Table of Contents

Advertisement

Quick Links

KEEP FOR FUTURE REFERENCE

INSTRUCTIONS

International Version

P.O. Box 368 – 908 West Main

Laurel, MT USA 59044

MODEL NUMBER:

VL411LDC

phone 800-548-7341

SERIAL NUMBER:

___________

phone 406-628-8231

fax 406-628-8354

(please see serial label and record number here)

VERTICAL LIFTER 700

DC-VOLTAGE

READ ALL INSTRUCTIONS AND WARNINGS

BEFORE OPERATING THIS LIFTER

DESIGNED FOR THE MATERIALS HANDLING PROFESSIONAL

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for WPG VL411LDC

- Page 1 KEEP FOR FUTURE REFERENCE INSTRUCTIONS International Version P.O. Box 368 – 908 West Main Laurel, MT USA 59044 MODEL NUMBER: VL411LDC phone 800-548-7341 SERIAL NUMBER: ___________ phone 406-628-8231 fax 406-628-8354 (please see serial label and record number here) VERTICAL LIFTER 700...

-

Page 3: Table Of Contents

NSPECTION CHEDULE Every-Lift Inspection ..........................15 Frequent Inspection ........................... 15 Periodic Inspection ............................ 15 Infrequent Use ............................16 ......................16 ESTING CHEDULE Operational Tests............................16 Load Test ..............................16 ....................17 AINTENANCE CHEDULE ....................... 17 ATTERY Rev 19.3/9-18 VL411LDC: #35162... - Page 4 Replacing the Intake Valve Flapper ......................23 Replacing the Exhaust Valve Flapper and Head Gasket .................23 ..................24 ACUUM WITCH DJUSTMENT Vacuum Switch Function ..........................24 Conditions Requiring Readjustment ......................24 Adjustment Procedure ..........................25 REPLACEMENT PARTS LIST ..................26 LIMITED WARRANTY ....................27 Rev 19.3/9-18 VL411LDC: #35162...

-

Page 5: Specifications

Model Number: VL411LDC Description: Designed for use with a crane or other hoisting equipment, the VL411LDC lifter employs vacuum to hold a load for lifting in the upright orientation. Power Source: 12 volts DC, 10 amps (with Thomas pump) or 3.5 amps (with Dynaflo pump) -

Page 6: Warnings

Wood’s Powr- Grip cannot be responsible for the safety of a lifter that has been modified by others. For consultation, contact Wood's Powr-Grip (see LIMITED WARRANTY). Rev 19.3/9-18 VL411LDC: #35162... -

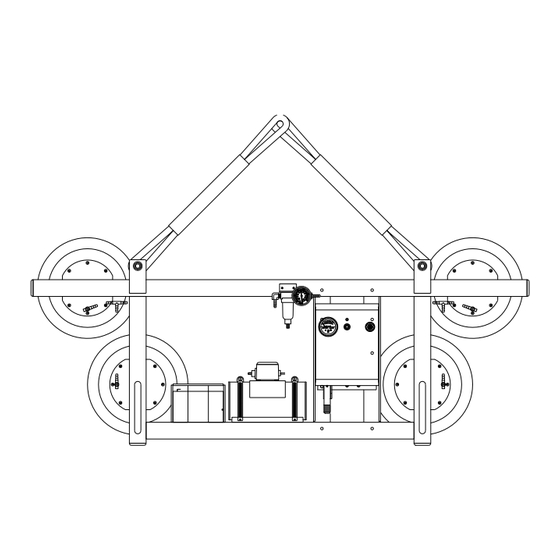

Page 7: Operating Features

OPERATING FEATURES Note: Components featured in the following instructions for assembling, operating or maintaining the vacuum lifter are underlined on their first appearance in each section. Standard VL411LDC shown. 1 LIFT SLING 6 Enclosure with VACUUM PUMP, 11 CONTROL HANDLES... -

Page 8: Assembly

3) Connect the electrical connectors uniting the battery to the battery charger and the vacuum generating system. The lifter is now operational. 4) Perform Operational and Load Tests for the lifter as directed in MAINTENANCE: T ESTING CHEDULE Rev 19.3/9-18 VL411LDC: #35162... -

Page 9: Intended Use

Lifters that feature concave vacuum pads can also attach to some kinds of curved loads. Since curvature affects the lifting capacity, contact Wood’s Powr-Grip for help in determining the Maximum Load Capacity for a particular curved load. Rev 19.3/9-18 VL411LDC: #35162... -

Page 10: Operating Environment

After the vacuum lifter has reached the end of its service life, you must dispose of the lifter in compliance with all local codes and regulatory standards that are relevant for the geographical region. Note: This lifter is equipped with a battery, which may be subject to special disposal regulations. Rev 19.3/9-18 VL411LDC: #35162... -

Page 11: Operation

WARNING: Make sure alarm is clearly audible over ambient noise at operator position. Rev 19.3/9-18 VL411LDC: #35162... -

Page 12: The To Adspply Thehe Padsds Theto Ads Ltoadsd

Although initially it may be difficult to apply the pad to a load, this condition should correct itself with continued use. Consult CE Standard EN 457 for alternative ways to determine whether the alarm is clearly audible to operators. Rev 19.3/9-18 VL411LDC: #35162... -

Page 13: Reading The Vacuum Gauge

Certain load materials are too rough or porous to allow the lifter to form a seal which can be maintained for 5 minutes without power. However, in geographical locations where CE Standards do not apply, it may be possible to use the lifter to lift such loads. Contact Wood’s Powr-Grip for more information. Rev 19.3/9-18 VL411LDC: #35162... -

