Table of Contents

Summary of Contents for Technosoft iPOS4803-SY3

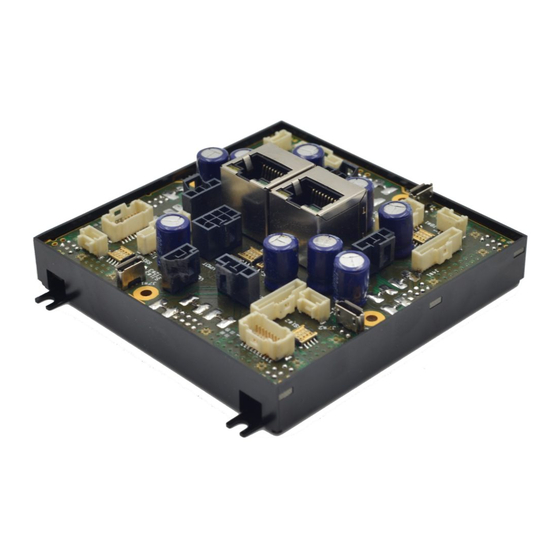

- Page 1 Multi Axis System, EtherCAT iPOS4803-SY4 Intelligent Servo Drives Multi Axis System, EtherCAT Intelligent Servo Drive for DC, Brushless DC and AC Motors Technical Reference Technosoft 2021 P091.020.iPOS4803-SY.UM.0921...

-

Page 2: Table Of Contents

Hardware Installation ..................... 12 iPOS4803-SY Multi Axis System Dimensions ............12 Mechanical Mounting ....................12 Connectors and Pinouts .................... 13 ..3.3.1 Pinouts for iPOS4803-SY3 Multi Axis System ............... 13 ..3.3.2 Pinouts for iPOS4803-SY4 Multi Axis System ............... 14 ..3.3.3 Mating Connectors for iPOS4803-SY Multi-Axis System ............ - Page 3 Encoder #1 Inputs (A1+, A1-, B1+, B1-, Z1+, Z1-,) ............... 33 3.14.13 Encoder #2 Inputs (A2+, A2-, B2+, B2-) ................33 3.14.14 Analog Input (AnalogIN) ......................33 3.14.15 Absolute encoder interface: SSI, BISS-C, EnDAT ..............34 Memory Map ......................37 Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference...

-

Page 4: Read This First

Whilst Technosoft believes that the information and guidance given in this manual is correct, all parties must rely upon their own skill and judgment when making use of it. Technosoft does not assume any liability to anyone for any loss or damage caused by any error or omission in the work, whether such error or omission is the result of negligence or any other cause. -

Page 5: Related Documentation

TML motion programming and motion evaluation tools. Help of the EasySetUp software – describes how to use EasySetUp to quickly setup any Technosoft drive for your application using only 2 dialogues. The output of EasySetUp is a set of setup data that can be downloaded into the drive EEPROM or saved on a PC file. -

Page 6: If You Need Assistance

If you Need Assistance … If you want to … Contact Technosoft at … Visit Technosoft online World Wide Web: http://www.technosoftmotion.com/ Receive general information World Wide Web: http://www.technosoftmotion.com/ or assistance (see Note) Email: contact@technosoftmotion.com Ask questions about product Fax: (41) 32 732 55 04... -

Page 7: Cautions

(Registration, Evaluation, Authorization and Restriction of Chemicals), which came into force on 01.06.2007. RoHS Compliance - Technosoft SA here with declares that this product is manufactured in compliance with the RoHS directive 2002/95/EC on the restriction of the use of certain... -

Page 8: Product Overview

EasySetUp shall be used for drive setup in all cases where the motion commands are sent exclusively from a master. Hence neither the iPOS4803-SY TML programming capability nor the drive camming mode are used. EasySetUp can be downloaded free of charge from Technosoft web page. -

