Summary of Contents for Fuji Electric IGBT-IPM X Series

- Page 1 Fuji 7 Generation IGBT-IPM X Series Application Manual Oct. 2021 MT6M MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 2 No right or license, either express or implied, under any patent, copyright, trade secret or other intellectual property right owned by Fuji Electric Co., Ltd. is (or shall be deemed) granted. Fuji Electric Co., Ltd. makes no representation or warranty, whether express or implied, relating to the infringement or alleged infringement of other's intellectual property rights which may arise from the use of the applications described herein.

- Page 3 If the product had been used in the environment with acid, organic matter, and corrosive gas (hydrogen sulfide, sulfurous acid gas), the product's performance and appearance can not be ensured easily. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 4: Table Of Contents

2. Important remarks 3. Optocoupler peripheral circuits 4. Connector 4-10 Chapter 5 Cooling Design 1. Guidelines for heat sink selection 2. Notice for heat sink selection 3. Mounting instruction of the IPM MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 5 1. Main power supply 2. Control power supply 3. Protection functions 4. Power cycling capability 5. Others Chapter 7 Troubleshooting 1. Troubleshooting 2. Failure tree analysis charts 3. Alarm factor tree analysis chart MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 6: Chapter 1 Features And Structure

Chapter 1 Features and structure 1. Features of the IGBT-IPM 2. Part number and lot No. 3. Line-up 4. Features of each package 5. Structure 1-15 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 7: Features Of The Igbt-Ipm

IPM is stopped by the over heating protection function. In addition, it is possible to prevent a decrease in productivity due to a sudden equipment shutdown. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 8: Part Number And Lot No

6: without MBP: Intelligent X: X series x 1 (A) A:P629 brake power module (IPM) (7th Gen.) x1/10 (V) 7: with X series B:P626 brake (RC-IGBT) D:P630 E:P631 F:P636 G:P638 H:P639 J:P644 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 9 2: February 20: 2020 21: 2021 9: September O: October N: November D: December Fig.1-1 shows an example of product indication for X series IPM. Production base Data matrix Fig.1-1 Indication ex.)6MBP50XBA120-50 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 10: Line-Up

P638 6MBP100XGN065-50 6MBP150XGN065-50 6MBP50XDA065-50 7MBP50XDA065-50 6MBP75XDA065-50 7MBP75XDA065-50 6MBP100XDA065-50 7MBP100XDA065-50 6MBP100XDN065-50 7MBP100XDN065-50 6MBP150XDA065-50 7MBP150XDA065-50 P630 6MBP150XDN065-50 7MBP150XDN065-50 6MBP200XDA065-50 7MBP200XDA065-50 6MBP200XDN065-50 7MBP200XDN065-50 6MBP250XDA065-50 7MBP250XDA065-50 6MBP250XDN065-50 7MBP250XDN065-50 6MBP200XEN065-50 7MBP200XEN065-50 P631 6MBP300XEN065-50 7MBP300XEN065-50 6MBP450XEN065-50 7MBP450XEN065-50 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 11 6MBP75XGN120-50 6MBP25XDA120-50 7MBP25XDA120-50 6MBP35XDA120-50 7MBP35XDA120-50 6MBP50XDA120-50 7MBP50XDA120-50 6MBP50XDN120-50 7MBP50XDN120-50 6MBP75XDA120-50 7MBP75XDA120-50 P630 6MBP75XDN120-50 7MBP75XDN120-50 6MBP100XDA120-50 7MBP100XDA120-50 6MBP100XDN120-50 7MBP100XDN120-50 6MBP150XDA120-50 7MBP150XDA120-50 6MBP150XDN120-50 7MBP150XDN120-50 6MBP100XEN120-50 7MBP100XEN120-50 6MBP150XEN120-50 7MBP150XEN120-50 P631 6MBP200XEN120-50 7MBP200XEN120-50 6MBP300XEN120-50 7MBP300XEN120-50 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 12: Features Of Each Package

