PROCEDURES contained in this Allied Systems Company Operating Manual. - Page 4 Should there be differences in interpretations to the text, please refer to the English language edition published by Allied Systems Company as the controlling document.

-

Page 5: Table Of Contents

Nameplate ..............2 Operating Procedures ..........18 Wire Rope Selection ..........3 Power Operation .............21 Recommended Oil List & Oil Capacity .....4 Inching ..............22 W8L Winch Description ..........5 Troubleshooting Chart ..........23 Optional Equipment ..........6 Serial Number Codes ..........7 Maintenance Maintenance ............27 Dozer Identifi cation and Gear Ratios ....8 Maintenance Points ..........27... -

Page 6: Contents

Contents (continued) Operating Techniques, Power Controls Operational Differences, Optional Equipment Dozer or Skidder Operation ........31 Fairlead ..............44 Drawbar ..............44 Operating Techniques, Electronic Controls Optional Gear Ratios ..........44 Dozer or Skidder Operation ........35 Operating Techniques, General How To Move A Disabled Vehicle......39 Working on A Steep Slope ........41 Tractor Is Down The Slope .......41 Other Equipment Is Down The Slope ....42... -

Page 7: Safety Summary

Safety Summary Safety Summary General Safety Notices WARNING The following pages contain general safety warnings which supplement specific warnings and cautions T h e “ WA R N I N G ” s y m b o l a p p e a rs appearing elsewhere in this manual. - Page 8 NOTE: All possible safety hazards cannot NOTICE be foreseen so as to be included in this manual. Therefore, you must always This signal word alerts to a situation that be alert to potential hazards that could is not related to personal injury but may endanger personnel and/or damage the cause equipment damage.

- Page 9 Safety Summary » Do not work with a damaged or worn wire rope. Obey the following cautions and warnings before using your winch to » Do not use a winch that needs repairs. avoid equipment damage, personal » If the wire rope and ferrule must be removed from injury or death.

- Page 10 • Do not leave the vehicle when the winch wire rope • Always inspect wire rope, tail chain and other rigging is under tension. components for wear, damage, broken strands or abuse before use. • Do not permit riders on the vehicle or load. •...

- Page 11 • Replace any parts only with genuine Allied Winch parts. Refer to W8L Parts Manual (P/N 599781W). • Do not attempt to pull loads in excess of the rated capacity of the winch.

- Page 12 » Infection and gangrene are possible when • This winch is neither intended, designed, nor rated for any application involved in the lifting or moving hydraulic oil penetrates the skin. See a doctor of personnel. immediately to prevent loss of limb or death. •...

-

Page 13: General

This Operating Manual contains basic information Removable covers on the winch case allow access for repairs and adjustments. necessary for the operation and maintenance of the W8L winch. When PTO is rotating, the hydraulic pump shaft is also rotating. Oil from the hydraulic pump is used to cool How the Winch Operates and lubricate the winch components. -

Page 14: Nameplate

Nameplate Each winch is shipped from the factory with a nameplate as shown in Figure 1. The nameplate is stamped with: • winch model • winch serial number • maximum bare drum line pull • maximum wire rope diameter DO NOT operate the winch with larger diameter wire rope. If the nameplate is missing, DO NOT operate the winch until its capacity is known. -

Page 15: Wire Rope Selection

General Wire Rope Selection WARNING Each winch model can have a variety of wire rope sizes Load loss hazard. installed by the user. The maximum wire rope size is shown on the nameplate. See Figure 2 for approved wire rope A loaded wire rope with fewer than sizes and drum capacities. -

Page 16: Recommended Oil List & Oil Capacity

Recommended Oil List and Oil Capacity The type of oil used in Allied winches affects the line control. Use the following oils in the W8L winch: Recommended Oils* - General Conditions Ambient Temperature Range Manufacturer Oil Type °F °C ExxonMobil... -

