Table of Contents

Troubleshooting

Summary of Contents for Whisper Power M-SQ27

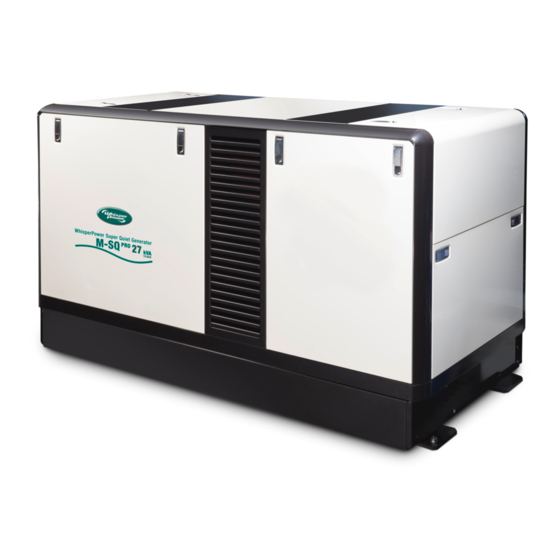

- Page 1 USER’S MANUAL M-SQ27 - 1500 RPM - Marine diesel generating set 230/400V / 50Hz Digital Diesel Control WHISPERPOWER BV Kelvinlaan 82 9207 JB Drachten Netherlands Tel.: +31-512-571550 Fax: +31-512-571599 V1 August 2020 www.whisperpower.com...

-

Page 2: Table Of Contents

Cooling liquid ........................... 15 2.5.14 Technical data ..........................16 2.5.15 Electrical diagram control wiring M-SQ27 ..................17 Terminal modes 115VAC – 230VAC - 400VAC 50H ............... 18 2.5.16 Generator Diagram 3 phase with AVR 230V – 400V 50Hz with AVR ..........19 2.5.17... - Page 3 OPERATION .................................. 21 General ................................21 Operating Instructions ............................21 3.2.1 Summarised operating instructions (daily use) ................21 3.2.2 Extended operating instructions ...................... 22 MAINTENANCE ................................25 Alternator ................................25 Engine ................................25 4.2.1 Preliminary instructions ........................25 4.2.2 Bleeding fuel lines ........................... 25 4.2.3 Valve clearance ..........................

-

Page 4: Introduction

During production and prior to delivery, all of our generating sets are tested and inspected. The M-SQ27 Marine Diesel Generating set is manufactured This generating set’s correct operation is subject to and marketed by WhisperPower. It is important to read this manual before installing and guarantee. -

Page 5: Liability

INTRODUCTION Identification Example 4: Neglect Whisper generators have an option for an auto start/stop mode or interval mode. 1.5.1 General WhisperPower cannot be held responsible for damage Before using this generating set it is very important to caused by the unattended running generator. identify the set correctly. - Page 6 This voltage should be within the specified tolerance at identify is not new you have to take into account the the nominal frequency. The M-SQ27 can be connected possibility that former users did change the settings. Check for different voltages in single phase or tri phase. The...

-

Page 7: Information

INFORMATION 2 INFORMATION Safety 2.1.3 Earth insulation failures According to local regulations and depending on the application it could be necessary to take measures for 2.1.1 General protection against earth insulation failures. When correctly installed and used in normal circumstances In the standard delivery “neutral”... -

Page 8: Operation

External moving parts like fans and V-belts are covered by Poor electrical connections or using wiring which the canopy and therefore the M-SQ27 is very safe when the is not suited for the rated currents can cause canopy is closed. -

Page 9: The M-Sq27

Diesel Control user manual). 2.3.2 Remote control The full automatic remote control panel including 15 mtr cable comes as standard with the M-SQ27. 2.3.3 Documentation Included in the delivery is this user manual (number: 40200441), an installation manual (number: 40200451), a user manual for DCC (number: 40200461) and a quick reference guide for the DDC (40200275). -

Page 10: Components

Fuel out Fuel in Raw water inlet Raw water pump Rubber engine mounting Fig. 4: Left view main components M-SQ27 Filler cap engine oil Filler cap engine coolant Rubber engine mounting Rocker cover Fig. 5: Top view main components M-SQ27... - Page 11 Oil filter Injection pump air bleeding screw Fuel lift pump for manual priming Fuel injection pump Heat exchanger Fig. 6: Front view main components M-SQ27 Temperature switch Hoist eye front Alternator Exhaust manifold (water- cooled) Hoist eye alternator Digital Diesel Control...