2. The terminal pitch is the value at the root of the terminal. 3. Dimensions in ( ) are given only for reference. 4. Terminal plating: Sn (for soldering) [Unit of dimensions:mm] Fig.1-2 Package outline drawing (P639) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 13 2. The terminal pitch is the value at the root of the terminal. 3. Dimensions in ( ) are given only for reference. 4. Terminal plating: Sn (for soldering) [Unit of dimensions:mm] Fig.1-3 Package outline drawing(P629) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 14 2. The terminal pitch is the value at the root of the terminal. 3. Dimensions in ( ) are given only for reference. 4. Terminal plating: Sn (for soldering) [Unit of dimensions:mm] Fig.1-4 Package outline drawing (P626) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 15 2. The terminal pitch is the value at the root of the terminal. 3. Dimensions in ( ) are given only for reference. 4. Terminal plating: Sn (for soldering) [Unit of dimensions:mm] Fig.1-5 Package outline drawing (P644) 1-10 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 16 2. The terminal pitch is the value at the root of the terminal. 3. Dimensions in ( ) are given only for reference. 4. Terminal plating: Sn (for soldering) [Unit of dimensions:mm] Fig.1-6 Package outline drawing(P636) 1-11 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

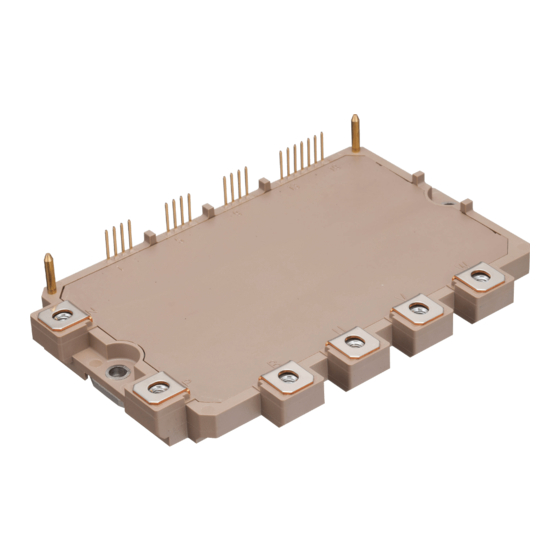

- Page 17 5. The guide pins located on both sides of a control terminal are made of brass. (They are insulated internally and are not connected to any object.) [Unit of dimensions:mm] Fig.1-7 Package outline drawing (P638) 1-12 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 18 5. The guide pins located on both sides of a control terminal are made of brass. (They are insulated internally and are not connected to any object.) [Unit of dimensions:mm] Fig.1-8 Package outline drawing (P630) 1-13 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 19 5. The guide pins located on both sides of a control terminal are made of brass. (They are insulated internally and are not connected to any object.) [Unit of dimensions:mm] Fig.1-9 Package outline drawing (P631) 1-14 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 20: Structure