Page 17: W8L Winch Description

15. Drawbar Pin Access Cover to Hydraulic System 10. Intermediate Shaft Bearing Retainer 16. Clutch Shaft Retainer Plug to Check Oil Level 11. Drum Shaft Bearing Retainer 17. Brake Shaft Retainer Plug to Drain Oil 12. Drawbar Figure 5 - W8L Winch... -

Page 18: Optional Equipment

Optional Equipment (See also Page 46 for details) • Alternate gear ratio - To allow better line speed control; • Electronic controls - Line control. The W8L winch may be equipped with the following options: NOTE: Not all optional equipment listed is available for each model of dozer. -

Page 19: Serial Number Codes

1555 Seals Manufactured By Blank = Standard Seals S = Extreme Duty Seals A = Allied Systems Company Vehicle Code Winch Model See Figure 7 W8L = Standard K8L = Special Design (Contact Factory) Sequence Number... -

Page 20: Dozer Identifi Cation And Gear Ratios

Figure 7 - Dozer Identifi cation and Gear Ratios Tractor Make Model and Starting Tractor Serial Number Where Applicable Caterpillar D6GC D7R SERIES II D7 BUILD 17A ... -

Page 21: Operation, Power Controls

Operation, Power Controls Operation, Power Controls Checks Before Operation Operating Procedures • Check that the wire rope and hook are not worn or The control lever assembly is connected to the winch damaged. Check that the periodic inspection and through a control cable to the control valve spool. This maintenance have been done at the recommended lever is used to select one of the following operations: operating hours. - Page 22 The BRAKE-OFF position is a detent position, and the control lever must be pulled back to the BRAKE-ON (neutral) position. Hydraulic pressure is applied to release the brake. The winch will not rotate easily because of friction in the clutches, the brake and the gear train. Wire rope cannot be pulled from the winch by hand.

-

Page 23: Power Operation

Operation, Power Controls Power Operation BRAKE-ON position is a neutral position. Neither clutch LINE-OUT position applies the LINE-OUT clutch and is applied. The brake is fully applied. releases the brake. The winch will unwind the wire rope at a speed controlled by the PTO speed of the dozer and the weight of the load. - Page 24 Inching is used for a fi ne control of the winch speed. When the power control lever is slowly moved to a position between BRAKE-ON and LINE-IN or between BRAKE-ON and LINE-OUT, inching occurs. The normal adjustment of inching for LINE-IN is different from the adjustment for LINE-OUT.

-

Page 25: Troubleshooting Chart

Operation, Power Controls Troubleshooting Analysis Chart PROBLEM POSSIBLE CAUSE CORRECTION Operation is rough or not regular. Hydraulic oil is too cold. Put the control lever in the BRAKE-OFF position, and run the engine at 1000 rpm to warm the oil to 80°F before operating the winch. - Page 26 PROBLEM POSSIBLE CAUSE CORRECTION Use the BRAKE-OFF position less. Winch has been operated in the Hydraulic oil becomes too hot. When the BRAKE-OFF position is used, BRAKE-OFF position for long the hydraulic oil fl ows continuously periods. through the relief valve. See the Service Manual for additional troubleshooting.

- Page 27 Operation, Power Controls PROBLEM POSSIBLE CAUSE CORRECTION Worn or damaged clutch. See the Service Manual for additional Clutch does not apply troubleshooting, checks and correctly. Control valve or control cable adjustments. needs adjustment. Low oil pressure. Accumulator not charged. Clutch does not apply correctly Check accumulator.

- Page 28 Intentionally Blank...

-

Page 29: Operation, Electronic Controls

Operation, Electronic Controls Operation, Electronic Controls Checks Before Operation Checks During Operation • Check that the wire rope and hook are not worn or • Check the winch indication light: damaged. - Any blinking indicates a problem. • Check that the periodic inspection and maintenance have been done at the recommended operating hours. -

Page 30: Operating Procedures

Operating Procedures This control lever is used to select one of the following operations: The electronic control lever is connected to the winch through electrical wiring, an electronic control module, • BRAKE-OFF and a solenoid actuated control valve. A winch activation •... - Page 31 Operation, Electronic Controls Consult Service Manual Brake for Error Codes Brake Line Line Brake Blade Figure 10-1 Control Lever...