-

Page 12: Generator Control Panel

INFORMATION 2.4.2 Generator control panel Technical Information 2.5.1 AC alternator The tri phase synchronous alternator is directly coupled, one bearing, brushless, rotating field design, 12 wire, four pole (1500 RPM) and regulated by an Automatic Voltage Regulator (AVR). The exciter stator has a residual magnetism, which guarantees self-exciting of the generator on start-up (that thereby generates a residual voltage of about 10% nominal voltage). - Page 13 INFORMATION Further technical data on the design of the alternator can be found in drawings and diagrams in this manual. Fig. 11: Automatic Voltage Regulator (AVR) Fig. 12: AVR Trimmers (potentiometers) The power comes from 12 wires that can be connected in star, delta or combined double / star and double / delta arrangements to take off different voltages.

-

Page 14: Engine

Engine 2.5.7 Control The M-SQ27 generating set is based on the Mitsubishi S4S The generating set can be operated by push buttons on the 4 cylinder 4 stroke diesel engine. The engine is indirectly panel on the alternator or by the remote control. By pushing injected. -

Page 15: Cooling Liquid

The engine is cooled by cooling liquid. The capacity of this boiling point above 100° C. The temperature switch in the system of the M-SQ27 is 9.5 litres. thermostat housing switches at 110° C. When keel cooling is applied the cooling system is not pressurised. There... -

Page 16: Technical Data

INFORMATION 2.5.14 Technical data GENERAL Model M-SQ27 1500 rpm Alternator 3 phase synchronous (air cooled) Engine Mitsubishi diesel, model S4S (Japan) Number of cylinders Displacement 3331 cm3 Bore X stroke 94x120 mm Combustion air consumption 10 m³/min. Continuous power 50Hz... -

Page 17: Electrical Diagram Control Wiring M-Sq27

INFORMATION 2.5.15 Electrical diagram control wiring M-SQ27 Fig. 13: Electrical diagram control wiring M-SQ27 EN / M-SQ 27 / August 2020... -

Page 18: Terminal Modes 115Vac - 230Vac - 400Vac 50H

INFORMATION 2.5.16 Terminal modes 115VAC – 230VAC - 400VAC 50H Fig. 14: Terminal modes... -

Page 19: Generator Diagram 3 Phase With Avr 230V - 400V 50Hz With Avr

INFORMATION 2.5.17 Generator Diagram 3 phase with AVR 230V – 400V 50Hz with AVR Fig. 15: Generator diagram 3 phase with AVR 230V – 400V 50Hz with AVR EN / M-SQ 27 / August 2020... -

Page 20: Ac Wiring Diagram Single Phase With Avr 230V Hz (Double Delta)

INFORMATION 2.5.18 AC Wiring Diagram single phase with AVR 230V Hz (Double Delta) Fig. 16: AC wiring diagram single phase with AVR 230V Hz (Double Delta) -

Page 21: Operation

INFORMATION 3 OPERATION General The generating set is operational after full installation and filling up with: fuel, engine lubricating oil and cooling liquid, filling the starter battery with acid (WhisperPower batteries do not need to be filled up and are sealed), connecting the remote control panel. -

Page 22: Extended Operating Instructions

In operation checks: Regularly check the siphon vent in the cooling water Check for abnormal noise or vibration supply. Check the voltage If no WhisperSwitch is used: Switch main Power Check sea water flow at exhaust outlet Source Selector switch to "OFF" or switch off all Power source selector... - Page 23 Power source selector switch (off/shore Stopping the generating set: power/generator power). Switch to power source generator. If a WhisperSwitch is installed, this operates Avoid stopping of the generator abruptly after a long automatically. period of operation at high load! Doing so, you avoid unnecessary thermal load to your generating set! Before loading the generating set up to maximum, have it Act as follows:...

-

Page 25: Maintenance

MAINTENANCE 4 MAINTENANCE Alternator The alternator does not require any maintenance. Periodic inspection and cleaning is recommended, depending on environmental conditions. However when the alternator has been idle for a long period attention to winding condition is recommended. condition windings assessed measurement of insulation resistance to earth. -

Page 26: Replacing Oil Filter

MAINTENANCE 4.2.5 Replacing oil filter Replacement has to be executed according to the schedule in this manual. Drain the oil using the sump pump and put some tissues under the filter. Fig. 21: Location rubber packing-ring oil filter A smear of oil has to be put on the seal of the filter before fitting the filter. -

Page 27: Regular Maintenance

MAINTENANCE Regular maintenance EVERY 150 HOURS: • Change oil. • Check the battery acid level (not for WhisperPower CHECK DAILY: • batteries). Oil level. • Check battery terminals for corrosion. Take care the oil level is never below the mark. Do not add •... -