Page 9: Product Features

Fully digital servo multi axis system suitable for the control of rotary or linear brushless and DC brush Very compact design • Sinusoidal (FOC) or trapezoidal (Hall-based) control of brushless motors • Technosoft Motion Language (TML) instruction set for the definition and execution of motion sequences • Standalone operation with stored motion sequences • Communication: •... -

Page 10: Identification Labels

P020.200.P404 – iPOS4803-SY4 – 4 Axis Motion System, 3A nominal, EtherCAT® • Where “x” can be 1, 2 or 3 for iPOS4803-SY3 or 1, 2, 3 or 4 for iPOS4803-SY4 Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 11: Supported Motor-Sensor Configurations

Each defined motor type can have any combination of the supported feedbacks either on motor or on load. Example: PMSM motor with Incremental encoder (from feedback #1) on motor and Incremental encoder (from feedback#2) on load Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 12: Hardware Installation

2.2 Watt (=7.5 BTU/hour) worst case while driving a motor. The recommended inserts and screws are: Image Connector Description Manufacturer Part Number PennEngineering® Self-clinching nuts M2 KF2-M2-ET (PEM®) Screws M2x10 Bossard BN610-M2x10 Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 13: Connectors And Pinouts

Connectors and Pinouts 3.3.1 Pinouts for iPOS4803-SY3 Multi Axis System • Where “x” can be 1, 2 or 3 Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 14: Pinouts For Ipos4803-Sy4 Multi Axis System

3.3.2 Pinouts for iPOS4803-SY4 Multi Axis System Where “x” can be 1, 2, 3 or 4 • Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 15: Mating Connectors For Ipos4803-Sy Multi-Axis System

Nano-Fit 105300 Series 26- Molex 638276000 J8#x Nano Fit 24AWG Socket Contacts, 207129 Series • Where “x” can be 1, 2 or 3 for iPOS4803-SY3 or 1, 2, 3 or 4 for iPOS4803-SY4 Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 16: Connection Diagrams

Multi Axis System connection diagram Figure 3 iPOS4803-SY Multi Axis System Connection diagram *Where “x” can be 1, 2 or 3 for iPOS4803-SY3 or 1, 2, 3 or 4 for iPOS4803-SY4 **For other available feedback / motor options, check the detailed diagrams below ***Pins are software selectable individually as NPN inputs/outputs ... -

Page 17: Digital I/O Connection

The outputs are compatible with NPN type inputs (load is tied to common +V , output pulls to GND when active and is floating when inactive). The I/O pins are individually software selectable as either NPN inputs or outputs. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 18: Analog Inputs Connection

(GND); shield is connected only at the drive side, to the drive PE, and is left unconnected at the source side. The source minus (negative, out- of-phase) output remains unconnected. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 19: Motor Connections

Typically the necessary values are around 100 μH. A good shielding can be obtained if the motor wires are running inside a metallic cable guide. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 20: Feedback Connections

SW1#x pins 1,2 and 3 on “ON” position. Length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 21: Feedback #2 - Differential Incremental Encoder Connection

SW1#x pins 1 and 2 on “ON” position. The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 22: Feedback #2 - Absolute Encoder Connection: Ssi, Biss, Panasonic, Tamagawa, Endat, Nikon, Sanyo Denki

The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. 3.8.6 Linear(Analog) Hall Connection Figure 14 Linear Hall connection for iPOS4803-SY Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 23: Digital Hall Connection For Motor + Hall + Incremental Encoder

The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. In case of an absolute encoder connection, if only just one wire is missing from a pair the breakage can’t be detected. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 24: Digital Hall Connection For Direct Motor Control Without An Encoder

+5V and GND lines. The capacitor value can be 1...10 μF, rated at 6.3V. In case of an absolute encoder connection, if only just one wire is missing from a pair the breakage can’t be detected. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 25: Power Supply Connection

If the wires are longer than 2 meters, use twisted wires for the supply and ground return. For wires longer than 20 meters, add a capacitor of at least 1000μF (rated at an appropriate voltage) right on the terminals of the iPOS4803-SY. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 26: Recommendations To Limit Over-Voltage During Braking