- Page 32 Winch On LED Off Winch Off LED On Winch Off and Error + Error Code Below, Repeating Detected Oil Filter Bypassing Line‐In Coil Fault Timing Line‐Out Coil Fault 1/4 Second Pulse Brake Release Coil Fault 1/2 Second Pulse 1 Second Pulse Accumulator Coil Fault 3 Second Pulse Cooling Oil Coil Fault...

-

Page 33: Power Operation

Operation, Electronic Controls Operation BRAKE-ON is a neutral position. Neither clutch is applied. The brake is fully applied. LINE-IN position applies the forward clutch and releases the brake. The winch will wind the wire rope at a speed Note: Grey dots controlled by the PTO rpm of the dozer and the weight represent the of the load. -

Page 34: Inching

Inching is used for fi ne control of the winch speed. When BRAKE ON the control lever is slowly moved to a position between Neutral BRAKE-ON and LINE-IN or between BRAKE-ON and LINE OUT LINE IN LINE-OUT, inching occurs. The following paragraphs describe the normal procedures for inching. -

Page 35: Troubleshooting Chart

Operation, Electronic Controls Troubleshooting Chart PROBLEM POSSIBLE CAUSE CORRECTION Operation is rough or irregular. Hydraulic oil is too cold. Put the control lever in the BRAKE-OFF position. Run the engine at 1000 rpm to warm the oil before operating the winch. Low oil level. - Page 36 PROBLEM POSSIBLE CAUSE CORRECTION Brake begins to release before Brake is worn. See the Service Manual for additional clutch is applied. troubleshooting. Winch brake does not apply or Brake is worn. See the Service Manual for additional release correctly. troubleshooting. Low oil pressure.

- Page 37 Operation, Electronic Controls PROBLEM POSSIBLE CAUSE CORRECTION Winch will not operate in any Control module not powered. Check fuse & replace if necessary. function. Control module fault. Consult error codes in Figure 10-2. Coil open or shorted. Error code on joystick indicates open or shorted circuit.

- Page 38 Operation, Electronic Controls PROBLEM POSSIBLE CAUSE CORRECTION Noisy buzz emanating from Air in relief cartridge. This is not a detrimental condition. Noise winch. may be intermittent. Control lever will not detent in Detent pin, plate, or spring worn or Replace control lever. BRAKE-OFF.

-

Page 39: Maintenance

Use the operating Maintenance Points Access Cover for Control Valve Cover for Filter & Strainer Plug to Check Oil Level Fill Plug Plug to Drain Oil Breather Figure 13 - W8L Winch Maintenance Points... -

Page 40: Maintenance Schedule

Maintenance Schedule INTERVAL PROCEDURE OR QUANTITY SPECIFICATION 50 hours or weekly. Check oil level at plug (item 2). Add oil as See Figure 3 – Recommended Oil List. necessary through fi ll plug (item 5). Do not operate dozer when checking the oil level. Check winch control lever (cable controls). - Page 41 Maintenance INTERVAL PROCEDURE OR QUANTITY SPECIFICATION 1000 hours or every 6 Change the hydraulic oil. Drain oil from plug See Figure 3 – Recommended Oil List. months. (item 3). Clean the oil strainer. Through fi ll plug † (item 5), add 20 gallons (75 liters) .