14 接着剤 (プリント基板) エポキシ樹脂 (表記なし) 14 Adhesive (PCB) 15 ハンダ すず ベース (鉛フリー) Epoxy resin (表記なし) (Not shown) 15 Solder Sn base (Pb free) (Not shown) Fig.1-10 Structure and materials (P639) 1-15 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 21 14 Adhesive (Case, Base Plate) Silicone resin (Not shown) 16 ハンダ すず ベース (鉛フリー) (表記なし) 15 Adhesive (PCB) Epoxy resin (Not shown) 16 Solder Sn base (Pb free) (Not shown) Fig.1-11 Structure and materials (P629) 1-16 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 22 16 ハンダ Epoxy resin すず ベース (鉛フリー) (表記なし) (Not shown) 17 リング ステンレス鋼 16 Solder Sn base (Pb free) (Not shown) 17 Ring Stainless steel Fig.1-12 Structure and materials (P626, P644) 1-17 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 23 14 Adhesive (Case, Base Plate) Silicone resin (Not shown) 15 ハンダ すず ベース (鉛フリー) (表記なし) 15 Solder Sn base (Pb free) (Not shown) 16 リング ステンレス鋼 16 Ring Stainless steel Fig.1-13 Structure and materials (P636) 1-18 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 24 Sn base (Pb free) (Not shown) 17 ナット 鉄 三価クロメート処理 16 Ring Stainless steel 18 ガイドピン 黄銅(しんちゅう) 17 Nut Trivalent chromate treatment 18 Guide pin Brass Fig.1-14 Structure and materials (P638) 1-19 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 25 (Not shown) 17 リング ステンレス鋼 17 Ring Stainless steel 18 ナット 鉄 三価クロメート処理 18 Nut Trivalent chromate treatment 19 ガイドピン 黄銅(しんちゅう) 19 Guide pin Brass Fig.1-15 Structure and materials (P630) 1-20 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 26 17 ナット 鉄 三価クロメート処理 17 Nut Trivalent chromate treatment 18 ガイドピン 黄銅(しんちゅう) 18 Guide pin Brass 19 内部端子 黄銅(しんちゅう) ニッケルメッキ 19 Internal Terminal Brass Ni plating Fig.1-16 Structure and materials (P631) 1-21 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 27 The guide pins located on both sides of control terminal portions of P638, P630 and P631 are made of brass. They are insulated internally and are not connected to any object. 1-22 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 28 The PCB height can be set to 18.5 mm or 17.0 mm by utilizing these protrusions. (a) When the height is 18.5mm (b) When the height is 17.0mm Fig.1-18 Selecting from two different protrusion heights 1-23 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 29: Chapter 2 Description Of Terminal Marking And Terms

Chapter 2 Description of terminal marking and terms 1. Description of terminal marking 2. Description of terms MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 30: Description Of Terminal Marking

IGBT (Y) ⑮ ⑲ ⑲ Lower-arm alarm signal output * Pin (15) of P626 and P638 is WNG. * Pin (15) of P636(6in1), P630(6in1) and P631(6in1) is WNG. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 31: Description Of Terms

Maximum screw torque when connecting the main terminal and Terminal external wiring with specified screw Screw torque Maximum screw torque when mounting the IPM on heat sink with Mounting specified screw MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 32 GND of lower arm control power supply Input signal threshold Input voltage which IPM can detect as ON signal. inth(on) voltage Input voltage which IPM can detect as OFF signal. inth(off) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 33 It limits the primary side forward current of optocoupler. Warning output Value of the built-in resistance that is connected in series to warning resistance terminals. It limits the primary side forward current of optocoupler. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 34 Dissipated switching energy of the FWD during reverse recovery Input current Maximum current into the V terminals Turn-off operation when protective operation is activated. Soft shutdown ― (Softer turn-off than normal) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 35 2.6 Operation explanatory diagram d(on) d(off) Fig.2-1 Switching times Fig.2-2 Alarm signal output hold time(t MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 36 Fig.2-3 Warning Timing Diagram Fig.2-4 Overcurrent protection delay time(t MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 37 Fig.2-5 Short circuit protection delay time(t Turn-off side Turn-on side Fig.2-6 Dead time(t dead MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 38: Chapter 3 Description Of Functions

Chapter 3 Description of functions 1. List of functions 2. Description of functions 3. Truth table 4. Block diagram of IPM 5. Timing chart 3-11 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 39: List Of Functions

Drive: IGBT drive circuit, UV: Control power supply under voltage protection, : IGBT chips over heating protection, OC: Over current protection, SC: Short circuit protection, ALM: Alarm signal output, WNG: Chip temperature warning output MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 40: Description Of Functions