Page 14: T O Lift And Move The Load

WARNING: Never attempt to lift load while alarm is sounding. Do not attempt to lift the load while the alarm is sounding; such an attempt could result in a load release and possible injury to the operator. Rev 19.3/9-18 VL411LDC: #35162... -

Page 15: Controlling The Lifter And Load

Then push the valve handle inward to the “release” ( ) position (power off), as shown. Do not attempt to move the lifter until the vacuum pads TO RELEASE disengage completely from the load. Rev 19.3/9-18 VL411LDC: #35162... -

Page 16: After Using The Lifter

Preferred temperatures for storing the battery are 32° to 70° Fahrenheit [0° to 21° Celsius]. Higher temperatures require the battery to be charged more frequently. Storage at temperatures above 100° Fahrenheit [38° Celsius] should be avoided. Rev 19.3/9-18 VL411LDC: #35162... -

Page 17: Maintenance

CAUTION: Be sure to use appropriate cleaning methods for each type of electrical component, as specified by codes and standards. Improper cleaning can damage components. Rev 19.3/9-18 VL411LDC: #35162... -

Page 18: Infrequent Use

V discussion for inspection, testing and adjustment ACUUM WITCH DJUSTMENT procedures. ASME Standard B30.20 requires the lifter to be tested to 125% of its Load Capacity. Flat Lifters are exempt from this requirement. Rev 19.3/9-18 VL411LDC: #35162... -

Page 19: Aintenance Chedule

The battery charger must be disconnected from its AC power source in order to test the battery energy; otherwise, the energy reading on the battery gauge would not be accurate. Rev 19.3/9-18 VL411LDC: #35162... -

Page 20: Battery Recharge

The charger is designed to automatically sense the energy level of the battery and reduce the charging rate when the battery is fully charged. Accordingly, the charger does not need to be unplugged until the lifter is going to be used again. Rev 19.3/9-18 VL411LDC: #35162... -

Page 21: Inspection

If the lifter is equipped with VPFS10T or VPFS625 pads, the sealing edge is the replaceable sealing ring. When it is damaged, install a new sealing ring insert. In such cases, see T to follow. EPLACE EALING NSERT IN ACUUM Rev 19.3/9-18 VL411LDC: #35162... -

Page 22: Vacuum Test

If these cleaning methods are not successful, contact Wood’s Powr-Grip or an authorized dealer for assistance. Any test material used must be fully and independently supported, and capable of bearing the lifter’s weight. Do not use the lifter to lift the test material during the vacuum test. Rev 19.3/9-18 VL411LDC: #35162... -

Page 23: Air Filter Maintenance − Small

The filter element kit may contain two sizes of bowl seals (O-ring type gaskets). If so, use the smaller bowl seal; or if in doubt, compare the old bowl seal to determine the appropriate size. Rev 19.3/9-18 VL411LDC: #35162... -

Page 24: Vacuum Pump Maintenance − Dynaflo Dv1032102

Depending on the product, the head assembly (3) may be rotated to an orientation different from the one shown. When removing the head assembly, always take note of its orientation and install it the same way during reassembly. Make sure that the intake and exhaust ports remain in their original positions. Rev 19.3/9-18 VL411LDC: #35162... -

Page 25: Vacuum Pump Maintenance − Thomas 107Cdc20

When removing the valve plate, always take note of its orientation in the pump head (2), and install the valve plate the same way during reassembly. In all cases, the valve plate must be oriented so that its intake hole is matched with the head port that connects to the check valve. Rev 19.3/9-18 VL411LDC: #35162... -

Page 26: Vacuum Switch Adjustment

In order to observe lifter functions while vacuum is decreasing, it may be necessary to create a controlled leak in the vacuum system (eg, by breaking the seal between one or more vacuum pads and the test surface). Rev 19.3/9-18 VL411LDC: #35162... -

Page 27: Adjustment Procedure

When the vacuum switch is adjusted correctly, the vacuum pump turns off only vacuum increases to a level higher than the minimum lifting level; and the pump turns on again before vacuum decreases to a level lower than the minimum lifting level. Rev 19.3/9-18 VL411LDC: #35162... -

Page 28: Replacement Parts List

Shoulder Bolt – Socket Head – 5/16" x 1/2" x 1/4-20 Thread (for mounting pads) * Length as required; vacuum hose is sold by the foot (approx. 30.5 cm). SERVICE ONLY WITH IDENTICAL REPLACEMENT PARTS, AVAILABLE AT WPG.COM OR THROUGH AN AUTHORIZED WPG DEALER Rev 19.3/9-18 VL411LDC: #35162... -

Page 29: Limited Warranty

Contact your dealer or the Technical Service Department at Wood’s Powr-Grip Co. for assistance. Wood's Powr-Grip Co., Inc. 908 West Main St. / P.O. Box 368 Laurel, MT USA 59044 phone 800-548-7341 phone 406-628-8231 fax 406-628-8354 Rev 19.3/9-18 VL411LDC: #35162... - Page 30 Rev 19.3/9-18 VL411LDC: #35162...

- Page 31 Rev 19.3/9-18 VL411LDC: #35162...

- Page 32 Rev 19.3/9-18 VL411LDC: #35162...

- Page 33 Rev 19.3/9-18 VL411LDC: #35162...

- Page 34 Rev 19.3/9-18 VL411LDC: #35162...

Need help?

Do you have a question about the VL411LDC and is the answer not in the manual?

Questions and answers