-

Page 42: Control Cable Adjustment

Control Cable Adjustment Check the operation of the power control lever to make sure it moves smoothly and will return to the BRAKE-ON position. The power control lever will stay in BRAKE-OFF when pushed into DETENT position. Make sure the control lever does not hit the housing at the end of its travel. -

Page 43: Operating Techniques, Power Controls

Operating Techniques, Power Controls Operating Techniques, Power Controls Dozer or Skidder Operation Note: Black dots indicate the position of the control levers. Step 1. The dozer or skidder is moved to an area where Step 2. A load (logs) is connected to the wire rope. a load will be connected. - Page 44 Step 3. The operator can move the control lever to the Step 4. If the dozer or skidder must travel through an LINE-IN position. If the load is less than approximately area with bad traction conditions, the operator can move 75% of the maximum line pull, the operator can begin the control lever to the BRAKE-OFF (DETENT) position.

- Page 45 Operating Techniques, Power Controls Step 5. When the vehicle is on fi rm ground, the operator Step 6. When the operator wants to disconnect from the can move the control lever to LINE-IN position to pull the load, the vehicle is stopped and the control lever is moved load toward the vehicle.

- Page 46 Intentionally Blank...

-

Page 47: Operating Techniques, Electronic Controls

Operating Techniques, Electronic Controls Operating Techniques, Electronic Controls Dozer or Skidder Operation BRAKE-ON LINE-OUT Step 1. The dozer or skidder is moved to an area Step 2. A load (logs) is connected to the wire rope. The where a load will be connected. The operator turns on operator moves the control lever to the BRAKE-ON the activation switch, and moves the control lever to the position. - Page 48 LINE-IN BRAKE-OFF Step 3. The operator can move the control lever to the Step 4. If the dozer or skidder must travel through an LINE-IN position. If the load is less than approximately area with bad traction conditions, the operator can move 75% of the maximum line pull, the operator can begin the control lever to either of the BRAKE-OFF (DETENT) traveling with the vehicle at the same time.

- Page 49 Operating Techniques, Electronic Controls LINE-IN BRAKE-OFF Step 5. When the vehicle is on fi rm ground, the operator Step 6. When the operator wants to disconnect from can move the control lever to LINE-IN position to pull the the load, the vehicle is stopped and the control lever is load toward the vehicle.

- Page 50 Intentionally Blank...

-

Page 51: Operating Techniques, General

Operating Techniques, General How to Move a Disabled Vehicle 4. If the vehicle travels faster than the winch winds the wire rope, disengage the transmission until the winch A. A vehicle equipped with a winch can be used to remove wire rope is tightened again. - Page 52 B. A dozer or skidder equipped with a winch can be used 1. Fasten the winch wire rope to the tow bar of the other to pull another vehicle from mud or other areas where it vehicle. The wire rope must be in a direction that is cannot move using only the drive wheels or tracks.

-

Page 53: Working On A Steep Slope

Working on a Steep Slope dozer, a structure or a tree that has enough strength to hold the dozer on the slope. WARNING A. Moving down the slope: Death or equipment loss hazard. 1. Set the throttle on the dozer for the required engine speed. -

Page 54: Other Equipment Is Down The Slope

Operating Techniques, General B. Moving up the slope: Other Equipment is Down the Slope (See Figure 20). 1. Set the throttle on the dozer for the required engine In this operation, the dozer and winch are on stable ground speed. and other equipment is working on a steep slope. - Page 55 A. Lowering the equipment on the slope: B. Raising the equipment on the slope: 1. Set the throttle on the dozer for the required engine 1. Set the throttle on the dozer for the required engine speed. Operator experience is required for this speed.

-

Page 56: Operational Differences, Optional Equipment

Operational Differences, Optional Equipment Operational Differences, Optional Equipment Fairlead Drawbar A fairlead consists of a set of top and bottom horizontal Do not use the drawbar as an anchor point for a two-part rollers and side rollers that the wire rope is fed through. line from the winch. - Page 58 To fi nd a dealer in your area, Call: 503.625.2560, Fax: 503.625.7269, or Email: marketing@alliedsystems.com, or 599018W-CAT 05/28/2020 Printed in U.S.A. Visit our website: www.alliedsystems.com...

Need help?

Do you have a question about the W8L and is the answer not in the manual?

Questions and answers