P and B. Voltage rise between terminal P and N can be suppressed by switching the brake IGBT. Fig.3-1 Typical application of 3-phase inverter (Example: 7MBP250XDA065-50 with built-in brake) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 41 Since the wiring length between the control IC and the IGBT in the IPM are short, the wiring impedance is small. Therefore, the IPM can be driven without reverse bias. PGND PGND ロジック回路 ロジック回路 SGND SGND Fig.3-2 Pre-Driver block diagram (Example:7MBP250XDA065-50) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 42 However, the pulse width of the alarm signal output through an optocoupler varies depending on the delay time of the optocoupler and the influence of peripheral circuits. It is necessary to take these influences into account in your design. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 43 ) elapses. During this period, the IGBT will not be turned on. Furthermore, an alarm signal to determine the UV status is provided at the time of startup and shutdown of the control power supply V MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 44 T is below (T This function is available only in the Fuji 7 generation X series IGBT-IPM in the following package. P626 , P636(6in1) , P638 , P630(6in1) , P631(6in1) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 45: Truth Table

The brake phase can operate normally even if the lower arm X, Y, and Z phases are under protection. When the protection operation is activated in the brake phase, all the lower arm phases including the brake phase go into protection state. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 46: Block Diagram Of Ipm

Figure 3-3 shows an example of P629 (6in1) without alarm functions on the upper arms. Figure 3-4 shows an example of P630 (6in1) and Figure 3-5 shows an example of P630 (7in1). Fig. 3-3 IPM block diagram (example: P629) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 47 Fig. 3-4 IPM block diagram (example: P630 (6in1)) 3-10 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 48 Fig. 3-5 IPM block diagram (example: P630 (7in1)) 3-11 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 49: Timing Chart

: Supply voltage of pre-driver : Under voltage protection level : Under voltage protection hysteresis : Input signal voltage : Alarm signal voltage : Alarm signal hold time ALM(UV) 3-12 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 50 ※1 Soft turn off : This means a slower than normal turn-off. : Supply voltage of pre-driver : Under voltage protection level : Under voltage protection hysteresis : Input signal voltage : Alarm signal voltage : Alarm signal hold time ALM(UV) 3-13 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 51 : Supply voltage of pre-driver : Under voltage protection level : Under voltage protection hysteresis : Input signal voltage : Alarm signal voltage : Alarm signal hold time ALM(UV) 3-14 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 52 : Supply voltage of pre-driver : Under voltage protection level : Under voltage protection hysteresis : Input signal voltage : Alarm signal voltage : Alarm signal hold time ALM(UV) 3-15 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 53 Fig.3-10 UV alarm output of lower arm : Supply voltage of pre-driver : Under voltage protection level : Alarm signal voltage : Alarm signal hold time ALM(UV) 3-16 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 54 ※2 Normal turn off: This means a normal turn-off operation. : Input signal voltage : Alarm signal voltage : Collector current : Over current protection level : Alarm signal hold time : Over current protection delay time ALM(OC) 3-17 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 55 ※2 Normal turn off: This means a normal turn-off operation. : Input Signal Voltage : Collector current : SC trip level : Alarm signal hold time : Short circuit protection delay time ALM(OC) 3-18 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 56 ※1 Soft turn off: This means a slower than normal turn-off. : Input signal voltage : Alarm signal voltage : Alarm signal hold time ALM(TjOH) : IGBT chips over heating protection temperature level : Over heating protection hysteresis 3-19 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 57 : Input signal voltage : Alarm signal voltage : Collector current : Alarm signal hold time ALM(TjOH) : IGBT chips over heating protection temperature level : Over heating protection hysteresis 3-20 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 58 : Alarm signal voltage : Collector current : Alarm signal hold time ALM(UV) : Alarm signal hold time ALM(TjOH) : IGBT chips over heating protection temperature level : Over heating protection hysteresis 3-21 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 59 ※1 Soft turn off: This means a slower than normal turn-off. : Alarm signal hold time : Alarm signal hold time ALM(TjOH) ALM(UV) : IGBT chips over heating protection temperature level : Over heating protection hysteresis 3-22 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 60 (1), an alarm signal is output and the switching operation is stopped. (3) : Supply voltage of pre-driver : IGBT chips over heating protection temperature level 3-23 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 61 Chapter 4 Typical application circuits 1. Typical application circuits 2. Important remarks 3. Optocoupler peripheral circuits 4. Connector 4-10 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 62 1. Typical application circuits Figure 4-1 shows the typical application circuits of P629 and P639 (6in1, only lower arm has alarm signal output function.) Fig.4-1 Typical application circuits of P629 and P639 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 63 Figure 4-2 shows the typical application circuits of P626 and P636 (6in1) (a) When using the upper arms alarm (b) When not using the upper arms alarm Fig.4-2 Typical application circuits of P626 and P638 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 64 • If the temperature warning function is not used, open the WNG terminal. If the WNG terminal is connected to the V terminal, the consumption current I increases when the temperature of the IPM reaches the temperature warning level. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 65 Figure 4-4 shows the typical application circuits of P630, P631, P636 and P644 (7in1, with built-in brake). (a) When using the upper arms alarm (b) When not using the upper arms alarm Fig.4-4 Typical application circuits of P630, P631, P636 and P644 (7in1) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 66: Important Remarks