Page 28: Maintenance Schedule

MAINTENANCE 4.3.1 Maintenance schedule 4.3.2 Taking out of service When not using the generating set for a longer period it is recommended execute engine preservation Check oil level daily procedure. Check water inlet filter daily Check the level of the cooling liquid daily Clean the engine. -

Page 29: Troubleshooting

AVR or in the windings and replace if necessary (see special procedures). • Rotor diode broken. Check the diode in the rotor (see special procedures). The M-SQ27 has one diode block/rectifier unit. EN / M-SQ 27 / August 2020... -

Page 30: Engine Faults

AVR if necessary (see special procedures). • Defective diode Check the diode in the rotor (see special procedures). The M-SQ27 has one diode block/rectifier unit. • When Generator output voltage too Bring load in balance. When slightly out of... -

Page 31: Troubleshooting Table

TROUBLESHOOTING When the engine does not start instantly, necessary shut off the seawater inlet. Open the prolonged cranking can fill up the exhaust valve immediately after the engine has started. system with cooling water because of the water injected exhaust. When the water enters the A failure code is displayed when a hardware failure at the cylinder through the valves this will bring generator is detected. - Page 32 TROUBLESHOOTING PROBLEM CAUSE SOLUTION • Low compression because of dirty Clean valves. Take off the injection bend and inspect the outlet port. When little rust in the valves. port clean the valve by taking off the valve spring and rotate until clean. When the outlet port is strongly affected by rust, the exhaust system is not properly installed (see paragraph 5.4.3).

- Page 33 TROUBLESHOOTING PROBLEM CAUSE SOLUTION • Protection system stops the engine; Engine starts, but stops after 10 See paragraph 2.5.5. and 3.2.2 for information seconds on the alarm system. Bypassing the switches this can be caused by oil pressure can help to confirm the failure. When there is failure, lack of cooling water (exhaust no real failure, it could be a faulty alarm switch temperature alarm).

- Page 34 TROUBLESHOOTING PROBLEM CAUSE SOLUTION • Faulty thermostat Check the thermostat or replace.

-

Page 35: Warnings

TROUBLESHOOTING • to terminals “0” and “115” for an output voltage 5.2.3 Warnings between 100 and 140V (factory setting); • to terminals “0” and “230” for an output voltage CAUTION! Generator must be shut off immediately if: between 200 and 280V. ●... -

Page 36: Residual Voltage Check / Excitation Procedure (Flashing)

A short circuit can cause heavy in the table below: sparking, fire and injuries. Resistance M-SQ27 When external excitation does not bring back voltage, the rotating rectifier diodes should be tested and a winding • Resistance main stator windings 0.33 Ohm... -

Page 37: Meggering

TROUBLESHOOTING 5.3.5 Meggering One can try to measure resistance between the housing and the windings with a multimeter which should read infinity. When readings are infinity but a fault is suspected one can do a high voltage resistance test (MEGGERING) This procedure should be carried out by an expert. -

Page 38: Adjusting Valve Clearance And Retightening The Cylinder Head Bolts

TROUBLESHOOTING 5.4.2 Adjusting valve clearance and 360° in the direction of engine rotation again. No. 1 piston retightening the cylinder head bolts is now at T.D.C. of the compression stroke. Both procedures have to be executed with a cold engine. After adjusting the valves of cylinder 1 adjust the valve When both procedures are executed be sure to retighten clearance of the remaining cylinders in firing order 1-3-4-2... -

Page 39: Disassembling Instructions

TROUBLESHOOTING 5.4.4 Disassembling instructions It could be necessary for repair or checks to disassemble the generating set. To take the generating set out of the canopy all hose and cable connections have to be taken off. The set is Reassembling the generating set one should take care fixed to its base by four rubber mountings and can be of alignment, cleaning the surfaces between engine loosened by removing the four nuts from the bolts of... - Page 40 SPARE PARTS...

-

Page 41: Spare Parts

SPARE PARTS 6 SPARE PARTS A complete parts manual in English is available as an option number: number: 40200187 (***) A work shop manual in English is available as an option, number: 40200174 (***). We recommend the following spares for service and maintenance. •... - Page 42 SPARE PARTS...

- Page 43 SPARE PARTS EN / M-SQ 27 / August 2020...

-

Page 44: Maintenance Log

MAINTENANCE LOG MAINTENANCE LOG first service after 50 hours: hour counter: remarks: next service (every 150 hours): hour counter: remarks:... - Page 45 NOTES NOTES EN / M-SQ 27 / August 2020...

- Page 46 Kelvinlaan 82, 9207 JB Drachten, Netherlands Tel : + 31-512-571550 / Fax : + 31-512-571599 www.whisperpower.com / info@whisperpower.com...

Need help?

Do you have a question about the M-SQ27 and is the answer not in the manual?

Questions and answers