[kg], the angular speed ϖ will become linear speed measured in [m/s] and the friction torque T will become friction force measured in [N]. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 27: Usb Connection

COM port. In Easy Motion studio, choose the following communication settings: Figure 19 USB connection Instead of COM1, choose the new COM value detected after the driver is installed. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 28: Ethercat Connection

Ports cannot be swapped. Port IN (0) must be always used for connection, while port OUT (1) can be • optionally left disconnected (inactive). Swapping ports can lead to packet loss, see EtherCAT documentation on circulating packets. Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 29: Disabling The Setup Table At Startup

“configured station alias address” with its AxisID value. The AxisID can be changed to a value between 1 and 255 using EasySetUp or EasyMotion Studio from the “Drive Setup” dialogue. The AxisID on iPOS4803-SY3 (P020.200.E403) and iPOS4803-SY4 (P020.200.E404) can be set also by hardware with the SW2 and SW3 switches. - Page 30 Drive #1 Drive #2 Drive #3 Pin 1 Pin 2 Pin 3 Pin 4 Drive #1 Drive #2 Drive #3 Drive #4 Figure 24 iPOS4803-SY3 (P020.200.E403) - Axis ID selection Figure 25 iPOS4803-SY4 (P020.200.E404) - Axis ID selection Remarks: The drive axis/address number is set when H/W is selected in Drive Setup under AxisID field or when the Setup is invalid.

-

Page 31: Electrical Specifications

Size ( Length x Width x Height ) iPOS4803-SY Multi Axis System (Without connectors) ~3.73 x 3.34 x 1.1 inch iPOS4803-SY3 Multi Axis System Weight iPOS4803-SY4 Multi Axis System Cleaning agents Dry cleaning is recommended Only Water- or Alcohol- based... -

Page 32: Motor Outputs (A/A+, B/A-, C/B+, Cr/B-)

Absolute maximum values, continuous Input voltage † Absolute maximum, surge (duration ≤ 1s) Input current Input voltage 0…+5V Interpolation Resolution Depending on software settings bits Frequency ESD protection Human body model Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 33: Encoder #1 Inputs (A1+, A1-, B1+, B1-, Z1+, Z1-,)

% FS Bandwidth (-3dB) Software selectable ESD protection Human body model For full RS-422 compliance, 120Ω termination resistors must be connected across the differential pairs. “FS” stands for “Full Scale” Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... -

Page 34: Absolute Encoder Interface: Ssi, Biss-C, Endat

† Stresses beyond values listed under “absolute maximum ratings” may cause permanent damage to the device. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability. For more details check “Figure 30-iPOS4803 Microdrive PWM Frequency De-rating @48V, 40 C” graph Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference... - Page 35 Figure 26 iPOS4803 Microdrive De-rating with PWM frequency Micro 20KHz, 24V Ambient Temperature [ºC] iPOS4803 Microdrive De-rating with ambient temperature Figure 27 Micro 20KHz Vmot [V] iPOS4803 Microdrive De-rating with motor supply Figure 28 Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference...

- Page 36 Microdrive Output Voltage De-rating with PWM frequency Figure 29 Micro PWM Frequency [KHz] Current capability for external loads on 50mA 200mA 375mA iPOS4803 Microdrive PWM Frequency De-rating @48V, 40 Figure 30 Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference...

-

Page 37: Memory Map

ROM memory for: TML programs Cam tables Setup information 7FFFh 8000h Reserved 8FFFh Data acquisitions C000h cam tables at runtime SRAM memory TML Programs FFFFh iPOS4803-SY Memory Map Figure 31 Technosoft 2021 iPOS4803-SY Multi Axis System, EtherCAT Technical Reference...

Need help?

Do you have a question about the iPOS4803-SY3 and is the answer not in the manual?

Questions and answers