An electrolytic capacitor which has low impedance and good frequency characteristics is recommended. In addition, it is recommended to connect a film capacitor with good frequency characteristics in parallel. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 67 Unconnected terminals (no contact terminals) are not connected inside of the IPM. These terminals are insulated from other terminals. There is no need of special treatment such as potential stabilization. Also, guide pins are not connected inside of the IPM. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 68 * The operating time of the constant current circuit (0.65 mA) is the period until V reaches V It is about 5 μs at maximum. (b) constant current operation timing Fig.4-5 IPM input circuit and constant current operation timing MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 69: Optocoupler Peripheral Circuits

PS9513 by Renesas Electronics Pay attention to safety standards such as UL and VDE. The reliability and characteristics of these optocouplers are not guaranteed by Fuji Electric. 3.1.2 Primary side current limiting resistor The current limiting resistor on the primary side should be selected so that sufficient current can flow on the secondary side. -

Page 70: Connector

TLP781-1-GR rank or TLP785-1-GR rank by Toshiba Pay attention to safety standards such as UL and VDE. The reliability and characteristics of these optocouplers are not guaranteed by Fuji Electric. 3.2.2 Input current limiting resistance The current limiting resistor for the primary side of optocoupler is built in the X-IPMs. -

Page 71: Chapter 5 Cooling Design

Chapter 5 Cooling Design 1. Guidelines for heat sink selection 2. Notice for heat sink selection 3. Mounting instruction of the IPM MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 72: Guidelines For Heat Sink Selection

• Convex (larger than +50μm): The copper base of the IPM may be deformed and the internal insulation substrate may crack due to Between screw mounting points mechanical stress. Fig.5-1 Flatness of heat sink surface MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 73: Mounting Instruction Of The Ipm

It is possible to achieve a uniform thermal grease thickness by mounting the IPM with thermal grease to the heat sink and tightening screws with the recommended torque for each product. Fuji Electric can provide recommended stencil mask designs upon customer’s request. MT6M15962a... - Page 74 Guide pins for IGBT Guide pins for Frame Guide holes for bottom tool Fig.5-2 Outline of a thermal grease application method MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 75 Table 5-1 shows the base plate area of IPMs. Table5-1 Base plate area of IPM Package Base plate area (cm P639 14.74 P629 21.71 P626, P644 22.77 P636, P638 41.17 P630 55.67 P631 141.24 MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 76 Screw position Torque Order ①→②→③→④ 1st time (initial tightening) 1/3 of specified torque ④→③→②→① 2nd time (permanent tightening) 100% of specified torque (b) IPM with 4-points mounting Fig.5-3 IPM mounting method MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 77 Please verify that the case temperature does not exceed 125°C, the chip junction temperature does not exceed 175°C and the thermal design meets the required life time of the system. Fig.5-4 Measuring the case temperature MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 78: Chapter 6 Precautions For Use

Chapter 6 Precautions for use 1. Main power supply 2. Control power supply 3. Protection functions 4. Power cycling capability 5. Others MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 79: Main Power Supply

• To prevent noise from entering from the AC line, connect a grounding capacitor of about 4700pF between each of the 3 phases of AC input and ground. • Apply measures such as provision of an arrester against lightning surge. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 80: Control Power Supply

- - The use of V <0V or >20V may cause malfunction - or damage to the device. <0, 20<V - - Never apply such voltage to the device. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 81 CTR. In order to suppress the influence of noise, design the pull-up resistor on the secondary side of the optocoupler as low as possible to lower the impedance. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 82: Protection Functions

IGBT is turned off normally. • There is no alarm signal output function in the upper arm of P629 and P639, but the OC protection works and the IGBT is turned off slowly. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 83 IGBT chip is over heated abnormally. Not building in a case over heating protection, the X- IPM is not protected against the case over heating. Please implement the protection for case over heating if necessary. 3.4 Protection of FWD • FWDs have no protection functions. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 84: Power Cycling Capability

⑥ If the IPM is restarted with a broken power chip, the protection function will not operate properly, which may result in a large-scale destruction. Do not restart the broken IPM. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 85 Please contact us if it is used for converter. ⑰ The brake section is designed on the assumption that resistance load is applied. Please contact us if it is used for inductor load or boost circuit, etc. MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 86: Chapter 7 Troubleshooting

Chapter 7 Troubleshooting 1. Troubleshooting 2. Failure tree analysis charts 3. Alarm factor tree analysis chart MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. -

Page 87: Troubleshooting

Section 3 of this chapter can be done. 2. Failure tree analysis charts Fig.7-1 IPM failure tree analysis chart (Symbols A to F are linked with those indicated in separate FTA pages.) MT6M15962a © Fuji Electric Co., Ltd. All rights reserved. - Page 88 (a) Mode A: Deviation from RBSOA specification (b) Mode B: Gate overvoltage Fig.7-1 IPM failure tree analysis chart MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 89 (c) Mode C: Excessive junction temperature rise Fig.7-1 IPM failure tree analysis chart MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 90 (d) Mode D: FWD breakdown Fig.7-1 IPM failure tree analysis chart MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 91 (e) Mode E: Control circuit breakdown Fig.7-1 IPM failure tree analysis chart MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

- Page 92 チング (温度サイクル、Δ パワーサイクル) 製品温度の急激な上昇或いは、下降によって発生する熱応力破壊(熱衝撃) 負荷の急激な変化等による半導体チップ温度変化がもたらす、製品内部配線等の 熱応力疲労破壊(Δ パワーサイクル) 高温状態での長時間電圧印加 高温状態での長期間使用 (高温印加(C-E間及び、G-E間)) 高温多湿状態での長時間電圧印加 高温多湿状態での長期間使用 (湿中印加(THB)) 腐食性ガス雰囲気中の使用 硫化水素等雰囲気中の長期使用 (f) Mode F: Breakdown related to reliability and product handling Fig.7-1 IPM failure tree analysis chart MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

-

Page 93: Alarm Factor Tree Analysis Chart

In addition, the alarm signal output voltage can be easily measured by connecting a 1.3 KΩ resistor in series between the IPM alarm signal output terminal and the cathode terminal of the optocoupler. Phenomenon Alarm factor and method for identification Fig.7-2 Alarm factor tree analysis chart MT6M15962a © Fuji Electric Co., Ltd. All rights reserved.

Need help?

Do you have a question about the IGBT-IPM X Series and is the answer not in the manual?

Questions and answers